-

Posts

174 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ttodhunter

-

L28 rods or L24?

-

I have a N42 head that I sent out for some head work, but during shipping, an exhaust valve was bent. I have a spare L20B head in my garage and the numbers for the exhaust valves match what is listed for the N42. Both the L28 and L20B list 35mm diameter and 116mm length in the "How to Rebuild" book. Can anyone confirm that these valves are interchangeable? Thanks!

-

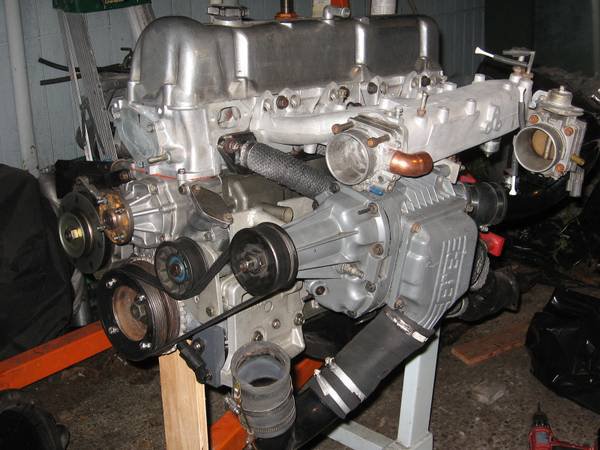

Saw this on Craigslist today. Does anybody know anything about this car/build? I have that same supercharger in my garage and always fantasized about putting it on the Z...

-

Looking to buy a running L28et, including exh manifold/turbo, injectors, oil lines. I'm in Seattle, but would make a day trip for the right motor.

-

If you don't already have the carbs, you'll probably pay as much, or more, for carbs as you would a programmable engine management system. The $1-2k you would spend on the 2JZ would get you some really nice headwork. That, a cam and full exhaust would probably put out decent power...

-

Looks like I'm at about 32.5" between the center of the struts. The car had a fender bender on the right rear corner well before I owned it, so I may need to get the frame checked out. Thanks for the input!

-

Thanks for the replies. My inner bolts, center to center with the wheels down measure about 29.75", and the brace measures approximately 30.125"...

-

Hey all, Just got my Top End Performance rear strut tower brace. I read all of the reviews, but had a good experience all the way up to fitment. I accidentally ordered the part for a 240z, but contacted them and was able to get them to ship the right part for a 280z. I was expecting a 5 minute install, but after a half hour, I can't get it to fit. I jacked the rear of the car until the wheels were off the ground, but it seems the brace is about .5" too long. I can get one side mounted, but the other side is off by about a half inch. If I got the 240z part, would that explain the difference or is my chassis that far out? Any input is appreciated.

-

1977 280z Got it Running.

ttodhunter replied to Brendan280z's topic in S30 Series - 240z, 260z, 280z

I had a similar problem on my '76 which turned out to be the computer. It would idle fine, but if you touched the gas pedal, it would kill the engine. I did go through every test in the EFI Bible and was lucky enough to find a computer on Craigslist for $20 which fixed the problem. Note: There are different ECM's for different years that aren't interchangeable. -

I just installed a SDS engine management system on my stock 76 and wrote a thread about the install. Maybe you will find it useful... http://forums.hybridz.org/topic/110231-my-sds-install/

-

No power whatsoever, the Usual suspects check out.

ttodhunter replied to m1ghtymaxXx's topic in S30 Series - 240z, 260z, 280z

How did you check the fusible link? Make sure both sides of each one have 12v; the hot side will always read battery voltage, you have to make sure it makes it to the other side of the link. You can also check the fuse panels hot side for voltage... -

In case you are still looking for information, you may find my SDS thread useful. I don't know how well it relates to Megasquirt... http://forums.hybridz.org/topic/110231-my-sds-install/

-

I would use the Toyota 2.8 N/A RPM fuel values x 70% and then ensure the MAP Fuel values match the chart at the bottom of the sample map page. Once you have it set up, use the knob to subtract fuel until you aren't too rich. Start at maybe -5%. If that's better, take 5% off of all of your RPM fuel values only. Make sure that your water temp values are at 0 at normal operating temperature. Make sure that your ET reads the water temp correctly, ie 158*.

-

Don't know if you're running turbo injectors or stock, but: 280Z stock injectors are 188cc units 280ZX Turbo stock injectors are 265cc units If you're running turbo injectors, you'll probably need to put in 70% of the RPM Fuel values, ie: instead of RPM fuel = 150, it should be 106.

-

I used the Toyota 2.8 map on SDS website to get a baseline. I'm still fine tuning, but using the knob to get things dialed in helps a lot. http://www.sdsefi.com/fuelmaps.htm

-

carparts.com is selling ball joints for 280z's for $6.55 plus reasonable shipping. Seeing that everywhere else is ~$50, would anyone consider these as an option? How can they be so cheap? They say they have a 1 year warranty... What do you all think?

-

We'll have to meet up soon!

-

WOOOOoooo!!! It was the magnet alignment. I bought spark plugs, but those didn't help, so I got under the car and moved the magnets until they (apparently) were aligned properly. I took the lady out for a spin and it flew through the rpms (I still need to get the tach hooked up so I know where I'm at). Jumped on the freeway onramp and hauled past people on the freeway. It feels great and I'll try to get some G-tech readings soon. I think I have the fuel and ignition dialed in fairly well, but will continue tuning and eventually hit the dyno. I'll work on preparing a summary of the entire process and will post my settings once dialed in. Oh, and I'll try to get some videos up.

-

I based my map on the sample on SDS's website for the Supra 2.8 n/a with Map sensor. http://www.sdsefi.com/fuelmaps.htm Fuel should be fine and I read rich up until the buck. Gotta do work stuff now, more later.

-

My ignition seems to be a bit more agressive, hitting 33* by 2750. Fuel cut is set to 6500. I re-routed the Hall Sensor wires so that they were nowhere near the plug wires or other major wiring. I guess the next easiest solution will be to check the plug gaps, but will probably have to do some tinkering with the hall sensor...

-

Troubleshooting section says: RPM ERR message or engine miss: 1. Check Hall sensor alignment. 2. Check Hall sensor air gap. 3. Hall sensor bracket is vibrating. Improve bracket. 4. Interference from plug wires. Try a different brand of spark plug wires. 5. Make sure that all SDS sensor wiring and Hall sensor cable is not close to spark plug wires or any high current/voltage wires. 6. Check plug gap. Reduce to confirm. 7. Check alignment of Hall sensor over magnets. Loosen Hall sensor mounting bolts and try adjusting Hall sensor. 8. Spark plug gap too high. Reduce gap. I think the plug wires do get pretty close to the hall sensor wires. I'll try that first.

-

So, first attempt at starting resulted in nothing but cranking. Did the normal troubleshooting tricks and found that I wasn't getting spark. I had previously tested and seen the magnets, but had moved the hall sensor once I got the alternator mounted. After some re-adjusting, I tested for spark, shocked myself and confirmed spark. The engine fired right up! I had to adjust the tb for a decent idle, and then it just purred. I ran it through the rpm range and all was well. I set the timing to a guessed 10 degrees initial (the hall sensor mount did away with the timing indicator, but I'd done it a few times and it looked like where 10 was). I tried to upload some videos, but my router isn't liking uploading. I'll try to get some up soon. I took it out for a test ride and it feels GOOD! The throttle response is incredible. It rained a little bit, but 1st gear broke traction with mid throttle. I found that there is a problem when it hits 4k RPM where it feels like a fuel cut and the handheld stops displaying RPM. I ran through all of the values and don't see anything obvious, so this will take some troubleshooting as I really want to feel some upper RPM's. My oxygen sensor won't move past lean... Before, with the key in 2, the O2 sensor would heat up and you could watch the lights move towards stoich. Not anymore. I'm thinking that my bargain sensor may be crap. So... Lots more tuning and finding out whats cutting at 4k. I think I know what I'll be up to tomorrow.

-

I think I'm all done. Going to try and start it. Back later with a writeup and hopefully an idle video!

-

OMGOMGOMG! I got the manifold back today, and WOW, it looks amazing! I quickly took off the other manifold so I could compare. I took some measurements with my super accurate $10 Harbor Freight caliper. It looks like there is about a 20% increase in the surface area of the runner. Good stuff. I was able to figure out which wire went to the coil pack and the TB by running resistance tests through the harness. I spliced and soldered the connections. I also tried to clean up the wiring a bit with some loom. Pics of that later when I'm done. I also had to order another knob from SDS since I think that got scrapped with the Legend... More to come.

-

The PCV is needed as it's part of a circuit. By disconnecting it, you have a break in a sealed system which will introduce vacuum leaks. I learned this in this post: http://forums.hybridz.org/topic/103938-alternative-afm-boot-replacement/?hl=intake&do=findComment&comment=972146 Good luck!