HowlerMonkey

-

Posts

1454 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by HowlerMonkey

-

-

Here is my L28 priming method.

I get some clear tubing and cut a taper in the tip so I can shove it into the hole that feeds the oil filter.

You have to shove the tubing forward relative to the car's front end into the hole that is in front of the threaded filter.

That hole is the termination of the gallery that leads from the filter boss through the front cover and to the pump output.

1 foot of this tubing works well for this.

So....connect the tubing to a skinny funnel however you can and fill the funnel halfway up with oil.

Put a wrench on the crankshaft nut and turn it opposite of the engine's normal rotation.

This will suck the oil through the tube, down the passage, prime the pump, and also fill the pickup tube.

One quart or less will do it.

Remove tube and quickly screw the filter on.

Crank car for a bit and then pull the oil pressure sender and quickly put a finger over the hole.

Hit a remote starter switch or have someone crank car while lightly holding finger over hole.

If oil does not come out of sender hole then something is very wrong with the pump or the pump drive because you just primed the absolute hell out of it with this method.

Once oil comes out of sender hole, put it back in and crank car until oil comes out of the cracked loose turbo supply banjo fitting screw.

I've actually had an oil pump push zero oil after this priming method was used so I slapped on another pump I had, did the same priming, and instantly got oil pressure/flow from a different pump.

It's not easy to jam that tubing into that hole because you have to point it forward but clear tubing is pretty soft which makes it easier.

-

Is it a 4 speed or 5 speed car.

4.44 could very well put the car at 5300rpms at 75mph.

That's not a fun cruise.

-

Ok....they all have squirters in the rod.

-

The question is whether whether the starter locations would interfere with your install.

The Z31 version of the fs5r30 has the starter mounted beside the skirt of the block with the snout of the starter pointed rearward.

starter pics are oriented as if front of car were at right.

z31 starter.

The Z32 version has the starter bolted to the side of the bellhousing and exists beside the bellhousing with the "snout" pointing toward the front of the car.

-

I used to think the non-turbos did not have the oil squirters but yesterday I pulled a piston from a 1982 f54 non-turbo shortblock and found that the rods had a hole on the top that the 1981 factory service manual states squirts on the bore and the piston.

It's possible that earlier normally aspirated engines did not have them, though.

-

Had a little time on my hands so........Added a supra intercooler using various saab and volvo intercooler piping and stock volvo/saab hoses (cut to proper lengths for a stock look) that allowed me to route through the headlight openings in the core support without cutting anything or moving the stock air filter box and intake tubing.

A little black paint on the one non-black tube in the system should look damn near like the intercooler came from the factory.........maybe a little dirt on the one silicone coupler I used would blend it into looking more stock.

Boost is now referenced from the intake manifold because the intercooler system has a pressure drop across it that takes away 1.5 pounds of boost at redline and 10psi.

Stock nissan L28et "blow off" (vacuum control valve) is augmented by much larger recirculation valve that routes the backed up boost that stacks up in front of the throttle plate to the turbo inlet.

This is necessary because of the larger volume of pressurized air in the intercooler system versus the stock "j-pipe".

Now that the entire factory infiniti M30 induction system is installed, I can no longer hear the recirculation valve operating.........all you hear from this car is a little bit of fan noise and turbo whine.........well....and tires burning.

Wastegate spring was threaded for length adjustment but is set to 6psi and the car's been run to 10psi using the boost control valve (my limit for flat top engine with 93 octane) without any pinging and the boost shoots right up to 10psi and stays steady all the way to redline.

A "grainger valve" was used for boost control.

With this "grainger valve", the wastegate actuator diaphragm does not see any boost at all until boost climbs to the value you have set by adjusting the valve.

It's also good to run this if you have moved the wastegate actuator's boost reference from the turbo housing to the intake manifold because this valve is also a one way valve which means your wastegate actuator doesn't see the intake manifold's 25 to 30 inches of vacuum when you drop throttle at high rpms. (good for a 20 year old actuator diaphragm that has never seen any vacuum).

Grainger part number 5Z763 for $9.73.

I swapped the orientation of the ball and spring around so the ball seats on the body end rather than the knob end as delivered by grainger and drilled a 1/8 inch hole almost all the way through the body of the valve (not all the way through) with the .025 inch hole drilled inside the larger hole for the final 1/16 of an inch.

Most I have seen on the internet are drilled on an adapter.........but I did not want an adapter.

You can just see the hole near the orange loctite in the pic.

Sure you can try to drill that tiny and fragile bit all the way through but I was doing this in a vise with a standard and relatively large hand drill so the 1/8 inch hole minimized the amount of .025 drilling required.

The hole is in the body in a place that would not interfere with operation of the valve.

I wanted a more streamlined installation with minimal size and parts so I got a double ended hose barp, cut it in half, drilled the hole in the knurled portion of the grainger valve larger, and pounded the barb through from the inside to keep it captive unlike most I've seen on the internet where it is pounded in from the outside.

I did have to grind the barb lip formed by cutting the double ended barb in half so it would go into the knurled adjuster of the valve as well as shorten the spring a bit (might not have been necessary to shorten the spring but the bit of hose barb does shorten the compartment by 1/8 inch where the spring seats).

I also sourced the proper hose barb for the other end and did not need an adapter.

This leaves you with a grainger valve that won't spit out the barb that some recommend you pound in from the outside.

$80 total expenditure on intercooler, boost control, and boost recirculation system........all sourced in two 1 hour junkyard trips, one trip to lowes, and one trip to grainger........and some vacuum hose.

I need to do a couple of things like making the EGR work, the IAC, and deleting the aux air regulator as well as routing the water lines from the regulator/throttle body to the water cooled center section of the new turbo slated for installation.

Waiting on custom a/c lines and finishing a support for the rear mount of the power steering pump......well....that and a proper upper radiator hose.

Nistune will be purchased with DLP designs 8 channel usb data acquisition system as well as a dished piston L28et for higher boost levels.

Note the walmart "neverstart" marine battery which has two extra terminals and, for some reason, cost considerably less than the automotive use battery of the same specs..........at least when I bought it 2 years ago.

http://www.walmart.com/ip/EverStart-24MS-6-Marine-Battery/16782694

Currently, the extra ground cable makes battery to body and battery to engine connections redundant and the extra positive terminal can be used for something that draws big current such as amps for a subwoofer or maybe a huge laser to blind chumps who cut me off.

I mentioned a subwoofer but I found that putting 6x9s in the rear deck of a car with a decent sized trunk offers up some pretty tight bass and enough volume to leave my ears ringing after a loud song.

I had originally tried infiniti kappa 6 1/2 components but it was not nearly loud enough behind a $75 buck pioneer head unit without supplemental amps so in went some 8 year old (6 years in a box) pioneer 4 way 6X9s that were purchased because they had the LOWEST wattage rating I could find for that speaker size.

Sometimes you get lucky with stereo installations and sometimes you spend tons of time and money for something that never does sound good.

Since the car originally had bose speakers, I had to fashion 1 inch thick shims carefully cut into bizarre shapes as to minimize any obstruction of the 6x9 speaker through the very odd shaped speaker holes.

While the front 6 1/2s in the doors are pathetic in comparison, the 6x9s are shockingly loud and friends make me open up my trunk to prove I have no subwoofer or supplemental amps.

Fronts also used 1 inch thick shims because the door holes are somewhere between 5 inch aftermarket speakers and 6 1/2 speakers........pretty easy....bolt speakers to shims and bolt entire assembly to the door though I may be tempted to play around with the factory bose enclosures with an aftermarket speaker installed later on.

All speakers are under the stock covers so any sideways baseball cap wearin' thieving ass'd nimrod will see nothing worth breaking into the car for.

I'll try to add pics of the speaker install for the M30 guys because I have shared in their pain.

At least 25,000 daily driven miles so far and here's how it looked during my trip to kennedy space center to do some aero testing on the twin turbo ford GT.

It is parked under a tree I used 22 years earlier to pull an engine in my 1969 ss chevelle (455 olds) that broke an oil pump as I was moving and had only money for gas........but plenty of tools and the parts necessary to pull off the job.

This is located in a state picnic area on Indrio road just east of I95 in florida and the engine was pulled during a monster lightning storm.

Sadly, moving the seat forward to get my tools out poked a hole in my can of "off" initiating a panic stricken and can tearing application of the insect repellent but the downpour of rain washed it off I was eaten alive by mosquitos anyway.

-

Infiniti M30 with L28ET swap trying it's best to look like it was put there by the factory.

It's shy

Build thread here....

http://forums.hybridz.org/index.php/topic/74589-l28et-into-infiniti-m30-begins/

-

I have 3/4 inch between radiator and fan and about 5/16 inch between the fan blades and the 280zx front pulley.

I played around with different fan clutches and blade combinations from the junkyard and am currently using the 240sx clutch and what I think is the 280zx blade......but it might be 1984 maxima.....might be the same as 280zx, though.

The 240sx clutch is 2.3 inches long from flange to the face with the thermo bi-metal.

It's 1.8 inches from the flange to the stock mounting surface.

This will definately put the blade into the radiator on my L28et Infiniti M30 so I simply mounted the blade to the other side of the clutch (same rotation...not backwards).

I used longer bolts and screwed them so the heads bottomed on the surface where nissan intended the fan blade to mate (bolts pointing toward back of car) and used what protuded through the other side as studs.......which I screwed standard home depot metric nuts to use as the "spacer".

You can always substitute the 3/16 thick nuts for thinner washers to get further away from the pulley or thickness to get closer to the engine.

I may have had to grind the inside metal lip on the fan blade at a 45 degree angle to clear the clutch fins but don't remember if it was necessary after using the nuts as spacers.

Because the center hub is no longer centering the blade, I just turned the blade and clutch opposite directions forcefully while tightening it which centered the studs in the holes far better than I thought.

This causes centering on the bolts/studs and I have driven this combination for 25,000 miles.

This setup gives from 1/4 to 3/8 clearance of fan blades to crank pulley with provision for a/c and power steering.

Remember to measure any washers you might use for spacing since many found at places like home depot vary in thickness.

Some L28 pulleys (maybe 1981 turbo?) have the outermost pulley being removable....just not sure which one.

One thing to do is to check for fan blade contacting anything whenever you are under the hood (you will see the evidence on the blade) and occasionally rev the engine while watching both with clutch cold and free and when warm and fully engaged since wear in the fan clutch can cause the blade to move outside of where you would like.

When things are this close, a wearing clutch or water pump can cause the blades to hit where they should not.

I sometimes use a timing light in the dark when viewing rotating parts to check for clearance.

Once you know your dimensions, it's easy to go to the u-pull yards and audition many different combinations there for measurement.....without spending any money but also keep in mind that nissan made at least two different bolt circle diameters with the trucks/pathfinders having a wider pattern than the 280zx/240sx.

That said, every single clutch I have come across has a different temperature at which it "comes on" and I've spent considerable time carefully bending the super brittle spring to get the perfect combination of noise vs cooling performance. (care must be taken since the aluminum shaft the spring acts on is fragile and will break internally if you turn it too hard or too far.........they should move very freely with light turning pressure from a screwdriver inserted into the gap between the spring and the shaft it mounts to)

I've got 25,000 miles on the setup at the very least but one thing to know about having a fan blade very close to the radiator is that drivetrain movement during hard deceleration at high rpms might induce it to strike the radiator when it would not under all other circumstances.

This can happen because high fan rpms will pull the fan blade tips toward the radiator a bit and hard deceleration will cause soft mounted drivetrain to move toward the radiator.

Add the two together and you could have issues if you are that close.

I'll try for some pics of different combinations later.

-

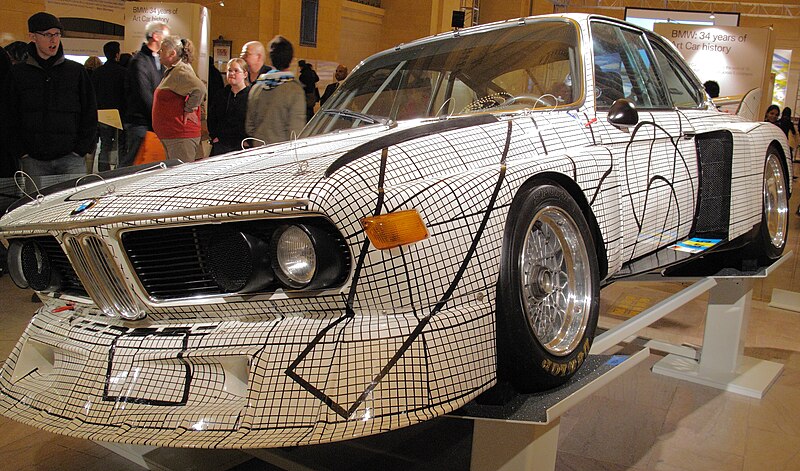

I have a good answer for the "why bmw?" question.

"because BMW was running 850hp inline sixes in the late 70s.

-

I'm curious what other beast you have that gave up it's magneto for this car.

-

I've never had to replace the 1981 sensor but have replaced 5 1982/83 distributors for intermittence issues.

-

I've started back up researching this which has become a quest to use obdII ecus that litter the junkyards of america and can be had for 30 bucks and the harnessing for about the same price.

I've settled on the quest/villager/frontier ecus for this reason.....and the fact that my current M30 ecu setup is getting hard to find anywhere.

The intent is to be able to flash the ecu through the OBDII port but I am having trouble finding anyone who makes an editor for the calibration files for these ecus and I believe the addresses for the critical values are in a different place making rev-up or osirus useless for this ecu family.

I guess it's time a huge amount of time to put the known values into the search dialog of a binary or hex editor so I can find where the values exist on these ecus......unless someone knows of an editor that has been successfully used on these ecus.

I really need to find an ecu for a supercharged frontier/xterra and see if I can run the non-supercharged ecus with these settings.

If you guys find one for sale, please let me know.

-

Stay away from any LT1 ecu that has the numbers 16159278 on it.

These are for the 92 and 93 cars....possibly other years and the ecu itself experiences failure rates about 10 bizzillion times those of other LT1 ecus.

Delco used a conformal coating on the boards that is applied as a liquid that hardens into a flexible coating.

Sadly, the formulation of this coating tends to expand with age.

This is not good because it expands under the suface mount components on the board like tree roots under a sidewalk and has been known to even pop large chips right off the board.

Standard, blue streak, and a1 cardone have varying degrees of failure fixing these and I have personally spent many an hour using super secret chemicals to remove the coating without damaging the boards and components yet these ecus still have a super high rate of intermittence........even after resoldering most every component.

It's best to go with a system from a later car.

-

Any of you guys worked with trying to attenuate the noise between the block and the knock sensor so the valvetrain noise doesn't trigger it?

I guess I need to do some capturing of the "sound" by various sensors and check the waveform under true knock and no knock conditions so maybe we can find out which sensor works best for the nissan L6.

The problem with knock sensing is that different sensors have different outputs determined by the knock frequency of the application for which they are tailored.

I just got done running 87 octane in a f54 with flattops and a p90 head with 8 pounds of boost (intercooled) and am finding no audible pings or knocks so it's possible my infiniti M30 ecu using a M30 knock sensor screwed into the f54 block knock sensor hole is actually working as it should........but I doubt it's optimum because I'm sure the vg30 sounds the sensor expects to hear are a little different in character.

One of the perks of having a dead silent exhaust system is being able to actually hear what's going on with the engine.

-

I use 1 1/4 inch long hex bolts that are of the correct thread and use a fender washer on between the chain and the block then I snug them up slightly beyond finger tight and pull away.

Never use the factory bracket on the rearmost stud of the exhaust.........unless you just screwed in a new one only minutes earlier.

-

Wow, that's really fast.

I'm guessing windshield rake is mandated to be stock?

-

The 240sx trans will not bolt in.

But....people have swapped the front case of your 280zx trans. onto the 240sx trans. with a certain amount of work and resizing some things.

Your best bet is if they have another one to give you and you might get one that had been reman. relatively recently.

-

You could send it in to blue streak for R and R or use the critical core program where you get a functioning unit returned to you.

http://www.bsecorp.com/products_remanufactured_services.php

You would have to do it through an auto parts store or a shop that deals with them.

Also....remember that the 280zx ecu is generally not compatible.

-

Doesn't the swap require similar work as a bearing and synchro replacement?

-

Bearings and a couple of synchros should quiet it up but definately look for gear damage as I suspect that a bearing has gone south and it's possible that bearing parts might have damaged other things.

-

If you don't have spark, it's possible the ecu is not seeing a rpm signal from the distributor which will cause it to also not fire the injectors.

Also......check whether you have +12v on one of the injector terminals when the key is on.

-

Good question.

I'm wondering where I can source a tank in either plastic or something without zinc for a future LD28 with turbo project.

-

Thanks......would check these out but there are no ford diesel trucks that seem to make it to junkyards.

I'll keep searching for the honda baro sensor or just weatherproof one from mouser.

-

I use boat gas tanks and connectors........they type you use for outboards on smaller boats.

You put a T fitting between the tank and the pump for the return line from the injection rail.

3.1 Stroked L28 Deceleration Afterfire

in Nissan L6 Forum

Posted

I would also look into the carburetors to see if you can see fuel dripping out of the main jet while idling.

This would indicate too high a float level or a stuck float.