-

Posts

2374 -

Joined

-

Last visited

-

Days Won

29

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Miles

-

-

13 hours ago, adivin said:

Was the fitment good with your spindle bushings? Tight enough fit? I see that MSA can still get the OEM rubber spindle pin bushings. Something to think about.

How did you like going to urethane over stock bushings in general?

Compared to the old worn out rubber bushings urethane noticeably improved handling. Much stiffer. Before replacing the steering rack bushings my car used to wander and track grooves in the road.

All of the bushings fit.

I did have a fitment problem with the Energy Suspension (ES) bushing metal inner sleeves that fit over the spindle pin for the rear outer control arm bushings . The ES inner sleeve was manufactured with the inside diameter too large resulting in a sloppy fit when slid over the spindle pin. I carefully measured the spindle pin and the inside diameter of the sleeves. I called ES and explained what I found and they admitted to a manufacturing problem and sent me new sleeves.

The three things I did to improve handling of my daily driver: replacement of all bushings with urethane, stiffer springs that maintained stock ride height and Tokico shocks. The ride is stiffer, but not harsh or bone jarring. Just right for a sports car.

-

36 minutes ago, adivin said:

Miles, thanks for sending these links. Seems like the outer sleeve has to come out despite instructions to the contrary. I can't find any post from someone with first hand experience who even tried to put the bushings in with the outer sleeve.

I did mine 14 years ago and experienced the same confusion. I bought a spindle pin puller from an Hybridz member and then did the whole suspension. The only sleeves I didn't remove were for the mustache bar bushings.

Some of the best posts about bushing replacement were made back in the early days of HybridZ.

-

7 minutes ago, NewZed said:

"Buy" a video from a carburetor rebuilder to learn how to install aftermarket suspension bushings? Seems wrong...

Wrong? How so?

The original owners of Ztherapy were Z car freaks.

-

Buy the Street Racing Suspensions video from Ztherapy. Shows how to install a complete polyurethane bushing kit.

-

Here are some really big ones you can look at.

https://www.zcar.com/threads/hacksaw-and-energy-suspension-bushing-installation.293838/

https://www.classiczcars.com/forums/topic/12008-rear-control-arm-bushings/

-

Here are some posts from other Z car sites:

https://www.zcar.com/threads/hacksaw-and-energy-suspension-bushing-installation.293838/

https://www.classiczcars.com/forums/topic/12008-rear-control-arm-bushings/

-

Searching old posts will set you free. Do a search and then read posts in reverse order. Why because most 240z issues were resolved almost twenty years ago. Think of HybridZ as an encyclopedia. Turn the page......................

-

1

1

-

-

3 hours ago, Twisted46 said:

Hmm, mine has an internal leak allowing fluid to flow between the reservoirs over time.

Yep. Two of my Wilwood 1 in. MCs leaked internally right out of the box. The third one had damaged bleed screws. I ended up buying a 1979 280ZX MC from Arizona Z Cars.

-

One of the problems with the stock stub axles is the mounting flange can become bent/warped. Not so much of a problem with drum brakes, but drove me nuts after I did the rear disk swap. One caliper got hot and the other caliper was barely warm. I finally set up a dial indicator and measured the face of the flange. Both flanges were warped so they would cause the rotor to rub on the brake pad. I tried having the flanges machined, but it didn't fix the problem. I ended up installing the stub axles from Chequered Flag Racing. No problems since then. I have also had a stock stub axle shaft break where the threads end (common) just pulling away from a stop sign when my Z was all stock. I see that MSA is selling "refurbished" stub axles.

-

Try Chequered Flag Racing if you can't find good used axles. I had problems with used axles so I caved and bought these:

http://www.chequeredflagracing.net/Datsun.html

-

55 minutes ago, JMortensen said:

You might want to check the crossmember for cracks. Plenty of ITS racers end up cracking the front crossmember that holds the diff mount with a weak 6 cyl.

I do whenever the car is up on jack stands. Ok so far. I have seen that center mounting bolt pull out of the crossmember and cracked crossmenbers.

-

"Also meant to say in last post will check the stub axle nut torque but wrote "gland nut" by accident."

- Torquing that nut beyond specs won't help unless the nut has actually loosened up. I torque mine to 180 ft lbs and quit. Be aware that the stock nut is staked down and turning the nut without removing the staked part with a Dremel grinder will destroy the threads on the axle. You can substitute a 280XZ nut which is self locking.

- The splines in the companion flange (connects half shaft to the axle) can become worn creating some slop, but not a clunk. Lock the wheel and move the half shaft to see if the splines are worn. There is always a bit of play.

- You should pull the differential and inspect for worn parts.

- Also check the three nuts (top of tower) for the insulators and the nut that attaches the shock to the insulator.

- All R180 and R200 differentials were a bit playful even when new and will clunk unless you engage the clutch smoothly. My junk yard R200 has clunked for the last 10 years.

- Check that the shock has no vertical play which could indicate the wrong shock, missing spacer or loose gland nut. Be careful around the threads that the gland nut screws into. If the threads get screwed up or the tube gets bent in the threaded area you will be looking for a new strut. Note that the spacer is unique to each manufacturers shock.

- The stock front differential mount flexes. I replaced mine with a solid mount (MSA) 20 years ago. No problems with a SBC 350 or you can do the Taylor mount.

Example of cause of clunk in a R200 differential:

-

8 minutes ago, jkelly said:

I unbolted each caliper and bleed them with the bleeder facing up at the highest point. Some air came out and the brakes are a lot better now and the car can actually stop. They're still quite squishy so I'm missing something.

There is still air in the system. Could be the MC. Have to get all of the small bubbles out and be sure you are pushing the piston full stroke. Take your time so the bubbles can form up between bleeds. Speed bleeders installed on the MC help insure that bubbles don't get suck back into the MC. Plug the outlet ports when transferring the MC to the car to prevent fluid leaking out and air getting in. Could be some air in the caliper still.

You are very organized and methodical. Just keep at it in a logical step by step way.

Don't mean to scare you, but I have stopped using the Wilwood 1 in. MC. I got three bad ones right out of the box. Two leaked internally and the other one had the bleeder screws smashed.

That is bad quality control. I am now using a 79 280zx 15/16 MC that I bought from Dave at Arizona Z Cars.

Now back to your push rod. If I recall correctly, the push rods came in two lengths. As I mentioned before, measuring from the tip of the push rod to the face of the spacer should be around 14mm to 15mm as a starting place. Too short = long pedal. Too long = brake lock up after 2 or 3 applications due to blocked return port. You mentioned that you added a spacer to the push rod to get the length you need. Not sure what you did, but adding a spacer to the push rod may not be a good idea.

-

33 minutes ago, NewZed said:

To Miles's point - #6 is the only step you showed that suggests pushing the pedal actually moves any fluid. Your pressure bleeder doesn't do that, it can move fluid with out any of the mechanical parts even connected.

Focus on the pedal linkage, brake booster, and master cylinder hard parts before worrying about the hydraulics.

Agree with Newzed.

-

Had to replace the 240SX rear calipers on my 240Z this week. Had a brain fart idea that worked.

Bench bleed caliper method:

Bench bleed the calipers before installing them: While prepping the new calipers I noticed my MC bench bleeding kit on the bench. The fittings used for the MC will also fit the caliper. I used the fittings/hoses from my MC bench bleeding kit (O'reilley's) plus a huge syringe I found at a grocery store. Connect the syringe with hose to the speed bleeder. Screw in a plastic push-on hose fitting (from a bench bleeding kit) into the inlet of the caliper with a hose to a bottle to catch the fluid. Push fluid into the caliper with the syringe being careful not to push any bubbles in the hose into the caliper. Once the caliper is full, and no bubbles are seen, close the speed bleeder and plug the inlet with a M10 x 1.0 bolt. I was amazed at how much air flowed out of the caliper. It took about three full syringes of fluid to get all of the fine bubbles out. After installing the calipers (see procedure below), and doing one side at a time, it only took three pumps to get a firm pedal for each caliper.

Steps:

- Bench bleed calipers being sure to tighten the speed bleeder and install a M10x1.0 bolt in the caliper inlet when done to keep the caliper sealed.

- Fill MC reservoir with fluid.

- Push brake pedal with your hand and block it in place with a stick between the seat and the pedal. This blocks the fluid return port in the MC so fluid will not flow out of the MC.

- Remove old caliper leaving the flex line attached and hang it from the spring with some wire. This keeps the brake line sealed and prevents any fluid loss while installing the new caliper.

- Install new caliper and pads.

- Move the flex line from the old caliper to the new caliper. Since you blocked the return port in the MC there should be almost no fluid drips from the open flex line.

- Attach hose and catch bottle to the speed bleeder. Open the speed bleeder and pump. The first pump will go to the floor because the piston will move out taking up the slack between the piston and the brake pad/rotor. The second and third pump will firm up the pedal.

I just did this this week. It was the quickest brake bleed I have done with Maxima/240SX calipers. No wasted fluid too.

MC bleeder kits are available from O'reilley's. They contain a variety of plastic MC outlet fittings, but for some reason only one M10 x 1.0 fitting so I buy two.

-

This may be your problem:

You wrote:

7. I then removed the spacer and adjusted the push rod to almost touch the master cylinder plunger. The brake pedal still went to the floor with no stopping power.

So you adjusted the plunger with the spacer removed? And then you put the spacer back on? That would move the MC away from the push rod by about .75 inch which would increase the gap between the push rod and the MC piston such that the piston would move a small amount if at all.

If I recall correctly, for my 280ZX and Wilwood MC I adjusted the tip of the plunger about 14mm/15mm as measured from the face of the spacer. You can also fine tune the push rod once the car is on the road for testing. Just be aware that if you adjust the pushrod out too far you will lock your brakes up because the MC piston gets pushed past the return port in the piston preventing fluid from returning back into the MC from the calipers - kind of like a line lock. Opening the MC bleeders will relieve the pressure.

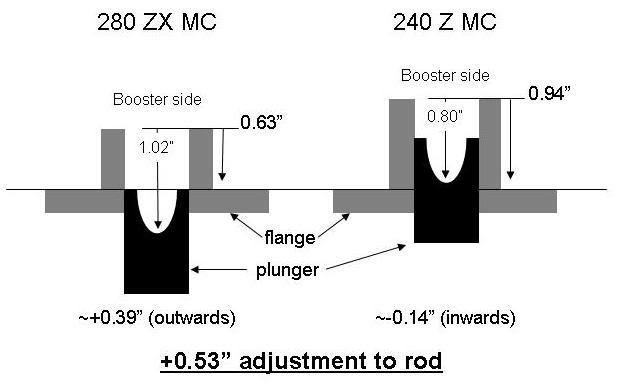

Picture is for using a 280ZX MC, but the math is fairly close for a Wilwood 1 inch MC

-

I have used both the Maxima and 240SX rear calipers on my Z cars. The problem is that the bleeders do not point straight up such that air remains trapped in the cylinder. Wasted lots of time and fluid.

Remove caliper with flex line connected method:

You can remove the caliper while leaving the flex line connected. Block the piston so it can not move otherwise when you pump the brakes you will just blow the piston out of the cylinder and you will be very very sad.

Hold the caliper so the bleeder points up and shake the caliper while your accomplice pumps the brakes. Repeat. Repeat etc.

Speed bleeders (type with spring and plug inside or check ball inside) make this job easier.

Bench bleed caliper method:

You can try what I came up with this week: bench bleed the calipers before installing them. While prepping the new calipers I noticed my MC bench bleeding kit on the bench. The fittings used for the MC will also fit the caliper. I used the fittings/hoses from my MC bench bleeding kit (O'reilley's) plus a huge syringe I found at a grocery store. Connect the syringe with hose to the speed bleeder. Screw in a plastic push-on hose fitting (from a bench bleeding kit) into the inlet of the caliper with a hose to a bottle to catch the fluid. Push fluid into the caliper with the syringe being careful not to push any bubbles in the hose into the caliper. Once the caliper is full, and no bubbles are seen, close the speed bleeder and plug the inlet with a M10 x 1.0 bolt. I was amazed at how much air flowed out of the caliper. It took about three full syringes of fluid to get all of the fine bubbles out. After installing the calipers (see procedure below), and doing one side at a time, it only took three pumps to get a firm pedal for each caliper.

Steps:

- Bench bleed calipers being sure to tighten the speed bleeder and install a M10x1.0 bolt in the caliper inlet when done to keep the caliper sealed.

- Fill MC reservoir with fluid.

- Push brake pedal with your hand and block it in place with a stick between the seat and the pedal. This blocks the fluid return port in the MC so fluid will not flow out of the MC.

- Remove old caliper leaving the flex line attached and hang it from the spring with some wire. This keeps the brake line sealed and prevents any fluid loss while installing the new caliper.

- Install new caliper and pads.

- Move the flex line from the old caliper to the new caliper. Since you blocked the return port in the MC there should be almost no fluid drips from the open flex line.

- Attach hose and catch bottle to the speed bleeder. Open the speed bleeder and pump. The first pump will go to the floor because the piston will move out taking up the slack between the piston and the brake pad/rotor. The second and third pump will firm up the pedal.

I just did this this week. It was the quickest brake bleed I have done with Maxima/240SX calipers. No wasted fluid too.

MC bleeder kits are available from O'reilley's. They contain a variety of plastic MC outlet fittings, but for some reason only one M10 x 1.0 fitting so I buy two.

With your brake set up your brake pedal should feel about stock.

I will post some pictures later today.

-

1

1

-

-

7 hours ago, Jaconense777 said:

Sorry for the late reply. Thanks for the help, I am going to replace the tach and power connectors, do you think it could be better if I replace the whole distributor? Not unless you think that the distributor is defective.

Because I believe the distributor comes with the wires. And they cost around $20 to $30 on O’rellys or auto zone. If I remove the distributor cap (with the cables attached) how do I Know if there is any damage? You can inspect the cap for cracks or electrical arching and check that the contact in the center is not worn/broken. You can look up the resistance specs for your wires and then check the resistance of each wire with a multi meter. A decent set of wires will run you about $100.

Does this affect the distributor in any way?. ??

Also can I replace the brake vacuum reservoir hoses without compromising air getting in to the brakes fluids? I assume you are talking about the vacuum hose that goes from the base of the carb to the brake vacuum booster. There is no fluid in the booster. If you need to work on or remove the the booster you do not have to remove the master cylinder (MC) or the hard brake lines. There is enough flex in the hard lines that you can remove the two nuts that hold the MC onto the booster and just pull the MC back out of the way leaving the hard lines connected. Note: don't touch the push rod that connects the booster to the MC piston. If you pull that push rod out too far the reaction disk will fall into the booster and you will very sad. Look up reaction disk for more info.

QuoteThanks for the help.

-

2 hours ago, wingwalker said:

The proper U-joint flange from JTR (the DAT-110-2 flange version) arrived in the mail--a nice piece, and I swapped it out for the improper one the previous owner had on it. Mated perfectly without any drama whatsoever. Tightening the four bolts that hold the flange to the differential is tedious, with two open-end wrenches achieving about a 1/16th turn at a time, but it's in . I finished rebuilding the brakes yesterday with the help of my son (who drove over from the Seattle area, about five hours from here). Wonderful father's day gift--two masked men getting grimy doing brakes on a car precisely as old as my son. When we flushed the brakes, we used up almost a liter of fluid until we achieved clear stuff--it was nasty stuff. Glad I replaced the master, the calipers and rear brake cylinders, along with flex hoses. Should be a tidy-clean system now.

Miles, you asked if I have a JTR manual. I do, and it has been a great help. But on the drive-shaft issue I didn't refer to it, since all I was doing was putting a part I had taken off back on. I am still astounded that that the previous owner was driving and racing with a driveshaft improperly mated and fastened. It depended on nothing more than the shearing strength of the four bolts--not the strongest way to use a bolt. Also, the flange had to have been misaligned. Must have vibrated like crazy! But thanks for the reminded; I plan on going to the manual as soon as something seems amiss--even if the P.O. had been using it that way!

My first 72 240Z was a father and son project. It was an old SBC v8 conversion that was badly done. There were so many conversion/mechanical/electrical issues with the car that we pulled it completely apart. It was worth the effort though. So I bought another 72 240Z and did the V8 conversion. The car had a severe vibration around 70mph. I ended up pulling the drive shaft and took it to a different shop. The shop discovered that the previous shop had welded the shaft off-axis after they cut it. The shop re-cut/welded and balanced the shaft. No more vibration.

The JTR manual is not perfect. Over the years I have found mistakes in the manual, but is does get you off to a good start.

Glad you found the vibration. A drive line vibration can make it impossible to enjoy a z car.

Mine is down due to a carb (Holley) issue and a leaking 240sx rear caliper. Got ten years out of that caliper (Nugeon)

-

Do you have the JTR Datsun V8 conversion manual? It covers all of the issues you are having.

-

-

TechnoToy Tuning is now selling their Micro Big Rear Bake kit. It includes a parking brake function and will fit under most 14 inch wheels. Has anyone purchased the kit?

https://technotoytuning.com/nissan/260z/240260280z-micro-rear-big-brake-kit

-

2 hours ago, madkaw said:

I hate to even say because my memory is so bad . I followed the instructions and recommendations that came with the kit . I do a a proportioning valves between front a rear brakes - set up where my old parking brake was. I remember that I had to put most of the bias to the front . I run wildwoods all around . It’s not the big kit , just two puck 11” I think

Is this a race car?

Door handle actuator rods

in S30 Series - 240z, 260z, 280z

Posted

https://zcarsource.com/door-rod-outside-handle-240z-260z-280z