rudypoochris

Members-

Posts

1409 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rudypoochris

-

Has anyone ever heard of CV joints being used at the drive shaft instead of U-Joints? Could a CV joint possibly reduce chances of vibration? Would a CV joint capable of handling the same load as a comparable U-joint be excessively large? Anyone know why CV joints are not used for drive shafts? Thanks guys!

-

^ I hope your not riding your bike in downtown SF! That would be intense. What is sweet about going to a college that has a bike campus is that there is a bike "church" which is basically a free pick-n-pull for bikes.

-

I go to college in a bike town. I ride everywhere between 2-8 miles a day. I used to like riding a lot, but I personally feel like maintaining a bike is a PITA if you ride every day. The brakes wear out, things break, tires, etc. Its not bad for what you get, but it is far from enjoyable in the rain even with fenders. Albeit I only have a generic mongoose which is a bit small, set with 1 gear, albeit upgraded the brakes to V's. The fun part about riding a bike around in a bike town is riding through traffic. Its a great rush, but can get a bit touchy if your not careful. Its mainly the other people who cut you off and don't know how to yield at the entrance to the round about. I think having a good high quality road bike is the key to success, unfortunately those are expensive and are much more desirable to steal around here.

-

Well I downloaded Nissan FAST (dealer parts search engine) and it seems like this bearing is going to fulfill my need since it is marked as a replacement for my 1986 R200 case. If oil starvation really is an issue, Champinon Bearings said they can hybridize the bearing by putting ceramic balls in it. They claim the wear is greatly reduced and that the bearing can run pretty much dry. All that good stuff, I will think on it and send them one of these bearings to get a quote. Seems to me this thread might need to be titled "R200 NLNLA Front Pilot Bearing" pretty soon... we can only hope!

-

Rota RB/RB-R, 4x114.3, 17", Z-Offset Wheels

rudypoochris replied to rudypoochris's topic in Group Buys

There will be a 9" front offered and a 9.5" rear. It is the buyers option if they would like 9.5" all around or 9" alternatively. The color options are posted here: http://rotawheel.com/rb1.htm Additional colors may be available if you ask the representative when he takes your information down. I will take pictures of the wheels mounted with a ruler next to them so you can judge if they will clear a stock suspension. -

That is a possibility. I am finding out about a possible lead on a renumbered Nissan version of this same bearing that NZeder tipped me off too. I also called Champion Bearings and told them the dimensions and the use. They are trying to whip up a quote for 25 pieces of a hybrid bearing to with stand the conditions (incl. metal shavings and starvation). They recommended ceramic balls with SS races. We shall see... EDIT: The part number for the possible alternative bearing is: 38335-N3220. NZeder tipped me off to it using the Nissan FAST (dealer part search) system. It is available through courtesyparts.com for $46. I have ordered one and will confirm if it is the correct size.

-

Interesting points all around. I will do some reading, looking into the Subaru diff (I think R200's are in the Legacys now...), and so on. I will probably also attempt to contact a custom bearing manufacturer tomorrow to see what they can do in an order size less than 5,000,000. EDIT: I can't seem to find that Subaru R200 rear end...

-

I'm not seeing it on Kragen.com. I wouldn't think a short nose would have the third bearing, but could be wrong.

-

Another option would be to run the bearing outer race in the lathe and remove .003" of material from the center. Freeze the bearing, boil the ring, attempt to mate them. Allows to retain 16mm width. Downside, not as strong, requires great precision, difficult.

-

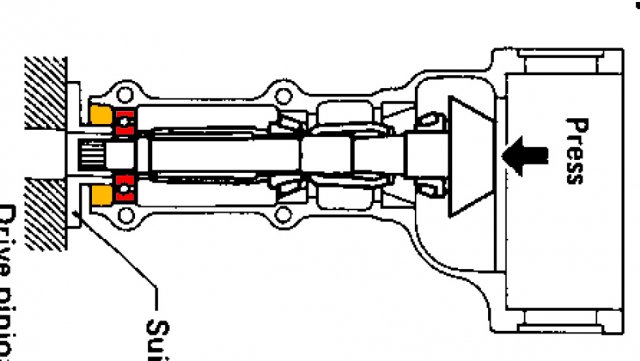

I have been using the incorrect terminology I believe, the bearing is actually the front PILOT bearing. If an admin could rectify the title that would be peachy! If I did not strive for a 16mm width though, would the differential need to be re-shimmed? I would like this to be as painless for myself and others as possible seeing as I just spent $200 to have the unit rebuilt. Heh. Just to make sure I am understanding this right... Image below: So. The red marks the bearing in question. The blue shows the axial force traveling through the pinion to the front of the differential. This force terminates at the outer race of the rear conical bearing. The green shows the axial force going towards the rear of the vehicle, this is the one that matters to us. I appears that the force is indeed transmitted straight through the inner race of the bearing in question. Thus, there should be absolutely no axial loading. If one were to add a lip which probably is not necessary due to the "pinion bearing spacer" pushing against the "companion flange", I would guess the orange (front) side in picture 2, would be the place to put it. What is in the orange space? The oil seal? Is there room for 2-4mm more out race thickness, can the seal be modified? The sleeve inherently cannot move towards the front of the differential, due to whatever is in the orange space (oil seal?), unfortunately it appears the path out the rear of the differential is open space and thus it could in theory slide that direction, a lip on the front would prevent this. In either case, a good interference fit SHOULD hold it with out a lip, but I rather not be the one to find out. After repeated vibrations and loading, it seems hardly a guarantee to me. Maybe lips on both sides with a weld down the center then ground down on the lathe may work, but that would be a pretty decent amount of work. BTW if I am misunderstanding anything here in any way, let me know! Also, apologies for the excessively large pictures, I felt it necessary to size them this large to understand them properly. EDIT: Here is the idea I have so far... Two halves to the sleeve. Each one 10mm total thickness. 57.925mm ID, 72.975mm OD, 54mm lip diameter, 2mm wide lip, .5mm chamfer. That would allow for the center of the two halves to welded onto the bearing. The bearing would be the type 62/28 discussed earlier. I believe SKF might mike a "No Wear" version which can withstand low lube environments. It might be better just to use a shielded bearing though which might, maybe, I don't know??? Keep metal shavings off the races.

-

Rota RB/RB-R, 4x114.3, 17", Z-Offset Wheels

rudypoochris replied to rudypoochris's topic in Group Buys

Me too! I just called the rep again to get information on the shipment. The representative believes the manufacturer sent it out yesterday by air. I doubt it will make it here before this weekend though unfortunately. On the flip side that gives time for the rubber, zg, flares, and the rear control arms to come in so I can get a nice mounted setup. The representative said it would most likely be 3-4 weeks after we give the thumbs up for our orders to arrive at our doors. Sorry about the delays guys, really. We are getting very close though! -

Would that require a thinner bearing, I think it would. There is a 12mm version...

-

Thanks for the help! I have spoken to the Koyo rep he says: I need to look at the differential a bit more to see if the sleeve moving is an actual issue. As for the SH4 treatment (he let me know it is a carbon nitrating treatment to protect the rings from metal shavings), I don't know.

-

Here you go: Nissan PN: 38335-N3100 Koyo PN: 83601ASH4C3 (83601A for short) Thanks!

-

Thanks, but that is not the correct bearing. There is something like 3 bearings for the pinion shaft. 2 of them are still available and clearly take axial loads because they are conical. The third is the one in question which is a deep groove ball type and hopefully does not take axial loads. It is not available though. EDIT... The steel pretty much matches the expansion of the irons I have seen. The aluminum has twice the expansion rate.

-

I could use iron... I think the lip is not necessary.

-

Interesting. Do you know if this will effect the backlash and all of the tolerances in the differential (requiring adjustment)? Or is this bearing really just there to support some radial loading? Do you think there would be room or necessity for a lip on the rear side of the sleeve? Thanks! -------------- Here is my initial drawing, lipped and chamfered .5mm for ease of installation: OD: 73.0mm ID: 57.5mm Width: 20.0mm Lip ID: 54.0mm Lip Depth: 4.0mm

-

I made a new thread for this idea just now right here: http://forums.hybridz.org/showthread.php?p=859954#post859954

-

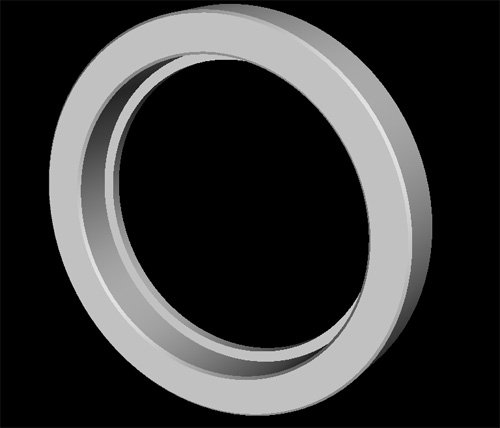

I had my R200 rebuilt awhile ago and unfortunately the front pinion bearing seems to be NLA. The dimensions on it are: 73mm OD 28mm ID 16mm Width From this thread: http://forums.hybridz.org/showthread.php?t=112388&highlight=r200+front+pinion+bearing In any case, thinking over this I feel like I should have the front pinion bearing replaced as well since it seems that this bearing goes "sandy" more often then not. One of the posters in the above thread mentioned that an SKF 62/28 common bearing could be used with a sleeve to up the diameter from 58mm to 73mm. What are peoples initial thoughts on this idea? Does this bearing see axial load? If so, in what direction? What would one make the sleeve out of? Lastly, what would be an acceptable ID to make this interference fit snug and "doable" with simple freezing and boiling of components? My initial thoughts are that axial loading would be minimal if any. If necessary a lip could be made on the sleeve, but that only covers loading in one direction. I think with the lip towards the rear of the case is the most feasible (I haven't looked inside yet, but I think there is a seal that might interfere towards the front). As for sleeve material, I would think 4130 or 4340 steel would be fine. Maybe even 7075-T6 Aluminum. I have no clue what ID would make an acceptable clearance fit w/o using a press, or maybe a press should be used. Possibly 57.5mm? Thanks guys!

-

Whoops! I meant power brute! Precision gear got mixed into my mind. Yea, thats whats really lame. The NLA bearing is the one that gets messed up. Wonder if something of similar size can be specified... I vaguely remember seeing a bearing source that goes by size once upon a time. EDIT: I researched some more. It seems a 58OD 28ID 16W bearing can be sourced for under $10 a pop. That would merely require a spacer of 72mm diameter and ~57.8mm ID to make it fit correctly. That can be made for ~$20 out of 4340 easily. Interesting... Too bad I had my differential rebuilt already.

-

It cost me a total of $900 or so to rebuild a standard 300zx non-lsd with a NEW PG in it. That includes all bearings, labor, and the carrier. One of the bearings is NLA, so I just sucked it up. All in all I think this would be the way to go for an LSD into an R200 long nose. Most all of the R200's I find have a bit of a sandy feel to the bearings, so I figure I might as well get the rebuild done and have a new setup. Which makes more sense. Used likely 100k+ mile factory LSD with few clutches, or new competition style LSD? Difference is $100-300. For me it made more sense to spend the extra money I made off of the used 300zxT LSD's I have sold on Ebay in the past.

-

TR-3550: http://ttcautomotive.com/English/products/TR-3550.asp TKO: http://ttcautomotive.com/English/products/TKO.asp I believe this is true too. They are known as the TKO/TKOII's in some instances, the TKO500/TKO600 are the updated versions that handle 500/600 ftlbs.

-

Hmmm. I liked the videos... The discussion already makes it look like this is going to the shed though.

-

Yes, I could. I don't want to though. Thanks for the suggestion, that is a nice engine.