-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

One of my customers lives in Beaverton, has NO cat, and passes easily. He does have an aftermarket EFI system, however. I believe he's familiar with various testing stations in the area. Member name datsun79z.

-

Got a tip from a member on Bimmer Forums that Bimmerworld is capable of EWSII deletes on OBDII ECU's. So I gave them a jingle to confirm. I was told it was car dependent (no go for some 328's), but yes they can flash E36 M3's. The price is pretty fair as well, at $200. You'll need to give them a call for your specific ECU/DME.

That sure simplifies the use of OBDII electronics!

-

"shape of RTz's head". Dum Bass.

-

I'm pretty sure you'll want another muffler though.

I'm pretty sure you're right! The only experience I have with these is in a turbo application (with a resonator) so I'm shoot'n in the dark. My gut tells me they aren't going to provide enough attenuation. Hopefully we'll find out soon

-

That's a heck of a present. Happy Birthday!

-

Magnaflows arrived. 3" in/out, 5" O.D., with a 14" case length. Time to get busy with exhaust work...

Trying to get both of them in the tunnel. Cut down and tacked...

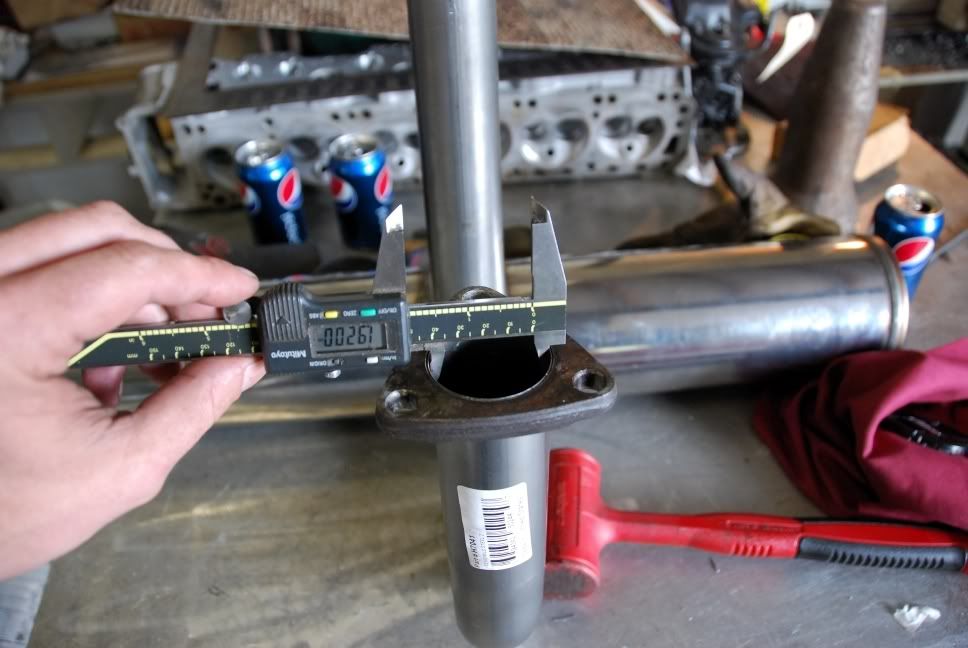

BMW put this honkin weld inside the collector flanges. Machined them out and picked up 30% free area. The header also has a weld bead inside, but it's not nearly as gnarly. A few minutes with a die grinder should take care of it.

I couldn't find a merge collector like I wanted, so I built one; dual 2" into single 3"...

All tacked up...

Plenty of framerail clearance...

Finished up...

It ends at about the middle of the diff. I'm leaving it that way until after it's running so I can decide how much more muffler I need, if any. There's room for one more in the stock location.

-

Magnecor has proven their worth many times over with Megasquirt. Also, be sure you are using resistor gap spark plugs.

-

2.5" race springs 185F 215R - 12" tall.

What is the purpose of the long spring?

Additional rubber or urethane insulation creating a pesudo rubber isolated subframe.Are you talking about putting a barrier between the crossmember mount pad and the frame rail?

new and custom door, window, and hatch sealing,Quality seals are something the community is sorely in need of. Is it worthwhile for a few of us to pool some money together and make a small run of improved seals?

-

An E30 or E36 BMW is not a "modern" sports car. They are 15 to 20+ year old cars.

A cars age isn't one of my criteria. If it performs equal to/better than a Z, is more comfortable, quieter, for similar investment, it's a candidate for consideration.

My E36 lacks some tactile qualities. It's somewhat boring to drive, but very capable. I think there is some latitude to trade off some comfort for tact, and still have an easy car to live with. I paid less for it than a typical used modern Honda.

My departed E30 was the closest thing to a 240 I've ever driven in terms of feedback and total performance, but it was light years more comfortable, quieter, and refined. It had a bit of suspension work, but nothing that kept me from driving it regularly, or on longer trips. I'm even willing to say it handled better overall than any street-able S30 I've ever driven. I sold that car for $14k. Another $6K or so, would've brought the power to supercar status.

And I'm pretty sure I can build a S30 to be comparable to a non-Z06/non-Z51 C5 Corvette for under $30K.If anybody can, it would be you. I think very few of us could, myself included. Still, $30K is a pretty good chunk and I suspect it's resale value would suffer (more so than the C5 anyway).

I'm not arguing just to argue. Honest. I would very much like to own an S30 pleasent enough to daily drive, without strangling it's general charecter, and not feeling like I've invested 1/2 my retirement or life. If there is a path to get there, I'm VERY interested.

-

Clean/solid E36 M3's can be had for under $15k. E30's under $20. C5's under $25. Might even be a couple older Porsche models that fit in this range as well.

Building a 'comparable' S30 for that kind of money is pretty tough.

-

-

Though for a lot less money, one could just buy a C5 Vette, M3, M5, comparable Mercedes, Porsche, etc.

That is exactly the issue for me. Do I think it can be done? Yeah, for the most part. But it will take money, time, and talent. A serious investment if you're serious about the outcome. And likely, when you're done, the cars finished value won't reflect the effort. That may not be an issue for some, but it's at least a consideration for me.

And yes, there are cars out there that perform well, deliver the 'right' sensations, and drive comfortably enough on longer trips. Some of them can be had for the price of a nicely built S30.

-

I've been waiting for J&S to come up with a system that supports the LS1 coils. The Vampire requires dumb coils. Is the Interceptor a new unit?

J&S has worked with LS1 coils for years... probably before LS1 coils were even available

John will be happy to build you a Safeguard without ignitors. Give him a ring. Tell him what you're doing and he'll give you what you need.

John will be happy to build you a Safeguard without ignitors. Give him a ring. Tell him what you're doing and he'll give you what you need.Edit- Now that I think about it, I recall us talking about this. It wasn't an issue of compatibility, it was that he didn't have a 6 channel system at the time.

-

What are you planning on running?

I'm using a 3.36 diff, and planning on 245/40/17 tires. This would put 60mph around 2800rpm. If you can find a 3.15 gearset, that would drop you down to roughly 2650@60.

-

Thomas,

BMW put a Hall Effect/chopper wheel in the diff.

I was originally going to put an aftermarket hall effect sensor on the drive-shaft and use an aftermarket electric speedometer. Not a tough thing to do and reasonably affordable.

I've since decided that I will eventually use a Speedhut GPS speedometer. Not as budget friendly, but a little 'cleaner' in my opinion.

-

One aspect that in my mind makes them more attractive than say the RB and JZ as a possible swap option is these German engines were not only used in production cars offered here in the states, but they there are LOTS of them!

Another perk is weight. While I can't provide irrefutable data, it's sure looking like the M50/S52 and it's cousins are lighter than the Japanese equivalents.

P.S. I'm digging the new avatar

V.

-

Good to see you guys and thanks again for the lights!

-

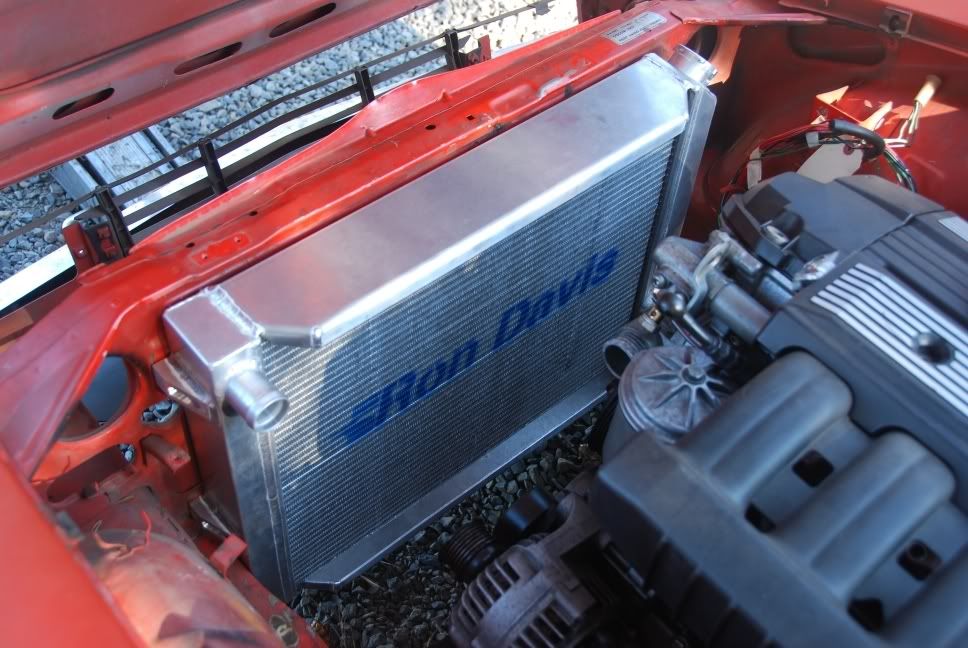

Thanks for the compliments guy's.

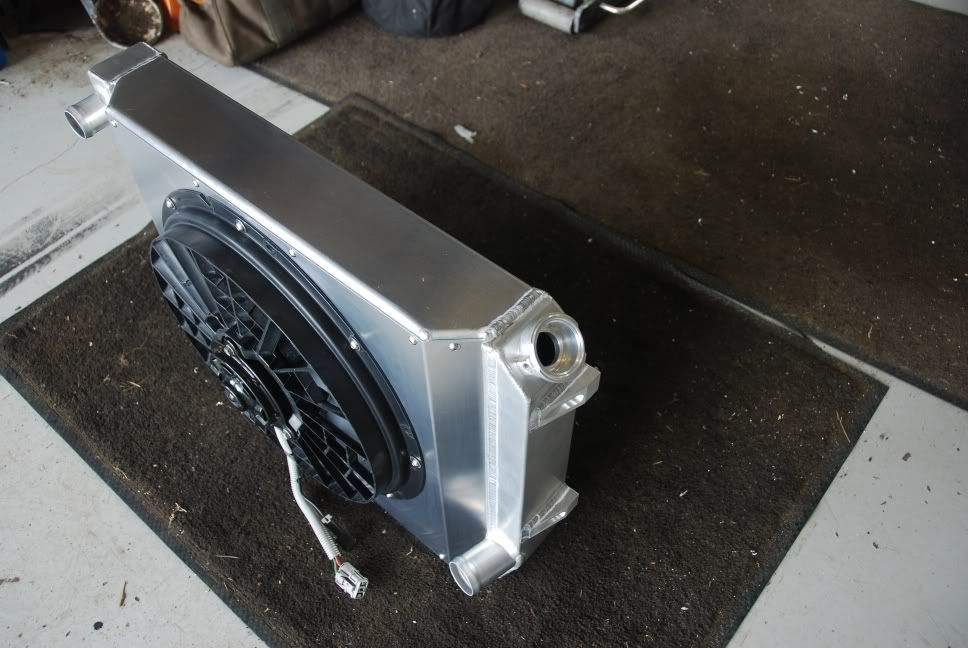

Joel, the fan is out of a '97 Volvo 850. It's no slouch, either. It moves more than enough air on low speed for this application. And it's quiet enough that I'll bet when the motor is running you won't be able to hear the fan.

Ryan, For enough money, just about anything can be available

-

I'd put Lego's in my car if I thought it was the right part for the job.

It's plain silly to to allow others to tell you what's best for you. There will always be concessions in these kinds of projects (investment, return, etc, etc), but that is your burden. Anyone that thinks they have a say in it can go put their head in a toilet.

If a TPI Porsche blows your skirt up, go for it. And please post your progress here. Many of us appreciate automotive challenges and solutions.

-

-

Finished the fan plate...

Fan is '97 Volvo 850. Two speed, moves plenty of air, quiet, and covers the radiator nicely.

-

1

1

-

-

I should be around off and on all weekend. Give me a call when you head out.

-

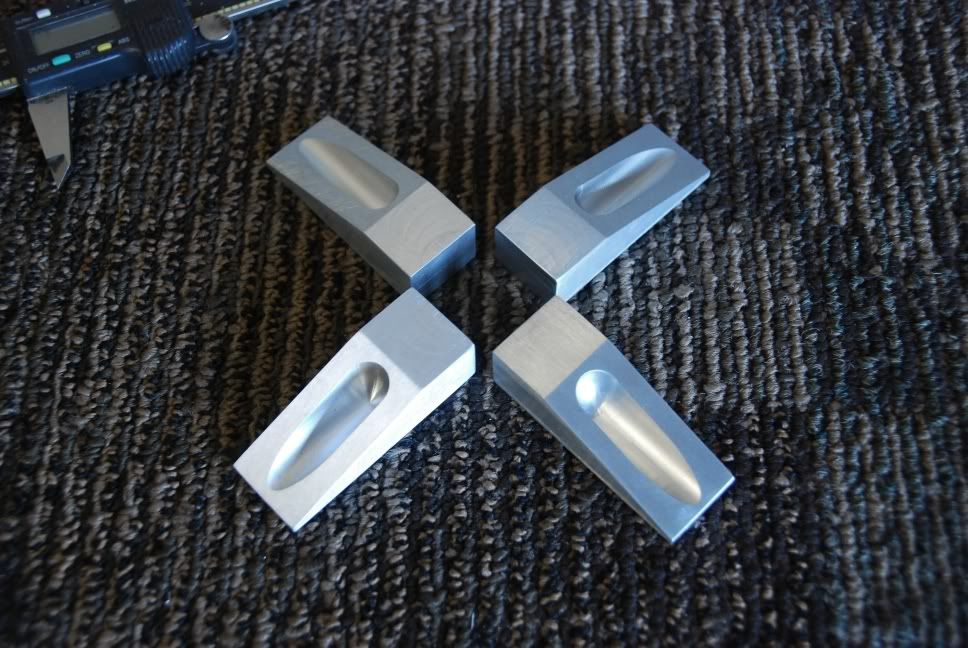

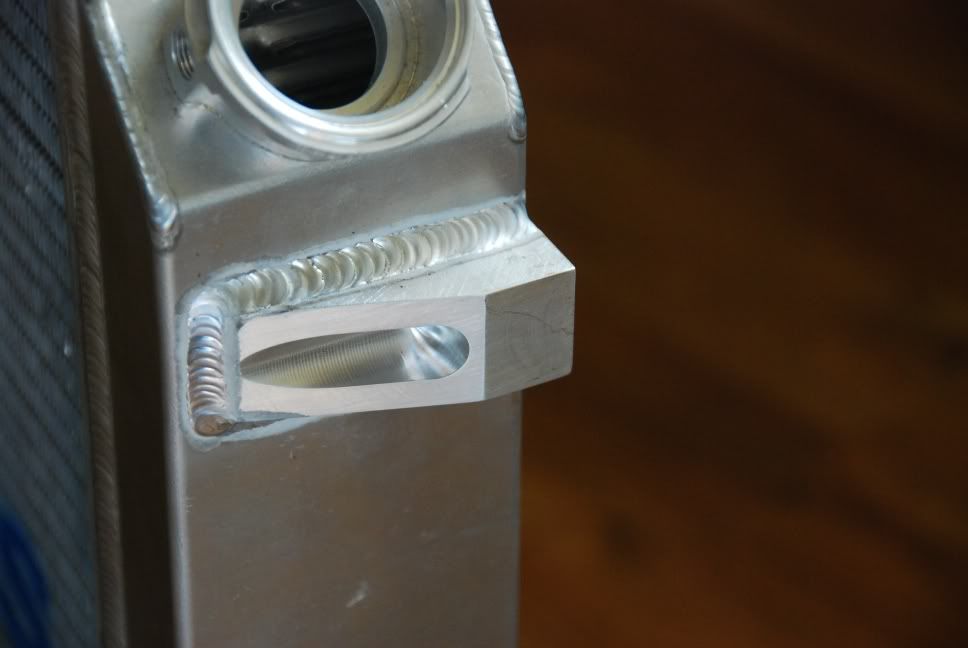

Radiator mounts are finished up (making use of stock core support holes).

I did make a revision to the mounts. These were easier to machine, and I like the look a little better....

Fan mount plates were also welded on, top and bottom...

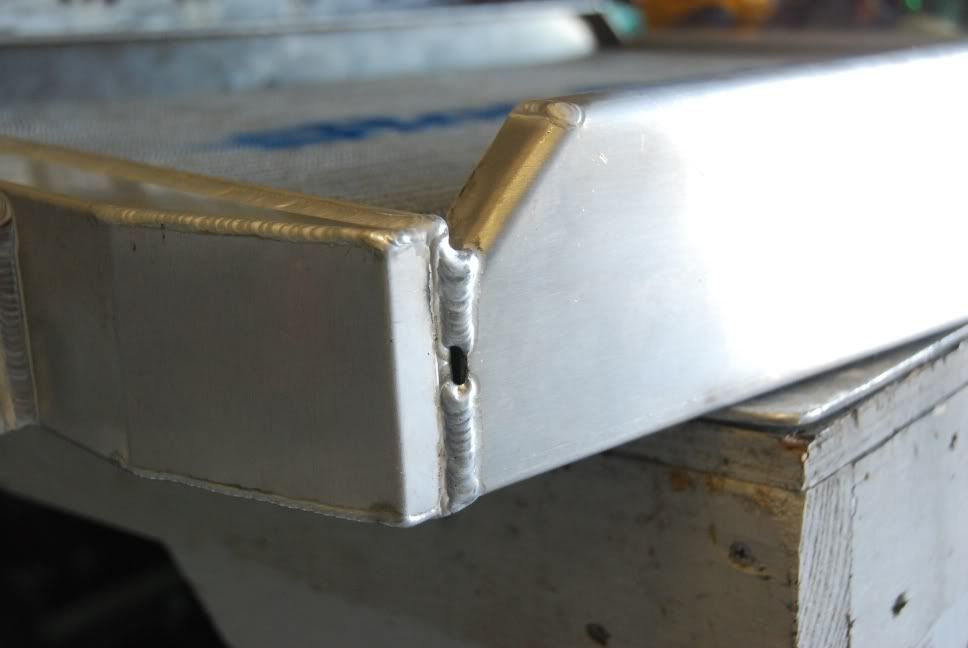

Weep holes in the bottom plate...

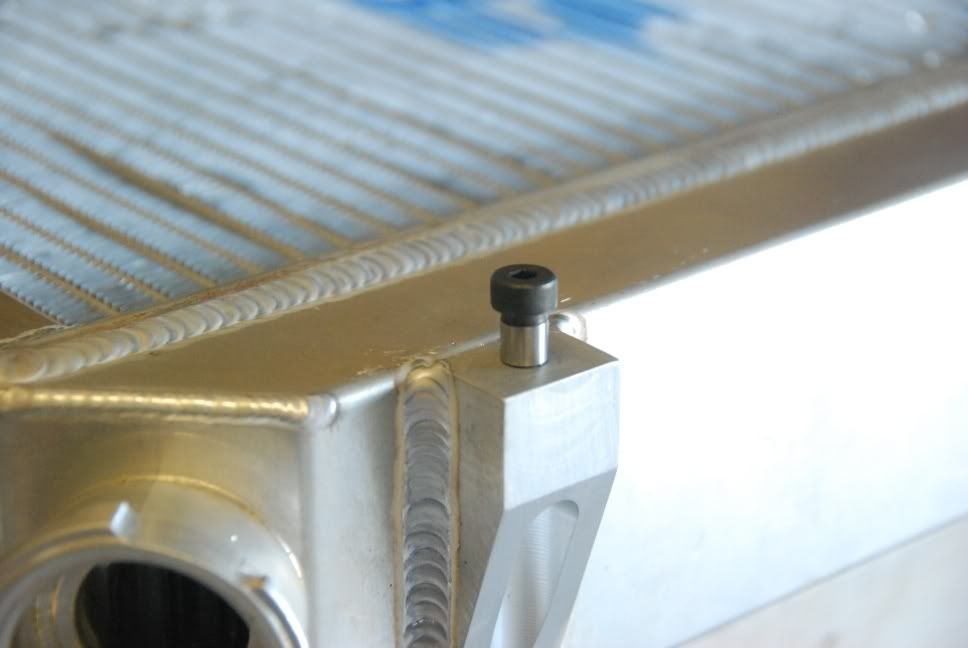

Drilled/tapped for shoulder bolts. Grommets and crush washers will provide a dose of isolation...

Test fit...

Still need to machine the crush washers, fab the fan plate, and attack it with some elbow grease.

-

1) Should I put a connector between Wolf and J&S Interceptor or just splice and solder the wires together? I realize that a connector will be more convenient but I am worried about resistance in the connection.

Minimizing connectors is generally considered good, but keep in mind those channels are logic level, current is minimal, and runs are generally short. However, resistance isn't the bigger concern...

Soldering is controversial. Disavowed in aviation, and for good reason. Subjecting solder to vibrations will fail, eventually. *IF* you're going to solder in an automotive environment, be sure to provide ample support/strain relief. That's the minimum in my opinion.

2) What are the pitfalls of wiring up the sensors directly to the wiring harness with no intermediate connectors?Convenience and convenience.

3) Where can I buy a quality shielded wire for the variable reluctance sensor?DIY AutoTune. Not so much shielded wire, but they sell a robust shielding.

4) Is there any problem running the VR wire (or any other sensor wire) and power wires thru the same firewall pass-through hole?If the VR is properly shielded, you shouldn't encounter any issues. It's ultimately up to you. How far do you want to take it? Are we talking F22's or Datsuns (with proportional budgets and risks)?

Generally... the lower the voltage and longer the wire, the more 'inducible' it is.

NEW.... Composite ideas!

in Body Kits & Paint

Posted

If we're talking real CF construction, I'll take a 240 dash please