-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Tony D

-

-

"This has all been discussed before"

Your ignorance of the function of the devices present in your ZXT manifold is not my problem to resolve. The part numbers have been posted here in the past. It exists, your ignornace of it's existence or not.

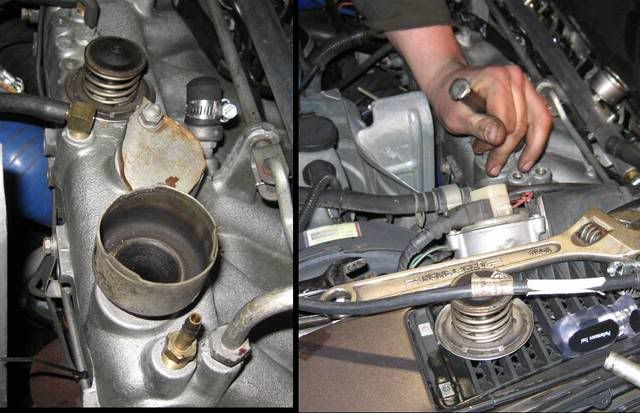

Left Photo, thing capped and with the hose clamp in the intake manifold #4 intake runner? There it is.

I get sick of arguing about wether something that is present in the manfold and can clearly be seen in photos of the turbo intake manifold with people who don't take the time to notice it's there. Or understand it's function.

"Search" The photo above was found in like 20 seconds using the search feature here to find an L28ET Intake manifold...

-

That could be a near repeat of what happened to myself, the late Kevin Keskimaki, Pecker Pete and Eino Kangas in 1978. We were out back of his barn, overlooking his pasture with one old Bull sitting out their minding his own business, while we were cutting up an old VW and doing some crap to Eino's tractor. Up rolls a International Scout, and this guy jumps out, grabs a gunsleeve from the back, and lays across the fencepost and SHOOTS EINO'S COW! MOOO! Drops dead right there.

We are all looking at each other like "WTF?!?!?" Eino says 'Pete, go call the cops, I'm getting my shotgun!' We go out into the pasture with Eino behind his double barrel with him screaming about what the f- this guy was doing shooting on his property.

Punchline: Guy was from a 'large city down south' and was stationed at the nearby AFB. He got the free hunting license and was just in love with our rural scenery and this new hunting thing... This guy thought an old brown bull was...er... 'a spikehorn'.

Biggest damn spikehorn I ever saw. Maybe he thought it was closer than it was, and that explained the size difference. I don't know. Sheriff showed up with Eino about ready to blow the guys head off for killing the damn beef. Ended up the guy got a citation for roadshooting (illegal in Michigan as well) as well as discharge within 400 ft of an inhabited structure (the barn) and eventually was ordered by the judge to pay restitution for the damaged livestock.

The prior year someone who shall remain nameless fell out of their treestand and broke his whitetails back... It was not me, but I was in prime position to witness it. You guys don't know how great digital technology is---I would love to have digital shots or video of either of these incidents!

I can't figure guys thinking they will violate deer in the presence of other locals with video and photographic means at their disposal. You won't get away!

Not like the old days when the guys would load the kids (under 14) into the truck with 22's to go get meat for the local unemployed families every Christmas (33% unemployment in the area... yeah today is soooo terrible!)

I digress...

-

I'm not up on all this pop culture stuff, but it's pretty pathetic they dismiss the guy ramming into another vechile while drunk... Especially when he pleads guilty and the BAC he had was a 0.29!!!!! I know personally what my view is to driving when lit like that.

To have it impounded... well... In California there is a law that governs the sale of impounded vehicles. I would be curious as to the circumstances aroudn the impound, because normally anything impounded can be bailed after a set time. If not bailed, it gets auctioned.

I dread to think what will happen to my inexpensive supply of cars if California ever figures out they can put the impounded cars onto E-Bay for sale at impound, instead of verifying bidders and payment ability at point of sale...

I'm not shedding any tears for a drunk that runs into parked cars, no matter what he's driving, or what branch of service he served in... that's just weak. Who can I kill because of my time in the USAF, I already got a list... I probably shouldn't have asked the question I did on the auction...it's probably not what they wanted to hear.

-

demonoidCFH

Not a lot there, but if you fancy an L twisting to 9500rpms you can hear it there...

-

Oh, you had to draw me to E-Bay, you (&^*&! Now I got 8 bids out...

I have a problem.

-

Dude, the factory BOV is in runner #4, and with the throttle plate closed, there is no airflow into the cylinders EXCEPT what is coming through the BOV, and possibly an anti-stall feature from the AAC.

If it goes into #4, it's lean? I dont think so... THEY ALL ARE! On drop throttle under boost, fuel cut shuts off fuel to everything - so a bunch of air pumped into #4 only cools the cylinder. And given #4 is somewhat detonation prone, perhaps the Nissan Engineers know what they are doing...

I don't know why it 'bothers you'---think about it some more and you will be relieved to find the logic of what I state soothing.

Like they say, a little bit of knowledge is dangerous... The fuel cut is not what makes it go 'rich' your inability to reintroduce the air you blow externally on your aftermarket BOV gives a false-flow signal to the AFM. You have to dump it BETWEEN the AFM and the Turbo, or into the engine (like the stock BOV does) or you go pig rich on drop throttle.

"This has all been discussed before..."

-

"This has all been discussed before" than why do you still call it a BOV when you should know it serves a whole different purpose. how do you supose the STOCK PRESSURE RELIVE VALVE to work in such a manor? if the intake has more than roughly 8psi it RELIVES it

your understanding of air flow is impressive, but PRV AND BOV are diffrent

Obviously you have not read a single word I said.

You have two devices on the manifold:

A BOV

An emergency relief valve...

The BOV (as I have consistently stated) is in the #4 intake runner.

The Emergency Relief Valve is in the manifold plenum, and serves absolutely no function on a modified engine and should be plugged/removed.

Either you have missed this entirely (and I can't see how) or you are simply ignoring it. My terminology is consistent and I have taken great pains to refer to the emergency relief valve in that manner specifically to prevent it's confusion with the other device being discussed.

OTHERS may be incorrectly referring to the emergency relief valve as a 'blow off valve' but I have not. Mainly because I call it an emergency relief valve and it's a TOTALLY separate function from what a BOV does.

Is this that difficult to follow?

-

I only play with 173.325 mph Z cars...

For now...

-

I'll take any help. It seems like when I put on the ported head, cam, intake. I'll make more power at lower boost, but i'll still stonewall around the same 20ish lbs of boost?? Still reading and learning.....

Now you're getting it! Your FLOW will be MORE than you would be at a lower flow and higher pressure (think Pounds Per Hour)...

What you will get is the inability to make any more pressure, but you will not be ANYWHERE NEAR the surge point.

I figure right now, you hit a minimum flow point to surge the machine---your BOV pops as a result and that flow stabilizes through the turbo and humps you to another spot on the map (eventually) where your engine is capable of taking enough flowfrom the compressor that you aren't in surge.

That one or two little farts keeps the turbo pumping.

At a higher flow rate through the opened up head and with hte bigger cam, you will be 'lower' on the compressor map, and 'to the right' in relation to flow.

PSI does not make power, FLOW makes power.

Understanding this is the first step in figuring out how to make REAL power with a turbo car. It's not as simple as Corky says to just throw boost at it. 8PSI on a GT35R is like 17PSI+ on the same engine, with the stock turbocharger. You have to find the PSI/FLOW relationship that matches the engines capabilites or your power goals. Garrett gives horsepower ratings, and they are based on PPH of airflow. You have to calculate the flow capabilities on the engine, and match that to power levels. If your engine can flow well, then you choose a turbo with the matching PPH to support hte power, at the boost you calculate it will take to move that air into the secondary compressor (the engine). This is where plenum sizing comes in as well, because a small plenum can exacerbate surge issues because the centrifugal compressor can overfill the plenum quicker than the engine can digest it--it can spike pressures, and cause a surge.

I digress...

As JGK says, stay away from that .82, the compressor and turbine setup you have should be able to support (oh, let me grab a number out of my hiney...say.....) 658RWHP at around 17-25 lbs of boost.

If you are running stock bottom end, limited to under say 6500rpms, then lop say 100hp off that, maybe 150. JeffP has run his head on a stock L28ET block and posted results on his web page or here I think. He was a little frustrated when he made more than 450HP to the rear wheels on his stock bottom end. Mainly because a large hairy inciter was there grinning and saying "I told ya!" LOL Nothing like finding out you spent $$$ on a bulletproof bottom end that will still break the pistons when you detonate, and finding you could have tuned the maps to that point on your old stock block engine!

-

After you're set like that with #1 cylinder, rotate the crankshaft 720 degrees, then pull it apart to measure the impressions in the thinnest part of the clay on the head of the piston. That is a direct reading of the piston to valve clearance at it's closest point.

This assumes camshaft timing is correct according to the cam card...but 4 degrees one way or the other shouldn't appreciably alter the results. And that is all the maximum you should have to move the cam to optimize the setup.

Valve clearance is per cam grinder's specifications, you quote numbers, but I don't know your cam. Defer to cam instructions.

-

How is RWD more efficient? Dude, no offense but you really do need to brush up on some research. John C pretty much hit it on the head with his post.

I had a huge wing on a RWD car 30 years ago, and it was on there for many years before I bought the thing. We only removed it to drive to and from the track.

"Unsightly" has nothing to do with it, Traction does...

I beat 7.4L V-8 powered AWD trucks with a little 2.4L air cooled street passenger sedan that everybody laughed at when I entered it in the 'Unlimited' class. "HAW HAW HAW that there little thang? WE promise we won't run you over, just try to keep out of our way!" I believe that was one of the quotes at the time. When I lapped the field the first time before they had made the second turn on their first lap a lot of the laughing stopped. I think spraying ice all over their shiny trucks made them angry...

"No purpose built racing vehicles allowed. No aerodynamic devices allowed. Street registration, mufflers, and current proof of insurance required. Studded tires not allowed." I mean after our resounding stomping of the conventional thinkers...hell it looks like the 'unlimited 4X4' class really had some serious limitations placed upon it!

Actually, by removing the wing and leaving our mufflers on we could have competed, but I think we would have been turfed into the wall by the sore loosers. We would have dominated without the wing and megaphones... but we wanted to make a spectale of it, and the crowed loved us. The other competitors didn't... but screw them!

I bet that is what he said after starting the engine and going out to set the fast lap as well...

-

Gilbert predates Dilbert by a good 20 years...

(Gilbert Below)

BEFORE ANYBODY SAY IT I KNOW I'M MORE THE "BOOGER" TYPE!

(Booger Below)

Admittedly I more resembled Ogre most of those formative years, with heavy Booger influences, and a dash of Gilbert in earlier years. Something changed in there to make me go from Gilbert to Ogre/Booger... I believe I will blame it on Ted Nugent.

(Ogre/TonyD...no laughing...)

Nugent:

-

Yep, exclusivity is sometimes misinterpreted by the hype surrounding the activity...

Some stuff simply gets easier to do as technology advances.

In the case of the 200 mph club, it's Catch-22. If you can go faster because of technology, so can all your competitors. And unless you break one of their records first...it can become increasingly difficult to acquire said chapeau...

Pretty soon, I'm expecting the only realistic 2 Club Attempt left will be in J/PS... everything else will simply be so high up or in the 3's that a J car is the last displacement you will be able to break in at a clean 200.001 mph...LOL

-

crap, it didn't post...

the clearance stated is fine, the only way to know where you're at is to physically assemble it and clay the tops of the pistons and go from there. I'd put in the flat top and check #1 before reassembly, and make the decision on which to reinstall from that check.

-

Found this as a 'read and comment' in my work inbox. The parts involving basic surge concepts is pretty good in explaining it. Since I don't really work with variable speed stuff (gas turbines) any longer, thought this take was interesting:

The graph I normally work with, and that I mentioned above is roughly approximated in this document on Page 1

http://www.osti.gov/bridge/servlets/purl/823041-YQ0uNi/native/823041.pdf

I don't expect many to read it...it's not your job. But the graph is there and you can see the axis' I was referring to and the surge line, etc...

Man, I read this stuff. I'm pathetic... I should be doing something else than reading technical papers on a nice day (er...evening) like this! I feel like Gilbert...

-

Boost Threshold Point is the rpm under load whereby the engine turbocharger combination is capable of making full boost. I'm figuring you make 2-3 psi at WOT at 1500-2000rpms, and as you pull under load, like clockwork at 3400rpms the boost gauge shoots to 17 or 25psi. Meaning your boost threshold is 3400 rpms.

If you put a .82 housing on there, the point where you make that transition from 2-3 psi to full boost will likely be higher---say around 4000rpms instead.

Stonewall is the point where the turbocompressor is flowing as much air as it can, and can't flow any more. Usually this is at a point below maximum pressure or design pressure. The hot side A/R will not affect this at all. The compressor sizing and operational speed, as well as the flow map will determine where flow stonewalls. Stonewall can stress the blades, but you won't hear anything. JeffP gets to 25psi or thereabouts and the horsepower graph just flattens out. It's a very distinctive curve on the dyno when you are out of air, as opposed to surging, or AFR issues. This doesn't taper off, it just flat plateaus (er...around the same HP that Garett says is maximum for the frame capabilities). You aren't hitting Stonewall at 20psi, you are hitting the SURGE LINE due to MINIMUM flow. Stonewall deals with MAXIMUM flow. Surge deals with MINIMUM flow.

jeff's GT makes more pressure than 25psi, but won't make appreciably more power. On a stock head he would likely run higher boosts than the worked head. Moves where the compressor is operating at all around the pressure/flow map. By upping the boost at that point (once stonewalled) you run closer to surge (natural surge) than stonewall, and that is bad. You can run in stonewall, you will just not make any more power. If you up the pressure from stonewall, not only do you not make more power, you run the chance of natural surging the compressor at some point and it's stressful on the blades.

in industrial compressors that are known to have to run in stonewall before being ordered, usually the compressor wheels will get extra treatments like shotpeening and stress relief so they can stand the continual stress of flowing everything it can at any given pressure.

I digress...

All the .86 housing will do is up the point where you make full boost, and maybe breathe better out the back end of the car---if you haven't taken exhaust backpressure readings you don't know if you need it or not. Likely not.

My life is revolving around surge at this point, see what you can take away from this article someone sent me a couple of weeks ago... I got to read so much of this crap it gets numbing and I wonder if I'm relating it even halfway cogently sometimes without getting to geekspeakish...

I thought the part about 'basic surge concepts' was pretty good. I think I will link this in the other post as wel...

-

No, it is not a matter of 'timing it all'... If your piston to valve clearance is insufficient they come in contact. There is nothing you can do but add clearance: Loose lift or cut notches in the piston.

Define 'bigger cam'... What kind of lift are you talking? 0.575"? 0.620" at the valve?

If not, and you are talking 1/2" lift or less...chances are good notching will not be necessary, especially with stock valves.

The only way to know is to assemble the works and clay it up. Then work the pistons for clearance. Notched pistons would add more clearance at a slight penalty of compression ratio (less than .1, .2 CR point...)

Only run the notches if you NEED to, but you were sounding like you wanted an 'assemble it with the least chance to screw it up' methodology and that would employ the notches. They don't affect CR that much. Anybody using a flat top in an L24 is not building a 'high compression' engine by any means. (Or even a stroked L24 like mine was, using positive deck height!)

BIG cams like compression, you will not be making it with flat tops on an L24. It will not like a "BIG" cam...so again, define 'big'... I'm thinking your cam will be 460 lift, and far less duration than you think you need because of the low compression you will have using stock components.

Now, running an 05L head, or even the early E31 head and the stroker L26 will boost the compression far more than any E88 flat top... You don't have 'dished' pistons, they are for all intents and purposes identical in terms of compression ratio with the head you use. This is all a stock buildup. Well under 10:1 compression no matter how you slice it, not high compression by any means---meaning again 'no big cams need apply'...

-

They laughed when we put the wing on the Corvair before the Perchville 4X4 rally too... Then when a 19 year old kid beat the field by over three laps in the final heats they did what all sanctioning bodies do to people who run fast using wings:

They Banned Us (or at least our configuration)

Meh...

1.22's are FAST there! I don't care what you're driving/riding. Can't argue with the results.

-

Yes, it sounds like the flow point through the stock components is causing a minimum flow surge situation.

JeffP has a GT35R with a .63 and the turbo is out of air before 25psi with his ported head. Going to a larger A/R on the turbine will only increase boost threshold point. By 'out of air' I mean you can see the HP level off and it's obvious the engine is nowhere near it's power potential...but the turbo won't make any more power or pressure no matter what you do. STONEWALL is what the compressor terminology is for that flow point.

It IS possible to surge the compressor at lower pressures than you would think, this is a minimum flow surge you are experiencing. Unfortunately it's the same sound as a natural surge (maximum flow, maximum pressure).

In essence they are the same thing...for the pressure you are at, there is not enough flow for stable compressor operation.

Have you tried manually lifting the BOV open slightly while under boost near the surge point to see if it supplies more air and doesn't surge? When a compressor surges you have to either lower the pressure, or give it more ability to flow...usually this occurs simultaneously.

BTW, the power and HP at 9psi is roughly very close to JeffP's testing. He was making 380Tq at 4500rpms, at 8.39psi of boost. It's more now, with higher pressures... GT35R. Jeff had some BOV or low wastegate spring related issues with his setup as well, you might get some info from him directly if you ask. He changed the spring to a heavier unit a couple of times to make it better. Different issue I suspect, though...

and after hearing it... yeah, low flow surge...

-

The notches are for valves... if you plan to cam the engine with big lift use the notched pistons. If you are sticking with a stock cam forever, then either will work just fine.

I had L28 Valves in my E88 on the original L24 in my 240. It had flat tops that had close to 0.040" positive deck height (head gasket accomodation) and no issues with a stock cam. The guy I sold the engine to put in a fairly large cam and still had no clearance issues. You only know when you clay up the assembly.

-

I have seen RHD conversions in Australia that are done without the firewall. I believe there is a thread here with one such conversion.

What about the pedal box mounting bracket?

OH, and I saw a 1974 260 Z converted to RHD at Spa this year where the gent used a racing style pedal box that was floor-mounted, the rest of the coversion regarding the rack and column, etc was done using RHD parts.

Actually I believe the Steering shaft and column itself is universal, but the stuff that bolts onto it (regarding key being in the right place, turn indicator and light switch, surround, etc) just bolts on accordingly.

Nice writeup, good luck with that conversion. The hidden welds and dissection photos should help anybody doing heavy rust repair in those areas as well.

As for the flexing MEASURE MEASURE MEASURE before the first cut, place the body on a solid BUCK, and BRACE THE HELL OUT OF IT! Give yourself room to get to what you need to get to, but bracing and solid support will prevent sag and more importantly "twist" once the boxing member is removed, the whole front of the car will be able to "turn parallelogram" once that firewall is out of there. Bracing up front between the strut towers will limit access, but you should consider it as well. Anything you tack weld on can always be removed and ground off afterwards with little trace. Better to be overbraced and rigid, than underbraced and find your panel wont line up and you have to tweak things to make it fit going back together!

Good Luck!

-

Motorsci cage build with some input from a Dutch FIA cage builder (z-spec):

The photos I have in detail are of Z-Specs Cages from a visit to his shop September 29, 2009 (and some earlier shots if I can find them).

I will supplant this post with the photos once I get them loaded, and reference the source.

-

People use the old o-rings when installing injectors? For heaven's sake why?

The things are like $3 for the whole body/tip set!

That being said, there's always RTV I guess...

I love the wordshifting. "Pintle" becomes "spintle"... this is up there with 'irregardless' for me. I must restrain myself when talking on the phone to someone who has continually referred to them as 'pinticle type injectors'... It makes it sound like a groin-based part. "My pinticles itch..." or "Dear, may I see your Pinticles?"

I digress...

-

foam could work, but you would have to find something that would prevent the plastic from melting when the resin cures. waxed aluminum foil may work

This is a non-starter. Any pressure rated piping should be constructed out of Epoxy Resin, not polyester. That takes away just about any foam incompatibility. You could use the styrofoam coolers cut up with epoxy resin. Epoxy is also fuel resistant...

As for melting it out, depending on the foam used MEK or even Gasoline will work. Same as when you make a car body or boat or anything else out of composite foam construction...simple solvent will get rid of the foam buck once you are all laid up and done. Making air cleaners for triples is a good example (with integral air horns...)

As stated above, there won't be any appreciable vacuum in the piping...you are talking maybe inches of water column. I get into this all the time with compressor people worried their intake ducting will collapse if the air filter plugs and the inlet vacuum goes too high... Inlet to the turbo MAYBE there you have some vacuum (then again, only the filter restriction at highest flow...) but between the turbo and the throttle plate, I'm betting you will have positive pressure almost all the time relative to atmospheric once the car is running.

If you want pressure rated piping, lay it up correctly and vacuum bag it with some of the UV or Heat Cured Epoxy Resins. Have a friend in the USAF take home some batch storage defunct resisn kits. Not that I would have ever done that...

DC Water Jet's 202mph Z-Car

in Windtunnel Test Results and Analysis

Posted

It's cryptic enough to go over my head as well Gary...

WTF?

I think the art of communication is truly dead. I can't find anything to link with that comment. I guess a reference to whom is was directed at, or if it was a totally unrelated Tourette's-Style utterance would go a long way to quell my curiosity!