-

Posts

163 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chris Duncan

-

Torsional Rigidity Testing, 280Z

Chris Duncan replied to Chris Duncan's topic in Brakes, Wheels, Suspension and Chassis

I hear you. But I think torsional rigidity is maybe the one key factor when it comes to chassis suitability. There is no standardized test for say beaming. And weakness in beaming would show up in torsion. In the past on the torsion tests I've done I have experienced several problems with repeatability. With this new rig took the time to address all those problems. Specifically the rear jig being rigid. The accuracy of all distances. The tightness of all fasteners. The accuracy of the weight and it's placement distance. Rear rigidity was confirmed with the dial gauge, less than .002" of movement. The dial gauge has .001" increments. Half a degree at this radius is .105". 200 lbs before welding pushed it to .105". After welding 200 lbs goes to .123" a difference of .018" All tests were repeated 3 times or more and all went to + or - .001" compared accuracy. I can try unbolting everything and re-bolting. I can agree though without going back to the before welded condition (which isn't possible) that there could be some overlooked variable. In addition the sample size being only one is not that great. I don't think this steel is hardened by treatment, but I'm sure it's a harder alloy than say 1018. The HAZ will cause migration of alloying elements. The HAZ of this type of MIG weld (3/4" long stitches) compared to a spot weld is probably 4 or 5 times larger. Not necessarily hotter just way larger because of the time duration of the weld. And it could be hotter also if heat soak is considered. All that said can agree though, take it for what it's worth. But for all the trouble and expense of seam welding it seems like it should have gone in the positive direction. Anything negative or neutral for me says it's not worth it. -

TLDR at the end of the post. Having done some torsional rigidity testing in the past, was curious where exactly the S30 comes in as far as torsional rigidity. Am also doing some things to attempt to improve the rigidity so want a way to test what is really happening. Also wanted to confirm a theory, that any strut brace that has any sort of kink or bend in it is not doing anything except bling and adding weight. 1.5" x .120" wall square steel tube jigs. The rear is solidly anchored to the concrete, bolted to the mustache bar and diff mount brackets, two studs and four bolts, and this tube frame bolted to the concrete with two 1/2" anchor studs. Rear totally immobilized and confirmed by dial gauge. The front has the same square tube configured to simulate the front suspension, bolted to the upper strut mounts and the lower arm inner pivots. Designed to introduce the loads into the chassis as close as possible to the existing suspension. This square tube jig is bolted to a 14' long 2"x4"x.120" beam which pivots at chassis center with a dial gauge to measure deflection. Now add weight to the end of the beam and measure with the dial gauge. Here is where I departed from the norm. Usually the end of the beam is loaded with weights. Sand buckets, barbells, dead batteries etc. But this is problematic for precise measurements and tedious and labor intensive lifting weight on and off. So I positioned a single chassis scale at the end of the beam, bolted a 4x4 beam vertically coming down from the rafters and positioned a hyd bottle jack on top of the scale pushing up against the 4x4. Everything precisely placed and measured for repeatable accuracy. At this point the chassis (1975) is bare, stripped, and sandblasted. All rust fixed to stock configuration. The first test is bone stock to establish a baseline. All tests are carefully set up and repeated three times to ensure accuracy. The dial gauge is positioned 12" from the pivot point. So a 12" (torsion) radius circle works out to a linear .2095" per degree (rounded to .210"). The load point (beam to front jig) is 24" from the pivot, and the pivot to beam force point (scale) is 128" so a 5.33 ratio on the weight. On the first test going to 1/2 degree since I was concerned about permanently distorting the chassis. .5 deg (.105") deflection @ 200 lbs. x 5.33, ----- .5 deg @ 1066 lbs. 2nd test in the stock configuration going to the full 1 degree, the chassis took a small amount of permanent set, only .010" and it easily tweaked back to zero. 1.0 deg (.210") deflection @ 368 lbs. x 5.33, ---- 1.0 deg @ 1962 lbs. So the S30 comes in a little on the soft side in stock configuration. Compare to a Dodge Viper a 6,000 lbs per 1.0 deg, a '65 GT40 Ford at 12,000 lbs. per 1.0 deg. A typical F-1 or Indy car at 25,000 lbs. per 1.0 deg. Then the chassis was fully seam welded. $50 of shield gas and a $40 reel of Mig wire. Four days labor. This is per some threads here on HybridZ advocating welding the seams to improve rigidity. This is also a general thought when any unibody car is concerned. Torsional rigidity test after full seam welding. 1.0 deg (.210") deflection @ 337 lbs. x 5.33, ---- 1.0 deg @ 1796 lbs. A LOSS of 8 percent rigidity. Thankfully this is a test mule car (The 2nd car is still sitting in the yard) as there is no going back on welding the seams. So the "weld the seams for rigidity" on a '75 Z info is TOTAL MYTH. Analyzing what happened, if you look closely at all the spot welds and try to surmise/ analyze them from an engineering standpoint they are at least adequate. There's no place on the chassis where they seem to be too far apart. Had a feeling from the start that seam welding wouldn't do all that much. But why did the chassis lose strength? Again just a theory but spot welds introduce very low heat and presumably Japanese steel is either hardened or a harder alloy than plain mild steel. Mig welding however, especially when you are trying to burn through galvanizing and seam sealer is much hotter. The HAZ reduced (annealed?) the strength of the steel, hence the lower numbers. Further testing will be with an eight point roll cage with different diagonal configurations and with strut top braces. Believe that torsional and beaming rigidity is just like aerodynamics. The chassis has to be treated on an overall basis. Just adding things here and there without looking at the overall picture is not going to necessarily gain much. One add on that is very popular is the strut brace. Most of these are not doing anything. The forces are so high and the movement distance you are trying to hold rigid is so small that any brace with any kind of kink, bend, or section change is not going to do anything. This will be tested to give proven results. TLDR version 1975 280z Torsional Rigidity Test Stock bare chassis----- 1962 lbs. per 1 degree Stock bare chassis, fully seam welded----- 1796 lbs. per 1 degree Don't bother welding your chassis seams on a '75 Z, it's a lot of trouble and expense and it only makes rigidity worse. Further testing will be with an 8 point roll cage and strut tower braces.

-

It doesn't need to be so tight it comes close to breaking the plate. Just brake clean off all the oil and put red locktite and stake the lock tab with a rounded punch.

-

You should be able to look at the edge of the threads and tell which way they are turning. Put the middle plate in a big vice. Take a small chisel and push back the lock edge on the nut. Put the trans in 2 gears at once. (detent balls removed) to hold the shaft from turning. A large crescent wrench will work with a cheater pipe if necessary to turn the nut.

-

Car takes long to start in 16 degree weather

Chris Duncan replied to FreddyZ78's topic in S30 Series - 240z, 260z, 280z

Actually it's a bi-metal switch that is controlled by two different things. First the temp of the coolant, 2nd the heating element. So 15 seconds is the longest it can stay open. Depending on engine temp it can be open before you even start the engine. -

I can access that site on either the desktop or Droid phone. basically there's 4 problems with almost all 1st gen Z's. 1. the fuse box has some undersized wiring that melts 2. there are some inline fuses that are inadequate near the pass left knee. 3. the alternators are underpowered and have external regulator. You want something after '83 w/internal reg. 4. the headlights don't have a relay/s, all the power goes through the switches. the biggest problem when sourcing parts is finding two-color wire. You can get a bunch of one-color but it's sometimes not enough and you end up having two wires of the same color next to each other. I solved this by painting the wires with a paint pen but it was a mediocre solution.

-

I would start with the wiring diagrams for the 260 and the car that the 2jzgte came from. Also some "how to" books might help like HPBooks "Automotive Electrical Handbook" Relays have two purposes, to allow smaller more compact switches on the dash and to shorten the heavy gauge wiring to "add lightness". Try to locate relays where they do keep the heavy gauge wire side of the circuit as short as possible. Also have a look at http://www.zspecialties.com/ on the left sidebar "tips and info" >> electrical. Basically you don't want to repeat the problems that exist with the early Z stock electrical. Waytekwire is the cheapest source for bulk wire, connectors and wiring accessories for automotive. One thing I've done on my Z's is to go to the next larger size wire on the headlights. I believe stock is 14 ga so bump it to 12 ga. (heavy side of the relay) There are three ways to build wiring looms. Wrapping with electrical tape, covering with plastic flex tubing anchored with tape, and just using zip ties every 3 inches with no further insulation.

-

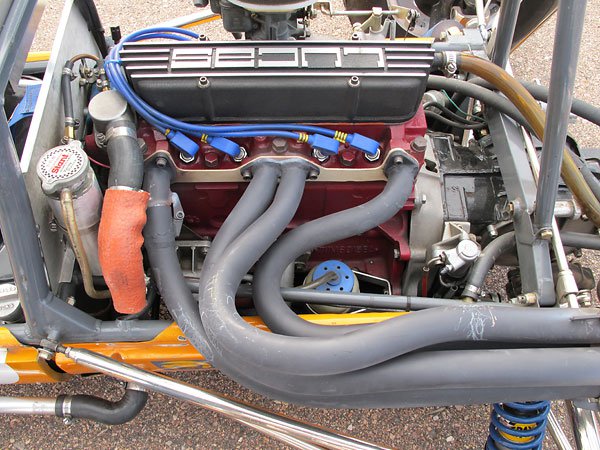

What you need is sand bent tubing. Basically custom. You pack a length of tubing with sand, weld caps on the end, heat it with a rose bud tip torch and bend it to wherever you need it. The sand keeps it from kinking. If you have any vintage race car shops around they can probably do it.

-

My bad. Have two '83 S130 parts cars, most of my experience is with the 1st gen.

-

Just bide your time, they come along pretty regular.

-

Wheel Fitment Issues

Chris Duncan replied to jsausley's topic in Brakes, Wheels, Suspension and Chassis

Why are you set on 16x9 or 17x9? Look at 16x8 or 17x8, there's a lot of wheels in those sizes with 0 offset. Looking at a 245-45-R16 on Tirerack the optimum rim size is 8". Why would you go wider, it's just heavier? Also thinking the 255 is just too wide for the average Chumpcar Z power, it's just extra rotating weight with little gain. And even a 255 will be within specs on a 8" wheel, although the tire may stick out more and be past your max backspace. Agree with you on the wheel spacers, not good on a racecar. -

Gonna go with the Grant Moly's since they are in hand and got them for $32.00 going with a 240 grit hone per the instructions. Not sure if the cast iron's would hold up to endurance racing anyway.

-

Yes I had that happen. The fan clutch seized and I had no money so kept driving it. Then I jammed the brakes one time because of traffic and like Tony says the motor mounts were old and allowed the engine to move forward enough to take out an entire row of tubes. Having no money I soldered them up, so there was a big circular depression in the radiator one row deep. All my stuff now gets an electric fan, better for so many reasons.

-

I'm assuming you are watching Craigslist? there's two V8 240's in the Seattle area right now, one for $5000 and one for $9500 http://seattle.craigslist.org/search/cta?query=240z&zoomToPosting=&minAsk=&maxAsk=

-

A daily driver should have a muffler. The noise from straight exhaust is tiring especially on a long trip. S130's have R&P I would get a S130 parts car and swap the engine and front/ rear suspension, it would take a lot of hacking and welding but it would be cool. I put a 240Z front suspension and drivetrain in a 510, it made a world of difference.

-

Roll cage for tall types

Chris Duncan replied to ericbauer's topic in Brakes, Wheels, Suspension and Chassis

I know this is an older thread but I'm going to comment anyway. Those seat belt pockets can be cut out pretty easily and a plate welded flat over the hole. Get rid of the stock dash if you are building this car for the track, it's really heavy and un-neccesary. You should look at the SCCA rules on rollbars. If you are going to the expense and trouble of a roll bar might as well make it pass tech so your options will be open in the future. It probably won't cost that much more to do so. Pre-fab weld in is going to be more economical than a custom build. -

I found the Grants for cheap but reading the forum they seem to prefer cast iron? I'm just doing a bare minimum hone.

-

Running a 280z in Chumpcar/Lemons endurance racing. doing a hone and re-ring on a used L28 out of a ZX should I use cast iron rings or moly? if cast iron what is a good source? I bought some Grant rings, the top ring doesn't look chrome but the instructions say they are moly?

-

I've never had any trouble only going to 400 on the last primer filler coat. Then going with a primer/sealer right before the base coat. And not sanding the primer/sealer as long as you go soon enough with the base coat. Go to 1000 sanding the clear coat then use Meguires "Cut and Polish Creme". This one product does both just by changing the type of buffing wheel. And don't kid yourself about isocyanates, which are in almost all 2 part paints. THEY CANNOT BE FILTERED OUT WITH ANY TYPE OF FACE MASK FILTER. You need two things. Ventilation and a fresh air mask. In other words a full face mask with a remote air pump and hose. Isocyanates are a potent neurotoxin. Boeing used two part isocyanate paints when they first came out. It took them a while to figure you that they couldn't be filtered out. Many of the painters from that time are functionally retarded.

-

So you used the stock r200 setup with U-joint axles?

-

The green one by far. Don't sell any parts until the project is near completion. most parts will cross over. I would use the 280 long block and some early 240 carbs

-

It's hard to accurately place value as condition varies so much on these cars. I would say between $2000 and $1500 if it's truly as rust free as you say and it runs. One thing you can do is see what they are going for on Craigslist in your area. But then again you have to look at the cars to compare and pictures aren't enough. I paid $1600 for a '75 and $1200 for a '77 off Craigslist. Both have more rust than you are talking. Has this car been garaged for those 23 years or outside? How close did you look for rust? Did you look under the carpets on the floorboards? They rust from the inside there. Did you look under the battery?

-

Spark at coil. No spark at spark Plugs

Chris Duncan replied to Ozzie831's topic in Ignition and Electrical

When you say "spark TO the coil" do you mean on the primary side (small wires), or do you mean spark OUT of the coil on the secondary (large wire)? If you mean spark out of the coil on the secondary wire going to the distributor then you probably have a bad distributor rotor. It's cracked inside and the spark is going to ground on the distributor shaft. Cheap aftermarket rotors are famous for this. Factory rotors do this very seldom. -

Front turbo

-

I would go for a 280. They are more plentiful, stronger, and better chance of being in good shape. Maybe not rust free but minimal rust. It's the same car except for bumpers and some interior trim. For $4K you might find something rust free. It probably wouldn't be that hard to make a 280 look like a 240.