-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Tony D

-

-

You aren't looking hard enough, there's a dark gunmetal 432Z Fairlady lurking around Oki near MCB SD Butler.

Okinawa's Okinawa, it's Japan Light.

-

"Posting here is like getting to speak and ask questions at a panel discussion with race teams. Know your subject matter BEFORE standing up and making a fool of yourself."

This is a good point. In my case and several other people I work with, we have spent more hours than you think seeking out the information referenced in vague terms in many of hte reference texts dealing with the L-Engine. In once particular instance someone quite well known was contacted. Nothing was insisted upon, but rather, a reference was given about checking out Land Speed Records if they wanted to know some more about what we were doing.

Several days past, then a week. Reports started to trickle back that people were asking questions about us... and then out of the blue the targeted individual calls back and puts forth a flood of information we vaguely asked about, then went into detail about more... and finally gave us a personal phone number to call if we had any more questions.

What gets me is WHEN I DO TRY TO DIRECTLY GIVE THIS INFORMATION OUT, people refer to it as 'hear-say' and demand documentation. Well, I'm not giving out the guys personal contact number. That was given to me in confidence. That I TRIED to share it was my effort at conveying it. There's little more that can be done---be a skeptic and miss out on the information. Eventually you will have it confirmed on your own...or not.

What I have found in the VAST MAJORITY of cases is that generally the knowledge gained is NOT SPECIFIC to the engine being developed. It's known by many different people in many different fields. It's not God-Knowledge, but what it does require in many cases is CROSS-DISCIPLINARY inquiries and a sharp enough mind to know what questions to ask. When you get someone like a team or engineering development manager on the phone who DOES know all these inter-related questions, the flood gates open up. They see you are at a level where you can handle the information they put forth. Specificity can be mind-numbing. Ron at Isky can literally talk for an hour on aspects of cam design. I don't deign to waste his time trying to impart it to me, it won't do me any good. And learning when to defer to a specialist is a key in good engine development. You can NOT know it all, you can have a good general knowledge, but likely you will get more farming out aspects of the job to someone who KNOWS his SPECIALITY far better than you will ever command it. Good managers know where to get the best people, they DO NOT try to know it all, nor do they waste time trying. Specifics are for hands-on workers and skilled trades. You won't win a race knowing what particular valve angle to put on a seat. You will win races knowing that beryllium copper is likely a better material than brass, and this guy at X Shop knows how to put in the seats so they never come out!

What it takes, primarily, is an open mind to NOT think like the herd when dealing with lower-level paradigms and myths that are propogated on the internet...but rather a lot of hard footwork progressively working up the ladder of knowledge diligently and asking a lot of questions along the way.

YOU WILL ONLY BE ABLE TO DIGEST INFORMATION WHEN YOU ARE READY TO DO SO---TO HAVE IT HANDED TO YOU WHEN YOU WON'T UNDERSTAND IT IS LESS THAN WORTHLESS, IT'S DANGEROUS AS YOU LIKELY WILL TAKE AWAY THE WRONG CONCLUSION DUE TO INEXPERIENCE OR IMPROPER TRAINING IN OTHER FACETS OF ENGINE BUILDING!

The answers and questions people give tell a lot about where their level is...if you're an 18 year old kid building his first engine most top NHRA builders will NOT give you specifics, they will give you generalities to best help you along the path. You are not ready to build a 10,000 HP engine, though you want to and think you are ready. They will give you the solid basis for the next step. You don't learn Hakatsuru the first day in Karate Class, you learn Pinan Sho. Or before that, how to fall. You learn and practice falling a LOT before you ever actually do anything!

It's not God-Knowledge like Gollum was talking about, he's absolutely right in most respects to what he says. It's simply a matter that I've been asking directed questions, and seeking out the TOP PEOPLE in particular disciplines for now going on 31 years CONSISTENTLY AND VORACIOUSLY and if I had more time, I'd give more time to it. The only way you are going to get to this level is not by getting spoonfed answers all at once---it's a process that takes 31+ years. It's not The Matrix where we hook up and ZAP! "I know engine building!" Oh how I wish it were.

No, in the real world you have to use patience, intelligence, and humility in some cases to garner the building blocks. Rome wasn't built in a day and most likely neither was a good running L-Engine. You have a long path ahead and the older the engine, the older the experts you will have to consult. One head builder couldn't get the flow he wanted on JeffP's head. He took the head to his DAD who originally ported and developed the Electromitive heads. Dad did something because it flowed a heluva lot more when it came back for testing.

And you couldn't SEE what he did. It LOOKED identical.

THAT is when you need to be REAL humble, and start asking questions to figure it out. It wasn't something cookie-cutter, that's what got it where it was on the first try. What got it to it's final stage was something SPECIFIC done to THAT head that a guy in his 70's noticed and applied. To learn what he did to identify what specific technique to that head is invaluable----if you are a head porter and wish to make a living at it. As a race team manager, or crewman, or owner of the car...it's an interesting bit of trivia and likely you shouldn't clutter your mind with it. JeffP is getting offers from people to 'do all your head work for free' now... Hmmmm, someone want to reverse engineer some stuff? Talk about humility! FREE WORK?!?!?! That is someone who WANTS TO KNOW!

The important point is if you don't find these people before they die, and milk them like sponges for their knowledge, it will DIE with them and it will be HELL 'rediscovering' what it was they knew for 50 years before their death.

Respect your elders, they really do know more than you do. And if you approach it right they are more than willing to share. But if your an a-hole about it, they are also content to be satisfied to know what they know and die that way. I know I am.

The person who looses is you.

-

I would think a small sized capacitance sensor in the bell of the regulator that gave an alarm light would work as well, given it's likely grounded pretty well on the fuel rail to the manifold. Sensor gets wet, gives 'broken diaphragm' warning light.

No vacuum leak, either! But more expensive and likely some electronics knowledge needed to implement as well as finding a small enough sensor that will fit in the regulator body, and not hinder proper function of the device!

-

There was a time before the internet...

Note the data was taken in FEB, and PLOTTED in APRIL.

So someone had a data log, and then PLOTTED the curve. MADE the curve. Not something done automatically.

This leaves stuff open for interpretation by the PLOTTER.

Ron was dead on my intent, piece of cake to fake.

But this is also HALF the story I was referring to... Perhaps someone has the original logs for the other half of the story.

It's like I said about confirming Thai Inscriptions that don't reference a date but which mention an event...one that can be found in other accounts that CAN be verified and cross-checked against indications in the inscription. FAR more reliable a research method than just trusting something on the internet.

Performance existed before commercialization of the internet. Because those people don't go and post up their accomplishments 30 years after the fact doesn't make them any less reliable or confirmable than some swarf posted in self-aggrandisement blogs using falsed-up data sheets!

Matter of fact, I tend to trust them MORE (as stated previously) because they DON'T have anything to prove. They won everything and conquered all. Their record speaks for itself. If you think they REALLY only had 750HP, and only ran 20.6 psi of boost... Take a gander at what Nissan had to to in 1991 to get that 1000hp out of their V6.

(FYI: 1 PSI of Boost is roughly equal to 2" of Mercury... do the math!)

-

Well, my car does it...

What's your source for arguing it won't happen---if the expansion tank was not needed, then why wouldn't Nissan leave it off?

Why, on cars WITHOUT the tank did they have a 5mm line in the filler neck vented to the atomsphere (wanna guess what happens when you fill the tank cold and then let the car sit in the sun...two guesses, first one doesn't count.)

Seriously JM, how is this a point of argument or dispute? Are you seriously contending that gasoline does not expand and contract by volume when the temperature changes? The tank is there for a reason. If you are content to short fill your tank to 11.7 gallons and leave 10% for thermal expansion every time then fine...

But if you fill that tank to the top of the filler neck and put the cap on some cold morning...and the sun comes out later in the day...

Well, there are PLENTY of Z's with gasoline stains from a leaky tank...and I have seen more than one overflow from thermal expansion when filled in this way.

Aircraft support equipment, too!

Sometimes, I think you dispute things just because you can. Where's the logic in your rebuttal 'because we haven't heard about it, it's not a problem'...well how many people do you know that remove the expansion tanks? Maybe you don't hear about it because people replace the vent hoses and don't hack-job a shadetree 'fix' into their car incorporating plumbing supplies and JB Weld.

-

The goal is to make the respective bonded discs to not be able to separate from the elastomer. Simply putting a bolt through the bottom side of the mount and thread it up into the aluminum spacer (as you have it drawn) with the bolt secured with loctite would do the same thing.

It's the same way you make the stock Nissan Mount tear-proof.

Really, it's easier to put a link or small chain to the K-Member to the Mount-to-Block portion of the stock motor mount.

Or a link from the upper starter bolt to a reinforced box channel laid over and secured to the unit body.

Keep the engine from moving (torqueover) --- either by solidly linking it to the chassis, or limiting it's movement to less than 0.125" will prevent the mount from being torn open from excessive forces. And if it ever does go, the link is there to hold it in place---same as a bolt through the mount itself.

Personally I prefer the links because you can preload them as you desire.

-

"This post will upset Tony. I was typing while he was typing, therefore I have written things he just mentioned."

No it won't, this stuff is standard on any engine, and any port. The reason you wrote things I mentioned is because these things don't change.

The common thing I see is that you don't like giving exact answer. I respect that, let us figure it out on our own, aim us in the right direction.

Some of that is what is going on, but I don't feel I need to type over and over stuff that is extensively documented elsewhere. If you are asking for an exact spoonfeeding of information that is already out there if you look...welll that ain't gonna happen!

However, that sort of system is inherently open to interpretation. If you don't say exactly, then some conclusions may be drawn that are incorrect. What else would be expected unless instructions were do exactly this, do exactly that. If you say "drill the oil hole out..." ok to what size? "Well figure that out..." Yes I could figure it out on my own, probably at the cost of an engine or two. Does anyone want that?

In the oil hole instance, someone asked about a particular thing and I believe my answer was "Why don't you call Frank Honsoweitz at Ed Pink Racing Engines and ask HIM instead of posting queries and getting vague responses by nobody who knows a damn thing." And I do believe he did, and got the EXACT answer he wanted, and then POSTED it. Why would I tell him when some internet a-hole would argue with me---EVEN THOUGH I would give you the same answer at Frank... If he calls Frank and gets FRANK'S ANSWER who will be able to argue with it? Nobody, he wrote the book and HIS MEANING is exactly what he will give you. Not someone else's interpretation of what Frank wrote. As for exact answers, it doesn't work like that. You are unskilled and your insistence that a 'one size fits all' answer is possible. That is a foolish position to take. In many cases ther IS NOT AN EXACT ANSWER. The more you get into building serious stuff, you realize that EACH ENGINE will be different. Major dimensions will be one thing, but the difference between a stock engine making 120HP on the dyno and the same components making 209HP in a competitive ITS engine is not something you will easily share by saying 'tab a into slot b with a 0.040" cut...' It doesn't work like that. As Leon says, you are getting upset at your own ingorance on the subject, and blaming other people for not spoonfeeding you EXACTLY what you want NOW NOW NOW! Well, as said above "that ain't gonna happen" when the stuff is already out there and documented already. That is not what this site is about. I'm tolerant as hell, but when someone comes insisting they are entitled to exact answers for their particular problem...well cut me a f-ing P.O. my rate starts at $1250 a day, and then we can talk about your EXACT situation. But discussing your EXACT situation doesn't help the other guy now does it.

Referring him other sources where he can learn the theory behind the answer will...

-

A nylock style nut on the bottom independent of the attachment studs would be all you need. Drill the hole through the bonding discs on the McKinney mount and install two smaller bolts (maybe M6 or M8) with nylocks and a wavy-spring to keep the tension on it without limiting the vibration dampening advantages of the mount.

You wouldn't really be able to use the center bolt, it would have to be tight and that wouldn't really leave the isolator do anything other than be compressed.

Corvair motor monunts were like this---not captive. The engines would fall out. Remedy was to put a through-bolt on the laminates to keep it captive.

-

Those dead dolls eyes on the link are what Captian Quint was talking about in Jaws...like you are just about to eat the camera...

Big-Phil, the Land Shark!

Da duh, Da duh

-

Daikoku wins the cookie! The Nissan Gallery is literally right around the corner from this parking area so it's very easy to spend the day at the gallery looking at the new Nissan Models, and whatever heritage vehicles they have on display, then make your way over to the parking area after the gallery closes (though that is VERY early on a Saturday Evening, we ate dinner in the interim...)

RTZ you don't get the cookie, your documentation of that horspower is posted in the wrong thread!

-

If it's going to have race gas in it anyway, 12:1 is low...

As for ports I already explained the difference between carbs and EFI, if the ports are 39mm, it's EXACTLY what I said: a constant taper from 44mm down to the backside of the valve to keep velocity increasing all the way to entry point.

If you are running 50's and run a 50 manifold, chances are damn good that the head side of the manifold will be BIGGER than the port in the head, and then the port in the head will have to be made larger to stop the step that will occur. This will not benefit from "Match Porting" it needs to taper all the way to the bowl area for proper results. You simple make a taper over an inch inside the head (definition of match porting) and you will upset flow due to the radically different taper introduced. A 7degree maximum taper over the length of the intake runner, from air horn to intake valve is what most describe as the most angle you can have.

I don't know where this other stuff is coming from, sometimes I shake my head at what conclusions people draw from what is said sijmply and in a straightforward manner. Some of this makes me realize the effects of 2+2=5 in the public school system. Everything is open to interpretation because it feels like it should be... OK, take the metal out. You will only ruin the head if it doesn't work. There are plenty out there simply get another one and make it again. Report on the results of the test if you 'wonder'... Sheesh!

-

Constand hiss with no letup, or with pulsations? Worse when it's cold or warm? What happens when you do a power balance test with the spark plugs?

-

First it's NOT an "Ansa Exhaust", it's a NISSAN exhaust. There is a Nissan Part Number for it. The extractor exhausts sold in Japan for years replicated this exhaust system.

As for the 'magnesium wheels' being standard on the 432, that is also incorrect. They had a magnesium wheel OPTION, but most were shod with standard ZS style standard stamped steel wheels and bias ply tires---the cheapest thing available to roll the car off the transport under the thought that the car will be used in competition and whatever wheels it's sold with would be used for roiing transport and not ever really used on the car for anything other than that!

I had the exhaust page stored on my computer, but I can't find it now...damnit. It's in the exhaust section of the 1972 Fairlady Z parts catalogue. The same exhaust (or very similar) is on the Rally Car I posted photos of earlier yesterday as well. It was a standard design for Nissan.

-

If there's time to resize everything someone posts beforehand, Erfanview works well and is free.

The size reduction from even standard 'low res' photos on many of todays megapixel wonder-cameras can be startling.

If there's time before posting. You should notice it when you are uploading as well. If it's taking a while...chances are the file is huge!

Erfanview it!

-

No offense Phil....

But any video that STARTS with your face full frame and runs for 10 minutes has more on it than I want to see!

Now if you attest to me that your face is only on for "X" seconds and the rest of the time is some goryphantasmic display of engine carnage I can simply run it and close my eyes tight for those seconds so I won't have the nightmares...

-

185-14's it's in one of my photos. Bridgestones 'For Rally Use' Can't remember if they were 85 or 65 series tires.

And I DID look for the camera with the GPS option. I decided originally on the S220 becuase it was smaller.

Bad decision. The first one failed in four months. I found an identical one in Hiknoe for about the same price and bought it to keep the documentation at the jobsite rolling. It failed. So I picked up the S3000 at Costco because it was cheaper and used the same batteries.

To be totally honest, I wish I'd gotten the one with GPS in it for the following reasons (some of which make a BIG deal to me due to this being a work camera):

DOES NOT FOCUS IN MACRO WELL AT ALL---8CM is the closest I can be. My old 4300 would go to 2cm and I could manually force some settings to allow closer if I had to...

THE LENS IS SHITE!---yeah, it's 12MP, but even on small photos on the screen, you can see the edges of the frame are blurry and out of focus, I put it at the fault of the lens. My 4300 was not like this, but it's lens was as big as the lens BARREL on this camera, and probably twice as long with real glass elements in it.

DOESN'T FOCUS WELL IN LOW LIGHT---really for work more than play. Not into my own pornos, but do need to take photos of stuff in the shadows and nothing sucks worse than getting a 'focused' indication and the flash going off....and then seeing nothing but a blur.

SHUTTER RELEASE IS GETTING DODGY---this one had a 'delay' in the shutter. I have recently come to understand this is due to having to press harder on the shutter button than either of the prior thee I've had. If it wasn't for the size and funky huge battery, I'd have stuck with my 4300, it was WAY more camera than this series of new ones.

If they had one that used a larger glass lens with close-focus capability and half the megapixels I'd be happy. I'd not buy one of these again. I was misled by the stellar performance of my old 4300. Even at 1280X960 which is my normal resolution before, the photos were much better quality.

Downfall of the GPS camera at the time was that it was almost the exact same size as my 4300, and I need something SMALLER THAN THAT to be able to pack it all over the world.

-

Wow, that was on my birthday...

I was at Spa Francorchamps that day. Saw two Z's all day long, both of which did fairly well in competition against their chosen foes!

We want to see the video blowing up the engine. Maybe in-car footage when it goes.

That is far more entertaining that clean passes and children squealing!

LOL

-

I don't kmow but I want to be there with you!!

No you don't---I pulled out of the Philippines the day before Supertyphoon Megi hit, and now I'm told it's IMPERATIVE that I be on a plane to Shanghai in the morning to meet another engineer flying out from PA as we type/read this!

Guess where Megi just landed and caused all sorts of carnage? Fujian... HongKong...

I can't escape that damnable storm! I know I'm going to get rained on this coming week, I just know it!

-

Hear-say?

I can put up a dyno chart tomorrow for my car showing 900 RWHP and have an impressive list of components.

What does that prove? That I'm good with a Mustang dyno and can skew a chart?

Seriously, I get a laugh when guys offhandedly refer to people who are automotive icons and proven winners and recordholders serious discussions and brush them off as 'hear-say.'

I can tell you what motivation someone has to post a current fraudulent dyno sheet.

Can you please tell me what guys who are no longer invovled in racing, have nothing to prove (since they won everything already), and who are simply answering direct questions put to them in a serious discussion about what their accomplishments were 20+ years ago...what exactly would they have to gain by lying? And with that thought in mind, these busy people (some of whom took weeks ahead in planning to talk with) all decided to conspire to fix the numbers at a set given level which did not correspond in ANY way to what was given out to the automotive press while they were STILL in competition?

I mean, when the 750hp figure was mentioned, one of the guys actually burst out laughing, and said "Oh yeah, THAT!" And then offhandedly said "I think that may have been the 2 liter number, it sure as hell wasn't the 2.8! We made XXXX out of the 2.8!"

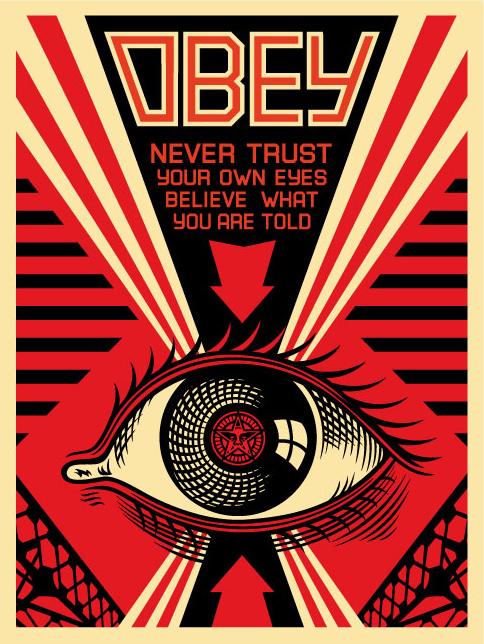

I can see where this is going now with this logic... This isn't the government telling us something, dude. We don't need to invoke the Obey Axiom here...

The incidences of falsed-up dyno charts I have seen makes me FAR more apt to disbelieve a guy trotting out a scanned dyno chart posted on the internet than some 60+ year old guy reminiscing about the things he did when he was in his 30's and 40's! ESPECIALLY when the record seems to back them up!

-

Hey! I think I know where that is! I was just there yesterday and that was NOT in the Gallery...

I, too would be interested in the whereabouts of a Z432 in America. I came within days of importing an original green 432 to the USA in 1989 and have recently been in contact with that cars owner... If there are other examples in the USA, I would like to at least know their geographic distribution... (PM Me if you don't want it public.)

-

"Longevity may not have been something that was of major concern to the engineers when they were selecting heads for some of their JDM turbo engines. They may have known the problems associated with liners and EGT's, but thought what the heck, they pass inspection now and before the liners cause trouble, most of the cars will be off the road anyway. If this becomes an issue, we can afford to deal with one off's as they occur...... mentality."

Planted a seed of doubt? Hardly, but you have convinced me you have a fully-entrenched mindset of a westerner!

If this was the case, why have an O5L at all? The reason the non-linered heads exist is due to places where they can not be applied. If you knew the testing that goes into each engine permutation then the additional governmental compliance documentation and testing as well as for the home market type certification and classification you would realize at once what such a thought process came from: total disconnect with the realities of manufacturing within Japan in the automtoive market.

Want an example? In the 70's when the emissions laws were changing, one Japanese Manufacturer came into a bit of type compliance issues with US EPA. They produced REAMS of documentation showing the statistical impossiblity that their engines would not comply, such was their rigid regimentation and control processes (this is not Jaguar...or Ford...or GM-H!)

What it came down to was someone asked the testing laboratory in the USA 'what kind of fuel are you using, send us a sample.' (This was done in a roundabout way by an American who worked in the service department and had run into a similar issue in the past with vehicles imported from Europe...) The engineers in Japan were AGHAST at the fuel quality in the USA. But more importantly they realized when tested with that kind of fuel, their engines DID INDEED FAIL!

The Japanese Solution? Air Freight vats of fresh gasoline WEEKLY to use in their emissions calibration and testing regimens.

If the Japanese mindset is that they will airfreight fuel by the planeload to pass an emissions test...do you seriously think they would poo-poo catastrophic engine failure? In 1970 they changed ALL the cranks in the L24 Cars. They STOPPED PRODUCTION.

Do you really think with almost 10 years of progression in Quality Control that they would seriously compromise longevity in such a manner? To even suggest it indicates unfamilarity with the process at the least.

You are also missing the point on 'inspection'---this is not a 'western style' inspection. This is something where serial numbers and casting numbers are checked against a master list provided by the manufacturer. A Y70 would be listed as an acceptable L20A/E type cylinder head to have installed. So would almost any other head. An E88 would pass. So in that respect it would pass inspection.

So would a 2T-G engine insstalled in a Celica where formerly a 2T engine (SOHC Pushrod) would have been, or a 2T-BR (dual carb 2T) because the BLOCK TYPE is still 2T and Toyota wisely chose to certify the block only, and not the head. (Similar to Nissan...)

Outside the USA and Japan, where engine emissions was not a big issue.... there were no exhaust liners! They were P90 heads on L28's (Europe) or N42 Heads on L28's (Carburetted downdraught engines in Saloons in Saudi for example...)

The presence of Liners in an engine or marketplace occurred where there was a requirement for EMISSIONS COMPLIANCE in N/A engines. The turbocharged engines got ECCS for emissions control instead. And in Japan where emissions requirements were slightly more stringent in some respects, they got both Liners AND an ECCS in N/A cars.

But they never got liners in a turbocharged engine.

Can you prove why you so doggedly believe this was a factory setup? Did you get a certification paper from Nissan stating so? Were there lead seals and safetywire on removable components like some of the emissions testing machines? Or are you convinced solely due to patina and lack of monkey prints?

I can take you to a place in Michigan were (yes, even on Detroit Iron) there were Corvette components (like heads and manifolds) installed into Impalas before the sale (in direct contravention to federal emissions laws probably) and the owners would be in the same boat as you: Thinking they had a 'factory assembled engine' with these special components.

If you know what you are doing, use the proper tools, and do it early enough in an engine's lifetime there will NEVER be any suspicion that the head, intake, or for that matter radiator hoses or water pump had ever been changed.

That you have the only example in existence, and it goes in the face of what Nissan stated in parts manuals the world over supports the fact that someone changed your head. If they did it to one, they did it to 10,000 and they would have turned up elsewhere before this point in time. Including America where L20ET's were available from mid 82 onwards through Tomic Honda, K. Watanabe & Co, and myriad other JDM importers.

Do you seriously think the people with engine blocks that were made of diamond-hard metal would so radically alter a basic foundational engineering tenet as to discard it wholesale on an EXISTING product line in extended development? Seriously, is that what you are contending? Think about that long and hard.

That's a pecularily western thought process. And in Japan at that time, that was NOT how things were done! Remember I was there, and right now I'm typing this from Tokyo! What you suggest would be akin to the Prophet Mohammed popping up and saying "Howzabout some delicious pork ribs, forget all that HOGwash from me before! This is my latest prophecy so that overides everything prior! EAT UP! Pork-Akbar!"

It just don't happen!

-

People do things...because of ease at the time.

When did you buy this engine/car?

If it wasn't 1981 through 1983 straight off the dealer floor, consider the fact that a service replacement head was put on a turbo block.

This CAN be done without a subsequent owner knowing, and it is the most logical explanation for it's presence.

I have seen P79 heads on turbo cars, I know better than to claim they were put there in manufacturing.

Same as I know that Y70 L20E was not factory in the Maxima Wagon (engine code said L24E on the California Emissions Sticker...)

Same as I know just because TA22 Celicas in Montana came with 2T motors, the presence of a 2TG DOHC engine means it could have migrated down from Canada OR been a swap as only ONE was ever imported to the USA (TA22-00005)

Never underestimate the ability of a professional to make it appear as if nothing has ever been touched before.

On an L-Engine that's deceptively easy.

Now, on the other hand, if you can trot out some Nissan Documents that show experimental engines, some development program, or irrefutably rebut the 'Financial Logic' of the prior post of mine consider the possiblity that the Y70 was a replacement. And making definitive statements like that without proof other than asupposition may provide bad information to someone somewhere down the line.

The logical deduction is that sometime early in it's life, a Y70 was more expeditiously available and was swapped to a turbo engine. This would not be untoward, and would not affect the vehicle's ability to pass inspection in Japan. But from the factory? I'm in the 99.99999999999% position that it wasn't, but I leave that 0.00000000001% open for someone with documentation to show it may have happened for one reason or another. But I wouldn't make bets on anybody ever showing up to contradict what Nissan has already stated as fact: No liners from the factory on Turbocharged Engines due to the EGTs involved.

If they differentiated oil cooled differentials from non, and oil coolers on engines from non...depending on market and vehicle to increase longevity or simply make things last -- I think they had a handle on what not to put on an engine to decrease longevity and would religiously stick to the plan.

Why would your ONE example have it? Doesn't make sense unless someone changed it. And that change logically would occur post-factory. Dealerships do a LOT of gnarly things customers don't know. They DID exchange crankshafts in the 240 you know. Not service engine assemblies, crankshafts -- that takes some work to not leave a trace new, but after 20,000 miles? Not a chance in hell you could tell upon disassembly it was monkeyed with!

-

Stop grease and bolts.

Find something that fits TIGHTLY. A wooden DOWEL will do it, but a piece of appropriately sized rod stock will work.

If grease is 'squirting all over' then you got something that doesn't fit closely enough, and are not holding it straight. You have to let it pilot in enough to let it go in straight and then hit is SMARTLY (if you worry you will hit your hands, grab it with a vice grip!)

I started with wet toilet paper, actually and not grease. Makes less of a mess. Sopping wet, the toilet paper is semi-colloidal and works just as well at building hydraulic pressure.

I have never used a pilot bearing puller. They have nice ones now. But an old input shaft, a hammer and some sopping wet toilet tissue or THICK grease (stick it in the freezer) will hydraulically force the old bushing out with little fuss. But only if you have a decent seal on the forcing plunger (input shaft/bolt) to the bearing housing.

I have seen at least one technician who chucked his assortment of input shafts into a lathe to knurl the shafts, and cut O-Ring Grooves in the pilot bearing end. Said it helps hold the shafts in there when he's aligning clutches (uses light oil on it I guess), and makes for a TIGHT seal when he uses the same tool to remove old bushings---you guessed it, using thickened grease. Though he mentioned in one case he used wet sawdust (?!?!?!) I would not recommend that substance, but I can see how it would work if that is all you had access to!

-

Because it was some time ago that I saw it!

It was in the same yard where we got Jocamin her Antlers and you snapped the photo of the Stretch Limo, matter of fact!

The O5L is in someone's posession, though.

Brand new, bare, never been on a block, still got the part number tag on it...

Replace plastic expansion tank

in S30 Series - 240z, 260z, 280z

Posted · Edited by Tony D

"The Z has a 16 gal tank."

I'll drain my 73 Tank, and see just how accurate your statement is...

You're right John, Nissan put a phase separation tank in the car because they had a friend in the tank building business and wanted to keep him afloat. There's no expansion of fuel, and it will never overflow if it's given no place to go. Pressure will not rise in a sealed vessel, Boyles Law is a crock. There is no 10% by volume of expansion on gasoline, and filling to the rim of overboard vent in the JDM filler neck on a 40 degree morning will never have gasoline expansion so great as to cause overboard leakage from the tank...ever. It can't happen because physical laws don't exist and there is no good reason for the tank to be there in the first place.

The 64 tablespoons of expansion mentioned would never be enough to fill a 5mm line from the back of the car to the front and dump it in the crankcase, therefore the phase separation tank is a communist conspiracy foisted upon us by the bastards at Nissan to make our cars weigh more, raise the polar moment higher, and increase the costs of production to therefore decrease the gross profit of every vehicle.

How could I be so stupid as to not see this!I humbly implore your forgiveness at 'seeking the truth' in contravention of physical laws which I thought applied to all things on earth, but not to the Z Car or it's fuel system.

THIS NEVER HAPPENS PEOPLE! GAS DOES NOT EXPAND!