letitsnow

Members-

Posts

866 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by letitsnow

-

I don't see a section in the manual about the rev limiter, but through searching, Ive found suggestions of retarding a large amount and setting it to cut 1 spark from 1 event, I have the max retard set to 25.5, which is the largest tunerstudio will take, it also won't take less than 0. It doesn't seem to do anything. The datalog shows that the timing retard works, but it won't prevent the engine from revving, testing at 3000ish rpm it knocks the timing from 36 degrees down to 10ish degrees. Fuel cut also works, but I'd prefer to use spark cut. I've tried cutting 1 from 5, 4 from 5, 5 from 7, 9 from 10, and 1 from 1. Nothing seems to make a change, it blows right past the limiter. I'm using a zxt distributor with the MS firing the coil directly. MS2/e 3.1.0

-

I think it's fixed, I haven't turned the boost up yet, but it's faster than it's EVER been, at any boost. Today, with the 'A' cam and my extra p90, the car ran a 13.4 at 101 with 8psi falling to 7psi around 5100.

-

Yes, you need to use a cam that had solid lifters to begin with. If you want to stay with a factory cam, go for one of the pre-'81 N/A cams, marked A on the back. I noticed a nice bump in mid-upper end power with little to no change down low.

-

Tony, I was wondering what your thoughts on reusing MLS head gaskets were. My kameari gasket has been used twice now that I know of. Last time some of the rubberized coating peeled off, so I scrubbed it to bare metal and liberally applied copper coat. Working under the valvecover, I noticed what looked like a small amount water pooled in the low spots of the head, the oil was not milkshakey and the water was clear, not antifreeze. Think it was condensation?

-

Who'd be interested if we made a L28ET trigger wheel?

letitsnow replied to Matt Cramer's topic in MegaSquirt

Not unless you want to run semi of full sequential, or coil packs(COP or wasted spark). If you had MS2, it would increase the timing accuracy somewhat. -

Who'd be interested if we made a L28ET trigger wheel?

letitsnow replied to Matt Cramer's topic in MegaSquirt

I'll take one. The vg30e(z31) should be the same, people swap those wheels in when they convert to a z31 ecu. -

Did you change the cam when you changed the lifters? I just did the same swap with a '77 N/A cam and adjusted to .008/.010 cold(per FSM) and they were very quiet.

-

The B and F are identical, except the F has a 4 degree advance, not worth taking the valve cover off. If your turbo cam is a J, then maybe, but I'd only bother if you have some time to kill. I think I'm going to pull the warped head and put on my extra P90(solid) head. The cam spins freely in that, so I don't think it's warped.

-

The FSM says to set it at 10 degrees at an 800rpm idle. Loosen the 2 bolts on the base of the distributor and turn while watching the timing light until you're at 10 degrees advanced.

-

So you're running a fixed advance? The weights are removed and the mechanism locked? You don't have an advance curve, you have an advance line, no adjustment is going to make it into a curve without replacing the internal mechanism.

-

Would it be a terrible idea to buy some .001" shim stock and make my own shims to get it to spin freely?

-

Well, I think the head might be warped. at least the top of the head. I can torque all the tower bolts(10ftlb) and head bolts(25ftlb, to test alignment) except the center and it will spin freely, tighten the center and it binds right up. I noticed what feels like a ridge in the shape of the tower under the center, like the tower indented the head slightly. Do I have any options other than: 1) put it together and forget about it 2) pull the head and have it machined I don't really like either.

-

http://www.atlanticz.ca/zclub/techtips/cam/index.htm That has the specs for all the factory L series cams, the '82 N/A is kind of in between the turbo and the s30 L28 N/A cam. My comparison won't be apples to apples as I was having mechanical issues that the cam swap solved. The p90a also has the smallest of all L series cams. I can say that it is leaner up top, meaning more air is being ingested, and the car does pull harder above 4000rpms, smoothly up to 6k. Now, off to tear it apart again.

-

I'm hoping that it's just a bit of crap under one of the towers that I didn't clean well enough, the old cam spun pretty freely, maybe not '2 finger' but better than this. I'm nearly positive I didn't mix up the towers. When I put it together last night I got 2 finger and 2 hand mixed up and thought I was alright until I did some research. Should hopefully be able to tear it back down tomorrow, if I. A major revelation I had turning it over while I was setting the lash, I could feel the compression stroke, I never could with the old valvetrain. I just attributed it to being a small low compression engine, being used to large-ish, high compression v8's.

-

Well, on 7.5-8psi it feels very strong all the way up to 6k. After I nail the tune down we'll see how it does on 12. *crosses fingers* Question: cam tower alignment, with all the M8 bolts torqued down, the cam spun pretty freely, after torquing the head bolts, it was pretty stiff, it took 2 hands to turn. Should I take it back down and try to get it to spin more freely?

-

sleeve coilover or complete S13 coilovers

letitsnow replied to Wedge's topic in Brakes, Wheels, Suspension and Chassis

I came to the same conclusion through my research. My car now has sectioned struts, unmodified bilsteins, and 200/225 springs on coil over sleeves. I couldn't be much happier, maybe if the valving was a little more digressive, but I'd do it again. It's FAR more comfortable than a good friend of mine's 240sx with Tein HA's, and has more grip. His seats are a lot better than mine too. -

They knob that put the head together stripped BOTH the bolts on the center cam tower. I've got them repaired now, so in an hour or so I should have it back together and ready to take for a spin. Edit: make that 5 total stripped cam tower bolts

-

The piston is how big in the adjuster? I'd say a MAX of 5/8". Assuming 75psi of oil pressure, 3/4" dia piston, I calculate that it's got maybe 33lbs of upward force, in my little best case scenario. 75*(.375^2*3.14)=33.11 How heavy is the spring in those things? I couldn't budge them by hand, so I stuck one in the vise with a piece of wood on either side for cushioning, it crushed the wood and didn't budge the adjuster a bit. Hopefully I can grab a helicoil kit today and get that cam tower bolt fixed, that certainly wasn't helping anything. The stock gauge reads over half way up the scale at cruise, it is questionable in accuracy though. I'm confident in the bearing clearances being alright, but maybe the pressure relief spring in the pump is weak. The cam is from, a '77 280z, so it should be the 'A' cam everyone says is an upgrade. AtlanticZ.ca says it has 8 degrees more duration and nearly a mm more lift.

-

loud turbo and exhaust could easily hide it, the turbo is LOUD. The oil pressure might pump it back up enough so that it doesn't clatter much, but won't open the valve. Really there are a ton of things that might make it do weird things, but that's not going to stop me from finishing the conversion to mechanical adjusters and an N/A cam, my confidence in these hydraulic adjusters is gone. It does clatter at idle somewhat, sometimes more than others. In the video, I grab the pivot ball of 5 HLA's(4 separate cylinders) and move them up and down through their full stoke with no effort at all, gravity would take them back down from the fully extended position.

-

I was all ready to put it back together, then I found out that the threads for one of the cam tower bolts was stripped. Hopefully I can find a helicoil kit, and not **** it up. I think this is the last week the track is open for the year. When I took the ones that were collapsed out, they sprang back and felt normal. I think the spring binds in the body. I decided to still convert to solids.

-

I think I found the problem, video incoming after I get a bite to eat and the camera charges a little.

-

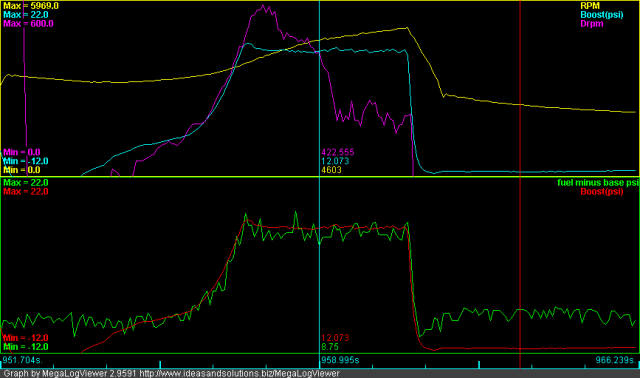

I believe it does fall off naturally because of the cam, but I don't think the 12psi graph is normal falling off. The 8psi graph doesn't have the sharp drop off at 4700 like the 12psi graph. If it was a smooth-ish drop I'd accept it, like the 8psi graph. It's not a consistent drop in power, sometimes I do get a clean 3rd gear pull, no sudden drop in power. I'm VERY confident that they don't all do it. Edit: the average for the 8psi graph is ~315, the average for the 12psi run AFTER it falls off is ~205, I see no reason why the power(or RPM/sec) should be lower at a higher boost in the same gear at the same rpm. The timing doesn't do anything funny at that point either. It does it in every gear too.

-

deltaRPM can basically be considered acceleration, calling it 'delta' was probably incorrect. I was trying to demonstrate how the power goes away rather abruptly. I think the units for deltaRPM should be RPM/sec, or somewhere near. The drop from 500 to 200 shows that after that point, it's making ~2/5 the power it was, yes it's a VERY rough estimate, but I thought it might describe what I was feeling better than just saying power fell off. Here it is again, but with some rather crude, but aggressive filtering.

-

The first picture picture is the same as before, but with the derivative of RPM as the purple line in the top graph. The second picture is at 8psi, the first at 12psi. dRPM falls from ~500 to ~200 on the 12psi run, just to give you an idea of the power loss. Gap is now .022"

-

Fuel pressure sensor is wired up, here is a log with fuel pressure-28psi vs boost pressure. The red arrow is where it fell off.