-

Posts

1201 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by duragg

-

Hah well see the dam thing makes my target 240whp at something like 4500rpm! In our racing class we are defined by a simple formula of Weight / Horsepower (average). I want to be in the class with 10lbs / hp and with a 2400lb car I need to average 240hp. NASA St3. Most cars have a relatively peaky power band, making lets say 200hp at 4500, 235 and 5500, 260hp at 6500 and 235 at 7500 (imagine for grins this averages to 240hp). But if you have another identical car that makes 240hp at 4500 and at 5500 and at 6500 and at 7500 you are maximizing the "Power under the curve" and all the guys that do this are just plain faster (not only for reasons just related to hp of course, but the idea stands). And so that is where the desire for a giant engine with a de-rated power band comes from. Just this year they made a new rule to address the advantages of this type of setup so therefore it must be a competitive advantage lol. Tj

-

Steering is a little stiff in the paddock but not too bad. I've considered installing the electric assist rack... Maybe this summer. Yes stock engine with Osiris for tuning and intake / exhaust. All the accessories are removed as well of course. We topped out at 314whp and 276 Tq I think. Next goal is to get the e-throttle control to work so we can reduce power for classing reasons to 240whp. 17x9 have more tire choices and ground clearance

-

15x10 all around. I have 2 sets. No idea the brand. Moving to 17x9 soon tho

-

Its not known at this moment if they are in stock and available. So I bought a Wolf Creek Setup and some ZXT CVs and will see what works first. Racing again in a few weeks so I need something.

-

Well I'm just gonna buy it all and see what works. Open to ideas. I need this done asap for an upcoming race. I have long nose R200 and 27 spline 280z stubs with stock u-joint halfshafts.

-

Gotta say I need some type of adapter to my 27 splines in the s30 but that's less likely a hit.

-

Looking for Left and Right (different length) 280ZXT CV shafts. Thanks..

-

Can you post a picture of which part you need? The terminology on these is a mess. I think it goes: Diff->Side Shaft?->Half shaft->Companion Flange-> Stub Axle But I could be wrong.

-

I may call for a consult today. I have 27spline stubs with stock u-joint halfshafts. I detect some bearing play and I get nasty vibration on hard corners. (275 Hoosiers). Time to open these back up, check runout and consider CVs etc.

-

Love that VQ35HR. There really isn't any RPM from 2500 to 7500 that it isn't pulling like a freight train. I ran both races at part-throttle and all in 5th gear just to shake the car out. Need to beef up the springs to prevent getting into 1st / 2nd gear and do some other tweaks before the next race.

-

Its just a few extra steps at the end of a long day to post a video with relevant content to Hybridz that is grinding my gears. Just barely worth it.

-

[sharedmedia=videos:videos:287]

-

Well let's see... Chassis welding done to give more room for headers and front cross member for oil pan. Some brake lines moved and heat wrapped to shield from the headers. Closed off the last of the water passages and mounted a 2nd H20 temp sensor. Should have motor back in this weekend and get to drive. Exhaust fab is Tuesday and Dyno tuning at UMSTuning is Wednesday. Then compliance Dyno Saturday. I will be on track at Chuckwalla exactly 2 weeks from today. Brought in a ringer for welding one fitting shut. Removed fitting, tapped and installed CTS-2

-

Jim at Turbo Toys in Tampa supplied the engine, trans, ecu, harness, running on a pallet. He was superb. Totally stood by everything he did. I think the actual wiring was done by Martin at RS Enthalpy. Here is another exclusive for my Hybridz brothers: https://youtu.be/yGfc3N5uVfg And now that it runs, time to pull it all back out again again lol

-

Exclusive for Hybridz, first post of VQ start attempt: https://youtu.be/qkg6BUW3CII F-it. HbZ doesn't want Youtube content I'll just move on lol. Its too hard to post it

-

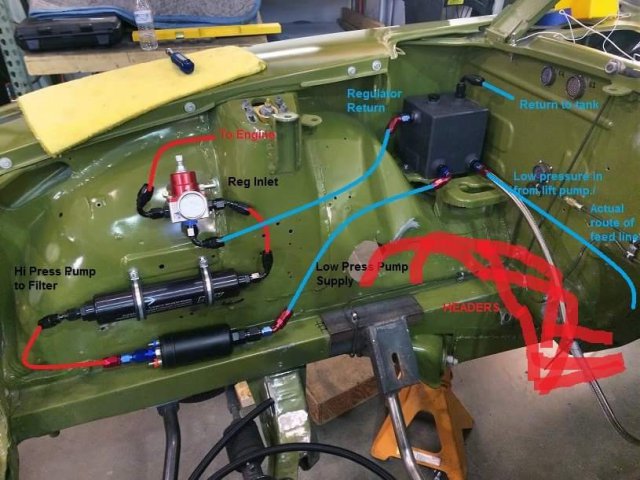

Decided I just needed a bit more room for the McKinney long tube headers. Fuel system planned out. ECU mounted and its sub-harness installed Reconfigured panel to provide power to ECU and 2nd fuel pump Mmmmm

-

4 hour marathon game of "pins and sockets" and got the harness terminated and tested into the MS connectors. Still need to mount the bulkheads and pass a few more wires back and forth (cruise control switches retained for tune switch but need to be under the hood). Then will finish the remaining wiring for Powers and Grounds, new fuel pump relay for the AEM 380LPH, few other bits and then finish the fuel system. Waiting for header to come back from McKinney with and adjustment. Finalize engine position and get the welding and repainting done..

-

Computer was fine (power was from a little charger), header adjustment almost done (Thanks McKinney Motorsports!) Decided to pass the harness (87-ish wires) through the firewall to the cockpit with 2 MilSpec disconnects. Using a 61 pin and a 41pin will give me plenty of spare holes.

-

Undoing aluminum valve cover warpage

duragg replied to seattlejester's topic in Fabrication / Welding

Depending on the gap, you can find a shop in town that does Lapping. Probably one of the aerospace shops has lapping tables. They can patiently lapp the surface down to perfectly flat. -

Drivers side header shipped back to McKinney to tweak the #6 tube for better firewall clearance and to update the production jig. Impulsively I chose to power up the computer to check a few sensors and had wires crossed. Doh! Likely fried computer, shipped back for testing. Have a swirl pot enroute which will be fed via a lift pump in the rear and then filter, AEM 380lph and filter into the VQ. Slowly making progress

-

-

Big thanks to Mack at McKinney Motorsports for getting the custom headers to me. They look WAY better than I anticipated. I pretty much now have all the physical parts to do the final mockup then weld down the mounts, close up the X-member and finish wiring and plumbing. But Christmas... So probably running some time in January and on track in Q1 of 2016. Headers.. Then an X pipe and single 3"? Not sure what to do yet. Since I will be taking a 300whp motor and detuning to 245whp the design of exhaust just needs to be light.

-

Mini-update. L series motor abandoned and being sold to other members. VQ35HR swap is in progress. Noodling with the idea of a sequential gearbox, but probably stick with 6 speed. Lots of chopping and grinding going on. Tom

-

Mack has spacer that go between the engine and his mount. They effectively move the mounts outboard which would cause the engine to move (down?) due to the angle on the frame. I used one on each side (he sent me 3). I deleted all the coolant to TBs and only using vacuum for my booster resevoir. I emailed you some harness data. I'm leaving mine all in the engine bay because of the tune switching cruise control feature of OSIRIS and by my classing rules I cannot have cockpit access to that.