getZ

Members-

Posts

510 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by getZ

-

Tokico setup with 17x9's

getZ replied to Slammed68's topic in Brakes, Wheels, Suspension and Chassis

Find Bartman's write up on his 18's. He ran a 275 out back and 245 up front. I put a set of 275's out back and thought they were just a shade to big. I could have brought them in just a shade more with the spring perch welded up higher and a shorter spring (8 inch), but I didn't feel like rewelding the perch and landed up going to a 225/245 combination. I wanted to run drag radials out back and you are limited by what is available. Nobody makes a 265/17 drag radial. -

I used the stuff before. There were two types and I used the ceramic stuff for better heat reflection. I saw the price of the gun and just decided to roll it on. It works about the same as undercoat but much lighter even with a pretty thick layer on it ( a bit more than an eighth of an inch). I like it but it is pricey. On my car, this was used on the spare tire area where I cut a section out to make room for another muffler. With a roller it looks like wall texturing, pretty rough, but it doesn't bother me being underneath the car. I will probably go back and insulate the entire transmission tunnel to keep the exhaust heat from coming up from the dual exhaust.

-

oops, sorry I didn't see the picture earlier. My advice was for a aftermarket switch not the OEM style switch, but the same starter wire will still need to be used. I cut into the wire around the ignition switch just because it was convenient. I also assumed there was a starter relay, but I'm not positive about that.

-

I wired mine finding the correct wire at the ignition switch. There is only one wire that is hot when the key is rotated all the way clockwise like you are starting the car. The switch I used was fairly heavy duty, rated to handle 10 amps, but the starter is on a relay so it shouldn't be running more than a couple of amps to be activated. A really heavy duty switch is not necessary. Anyway to make a long story short. The switch is directly in series with the wire in the ignition switch. Depressing the switch in either park or neutral will complete the circuit. Just make sure you have the mechanical arm that activates the switch in the correct gear position. Of course the depth of the switch also has to be adjusted. I wish I could tell you the exact wire, but I'm out of town right now. To find the wire, open up the plastic housing around the key switch and test with meter looking for voltage while turning the key. You can unhook the starter if you don't want the car turning over. It's really difficult to find the wire measuring resistance since a car has so many natural shorts (starter, alternator any other motor across the battery.) So measuring for the 12 volts going on while turning the key is much easier. Good luck and success.

-

I think I have those same heads you have. The Dart Pro 1 200cc's with a moderate cam 230 @.050 and .480 lift in the car has a nice broad torque band. My engine is a 383 with about 10:1 compression (also a 3.9 final gear ratio) My only complaint with those heads was the final finishing. It took a couple of hours into the head to clean up casting flashes, recheck thread holes and smooth the inside chamber. If I was to do it over again I would have gotten the 195 or 200 AFR's for another few bucks, but I'm happy with the power the heads are making. The car is light enough I was thinking of tightening up the convertor from a 2300 stall to around 2000. The dart heads can make bigger power with a raunchier cam if you don't want as much torque. Other then that those heads should work fine in a 350, unless you are worried about emissions.

-

I've never worked on an LS series engines, but I would still follow the cam manufacturers recommendations on valve springs. I know a lot of guys have gone to dual springs depending on their cams, but everything I've read on beehive springs says that is the way to go if your cam is not to radical. You get variable damping characteristics without the heavy seat pressure, it's worth a few horse just with those springs alone.

-

check out the centerline website. There was a z with those on them.

-

I was planning on using that manifold on my car as well. I saw a picture of somebody who was running one a while back and it seems to fit without a problem: http://www.gmhightechperformance.com/tech/0307htp_hollley_stealthram_intake_third_gen_iroc/index.html http://stealthram.com/ I still haven't decided which route to go yet with either a stock 88 computer or an after market ecu. If you have an older style tpi (I think it was 89 and earlier) there is no provision for a ninth injector so you need a chip burned for cold startups.

-

Am I Crazy: New but Quick Turbo/Supercharger Math?

getZ replied to Kevin Shasteen's topic in Turbo / Supercharger

The math is all fine and great but they are only to get you to a reasonable starting point. There are way to many variables and unforeseen items to get perfect calculations for everything, weight of vehicle, gearing, type of driving, homogeneous chamber burn/swirl, adiabatic efficiency, and the list goes on and on. You can nail everything on a dyno and still not be happy how the car, boat or whatever performs because the load on the engine has now changed. That's where experience of the tuner/crew chief comes into play and why winning race teams have good crew chief along with solid engineering. -

need a little coil over help

getZ replied to dlouis7's topic in Brakes, Wheels, Suspension and Chassis

something nobody told me about installing the sleeves was they fit a little loose. If you want them to fit a little tighter, silicone or gasket sealer bead spread evenly up the strut tube does a nice job of holding the sleeves solidly in place. -

need a little coil over help

getZ replied to dlouis7's topic in Brakes, Wheels, Suspension and Chassis

It's pretty straight forward, cut the old spring perches out. If you get long threaded sleeves, you simply slide the whole length of the sleeve and figure out where to weld the sleeve perch, which is just a ring that is a pretty tight fit. There are a few writeups on the internet, this one had good pictures. http://z31.com/mods/coilover.shtml -

Pressure drop when using a fuel rail type carb feed?

getZ replied to z383z's topic in Gen I & II Chevy V8 Tech Board

I'm not sure what you are asking. The first link is not a regulator. It's a pressure guage with a built in filter. The second is a typical dual feed setup and the third link is just a dual feed line. If you're asking if one feed line needs a bigger volume of gas I would say yes in theory, but I have never seen anybody go out of their way to design a line or log that would do that. I've seen them facing forwards and backwards and not make a difference. Hope that answers the question -

nice ride! Can you post the specs on those half shafts? BTW, how much is the car lowered?

-

NEW/HEADS, you should NOT just bolt them on!

getZ replied to grumpyvette's topic in Gen I & II Chevy V8 Tech Board

I completely agree with your post. Not to name any names, but it rhymes with "fart" heads, a nice set of heads once the casting flashes were cleaned up and the chambers were smoothed out from a rough cast. It would have also been nice if they helicoiled some of the other holes like some other brands. I don't how true this is, but a guy who personaly knew some of the guys at PAW said they actualy took apart the new heads they got and cleaned them up because they got tired of being blamed for things like casting flashes. Good to know if I need another set of heads. -

-

There is somebody around here (I think one of the Aussies) that made a bracket for that wilwood parking brake with wilwood calipers. I have an e-brake like that on another car from a wilwood rear brake kit. The bracket is a real simple piece of flat 3/8 aluminum with the appropriate holes drilled out. I think figuring the e-brake cable should be pretty straight forward. I'm hoping enough people grumble about Dave's rear kit not having a parking brake he'll make it available. It's would be a modified version of what he already has. His website recommended a brick, but I wasn't crazy about the idea.

-

Modern Motorsports LTD coil over kit

getZ replied to deadlydatsun240's topic in Brakes, Wheels, Suspension and Chassis

I have the long blue MMS coilover kit with 200lbs springs up front and 225lb springs in the back. This combination is comfortable to me, but I know a lot of guys who road race and autox run much stiffer springs. My car is more for drag racing so I don't want to go too stiff in the back anyway, besides that the tire combination I'm running 225 up front and 275 drag radials out back it's going to push (understeer) badly anyhow. In hind sight I did not really need the longer sleeves, some better measuring would have worked, but it made it a no brainer for installation and setting up ride hight. Read the strut thread sticky. There's some good info in that thread on spring rates and bunch of other stuff as well including a problem with the Tockico Illuminas which is the shock I run on all four corners. There should be enough info in searching to get you started. Ultimately fine tuning will be up to you and your personal perference and driving style for your combination of parts. -

Custom 5 bolt stub axles with or with 3/4" offset

getZ replied to ezzzzzzz's topic in Brakes, Wheels, Suspension and Chassis

Part of the problem getting a larger spline count and larger diameter axles is the bearing size. The bearing diameter gets to large to fit in the stock strut tower. You will also have to find a smaller bearings (ball size) with the same outer diameter and larger inner diameter. Another point to think about after looking at some of the pictures of a broken stub axles including the MM stub axle is the weak part seems to be more at where it tapers to threads. I thought about getting larger thread diameter, but if it has to break. Where would you rather have it break? On the inside the wheel will probably stay on the car. If the axle breaks internaly who knows what the wheel will do....just my 2 cents. -

If you are looking for a guarantee saying an r200 will not break with 500ft/lbs of torque I don't think you are going to get it. There are guys who have broken an r200 with a normaly aspirated L-28 (or at least thats what they claim) and you see the other extreme with guys with big horsepower doing fine. The weakness seems to be the cross pin getting loose, the sticky has more info in it. That's why some guys have chosen to go to the r230. A lot of tracks will boot you off the drag strip once you dip into the 10's regularly so it forces a lot of guys that are that fast to a solid diff anyway.

-

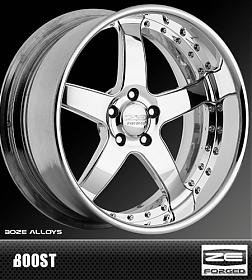

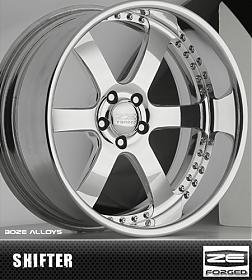

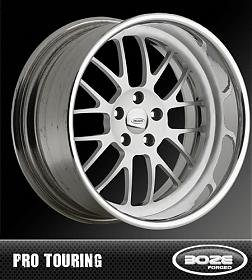

I found another vendor that will do custom offsets and bolt patterns: http://www.zeforged.com/ Not cheap, but cheaper than a lot of other custom made wheels with custom offsets and bolt patterns. Mines were $500 a pop, if you get another style with out the rivets they are about $25 less a wheel. I have no idea what the wheels weigh, just happy not to have to go with big wheel spacers and go with a 5 lug pattern. The pictures don't have any four lugs, but they can be made with a four lug pattern

-

I've heard of electric vaccum pumps and I have a hydraulic one that uses presssure off the power steering pump for another car that I haven't installed yet, but it requires a modified master cylinder. I think the companies name was hydroboost.

-

I would think it's the length of the driveshaft rather than length of the tailshaft. The longer the tailshaft, the shorter the driveshaft.

-

I have a level 2 200r4 from Bowtie Overdrives and am very happy with it. Personaly I like the gear spread on a 200 versus a 700. The drop between 1st and 2nd isn't as drastic. For a rearend gear I have a 3.9 and a 2400 stall. I have approximately 400 normaly aspirated horspower and find the 2400 slips more than I need. It's a personal preference sort of thing, but I would prefer a little less stall, maybe more like around 2000, unless you spend more time on the drag strip. As for the speedometer cable, no a GM cable does not fit into the stock speedo. JTR makes one that will work. Hope the rear driveline survives. Stock half shafts will break with a decent set of tires.