toolman

Members-

Posts

589 -

Joined

-

Last visited

-

Days Won

22

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by toolman

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Transmission Cross Member- As always, the first thing to do is to create a card board template of the Transmission Cross Member. Then, the Trial Fitting of the Template. As you can see, there are plenty improvements to do the card board board template. The Transmission Crossmember will have to built with a much "tighter fit" to accommodate the big exhaust pipes (2 1/4" to 3") with sufficient ground clearance too. A 14" Chop Saw was used to cut the 1/4" steel plate. I bought 1/4" x4" x 20 foot steel plate for $67 to save time in cutting the long lengths. That left me more time to work on just cutting 4" width cuts. By cutting only half away through through the plate made it easier to bend since I did not a Heavy Metal Press Brake. If you cut it right, you can still bend it by hand but it will be strong enough to test fit it on the car. . The Klein Angle Finder was utilized to check the plate angles. The Stock Transmission Mounts was trimmed to gain additional clearance. Stock Mount Before Mount After Trimming Four Corners This trimming allowed the Plate to be closer to the Mount. The Cross Member was first tack welded then test fitted then fully welded. The Cross Member was tack welded to another 1/4" steel plate to prevent warping / Note-There is a change in the shape of the Trans Crossmember. These changes created maximum space for the exhaust pipes. Cross Member Powder Coated Black. Because of the Extreme Motor/Trans setback, the Reverse Lock Out Solenoid was touching the trans tunnel. I could have eliminated the Solenoid or Modify the Trans Tunnel. I decided to do the Later. I fabricated a small Sheetmetal Hump to provide Solenoid clearance. Interior View of Tunnel Modification I also added Four 1/4" Steel Plates to reinforce by "sandwiching" the interior floor panel between the Transmission Cross Member. Remember, that they are Two !"X 3" x !/8" Rectangular Steel Tubing Frame Connectors under the floor pan, too. These are the Two 1/4" Reinforcing Floor Plates being fabricated. Trial fitting of Reinforcing Plates and Crossmember bolted together. Cross Member Powder Coated Black Passenger Side Interior Reinforcing Plate Bottom View of Cross Member Back View-Note Tight Fit compared to First Version Bottom view-Cross Member Cross Member, Upper and Lower Reinforcing Plates held together with 3/8" Yellow Zinc Bolts Outer Reinforcing Bottom Plate( one on each side-Left and Right Interior Upper Reinforcing Plate( one on each side-Left and Right Left Side Interior Upper Reinforcing Plate( Note-Frame Connector passes under this plate Close Up View of Trans Mount Next-Finalizing Fuel Tank Venting Hoses -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Drive Line Angles Now that I have my Motor Mounts made and LS motor installed, the construction of the Transmission Cross Member could to be done. But first, the measurement of the Drive Line Angles is necessary. This because the Transmission Cross Member will determine the Motor and Transmission Drivetrain Angle #1. If the Crossmember was constructed before checking Drive Line Angles and I needed to adjust Angle #1, it might require making a new Crossmember to change the angle. So checking the Drive Line Angles now and establishing Cross Member height before makes sense. Angle #1 is the Motor/Trans Angle Angle#2 is the Drive Shaft Slope. The Last one is Angle #3 -Pinion Shaft Angle. The measurements (if possible) should be with the Vehicle Level and at normal Ride Height. How To Measure Drive Shaft Angles – Tom Wood's Custom Drive Shafts (4xshaft.com) This article gives a good overall view of the measurement procedure. I downloaded the Tremic App from the App Store to my IPhone. I used the Klein Digital Angle Finder from Home Depot-$39. It has a strong magnet and very easy to use. The digital readings are big and with the black background readable even outdoors. All measurements were made in the Center Line of the Drive Train. Angle# 1 Motor/Trans Angle measured at Front Driveshaft Yoke Angle# 2 Measured at Driveshaft Center-Driveshaft Angle Angle# 3 Measured at Rear Driveshaft Yoke-Pinion Angle I transferred these measurements in the Tremec App. The Results-Everthing in the Green-PASS If there was a measurement in Red, there would be a problem with that Angle or Angles and should be corrected. Shimming or other methods can be employed to adjust the angle. For those without Iphone or Digital Angle Finder can get a similar results with a manual Protractors and a Straight Edge. The Formula is: Motor/Trans Angle-2.3 Degrees minus Drive Shaft Angle-2.0 Degrees =0.3 Degrees Pinion Angle-3.9 Degrees minus Drive Shaft Angle-2.0 Degrees = 1.9 Degrees Using my measurements in this case Next-Transmission Crossmember -

Has anybody have problems dealing with ZCAR DEPOT?

toolman replied to toolman's topic in Non Tech Board

After couple of days of emails, I am happy to say that ZCAR DEPOT finally realized that there was a fitment problem with their booster. They are working on a solution. If they improve the customer service, I think everyone will be happy. ZCAR DEPOT will also get increased sales. -

Has anybody have problems dealing with ZCAR DEPOT? Previously, I have purchased mostly small items and stuff. But recently had a fitment problem with a brake master cylinder from them. I tried to call them at 844-8652473, you get a answering machine which is full so you can not leave a message. The only alternative coarse of action is to email them at sales@zcardepot.com and hope they answer you. Their products are better than others but to me, their customer service is really terrible. If you had problems with them, please comment here so others will know too. Maybe they will improve their customer service.

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Prelubing the LS3 Motor- I borrowed a Oil Pressurized Tank to prelube my LS3 motor as LS motors can not be easily prelubed like the older 350 motors. The operation is simple-Motor Oil is pressurized in the tank to about 50PSI and fed though the oil gallery plug. On the LS motor, it is located on the Front Left Lower Side. After starting to pressurizing the oil gallery, I rotated the motor about 1/4 turn to allow the oil enter all of the passages. Keep rotating the motora 1/4 turn while checking the amount of oil in the tank to prevent creating air pockets in the oil passages. Continue until the oil reaches the rocker arms and springs or the recommended oil amount( 5 1/2 quarts in this case). Motor rotated with a 1/2 breaker bar. Clutch Slave to Clutch Fingers Clearance- The Holley T56 Shim Kit ($39 from Amazon) arrived. The kit consists of 3 Thickness of Aluminum Round Shims 0.059, 0.125 and 0.185. The shims are installed to obtain the recommended clearance of 0.125" to o.200" between the measurements between the Throw Bearing(fully compressed) and transmission case face subtracted from the measurement between Clutch Fingers and Bell Housing Face. See pic below. Holley Shim Kit Bell Housing to Clutch Fingers Measurement Using Straightedge and Machinist Ruler s Clutch Slave(with Spring Removed) to Transmission Case edge Measurement Do not forget to remove Clutch Slave Spring while measuring. In my case, only the 0.185 Shim was required to obtain the Proper Clearance. Clutch Master Cylinder- I used Wilwood 3/4" Clutch Master Cylinder( $49 on Amazon). Also, used Russel 45 degree Banjo Fitting with Copper Sealing Washers for it. Bench Bleed the Wilwood Clutch Master before Installation. Wilwood Clutch Master installed with 36" Braided Stainless Steel 3AN Hose Testing the Clutch Master and Slave before installing Motor and Trans into the Car Most people probably would bother to test the Clutch System before putting it into the car but I rather be ":Safe" than "Sorry" and having to remove the motor and trans for a leak. I picked up a 3AN Union fitting to extend the clutch line to about 6 feet to do the system testing. Before the Clutch Testing, Clutch Pedal Endplay and Pedal Stop adjustments were done. To physically test clutch operation, Put the transmission in gear. The output shaft should not able to turned by hand. Now, pushing in the clutch pedal should release the output shaft and allow it to be turned by hand. This test verifies that the clutch is functioning properly. Also, a Visual Inspection was done utilizing my Borescope. No leaks at Bleeder Screw or Clutch Line Inlet. Video of Throw Out Bearing operation MELS8541.MP4 -

This is Toolman, I just removed my T56 transmission from a crate LS3 motor last week from under the 240z on jack stands. Jag that Run has their motors mounts. very forward on the LS motors like my mounts( check out my recent posts). I put a floor jack under the rear of the LS oil pan to prevent the motor from smashing the brake lines on the firewall. This engine setback lets very little room for trans removal though. I used long 3/8 extensions with 12mm or 14 mm swivel sockets to loosen trans bolts. I removed the LS intake manifold because the plastic PCV valve was real close to the firewall. Also. there is only ten 8mm bolts holding the intake manifold. Installing the T56 transmission from under the car will be tricky. I borrowed a old floor transmission jack and will use two aligning studs to make the job easier too. Since the transmission is out, I am going to test the hydraulic clutch by adding additional 36" of 3AN line to test everything is working under pressure before reinstalling motor and trans into the car. I will use the borescope to see if the clutch is working OK. Some people will think it is a waste of time but I rather not take the chance of the clutch slave leaking.

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Sorry about the delay in posting but I ran across an unforeseen problem: my used T56 transmission that I picked up about 15 years ago would not bolt up to my crate LS3. After a lot of research, I found out to correct this problem there were basically Two Methods to convert my LT1 T56 to a LS1 T56 transmission. First and cheapest was shipping the Front Midsection Plate to a Mainland Machine Shop to machine it to accept a LS1 input shaft. The cost would be about $100 plus shipping( To and Back). Also, beside that I would still need a LS input shaft( used about$120) and LS Bell Housing( used about$150) The Machine Shops are in Washington State and Texas. I didn't want to ship the Front Cover to them and have something happen. So the other option was to purchase a new or used Front Cover Plate, LS1 Input Shaft, and a LS Bell Housing. So I purchased a new LS1 Input Shaft and LS1 Front Cover from AMP Distributing in Texas( for $210 and $240). Shipping was $60 First Class Mail. The GM Bell Housing was about $280 from Amazon. Total= $510 including freight. Fortunately, I only paid $1000 for a low mileage Iroc Camaro T56 trans back then. Engine Side View of LTI T56 LS1 T56 Difference mainly around Input Shaft Area and Casting Holes for LS Hydraulic Slave and Bleeder Difference between LT1 LS1 Transmission Side View Relatively No Difference Input Shafts Differences LT1 LS1 much longer Bell Housing Differences LT1- Top LS1- Bottom required Bigger Flywheel Input Shaft Replacement- First, Remove Front Cover while pushing the Input Shaft inward to prevent Blocker Ring from falling out(can use a small screwdriver to hold it in position). LT1 Input Shaft Removed by rotating it and "wiggling" shaft. At the same tie, Keep pressure on Input Shaft to prevent Blocker Ring from falling out. Take your Time. Remove bolt Input and Counter Shaft Bearing by placing Eight Fingers on the inside of the races pulling outward while Rotating the Bearing Race at the same time. The Races should come out easily. Once out, remove shim under races and measure their thickness. Input and Countershaft have different diameters shims. I used a Felt Pen and write their thickness next to their bores. I ordered a Tremec T56 Shim Kit ($50 from Ebay). Then, after cleaning I replaced the Input Shaft Race with the New One and original shim. Then. put Counter Shaft Race with original shim inside. Setup Dial Indicator to check end play of both Input and counter shafts. I followed the Tremec factory manual to obtain Endplay and PreLoad for Input and Counter Shaft. Even made their Special Tool(consisted of a Metric Threded Steel Rod) to insert in Counter Shaft. But I found the readings were too erratic. So I searched the Internet to find another method. A Transmission Rebuilder came up with this method. This method was basicially over shimming the bearing under till the shaft "Binded" then remove .002 shim. Retorque it and test it again. The Test consists "Feeling by Hand" . DO NOT LAUGH!! I have seen racers adjust Rear Differentials by Hand and come out with Perfect Tooth Pattern. Note- The Tremec Shim Kit has 8 various thickness shims so you have to "play" (add and subtract ) shims to obtain .002 removed shim. Dial Indicators don't lie- .002 Endplay and Preload If you need to check Pressure Plate to Clutch Throwout Bearing Clearance- Using Straight Edges-One across the Bearing, measure distance to transmission face. Place Straight Edge against Bell Housing Face and measure the distance to Clutch Fingers. To get Clutch Fingers to Throw Bearing Clearance, just subtract the Two Measurements for Clearance. Engine Stopper- I fabricated my Engine Stopper out of 1/8'" steel to hold motor from turning when tightening flywheel and pressure plate bolts. Installed on Block Next-PreLubing the LS3 motor -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

I used 1/4" Steel Plate. Toolman -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Bottom View of Bell Housing Clearance Left Side Top view Removed Hood Lock Mount to gain more clearance. Right Side Room for Exhaust not bad Front View-Motor Mounts 1/2" Clearance between Balancer and Steering Rack Bottom View-Right Side Tight Clearance between Firewall and Motors Tight Firewall to Motor Clearance Front view of Both Motor Mounts Next-Transmission Crossmember -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

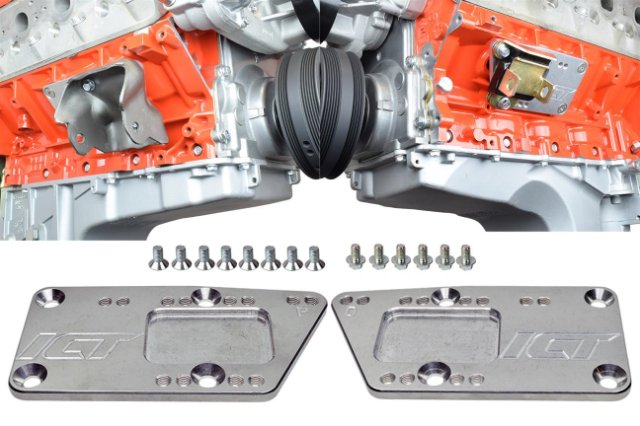

Motor Mounts- Originally I planned to used Dirty Dingo Z LS conversion motor mounts. But after installing on my Dummy LS Block in my car, I decided I wanted more engine setback than they could provide. Also. looked ICT BILLET Mounts So I decided to basically make my own mounts of 1/4" Steel Plate. As you can see, my version is 4" to 5" longer. I knew this was longer than necessary but usually go longer, just in case,, i need extra area to construct AC mounts too. I can always cut them shorter later. On the left bottom side of LS, there are two plugs. The front one is a oil gallery plug. I plan to use this one to lubricating the motor before firing it up. The other plug is a freeze plug. The left mount was modified to give clearance of the oil gallery plug. I took the oi pan measurements from my LS motor on the engine stand and place them on the Dummy Motor to check clearance between oil pan and rack. It had. Checking engine level (length and sideways) Checking body level (length wise and side side ways) Checking engine rear clearance The Steering Shaft was also checked for clearance. Motor to Firewall Clearance checked Note-Use of Wooden Blocks to temporary suspend engine while constructing mounts. Tack welding the Mount Motors Note- A Square Tubing Spacer was created to limit welding distortion. Also, the mount was tack welded to table for the same reason. Between this final version of the Motor Mount and the first version, there were probably Three others (some only 1/ 4" difference in height). Trial and error had to be done to achieve the necessary results. Also, while designing the mounts, one has to consider for other things(like air condition condition, power steering, alternator,etc). Motor Mounts- Powdercoated Note-access holes drilled for oil gallery and freeze plugs. side view Left Side View Top View -

Door Weatherstripping Not Meeting Frame?

toolman replied to Witchboard's topic in S30 Series - 240z, 260z, 280z

Witchboard, If your door adjustment is not the problem, you can try this procedure. The 240Z window door glass frames are rather flimsy. So you might need to bend the top door edge more inward. You accomplish this by: Open the door and stick a 2 x 4 between the lower edge of the door and rocker panel. Now just push the top edge of frame inward. By moving the window frame inward, it will decrease the window gap and hopefully stop the water leakage. Push easily at first and harder if necessary. Also, check the driver's door for sagging. The upper door hinge pin wears and creates play. Toolman -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Rear Rocket Bunny Flares Moduicications The Front Lower section of the Rear Quarter Panel Flares was not sufficiently secured down So. I installed one 6MM x 1.0 nutsert to the underside of the rocker panel. Then, made a 16 gauge sheet meta; plate to go over the nutsert. To give this plate additiona; strength, another plate on the exterior of the flare. A hole was drilled through both plates. So you ended up with the flare sandwiched between both plates. Also, a right angle was added the inside edge of the plate so it was against the rocker panel pinch weld. Side view of Quarter Panel Reinforcing Plates. Late Christmas Present Santa Claus delivered my Christmas Present at the end of December: 2020 Chevrolt LS3 #19370416 6.2 Liter 430HP/ 425 Lbs Ft torque. It came from Scoggin Dickey Chevrolet in Texas. Cost was about $7600 plus $900 freight( truck and ocean freight). The shipment took about 3 weeks from Texas to Honolulu. My local Machine Shop offered me the use of his Dummy LS Motor to make mounts and check fitment issues. Side View Bottom View Because its light weight, it was very easy to put the motor in and out of the Z to check fitment issues. Differential Mount Modifications With the additional torque from the LS motor, the original Differential Mount was modified. Some people use solid Differential Mounts but didn't want excessive vibration and noise. However, the factory Differential mount has a low profile and is small in size. My solution was the cut off the corners of the original mount then add Four 1/4 Right Angle Tabs. The Right Angle Tabs being welded to original mount with a piece of 1/4 "steel providing the "Air Gap". This design allows the Differential mount to operation normally until Load is applied then it will be "solid" mount. Finished Differential Mount. Bottom View Rear View Side View Rear Differential The Differential Cover was Glass Beaded then hand sanded with 400 grit sandpaper. Then the cover was polished wih Aluminum Buffing Rouge on the Buffing Wheel. The Cover was painted with Polyurethane Clear. The Clear will prevent the cover from dulling out. The Carrier was painted with black Polyurethane. I had forgotten that this R200 differential contained 3:70 gears. This gear ratio is much better suited than the usual 3.34 gears in most 240zs. Especially since, my T56 has a 2:55 First Gear. The combination should provide Wicked Acceleration. LS3 Motor awaiting installation. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

NEW CAR DOLLY- I constructed a new car dolly to move the body around for engine and transmission installation. I used a lot of materials from "old car dolly". This dolly was about one foot higher off the floor to make working under car easier. Bottom view of Dolly Side view After it was completed, I removed the jack stands and slid the Dolly in. WIRING HARNESS- The original wiring was in bad shape. The tape was starting to unwind and was covered with Rustprooting from in the quarter panels. What a mess! The wiring harness was hung from ceiling to straighten it out while I wait for the new harness wrapping tape from Ebay. Fuel Evaporation Hoses First, the Vapor Tank was cleaned and sandblasted. Using the Borescope, I checked inside the Vapor Tank. It surprising clean. Then PowderCoated. The !/2" and 3/4" vapor hose had springs added to the hoses from pinching. These were regular springs for now as the proper hose protectors were unavailable until January. Vapor Hose diagram Hot Wheels 240Z modifications HOTWHEELS240PRIECT.mp4 I started this project about May 2020. Using the Hot Wheel Fugu 240z, I wanted to make it have opening door, hood and hatch. When I was a kid, I made model cars then modify them with opening doors and trunk. Then, made tube frame and working suspension. Even, advanced to lettering the race cars by hand. I am keeping my eyes for a Hot Wheels LS motor and transmission, racing seats, roll bar and exhaust system. Then, paint this car when I am not working on my Big Z. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Sorry for my delay in posting, I was busy putting up Christmas decorations for my house. AN Fitting Installation- Wrap Electrical Tape 3 or 4 times tightly around Braided Line. The Tape prevents the wire from unraveling. Cut across the tape with a 24" Cable Cutter or use a Cutoff Tool. Cutter will crush the hose like this but just squeeze it till round again. Tip-Wrap a Plastic Cable Tie slightly down from the cut. I find it holds the braided wire tightly together ,otherwise the wire tends to spread outward when pushing into the socket. I wrap the socket fitting with a wrap of masking tape to prevent scratching. Put Socket Side in a Vise to hold it tight then push the Braided Wire Counterclock wise while pushing inward into the socket. When the leading edge of the Braided Wire fully enters the socket, cut the Cable Tie off. Continue push the Braided Wire in until the inner Black Rubber Hose( check by looking inside the opposite end) just barely touches. Once that happens, use a Felt Marker and put a line on the Braided Hose and edge of the Socket. Lubricate the Threaded Section of fitting with Light Machine Oil or WD40. Screw the Threaded Section in by Hand Clockwise until it gets tight then use a wrench to tighten it down. Remember to watch the Felt Line that you made. If the Line moves away from the fitting is means that the screw is pushing the fitting outward and not screwing into the rubber section. If it is, you have to disassemble it and cut it off and start over. Finished product. Of course, the Real Test is to check under pressure. This procedure was utilizing 6AN fitting which is 3/8" Fuel Line size. Braided Fuel Line Installation From the Fuel Pump to the In Line Fuel Filter then to the 3/8" 4Life Nickel Copper Fuel Line heading the Engine Compartment. The other( the closest) Braided Line is the Return Fuel Line to the Pump. Both 3/8" Fuel Pressure and Return Line in the transmission tunnel. Pic of Fuel Line Clamps. Made from sheet metal then powdercoated Gold. Used Nutserts to attach the clamps to the tunnel. Replacing the Door Hinge Pin- This replacement two Door Hinge Pin came from Malta and cost about $50. It normally takes about 4 months to ship but the first shipment was lost in the Mail. So I finally got my set in about 6 months. The pic shows the measurements of the replacement pin and brass inserts. A machinist should be able to make in no time. Usually only the Upper Door Pin wears out as the weight is mostly carried on this pin. pic of assembled hinge pin The Pin Bushing is removed tapping the pin out with a punch and hammer. I used Anti-Seize on the pin to prevent further problems. -

Robert, I think you are correct in assuming that a leaking hatch hinge liner was the main cause of the corrosion. I inserted my borescope into that INTERIOR LIGHT channel that holds both Right & Left hinges. Only the hinge boot keeps water from entering the channel. If you didn"t have those big rust holes there under the R/hinge, water would mostly flow along the channel then go down the inside of the rear quarter panels. Then the water would exit from either the front or rear wheel well edges. To repair it. by cutting those rust holes out and cover the area with a sheet metal patch welded on the botton side of the channel. Use polyurethane seam sealer to the top side of the patch. A new hinge boot will keep the water from entering.

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Yes, I am trying to keep some things original as possible. Back to Fuel Pump Modifications: After measure the tank depth and setting the pump length. the pump was installed. This pump can be rotated any direction that you prefer without drilling new mounting holes. Left to Right- Return Line, Fuel Feed Line and Vent Line. The pump mounting bolts were torqued to 50 in lbs in a Star Pattern and three increments. Using the Borescope, you can see the filter on the bottom of the tank inside the surge tank. View of upper side of Fuel Pump Because of the Fuel Pump location, the new Fuel Sender Unit had to be modified to clear the walls of the Surge Tank. Using a Vise Grip, the Float Arm was bent to clear the Surge Tank Walls. The Float Arm can be adjusted further after putting Fuel in the Tank and comparing Fuel Gauge reading, A 100 micro Inline Fuel Filter was installed between the Pump and EFI fuel Inlet. This Filter This Filter uses a Stainless Mesh Filter so it is reusable. A Two Piece Bracket is constructed to hold the Fuel Filter. It was made of 1/8" plate Steel. 4Life Nickel Copper Fuel Line 3/8" x 25 feet purchased from Amazon. Came by Federal Express in a small 18" x 18" x1" box in one big coil. Start by slowly unwinding the coil slowly keeping the roll as straight up and down as possible. When the roll is about 6 feet high, it is time to go outside. Use you feet to hold the lower part of the roll as you are unwinding and sliding your feet on the line. Keep going till the line is relatively straight. Cut the line in half to about 12 1/2 feet long to make it easier to handle. A straight piece of 1/2" electric conduit(about 7-8feet) was fastened to a portable work bench using two Vise Grips. The conduit should be small as possible for the best result. Sliding the tubing back and forth rotating the tubing at the same time. Eventually the tubing should come out relatively straight. Next Step to Make AN Fittings and Braided Steel Hose for the Fuel Lines. Happy Turkey Day to All!!! The bracket will be powercoated when completed. -

The picture is not that clear. Can you take more at different angles? The center section is cast and can not be welded. The other possible fix is to braze the lever (stamped steel) to close the gap and file to fit. Filing will take awhile so do not braze more than necessary. This will work as long as the cast side can take the turning torque.

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

I was fortunate to come across a Great Deal. I sold my "old" sandblast cabinet for $350 then upgraded to Bigger One for only $150 more. This cabinet is twice as large and has top and side access doors. Plus it also came with a 4 foot high dust vacuum. Fuel Tank Modifications: My Fuel Tank was really rusty inside and had a lot of large dents on its bottom. Note-Remember the Pads positions. After Blasting, the dents were more visible. The only way to remove most of the large dents was to cut open the top of the tank and push the dents out. This method would however allow for sand blasting of the inside of the tank. After cutting the tank, a patch was created to repair this area. Visegrips and Cleco Pins hold patch. getting ready to weld All the mig welds were brazed over to further prevent tank leaks. after Brazing. The welds were checked by applying 2 PSI of Air while spraying a Soapy Water. Leaks are easily found with this method. KBS TanK Sealer Kit is an additional step to further prevent tank leakage and provide corrosion protection.' This sealer covers the entire interior of the fuel tank. It is also one of the few tank sealers that is not effected by ethanol fuel. Cost about $80 from local industrial hardware store. Bottom of tank after KBS Sealer install Upper side The KBS Sealer was also applied on the exterior welds for additional sealing. I borrowed a Snap On Tools Smoke Machine. This machine is used to check for leaks in automotive fuel and vapor systems. All openings first plugged up. Then, Smoke is pumped in and for any smoke leaking. The Fuel Tank passed the Smoke Test so painting the exterior was next. Epoxy Urethane Primer was applied. Bottom View-after Urethane Black painting. Side View Holley #19-350 EFI Fuel In-Tank Pump( from Amazon $325) was selected for the task. It is a very compact and well build unit. Next- Fuel Pump Installation and Fuel Sender Modifications Happy Halloween!!!! IMG_1855.MOV Got this borescope from Amazon for about $30. It also can take very good pics too. The Fuel Pump Slump was constructed out of sheet metal and brazed to the tank bottom. Note the maze shape protects pump from excessive fuel movement. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Sorry for not posting for awhile, I had some home repairs to do before the end of Summer. Undercarriage Work: Disassembled and cleaned then lubed and reassembled the steering components. Disassembly, inspection and relubed All parts were painted with Black Single Stage Urethane paint The Gas Pedal Bracket was left as it depending on LS Electronic Pedal Assembly. Brake, Vent and Fuel Lines All Lines were wire brushed, primed and paint with Single Stage Silver Paint. One Part of the Drivetrain Tunnel was the Hand Brake Mechanism which was missing its Dust Cover Rubber Cap. I found a !" chair leg plastic cap from the local hardware store that fit perfectly to seal the Hand Brake Swivel Ball grease in. Cap with hole cut on top Front Disc Brakes Modifications My WILWOOD 300mm Rotors and Four Piston Calipers arrived in time for installation. From Techno Toy for about $1200 comes with braided stainless steel lines. I replaced the Master Cylinder Assembly with another 7/8" one from ZDEPOT. OEM master cylinder assemblies were only available for about $300 as compared to ZDEPOT for $100. But the output brake lines must be bend to fit for ZDEPOT one. ZDEPOT OEM Master Cylinder Note- Difference in Outlet Fittings in both assemblies Also Note-Differences in Reservoir positions New Brake, Vent and Fuel Clamps were fabricated for the drivetrain tunnel section. Next thing to work on will be the Fuel Tank modified for In-Tank Electric Fuel Pump. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Mounting Rocket Bunny Rear Soiler The Rocket Bunny Body Kit does not come with any instructions for installation of its components. So the builder has to come up with his own methods of installation. The rear spoiler is no exception. I decided to mount the spoiler by fabricating Two mount plates that were installed inside of the spoiler. Each mount consisted of Two 5mm x .8 x 16mm bolts that were tack welded to a 1/2" x 3" long 16 gauge sheet metal plate. The mounts were mounted on the both side edges of the hatch. The existing hatch edge was 1/8" thick already and strong enough to hold the spoiler on. Test fitting the mounts Create a cardboard template of mount to make sure the mount would fit inside of the spoiler. I determined that a 1" hole drilled in the bottom of the spoiler would sufficient for installation of the mount and not be "too large". The bolt holes were also drilled at this time using the template. Using a long nose plier and a little manipulation, the mounts were installed in the spoiler. Fibeglass resin and cloth were used to hold the mounts to the inside of the spoiler. Installing the two mounting nuts would hold the mounts in place until the fiberglass cured. Note-Inner Single Bolt Spoiler Mount Two Black Plastic 1" caps from Lowes were a perfect fit to seal the holes. I also added two 5mm bolts closed to the middle of the spoiler for added support. Restoring the Rear Tail Light Assemblies A picture of the "Before" restoration of the Tail Light Assemblies. Note: dull finish, dents and chips. The Lens was polished with buffing wheel and chips were filled in with epoxy. Krylon "Lookinh Glass" spray paint was utilized to provide the "Chrome Like" twin parallel bars of the lens. To give the Tail Light Assemblies additional "POP", Polyurethane Clear was sprayed over the lens. Tail Light Assemblies installed. Spoiler Installed. -

For instructions to construct your own Spindle Pin Removal Tool, Go to V8t forums-Gen III & IV Chevy V8- Heavy Duty Frame Rails and Connections- #9 dated January 16,2019. I bought only a few parts of Home Depot to build and construction was only about an hour. Otherwise, a Floor Hydraulic Press could be utilized.

- 9 replies

-

- spindle pin

- how-to

-

(and 2 more)

Tagged with:

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

"Lost Part" I somehow lost one of the Hoods Accessory Door Spring Latch. So I was forced to create one using the other one to copy from. Original, the Copy and Template It was constructed from sheet metal using pliers and a drill. Test Fitted then to be Painted to match. Restoring Damages Masonite and Plastic Interior Panels cracked Masonite Panel Fiberflex Rods and Fiberglass Screen Window Mesh were used for these type of repairs. Mesh with plastic melted over it created a strong repair. One Masonite panel was missing a large section so I glued a piece of .0025" Aluminum Sheet to fill in the missing area. Fast Drying Epoxy did the job. Vise grips held the patch in place until the Epoxy cured. Note- The hole in the panel is for Radio Speakers. Plastic Interior Panel Repair Big crack in Rear Plastic Panel The Crack was aligned then "tack welded" with the Plastic welder. On the other side, Stainless Steel Mesh was covered with FiberFlex plastic rods to provide a study backing. Then, the otherside of the crack was gone over completely with FiberFlex rods too. Painted with SEM TEXTURE Black paint and prep for painting. Plastic Interior Panels painted. Console painted Closeup of Hand Painted Console Switch Lettering -

Wheel Show! Post your pics of you wheels

toolman replied to k3werra's topic in Brakes, Wheels, Suspension and Chassis

I was wondering if anyone out there, knows anything about Love20bee-a custom wheel maker in El Monte, Los Angeles. He specializes in making custom 3 piece wheels especially for 240zs. His shop was featured on Hoonigan Auto Focus on You Tube. Toolman His website: Love20bee.com has numerous pics of his custom made wheels-mostly JDM stuff. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

idiot280, I don't think the Precision Weatherstripping is made with Silicone in it. But they probably coated their rubber molds with silicone for easy removal of the weather stripping. I always wipe the areas down where the adhesive is going with lacquer thinner before glueing. The Precision Weatherstripping is well made but is "Fatter" than the original 240z one. So you might have readjust your door and hatch latches to allow them to close. The rubber will eventually wear in. Or if you can not wait for it to wear in, construct a similar "pull cable" that I made for the doors and put heavy weight on the hatch. But remember to remove the latches so they can compress the rubber more. . Also, if you still have problems with the weather stripping not sticking, use clamps or similar tools to hold the rubber down. Especially around the corners, the adhesive on the rubber must contact the adhesive on the body. I always check this by tugging on the rubber after an a hour after application. If rubber loose, glue and clamp down again. I hope this information helps you. IMG_1564.MOV -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

My Weather Stripping Kit from Zdepot arrived just in time. It costed about $300 but was high quality and fitment was good. kit parts list The Hatch Weather Stripping was installed with 3M Super Weather Stripping Adhesive. I found the older yellow version to hold better than the newer Black Version. Note-Be sure to let the adhesive to dry(5 - 10 minutes) or until "tacky". Then hold both together for at an hour. I used masking tape and duct tape. on weather stripping on body edge then hold together. When installing New Replacement Door Weather Stripping, if you having trouble closing the door even after adjustment, you try this tip. I rigged up a 1/8" steel cable connected to the inside seat belt mounting hole. Put a Turn Buckle in between the mount and cable. The other end was attached to the latch side of the door. A 3/4" x 2" board was utilized inside of the door to prevent damage to door. The operation is simple-Turn the Turn Buckle to shorten the cable. This will force the door to squeeze the weather stripping tight. Remember to remove the latch plate on the quarter panel otherwise maximum force will not be achieved. The weather stripping must be squeezed a lot to compensate for the"rebound factor". seat belt mount side door anchor side of cable-note board inside the door Another tip- To cut the excessive door weather stripping, a 4 1/2" right angle grinder with a 1/32" cutoff wheel was used because the door weather stripping contains a metal webbing inside. cross section of door weather stripping Another tip: When Powder Coating. I sometimes use a piece of cardboard to hold screw and bolts while sandblasting. Next to the parts, their location was written to aid in assembly. To hang screws, bolts and washers while baking the powder coat, .030 Stainless Aircraft Safety Wire is used. This zig zag type of hanger is utilized to keep parts apart when baking. Rethreading of all Powder Coated items is necessary as the Powder Coating will add additional material to them.