-

Posts

229 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Sirpent

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

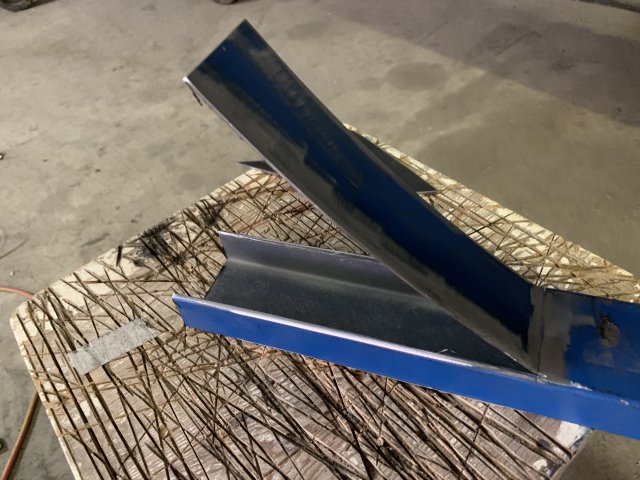

Well that’s the second rail in and blended front and rear into the body along with the (What I’m calling) tunnel horse shoe with ladder chassis bolt points Now for the pans which are almost ready to pick up along with some additional weld clean ups cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Well that’s it for the weekend Ran out of gas as I was finishing off the gussets in the rail floor pan cross member Managed to weld in the ladder chassis pick up bolts, close the ends after reducing the deck height by 5mm and welding one gusset in All in all, extremely happy with the progress -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Another day of fabrication removing the remaining tunnel section and fabricating a new cross support. After centering all up I realized that the entire sections are not symmetrical and are off some 15mm to the passenger side, meaning the drivers foot well and gearshift position are 15mm more to the left. All good, I’m having new custom pans cut, bent and pressed which should be ready this week. Happy to report, no exploding cutting discs and flying metal this week. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

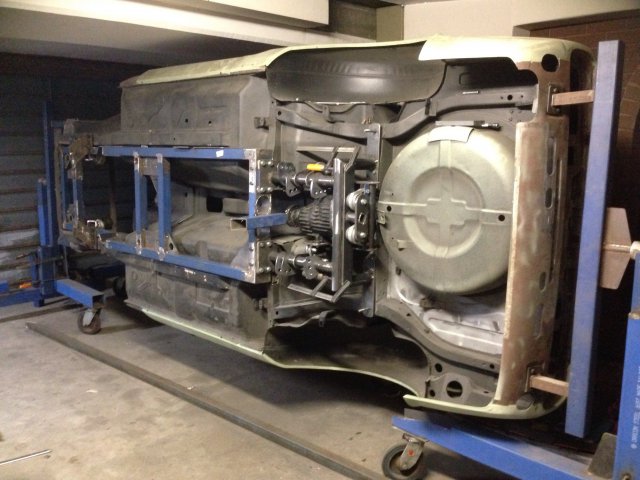

Trial refit of the ladder chassis to check rail positioning. The combination of the rails and ladder will reinforce the entire rear bracing using original bolt points -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

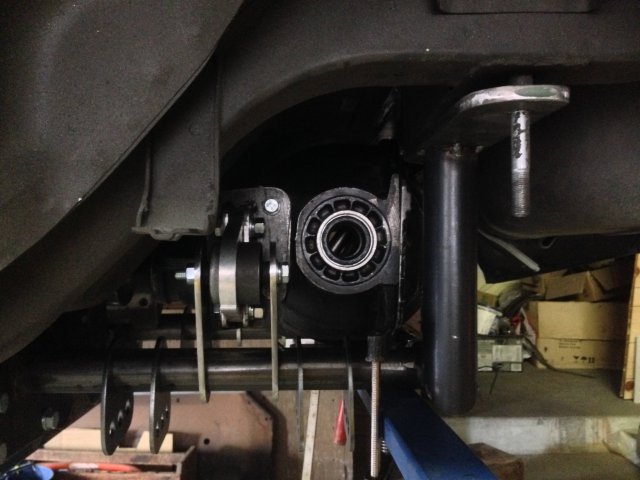

No room as Im running a Ford FPV M86 LSD EA3F00DD-20B5-4706-8A10-C5EC78BAC130.tiff 16E45660-D7A1-44FB-ADB2-60110DA8F1AE.tiff 174A2042-A310-401C-8279-E3CBF97D88E1.tiff -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Many thanks Nelsonian and Ironhead -

I’m back, where are you Finland? Update time ! Lol

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Thanks Buddy -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Olli Not to far off the mark, but I.m afraid its rust setting in on me, I had a major fall doing some cleaning up after some renovations at home and almost sliced open my jugular while causing a back injury. I am on the mend and will be back on the tools as soon as possible. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

#1 LCA's are waiting to get fab'd #2 I use a paint brush when I remember too LOL #3 These fine young cannibals http://www.ebay.com.au/sch/Industrial-Flap-Discs/170801/bn_2209894/i.html -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Just some seam overwelding and linishing back today and boxed in the lower torsion bar mount points leaving boxed in access points for the torsion bar nuts. Cheers John -

To me This is probably the best build thread with such attention to detail I have seen. I only wish you were down the street so I could stick my head in and admire this in real life. Cheers John

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

While waiting for the rear diff cradle to return with the new LCA's............... Decided that the front torsion bar mounts needed some reinforcement. -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

I will take it that you mean "Z" literally and that "Z" doesnt represent some other meaning LMAO I doubt yours would need the amount of grinding mine did as your work is pretty exceptional to start with Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Well after all that grinding, I can say that I no longer have an iron deficiency LMAO -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

What fabrication skills ? I'm a hack compared to many on here but thanks none the less I actually did 2 walk around vids which I will post the links to shortly -

About time ! Interesting project which I will be watching

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

A day of "Spit and Shine" grinding on the welds today Chassis weighs in at 112 Lb, rear diff cradle is just over 33 Lb.............. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Chassis all welded now, just a few pics for now but overall really happy as it looks and is a hell of a lot stronger and sorted now. Heaps of gussets especially around the rear diff / LCA cradel. Lots of deburing and clean up of some of the welds, can now also get the rear LCA's fabricated now that the cradle is stable welded and transportable. A final fit up of the chassis complete with engine trans and diff followed by welding in the new tunnel then all off with the body to all be plastic bead blasted and locked up in EP before going any further. Additionally, picked up a set of Honda S2000 door mirrors with electrics and these Uber dash air vents out of Germany for an A3 which will go into the dash mod and build. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

I'm afraid not The company that turned it all for me went bust after a supply deal to the U.S. went down the drain so you are looking at the one and only ever produced and as far as I am aware the only M112 manual conversion ever done. -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

So after a morning of trimming, and hacking further into the rear of the cars floor pan to work out how to close the rear off, I finally set the new section in place only to get half a dozen tack welds in before the MIG started pushing out bird sh*t welds and packed it in ;( Nevertheless, its in place of sorts.