-

Posts

123 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Racer Z

-

Please do that. I definitely want to be part of the first buy group. I need to get a drive shaft made first. Any suggestions as to what shop to use for drive shaft work?

-

OMG! They're beautiful! That's our plan. There is a January event on the big track (Willow Springs), but we can't afford to go to both. The car is drivable, we can test around town, and up in the hills. Let me know if you need / want our help.

-

Why do I have a Blog? Because I can! Maybe I will add more dribble later. My web pages that I host: Escargot Racing Qwildurn's DND Server

-

I'm crossing my fingers for you. Let me know if you need a tester. We are planning on going to The Streets (Streets of Willow) in February. This will really put the rear-end through it's paces. This will be a driving school run by the Alfa Club (AROSC). No official link yet, just this forum chat. http://www.alfabb.com/bb/forums/arosc-alfa-romeo-owners-club-southern-california/157940-high-performance-driving-school-feb-27-28-a.html The date and time are correct. All are welcome.

-

The nature of the IRS (Independent Rear Suspension) that is in the 240Z is that it can maintain equal traction during hard acceleration. The solid axle in our American cars will unweight the right tire because of torque transfer. The 240z diffy is SOLID mounted and won't unweight the right tire. It is possible that somebody did upgrade your car to an LSD, but, even with an open diffy, it will usually spin both tires while going in a straight line. With both tires off the ground, put the shifter in first gear and spin one wheel. If the other wheel spins the opposite direction, you have an open diffy or a broken LSD. If the other tire spins in the same direction you have a LSD.

-

I re-read the original post and that clears things up, a lot. I must have got your web page mixed up with this item (http://www.betamotorsports.com/products/products.php?cat=11). $500.00 is worth it to me to finish this conversion. We were on the track (Buttonwillow) this weekend. Could feel the inside tire spinning coming out of the hairpins (both east and west).

-

Is that still your guesstamation price John?

-

I'm under the impression that this will be a complete new output shaft with mating flange this time. I hope I'm right, cause I'm having trouble finding a pair of STI axles and the few I did find cost toooo damn much.

-

Excellent! Keep us posted. I want a set please. Any idea on the price?

-

Disk Brake Upgrade Ideas for 77 s30

Racer Z replied to Zerocell5688's topic in Brakes, Wheels, Suspension and Chassis

You two butting heads makes me laugh my ass off. Both of you make some good points, but you both take away from the discussion of GOOD BRAKES. Good Braking Habits is a good discussion, and should be in it's OWN thread. I (we) are setting up a track car and I (not we) am thinking about using the same size vented rotors on all fours along with matching 4-piston calipers (the 300zx vented front disk and Toyota 4x4 calipers). My thinking includes a dual master set-up with a balance bar (no need for a proportioning valve). Probably a 1 inch master on the front and a 7/8 rear. But, there is a lot of unknown for me with this set-up. (Our track does not need an E-brake). For the purpose of being able to run with VARA and certain other clubs, I'm limited to what I can modify and how I can modify it. Simply adding more pistons at the rotor won't increase your braking power, it applies the load more evenly to the pad. More pistons usually mean a larger pad can be used; a larger pad means more braking power. A larger piston in your master also means more braking power regardless of what you do to the calipers / pads. All of the (stock) 280ZX's and 300ZX's have larger rear disks and more rear pad area except some of the turbo models. Good looks don't get my car across the finish line any quicker. The winner of the race sets the new precedent for "Looks Cool!" -

Try this link: http://www.ultrarev.com/product.php?productid=45534 The stock studs seem a bit short for racing purposes. I haven't changed mine yet, nor have I bought any replacements, but I will some day.

-

I do want to test these for you. We're hoping to be at Buttonwillow in October with the Alfa Club. http://www.aroschpd.org/ ATM, we are in the process of installing all new neoprene bushings, shocks and springs. Front is done, rear is almost done. While the stock diffy was out we tried to fit the stock axles into our STI LSD and found it won't fit because of the spline count. We knew it wouldn't work because of the bolt-in VS snap-in style, but were surprised to find a spline count difference. From here I tried to buy some used WRX axles (taking my LSD with me) to find that the WRX did not fit our LSD. The seller was doing a STI upgrade to his WRX and let me try his STI axles which did fit. Our LSD is an 06 STI clutch type with 27 splines. Subaru also uses a Viscus type which probably won't take any real abuse. Both look the same on the outside and are a direct bolt-in to the 240z (except for the axles and drive-shaft). Yes, there is a difference between the WRX and STI drive-shaft.

-

I need to point out one thing here. The 240Z uses a 25 spline output shaft and the 2006 STI uses a 27 spline output shaft. The WRX uses a 25 spline, but, this WRX version is not as beefy as the STI LSD. I'm not sure, but I thing the late-model 280Z uses 29 spline. Someday we will have a 240Z / STI, but I ain't holding my breath.

-

We might be able to help with the testing. We can drive to you shop to take care of whatever needs to be taken care of. Our 73 240z is drivable and has had some track time as well as still being street legal. We have a Subaru CLSD 27 spline.

-

I sent John Coffey an email the other day, to which he quickly replied, and I thank him for that. I explained to him that we have a WRX LSD (R180 clutch type) and we're thinking of modifying the stub-axle to fit the Subaru axle-shaft. I wanted to know what his thoughts, insights or experiences were here. Without wasting words, John said he thought that building a new output shaft to fit the stock Datsun axle-shaft would be a better approach. DING DING DING Now I'm not a machinist, but I do have access to a machine shop with a machine lathe and an end-mill. In my simplified yet overly complex mind, it seems pretty straight forward to get a Subaru axle and cut off the splined output shaft at the correct length, then weld a plate on the end. I don't have a TIG / MIG welder so I would have to send it out to be welded. Third step would be to chuck it up again and turn down the over-sized plate then used the end-mill to drill four holes in the new companion flange. Finally, send it out to be heat treated. Having the new output shaft balanced would probably be a good idea. Now, if I have done all this correctly, and there aren't any other surprises, the Subaru Differential should simply bolt into our 1973 240z using the stock drive-shaft and stock axle-shafts. In theory. In my head it is easy and painless.

-

I saw this in Craigslist today and it points to here. http://losangeles.craigslist.org/wst/cto/1060655501.html After looking at all 14 pages of pictures, I must say that your Z is one sweet looking ride. But seriously, $5,500 is way to low. 10 or 12 grand would seem a lot more fair to me.

-

I've bought some stuff from MSA that was sold as "MSA" but was actually made by a differant, excellent company. The roll bar was made by AutoPower. I doubt if MSA actually makes anything. They might have some stuff build to their specifictions with the MSA name on it. If you call MSA and talk to a sales tech, they will tell you what you want to know. I have asked them questions about stuff and they have been able to find things not listed or listed incorrectly. Unlike a few other places, MSA is not in business to screw us. In my research to buy polyurethane bushings, I found that there is not very many companies make this product, only two or three major companies with Energy Suspenssion being one. All the other 20 or 30 are actually made by one of these few with a differant name.

-

I didn't know there were fuses in the kick panel. Is this a 260 thing? or does my 240 have fuses there as well? And, no, I just can't go look at mine, it's 30 miles away (about an hour in our traffic).

-

Well, that's not what we started out to do, but in the end, it seems we are. All we really wanted was a fun, affordable track-car with some potential. The 240z seemed to fit that. I looked around until I found one in good shape. No rust, no crash damage and no cheap mods to undo. Being 35 years old and having sat for 10 years meant that all the rubber was shot. And there was an oil problem that burned up the cam. But most of that seems to be sorted out now. Hopefully we can be on the track 24-25 Jan 09 for the cars virgin run. We hope the do a track event every 3 months while fixing and modifying between events. For now, she is stock and street legal. Some track time will reveal her worst flaws so we can work on those first. If there is no "worst problem", then suspension mods would be my focal point before more horsepower. Can't take advantage of extra horsepower if the tires can't hook-up in the turns.

-

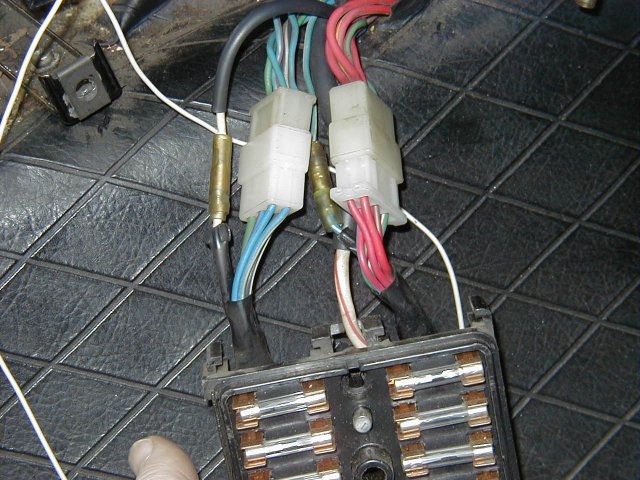

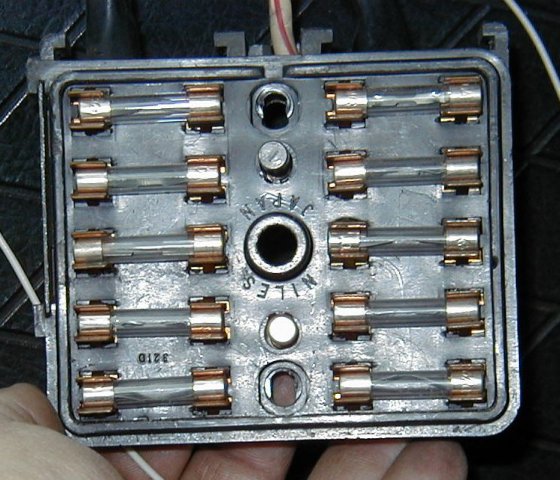

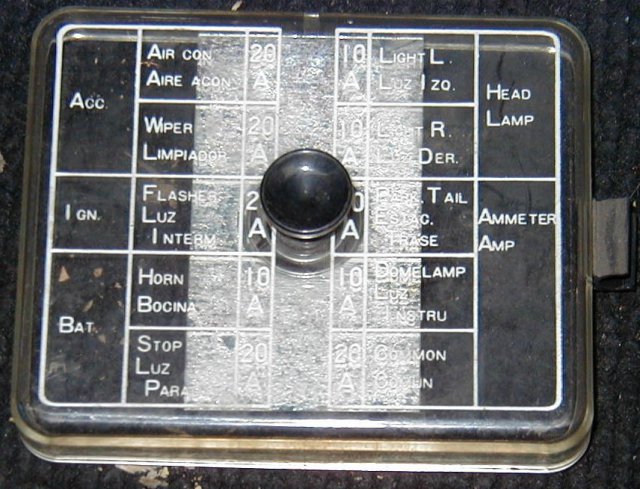

It seems that you don't really need these pics any more, but I'll post them anyway. Hover over the pics to see the file names. 73_fuse_cover_1 : Shows the printing that lists what each fuse controls. Probably the best shot of 4. Please note the tab in the top center that goes in the notch of the box. 73_fuse_cover_2 : Just a different angle. The printing is hard to read. 73_fuse_cover_3 : Another angle to try and capture the hard to read printing. 73_fuse_cover_4 : The white or silver is part of the fuse bog cover. 73_fuse_box_front : The front of the fuse box. Please note the wires exit the top near the notch. 73_fuse_box_back : The back side of the fuse box. Looks factory still. 73_fuse_box_connectors : Just the wire connections that plug the fuse box to the wire harness. The single wire with in-line-fuse looping to the right of this shot is the electric fuel pump fuse. We replaced the damaged fuse holder with a newer style. I think this was a last minute add-on at the factory to add an electric fuel pump for the late model 73 240z. 73_fuse_box_wires : The fuse box hanging from the wires. The wires are routed into the center console. The box mounts on the drive shaft tunnel where the center console meets the under-dash just below the radio and is easily accessible. 73_fuse_box_complete : The cover mounted to the fuse box. We have the dash and center console removed or out of the car while we are fixing various old-age problems and setting up for the track. Our wiring seems to be original and un-damaged. The switches and connections are all dirty. As we take apart and re-connect the different connectors, the assortment of things start to work again. Please note: The single white 20 gage wire is not factory nor going into the fuse box. We added it for the electric fan and switch. We will put the under-dash and center console back together when we feel we are done with all the little things.

-

When we bought our 73 240z, it was 35 years old and the seat belts did not even work. The only one that actually did work was the passenger lap belt. The drivers side and the two diagonal chest belts had broken ratchets, or were frayed to a hanging thread. I'm not sure what our laws are here in California, but surely the laws include "working properly". A "SCCA" approved role bar (we bought ours from MSA http://www.thezstore.com/), (AutoPower http://www.autopowerindustries.com/ is a major manufacture but won't sell direct), is the best way to get good mounting points. And will be needed if you want to do any real racing. We found, on our 73, that the factory mounts at the floor have an extra plate welded in that wraps around. Since it is best for the belt to pull straight on the bracket, we drilled a new hole in the side of the drive shaft tunnel, staying in this factory seat belt plate. For the outer point, we used the factory location as it was already in a good location. Our SCCA role bar (from MSA) included a welded in bar for the purpose of mounting the shoulder belts at the correct angle. This leaves the Submarine strap. A 5-Point Harness expects a hole in the seat cushion (all real racing seats have this) for this strap to drop down through. We have stock seats and don't want to cut a hole (the 35 year old seat will probably crumble). You don't really have a choice here with the 5-point. Our free 5-Point expired before we could finish anyway. So, we will get a 6-Point, which I think is the new rule anyway. The submarine belt has 2 straps, running from the buckle, down under each thigh and to mount somewhere comfortable with it's own bolts. We are thinking of going to the massive bolts for the waist belt. note: we don't have a 6-point yet, nor have we made it to the track.

-

We have a 73 240z. That's my only experience with the Z Car. The web site offered a few other service manuals for the Z, but all were for newer models. After breezing through this 1973 240z manual, it seems to cover all 240's from 70 to 73. Most service manuals do try to cover as many years as they can until there is enough of a change that forces them to re-write. Our car is not stored at my home, next time I go out to my brother's house (probably this Saturday), I'll take a few pictures. The dash and wiring are apart still and I can get some good shots. Our 73 is still stock and in good order. I found the source of my manual: http://carfiche.com/manuals023/cars/ 1.5 minutes download? Nice. We had to get a second motor for our 73. We ended up with a 72 motor (so we were told by the seller). So far, we have found that there are some differences. The carbs, intake manifolds, throttle linkages, and exhaust manifold are different. We couldn't just mix and match at will. We had to use the linkage, intake manifolds and Round Tops as a set. Not to mention that the 73 has more EPA crap as mandated by the FED's. And we live in So Cal, so we get heavy-duty EPA crap.:burnout:But that's all gone now:emo: This won't effect your wiring. I expect the wiring to be the same. Very minimalist.

-

I'm not sure how legal this is, but I got it from a web site offering about 20 different FREE service manuals. This is the original 240z Datsun/Nissan Service Manual in PDF form. I can't recall that link, so you can get it from my server. THEY CLAIMED THEY HAD LEGAL RIGHTS TO GIVE IT AWAY http://qwildurn.game-host.org:8080/temp/73_datsun_240z.zip I don't know how long I will keep available. It's only about 40 megs. Took me about 20 minutes to download it. You should be able to get it from me in less than 5 minutes. I would be interested in your download time.

-

More than one person has put a new engine in a junk-heap of a car only for the transmission to let go the next day. At which point the dump the whole car and some lucky scavenger finds it and gets a real deal. I have been that lucky scavenger at least once. I've heard, but don't quote me, that an early Mustang radiator (289) fits into a 240z. There is nothing "thick" about the stock 240z radiator, it's just two cores. We would have sent ours out to the Local Radiator Shop, but it has closed down. The others wanted to much to re-core the old, so we bought a new ALL BRASS 3-core, from MSA http://www.thezstore.com/store/merchant.mvc?Screen=SFNT about $230 Keeping the engine cool is one place you can't be cheap. Hot engines will wear out real fast. A good radiator costs a lot less than a cheap motor and is a lot easier to replace. If you drive hard, like most of us do, you're producing more heat, for longer periods of time, than the manufacture intended on. Keep it cool, or you will be inviting trouble.

-

Suspension for the rest of us...bolt on options

Racer Z replied to streeteg's topic in Brakes, Wheels, Suspension and Chassis

As we all know, the 240z was not built with any suspension adjustments except for toe-in at the front wheels. I am not familiar with the 260/280, but I suspect there is still no adjustments. It is my belief, that the BRE Team adjusted their SCCA winning car by grinding the mounting hole at the body just (oblong) enough to allow for the adjustment they wanted. I have seen replacement lower control arm bushing kits that include an eccentric bolt to allow for some adjustments. I don't remember where now, but it was not expensive. No modifications to the car were needed, purely bolt on. The "weld-in" plate for the top of the strut tower is probably your best bet though. The plates don't cost a lot and most welding shops can do the job for not a lot of cash. After that, you should be able to use any shock/spring setup you want. note: some coil-over kits will require further mods anyway. There is also the idea of custom control arms with built-in turn-buckles. I have helped friends adjust their cars (Alfa Romeo) at the track and it was sweet. I have seen these new control arms advertised for the 240z. Although it is "bolt-on", it is not "low-budget". The weld-in plate is probably the best compromise and is probably what we will do to our 240z when the time comes. Rustyfriend's post sounds like a good way to go after deciding how to get some suspension adjustment working. Just in case you missed this thread, http://forums.hybridz.org/showthread.php?t=138753 , it is a very good suspension replacement documentary. Excellent photos and descriptions.