-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

I'm going on the assumption that the only change besides rebuilding the motor is the cam, hence can't see that the exhaust would be the issue. Now if he was putting a bigger turbo on and increasing the boost pressure, then that's another story... BTW, I didn't mean to suggest that cam has a torque peak at 3800 rpm. In my engine, using the Megasquirt VE table as an indicator, the torque peak with that cam was between 4500 and 4800 rpm. I can't comment on how much of a difference a freer flowing exhaust would make. I never ran with the stock turbo or exhaust - I started with a T3/T4 and 3" pipe all the way. I also use a larger wastegate housing from ATP Turbo. But if you think about how a turbo harvests the energy from the exhaust, it makes sense that you'd want as little back pressure as possible.

-

In your original post you said you had verified timing so I'm assuming that isn't the issue. The new cam has longer duration so you can probably run a little more advance, but it's hard to imagine that would explain it. With an all stock turbo motor except for the cam, you should be able to hit 7 psi long before 3800 rpm. If you want to do it right, there's an excellent post by BRAAP about how to degree a cam. But if you want to do a simple test (and I'm assuming you don't have an adjustable cam gear), you could try moving the cam to the 2nd or 3rd hole. IIRC, each of those advances the cam 4 deg to correct for timing chain stretch (not sure that "4" is the right number going from memory). It's a simple experiment, just make sure to put a spacer down into the timing cover so the tensioner doesn't pop out.

-

Everything you listed is for the drivetrain. What about the suspension and brakes? If you're going to build a street/road course beast, expect to spend anywhere from $3k to $5k depending on what you already have and how far you plan to go. For example, with that kind of power, brakes that will do well for 20-30 minutes on the track with good f/r balance are at least $1500. You'll need new bushings, springs, struts, camber plates and/or adjustable LCA/TC rods. 250 hp in a stock chassis won't be much fun on the track

-

Without a dead short (which would be very obvious due to sparks, heat, etc) there is no way a fully charged battery will discharge enough in 5 minutes such that the engine will die. Most modern batteries are rated to run the car with headlights on for more than an hour. The problem is something more than just a failure to properly charge the battery, or your fully charged battery wasn't. Have you verified that the wiring is all in good condition, with no splices or junctions that are frayed, corroded etc? All the symptoms you describe could be explained by that. Start with the wires between the battery and starter, also check everything between the alternator and the fuse block. Look for ground wires connected to the chassis that are corroded. FYI, I had a similar situation where sometimes the alt would not charge after the car was first started for a few minutes and then after reving the engine it would charge properly. Turned out one of the wires to the connecter under the alternator was frayed where it met the crimp to the connector. Replacing that solved my issue. Reving the engine was a red herring - it was a loose connection that had nothing to do with engine revs.

-

From the original post I assume he has a T3 running at 7 psi which is about 150 kPa at sea level. At that level of boost my tune is 24 - 27 deg and could probably add a few more. (My wastegate is set for 200 kPa so it's not easy for me to tune at 150). I'm sure that adding more timing advance (assuming it doesn't cause detonation) would help spool faster, but I doubt it would explain the change he's seeing of getting to full boost at 3800 vs. 2500 rpm. I still think it's most likely cam timing...

-

Just re-read your original post and want to confirm that you're referring to accelerating at WOT or close to it. Also, you didn't describe the engine other than it's an L28t. What turbo, cam, boost pressure are you running? Lastly, before you tune anything, post a datalog from a stop accelerating thru 3rd gear. That way we can quantitatively see how the boost is affected by the 2-3 shift.

-

Got it all back together this weekend and all is well with the universe again. But for those who may be doing this for the first time, here's a summary of what I learned about attaching the T3/TO4E turbo to the stock manifold: Make sure you use the Plate-lock 14495-V5300 to secure the nuts on the exhaust manifold studs. Without those, expect the nuts to back off after a few thousand miles. This shows NLA for the 280ZX turbo, but still shows up for the Z31 300ZX with T3 turbo. The deformed thread nuts from Nissan must be some other thread size as it destroyed the threads on the first stud I tried. Save your money and avoid them. Instead, use steel conical-top nuts from McMaster 93795A240. Much cheaper too. For studs, I ordered 2 types from McMaster 93275A039 (M10 x 1.5 50mm) and 91059A561 M10 x 1.5 52mm). The 561 are described as self locking, but I didn't notice any difference. However, they have shorter threads on one end which is useful when using the T3/TO4E which requires a spacer. With the 039 it would be easy to put them in too far and not have enough threads left for the nuts. Lastly, I found that assembling the turbo housing to the manifold BEFORE installing the turbo wheels made it easy to get the wrench properly on the nuts. With the turbo fully assembled, it's not easy. Lastly, before you pull the turbo apart, make sure you scribe a line for the alignment of the center section. I used a sharpee and I think the Kroil removed the mark. Having to line it up and tighten the center section bolts on the car isn't that much fun, but it is a good excuse to get a set of stubby metric wrenches.

-

S12+8 Toyota Upgrade Rotor questions

Zmanco replied to Wesley's topic in Brakes, Wheels, Suspension and Chassis

Even with the rear pads having a higher coefficient of friction, I can open the prop valve all the way up and the fronts still lock first. I am no longer a fan of this combination for track - there are a limited number of pad materials available and so far I have not been able to find a combination that gives enough rear brake bias and is also track worthy. I think the Silvermine approach for rear brakes (GT500) coupled with Toyota 4x4 front vented might be better. Gerry (30ounce) runs this on his stroker 260z and has been very happy with it at the track. It seems to have a better inherent balance front to rear. -

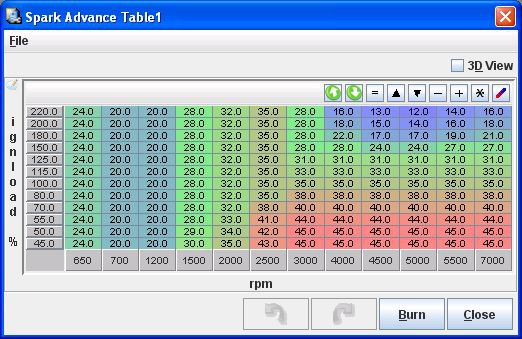

I've found pulling timing around the torque peak is a good way to manage detonation as well as yielding a flatter torque curve, at least as measured by my butt meter. So there isn't one number to report. FYI, this is a very conservative tune with only minor det events at the track on warm summer days that MS manages via the det sensor. If I only drove on the street, I could probably add 4 or 5 deg.

-

5 second fuel prime when key is switched to "ON" position

Zmanco replied to MazerRackham's topic in Ignition and Electrical

The default on megasquirt is 2 ms but a year ago I experimented with turning this off and even after sitting for a month, I don't notice any significant difference in cold start time. For my car, if there is a difference, it's less than 1 second. -

I used that cam with a T3/T04E turbo and live at 6k feet elevation and 3800 rpm was about right to hit 15 psi boost. Given you have the stock turbo and are (I assume) close to sea level, I'm surprised that you don't see full boost sooner. Again check your cam timing as a retarded cam will push the power band higher up the rev range. Side note: make sure you run ZDDP in your oil and if possible, add the external oil bar. I did everything right with that cam (except the external oil bar) and it still failed (pitting and galling on lobes) in 10k miles. Schneider cam metallurgy is not very durable in our Z engines.

-

What do you mean by boost threshold? If you're referring to the rpm when the turbo begins to build boost, then both RPM values sound too high. But if you're (improperly) referring to creating full boost, then the cam, along with the cam timing, is definitely a big part of it. You should verify the cam timing is correct, or even advance it some with an adjustable cam gear to generate more boost at a lower rpm if you prefer that. Keep in mind that this cam should make good power to at least 6500 rpm, which is significantly higher than for the stock cam.

-

Yes, I have a kit like that for the valve cover bolt holes Hardest part I found for the exhaust stud was drilling the pilot hole in the center of the broken piece. Even after using a punch, the drill bit wanted to walk as the surface wasn't flat in the center. In my case it was the stud that connects the turbo to the manifold. Interesting that one of the other studs was slightly bent which probably explains why it broke off. I installed those new when I first built the motor so know their history. The only things I can imagine is that the vibration from driving with the turbo loose (not very loose, could just begin to hear the exhaust leak) might have bent it? Not sure I like that explanation, but don't have a better one. As a side note, while the L engines are rather durable once set up properly, these little nagging issues are frustrating. I suppose if I didn't track it I might not see these though ... or at least they would take longer to show up.

-

You didn't say what year car this is, but assuming it's factory installed AC (and not dealer installed) the compressor is attached to the bracket with 2 or 3 bolts IIRC. The bracket is attached to the block with 4 bolts. Have to ask: why does the number of bolts matter? It will be obvious when you're removing it.

-

Simple answer: If you don't go with coilovers, you'll be bolting in adjustable LCA and TC rods. Those parts are not cheap, and there's very little to choose from for springs. And you'll be limited to about 3 deg caster. If that is not enough to hit your performance goals, then coil overs are the better way to go.

-

I think there are two issues: 1) Usually when a head is shaved, cam towers are added to maintain the same length between the cam and crank gears. There is a tension adjustor for the timing chain, but it has a limited range it can adjust. You didn't say how much the head is shaved, but I'll guess it's much less than the .080" that most do when they're looking to bump up the compression. The fact that you've run it for 2 years suggests that you can get away without adding shims. 2) Shaving the head without adding shims to the towers will affect cam timing by retarding it. This will typically shift the power peak to a higher RPM range. You'll notice the difference by feeling less torque at low revs and then the engine will surge as the revs build. Ok, that's an exaggeration, but that's the general affect. If you want to experiment with cam timing, get an adjustable cam gear and make small changes and see which combination gives you the balance between low end torque and high end power that you like. I'd argue this is a personal preference so try a few combinations and then settle on the one you like best. Keep in mind that if you're still running the stock turbo and cam and are pulling 2 deg timing for every lb of boost, it's not surprising that you aren't making much power after 5500 rpm. If you want an engine that does, you'll need a cam with more lift and overlap, and depending on how much more power you're seeking, a bigger turbo. In short, there's a good chance that you're near the limit of what you can get out of the setup you have. Putting it on a dyno would be a small investment that would show you just where you are.

-

Remember that an O2 sensor measures unburned oxygen. If there's no combustion, then even a very rich mixture is going to read lean.

-

Could be timing, but more likely it's After Start Enrichment (ASE) or WarmUp Enrichment (WUE).

-

In theory, I will have it back on the road this weekend. But based on all the unexpected delays so far, I wouldn't bet on it.

-

Yasin, the T3/TO4E turbo with spacer blocks access to getting a wrench on some of the turbo nuts unless the manifold is removed from the head. And it also makes it really hard to get to the manifold nuts while it's on the car. It's easier and takes less time to remove the head, at least for me. FYI, thought I was going to put it all together last weekend but turned out one of the exhaust manifold studs broke off. Easyout failed so I had a local shop take it out yesterday with a plasma tool (way cool) and am now waiting for the new studs to arrive from McMaster later this week. This "little" issue has turned into quite a project. Car has been off the road since the last track day 5 weeks ago ...

-

A fuse between starter and battery

Zmanco replied to heavyweight280's topic in Ignition and Electrical

A typical starter can pull a few hundred amps but I haven't seen the specs on the ones used in our Zs so don't know what the value is. You could start with the 300 amp unit you linked to, and if it blows, go up from there. But keep in mind, that even 300 amps is a huge amount of current and is going to damage something if there's a short, so I don't know if the addition of a fuse is going to buy you much protection. -

Make sure your torque wrench is accurate. I checked my several year old Sears using a hand held suitcase scale and found it was indicating about 10% higher than measured. (I verified the suitcase gauge was within 1/2 lb of my bathroom scale.) I run 15 psi with Felpro and have not had problems that I can blame on the gasket, including around ten 100+ mile track days.

-

Sounds like the owner is being reasonable given the long time that has passed and the visual indications of poor lubrication. Sounds like you need to verify oil pressure once you get the engine running again. You may need to shim the oil pressure relief spring in order to get enough pressure at high revs. Hopefully you're using something more accurate than the stock gauge ...

-

Isn't the main issue that without an ECU it's not possible to optimize spark across the rev range, adjust mixtures at a variety of engine conditions, etc? Nothing wrong with going old skool, but to Mack's point, seems strange to spend so much on a premium bottom end and not take advantage of optimizing fuel and spark to get the most out of the motor.

-

Keep in mind how much air is flowing through the intake manifold vs. how much will leak through the valve when it's sealing properly. I can't see any good reason to remove it. I'll also add to Gollum's summary of good things that come from a properly configured PCV system: if you run the engine hard for long periods, such as on the track, you'll want to route the breather through a separator/catch can. Without one, expect to clean the engine and underside of the hood regularly.