getZ

Members-

Posts

510 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by getZ

-

Very stout IRS setups. I didn't realize that IRS suspension could be legal for faster than 10 second quarters...isn't the internet awesome? I've seen an aritcle on a 8 sec IRS viper once upon a time as well. http://www.hotrod.com/techarticles/113_0502_1963_1979_corvette_irs_buildup/index.html

-

I decided this is an excercise in futility, at least for me. You can fab something up, but you won't save any money, unless you have access to a full machine shop. If your track is like mines where you get kicked off the track for having an indepent rear end running sub 11's (I'm not that fast, but that is the track rule), there is no point in having an absolutely bullet proof indepent rear suspension that can handle 500 horsepower.

-

I just passed a good looking s-30 on the way home a few minutes ago cruising east on ray road. It was black, definitely v-8 powered, running drag skinnies up front with a rear spoiler, and aluminum wheels.

-

I'm thinking, as the axle starts to twist, it starts to bow. A weaker axle would break immediately because it cannot stretch. The billet axle will stretch until the spline starts to come out of the companion flange, then it breaks. I can't see a spline breaking inside the flange where the flange is surrounding the spline Of course, if you have enough power and traction you can break anything, but I was thinking if there was another bearing between the two it would keep the axle from bowing. I dunno, it was just a thought. I'm really looking for another solution besides after market axles, but in the end I will probably install a set of billeted axles anyway. I don't have enough power or traction to break a billet axle and MMS axles are a straight "bolt in".

-

A flange breaking is down right scary. Even with disc brakes it looks like you could see your wheel rolling right past you. The one in the picture from the sticky looks like it broke from a hard sideways hit not a 1.3 second 60 foot time. I guess I'm more concerned about drag racing stuff, because that's what my car is set up to do. I keep going back and forth with this, but I keep going back to my original thinking that the weak point is the taper going to the threads and not the spline. The axle twists under hard acceleration and actualy starts to shorten it's length due to twisting, putting a lot of strain on the nut. I think I will call moser or one of the other racing axle manufacturers and ask what they think since I'm sure they have seen it all with axle breakage.

-

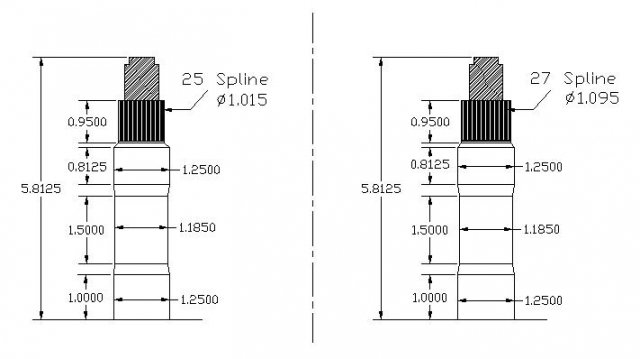

I made a mistake earlier about two pictures of broken axles being at the same point. After looking at JBC3's broken axle I think I understand what happens. The axle starts to distort and the splines jump out of groove while pulling away from the companion flange. A larger spline count keep it from twisting out and putting pressure on the threaded part.

-

Work was boring, waiting on some other tools to come back up so I start looking for information on 280z stub axle since I want to upgrade to CV's and I found this picture of the two side by side. I can't validate the correctness of the dimensions but if they have the same thread size, what the advantage of using the 280z stub axle? The two pictures I have seen of broken axles have both axles broken off at exactly the same place, where the thread ends and the spline begins. My thoughts being "what is the advantage of the greater spline count if that is not the weak point?" It's the same size everywhere else. The article said 240z axles will break in other places, but can sombody shed a little more light on this, like where they break? I can understand why Rosses stuff is so much stronger, but not why a 280z stub axle would be stronger 240z stub axle. Do the later axles have a better tempering or shot peening? This is the site I was looking at (I believe a fellow hybridz member): http://www.magshooterz.com/280z_stub_axle_swap.htm

-

arizona zcar brake question.

getZ replied to v8dats's topic in Brakes, Wheels, Suspension and Chassis

it's a little hidden: http://www.arizonazcar.com/5lugzfrontinstall.html -

A while back in the earlier days of the NMCA I remember an interview with a guy named David Henninger (I think I got that last name right). He ran an early seventies camaro with an 8.5 inch ten bolt, I assume he had the 28 spline axles running high 8 second times. He made a point to conserve his rearend by keeping away from dry burn outs. I know that kind of take the fun out it, but it was a way to preserve his rear.

-

If Ross is watching, is it possible to make a bigger axle with say a 30 spline with a custom companion flange?

-

Centerline autodrags on an S30?

getZ replied to Z24O's topic in Brakes, Wheels, Suspension and Chassis

I saw some 15 x 7's available directly through Centerline or you may try summit racing. -

B&M shifter trans tunnel cut out question

getZ replied to gretchen/jason's topic in Fabrication / Welding

I did exactly that. The exhaust directly underneath the shifter is wrapped with header wrap and I built an aluminum box out of thin sheet metal underneath the shifter. On the inside of the sheet metal I used something like dynamat with the metal foil covering. Sorry, I forgot the manufacturers name. It works fine, but if I were to do it again I would have made the box airtight as well. It took a while for the exhaust paint to stop smoking into the cabin. Then again, you are supposed to cure the paint first. -

What year is your car? The later 280z had taller rear shock tower caps that added about 3/4 inch.

-

Here's a link to give you an idea of what is possible with some of the older v-8's. Not completely apples to apples comparison, but it gives some perspective. In a nutshell, as the technology got older the mileage got worse. Like anybody needed a website to figure that out. http://www.fueleconomy.gov/feg/findacar.htm If an LS engine out of a corevette or camaro is out of reach, you might consider a 6.0 liter out of a truck or cadillac as an option, but you won't have a 6 speed for an option. I think my old 2000 silverado did pretty well around 20 mpg with an automatic, headers and cat back, but it was a much heavier car then a Z. When you kept your foot out of it, the engine would run about 1200 - 1500 rpm. By the way I'm in the east valley if you want to see a small block chevy fitted in a 72 z car with ac to boot.

-

I don't know how true this is but the newer style vortec heads off late model trucks are supposed to be more efficient so that would translate into better mileage. The down side is they require a different manifold as well just for a vortec style setup.

-

If mileage is that big a concern, put an LS v-8 instead of standard small block chevy. With the prices of all the after market stuff dropping, it hard to go to the venerable sbc anymore. I look at the power the LS based engines are making along with idle quality and I don't know if I would build another standard small block. As an additional plus you can get all the ac stuff with the engine as well. I installed a vintage air setup and it added up to almost another grand, of course there are cheaper ways to do it, but mine was a complete kit that other members had installed so it was easy.