-

Posts

229 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Sirpent

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Pulled my finger out today, finished the exhaust portals and hangers, squared it all up for the last time and buttoned up the rear end. The gutts of this chassis is now finished and now the gussets, laminates and fish plates plus the cross bracing starts. Diff mounting then follows which will be fun. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Thanks Buddy I will be using mounts incorporating Nolathane's urethane bushes at 4 points The Dana M86 IRS diff I am using is a bit beafier than the 8.8 IRS diffs I see in the States, but when I finish, the rear cradle set up I'm configuring would work for either. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Well got stuck into the rear end geometry today and working around small factory tolerances when the sheet metal and rear mustache bar mounts were welded in place. Going with a solid rear means that the play in items such as the hangers and rear lower LCA support's that allowed everything to bolt up and line up with a bit of manipulation just isn't there and things get pretty tight with bolt points etc when you are working with substantially larger chunks or metal. Anyhow, the picture series below tell the story, the original hanger plates pictured for the last time will now be consigned to the parts bin, in their place 5mm walled RHS beam utilising the hanger bolt points and the 2 mustache mounts, this should give a good foundation for the suspension set up and mounting the diff off. The forward member that the LCA's will eventually be grafted to utilise the 4 bolt mounts from the old LCA forward cross member. YES, crush tubes will be added to all these bolt points shortly. From there 205mm hangers from the same material currently held in place by some plates and clamps. and off of these 42mm OD pipe with a 4mm wall thickness. These are welded to the hangers and will act as the pivot rods for Arizona Z type LCA's, all that will need to be done is to weld on 4 brackets on each so that the Rose Joints/ Rod Ends can bolt up to. Speaking to Peter Mac, these will have 3-4 bolts points on each to allow for the joints to be bolted higher or lower to help with adjustment should it be needed when the suspension is lowered etc etc etc. So that was all for today, new "D" size gas bottle is great, no problems running out of gas, but of course I ran out of mig wire this time. Stay tuned Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Added the rear cross member today and started to add in twin exhaust portals, everything's squared up to the millimeter. Now I will start thinking about incorporating an "X" support member in the chassis, at this stage it looks like it will slot in from the inner corner points at the rear, to the tunnel support brackets I fabricated. Sitting back and taking it all in I realise I will probably be able to flat bottom the area under the chassis now, so will see how things pan out down the track. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Spent today checking clearance for the new Tremac T56 box and as suspected the Z box mounts had to go. I negated the brackets but left the reo saddle which I used to create new mounts for the new chassis. -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

A bit more work done today. Decided to leave a bit more room between the cars rails and the new chassis so unplucked the temp weld's and narrowed each side by another 5mm. This will allow me to comfortably put in 4mm reo plates on both sides of each dog leg without worrying that they will foul up against the cars rails. I also wanted to check everything with an inclinometer, and came across an article that suggested using an iPhone app, downloaded it and it worked a treat. Got everything repositioned and then started welding things up again along with the 2 long extensions leading to the rear. removed a group of redundent brackets from the body at the rear and tomorrow I start on the back cradle section. Cheers John -

Congratulations! As others have mentioned, the rust sections are minor compared to mainstream S30's of the era, you have a good starting point, time patience and above everything else "PLANNING" is the key now. Cheers John

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Well that's a wrap for this weekend, now starting on the floor rails and have twin tubed the junction dog legs on each side, eventually these will have additional profiled plates added over the top to strengthen this juncture. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Update A bit more done this morning, the plan to go with the 2 additional mount points at the tow hook points have given way to using the sway bar mounts as per the pics below, this seems a better way moving forward as now although the mounts will be a few mm's lower, this will give more rigidity to these mount area points and the sway bar as well. The front cross brace between the rails will be perfect for mounting a new custom radiator. Alignment of the new BMW rack is great and there wont be any issues with mating it up to the S30 steering column and clearing the new rail assy. This afternoon I will be working on the main chassis rails under the floor pan, so far everything is plumed up really well. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Some progress today on the chassis build. Having had all the time in the world since Lurch and I made a start on the chassis over a year ago, and with the completion of the new cross member, I decided that some major redesign needed to be undertaken due to the impediment of the front tension bar mounts which we initially built around and meant that the chassis couldn't be dropped out of the body. So unfortunately they came out today and I started to fabricate new sections. With the new cross member assy now bolted to the car rail mount points, I was able to fabricate the new chassis rails which sit on larger mount plates on the cross member. These new chassis rails will eventually be welded to these plates permanently therefore forming part of the new chassis. The tension bar mounts will now be fabricated and mounted to the new chassis rails therefore removing additional stress on the original rails and skirts. Forward of the new cross member, I will be adding mount plates in each corner where they meet the front radiator support and using the tow hook mount points on the bottom of the radiator support panel so as to further anchor the body to the new chassis. Working back from the front cross member, I will be fabricating mounting plates on each new chassis rail which I intend securing to the originaltransmission mounts on the "Z". Stay tuned............. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Mr Montana I just wish I was an 18 year old like you again when I first got my girl, so long ago now. I couldn't see you posting to your own build thread yet anywhere so I can only imagine that you are just starting off on your Z journey. Hope that along with my effort and all the fantastic other threads on here that you are inspired, there are some great idea's and sharing of knowledge on this site. And never hesitate to ask what ever you want. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Thanks gents........ LMAO, "Rust never sleeps, neither does this project" -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

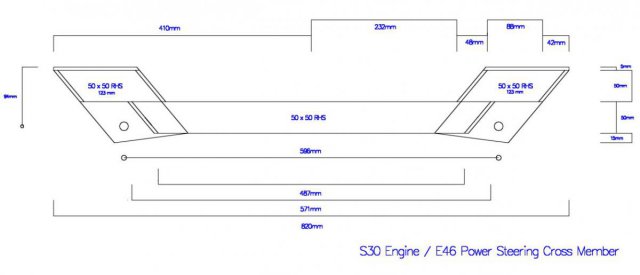

Illness, work, 2 boys turning 18 and 21, and a massive home improvement project meant this project went into moth balls, but started up again where I finished off and have made progress with a new cross member design and fabrication to carry an E46 power rack. This is still in mock up stage so just some heavy tack welds to hold it all together until I can get it TIG welded up and smoothed. LCA mounting pivot holes will come later down the line. RH Mount plate to chassis sorted, LH still needs to be cut and drilled, these plates will be welded to the ladder chassis to form a permanent cross member in the structure and secure it using the cross member bolt points on the S30's monocoque body. There will be a number of such bolt points along the chassis using as many of the factory bolt mount points including a few to be added along the way. Cheers John -

Good to see things are progressing Those mirrors look the part, nice pick, and that dash looks a lot more organic with the mods to the vents, should look great once its all trimmed up. Wish I was closer, like 16K miles closer, would be happy to do the welding on your centre console with that small error you made, but all in all, impressive Cheers John

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Thanks Buddy. As far as the exhaust, no I wont have any issues as first this is a V6 as opposed to an L6 and I can afford some more space between the firewall and the rear of the motor if need be, other point is that the manifolds rake directly downward so plumbing the piping wont fowl the new rail set up. Cheers John See attached side view pic -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Visited the old girl today, its been weeks due to work, but took a few minutes to see how the lenses sat....................Happy -

Well I ended up picking up my sets off Yahoo Japan Auctions a few weeks ago and they were delivered last week Quality is fantastic as per the photo below Seller was nagisa240 Cheers John

-

Updates ???????????????????

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

They survived 40 odd years sitting in a carboard box somewhere in Japan, and the odd earthquake and Tsunami along the way, and today they arrived at their final destination -

Excellent Build and fabrication Glad I havent had to rip into mine as much as you have in fabricating a chassis, Im impressed by your tenacity and dedication. Great work Cheers John

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Well the major hurdle no longer seems to be one after 2 days work. The following is a series of pics starting with fabricating a rotiserie from the plan and pre cut pieces I ordered a month ago. In order to get this chassis even half way set up correctly with the limited tools and technology we had on hand, this had to be done. Afterwards you will see the genesis of the chassis as it developed, a friend of mine and fellow clubman Z owner and I finished the entire mock up squared and true on the car up to the rear section where it dives upward back to the rear hatch floor pan, that will have to wait for another Saturday as there are fair few redundent mounts etc plus a sectionisation required in two sections to accomodate the set up. All in all, even though Lochlan was pretty reserved when we first started the new chassis, I think even he saw the versatility it will deliver..............I hope anyhow. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Hi Colin Read back a few pages in this thread, Im building a chassis for the car due to the powertrain I have prepared and am installing. Most of the heavier pieces are for a rotisserie I will be knocking up like the one shown below. Cheers John -

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Sirpent replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

New bling Courtesy of Yahoo Japan, the 997 GT3 head lamps are now on EBAY, hopefully I can flip them for a few pennies more. And finally, chassis being built 15th and 16th of Feb, as you will see all materials delivered and waiting. Cheers John -

Sellers details?