-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

I like Tony's rotor idea

A couple decades back, I had a 260. It looked far nicer than it actually was. I'm tall, so the seat was always in the most rearward position. I lived in an apt. complex in a not-so-nice area. One evening, someone stole it, parked it under a bridge, and took the wheels and stereo. It was recovered the next day, with the seat *very* forward. Once back in my possession, with fresh equipment, I would swap the coil wire with one spark plug wire (at the cap). I reasoned, in the dark, the chances of the average Datsun thief figuring this out would be slim. A few mornings later, I found the door unlocked and the seat *far* forward. I'm reasonably certain it was the same pond scum. It worked at the time. And depending on the level of thief you're dealing with, it may work again.

-

It is likely to cause you trouble. The problem is, the engine/trans will move rearward and slam into the yoke, especially as you transition from hard braking to hard acceleration. The least that can happen is seal failure. A good friend did something similar with an S130. He cracked two tailshaft housings before figuring it out. I shoot for 1/2", but I suspect most people could get away with 3/8". Anything less than that (with rubber mounts) would have me uneasy.

-

Yes....but do you have a Dennis the menace visiting you???

-

If you're not interested in the bike, don't post.

-

Please can you explain how the 78 280z tacho is different to other years?

Nope, sure can't. All I can tell you is I've tried several with HEI's and aftermarket EFI's, with no luck. I haven't been able to get one to respond. BRAAP has run into the same thing. They can be *made* to work, but I've never been able to get one working without resorting to trickery.

-

-

6'-4", and over 230lbs <hiccup><belch>, and the 240z is one of the DARN few sport cars that work for me. Legs and helmet both fit, well sometimes the helmet doesn't, but that's another issue (I learned to digress from Tony D, another big boy that fits).

-

Hi Derek,

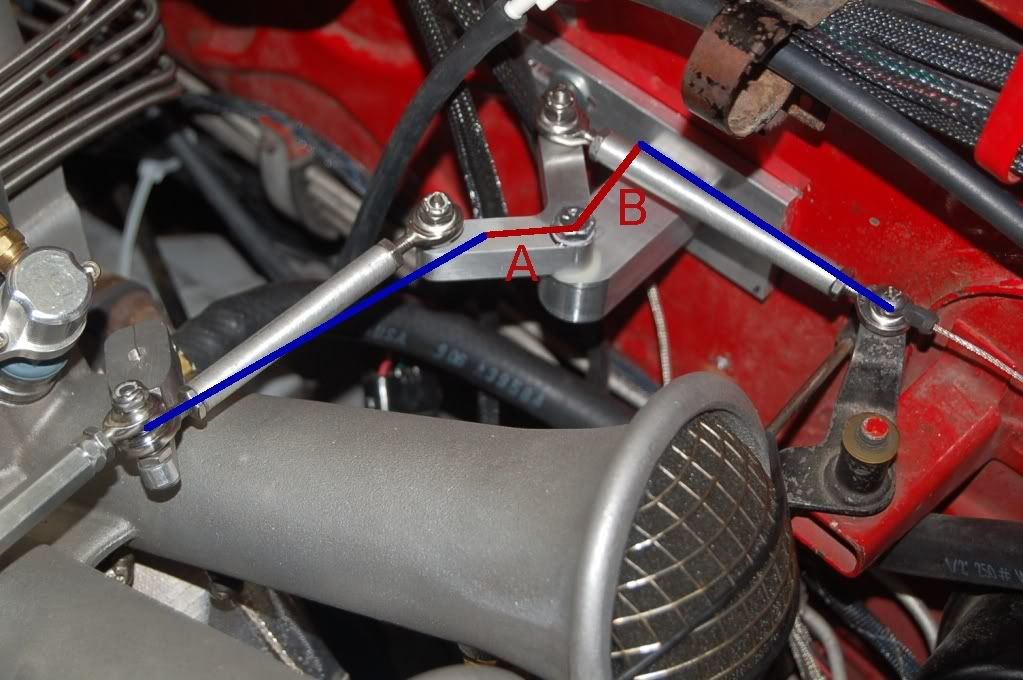

You should be able get closer to what you want by adjusting the geometry of the middle pivot....

Shortening "leg A" would slow the throttle down.

Making the angle shallower, between "leg A" and "leg B", you'll get a slower initial response, with increasing rate as you get closer to WOT.

It will probably take a few trial's to get it working fully, and to your liking. You might try building a simple sacrificial circular part (to temporarily replace the L-shape link), with multiple holes, so you can easily experiment.

-

I know my 280Z tach doesn't work with my R34 RB25. I will be putting a scope on it soon to figure out why. I'll post when I figure it out.

Pete

Pete, What year tach? The '78 is a different beast. I haven't had much luck with those without an adapter.

-

...though mounting the transmission like you show in this picture will make the 'ears' rip off the gearbox, you need to insulate them. I have seen it happen to all the v8 and m50b24 swapped e30's i have run into that swapped without insulating them.

Hi Frank,

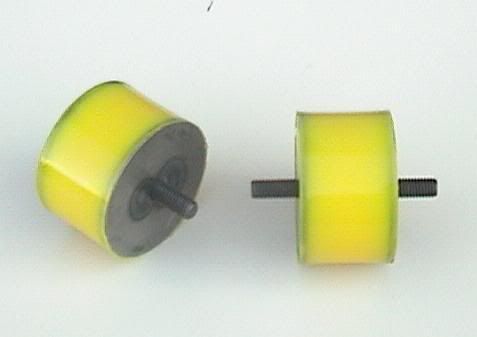

The cause seems to be mixing stiff trans bushings with soft engine bushings (or some similar relative combination), allowing the drivetrain to torque-over and stress the ears. My plan is exactly opposite... use the soft OE Datsun trans bushings and poly engine mounts from Ireland Engineering...

I can't say with absolute certainty this will avoid the failure, but I believe it will.

It may seem stubborn of me to take this risk, but I do have a reason. As I'm sure you know, in high G corners, the trans moves laterally, and the rear shift mount doesn't, causing the oh-too-common BMW money shift. This approach *should* cure that demon.

I sold my BMW v8 with 6 speed and dropped in a sbc i had laying around.Bummer. I was looking forward to seeing that one. I'll be waiting for the N series!

-

Mag's Merc Zcar vs Ron's BMW Zcar.

I think Bob and I are both looking forward to that day

-

why not just use the stock ECU? Or, is it too tightly integrated with the rest of the vehicle electronics so that it is not worth the effort?

Exactly. I touched on it a little in post #4.

Or, are you saying that you can tune a BMW I6 better than the engineers at BMW ?

?

Not at all.

I am saying, however, that I have choices no OEM has. I don't have to build a mass produced tune, for a mass produced engine, driven by clueless and inattentive owners. I don't have to manage my risk with a conservative tune because two million people aren't going to drive it. I am in a position to closely match the tune to this specific engine. Keep in mind not all engines are *exactly* the same. Even BMW reserved thier 'best' motors for the LTW cars. They didn't build 'special' engines, they mearly hand-picked them from the mass produced lot (and fitted them with alpha-n

)

)Additionally, standalone opens a few doors... turbocharging, cams, cam timing, intake, exhaust, etc. I haven't committed to how far I will go with this engine, but I want the choice.

-

Are you saying the timing has changed with no change to the software? If so, the most likley cause would be the spur gear on the quill shaft slipping. It's only pressed on... a roll pin is a good idea on these motors.

Set "Timing Lock" to something reasonable (10 degrees, for example) and make absolutley certain actuall timing matches. If it doesn't, it will need to be adjusted either mechanically, or via the software. If adjusting with software, use the parameter "REF Degrees BTDC". Once matched, turn "Timing Lock" off.

-

Will you be putting up the drawings for those mounts? Looks even easier to make than your RTdiff mount. (assuming you don't go for the swiss cheese look)

What? No one likes my light weight mounts?

But seriously, you'd be surprised how much weight dropped off. In 'solid' form, they're way overbuilt for the job.

As far as drawings... they are virtually complete. I just haven't decided when/how they will be available. The only thing I'll say at this time... they will not be publicly available until after this car is running.

-

I know somebody who could use the M3 suspension from your new parts car.

I bet you do

-

So, he got a parts car for the RTz? Excellent, maybe it will get done quicker then.

Yeah, that's the plan

Thanks for the pics, Paul!

I got lucky with this one. I could probably count the blems on one hand. I caught it 4 hours after he advertised it, I was the first to see it... and I snatched it up for a whisker over wholesale.

-

Hey RTz, you up for that.. he ehe hehe hee

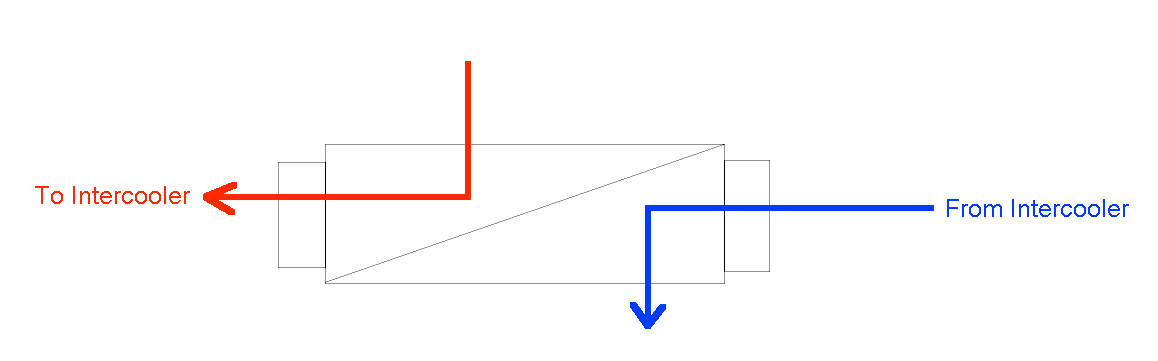

If you have enough hood clearance for a 2 1/2" (or so) spacer between the SC and intake, you could build a diagonally divided plenum. Two ports, one for each chamber, plumbed to an air-air intercooler. Kind of like so...

Ports could be oriented like shown or from the side, etc. Maybe not the most efficient idea, but it would 'work'.

-

-

Interesting choice of EMS Ron. What drove the choice?

Stop by Wolf, say "Hi" to Robbie, and ask him who Ron Tyler is. He'll probably kick dirt, and growl "One of my stubborn US dealers", or something similar

Im looking at sourcing a Euro S50B32 from the UK for my project...

Im looking at sourcing a Euro S50B32 from the UK for my project...Cool! I was hoping you'd go for it.

-

Get it done by June and we'll talk!

2011 or 2012?

-

Great news! I'm bringing a truck next time I come out

-

EMS decided on and aquired...

Big surprise, eh?

-

Probably my most eagerly awaited built... you can't get this one done fast enough for me Ron, been dreaming about this one since Hybridz started!

So, I can count on you stopping in for a visit once it's drivable?

-

Even a stock, 185 HP SBC, will cause traction 'problems' with an otherwise stock S30.

I've seen a very mild, very budget built, 355 do consistent 12.3's in the quarter. That's Viper territory. You could roll into the throttle in 3rd gear and both tires would spin up... at 60mph.

You'll have to decide how far you want to go with the rest of the chassis and drivetrain before you can make a decision on practical power limits. And, of course, for some people, stupid power is still not enough. Only you can decide when enough is enough.

How to steal a S30

in S30 Series - 240z, 260z, 280z

Posted

Trunk Monkey rocks!

This dealership is about 5 minutes from me, so the ads are pretty prevalent around here. My favorite is the one you linked