-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

Mod to control eFan via MS? (Forget what DIY calls it). GM coolant sensor 2nd Baro sensor is good too, but if I recall from my high school geography classes, Oklahoma is pretty flat so maybe not necessary.

-

I ordered the Plate-Lock and Nuts from Courtesy Nissan today - I'm assuming the nuts are deformed thread to justify their price of $6 each. A few of you mentioned Loc-Tite. I had looked some time ago but didn't see anything rated for exhaust temps. Is there a version for that application?

-

I'm looking for the Maxima diesel water pump and part number 21010-17SY7 is coming up NLA. I think some of the car part chains are substituting the gas version which is of no interest to me as that's what I already have. 2 Questions: 1) Anyone know a source for the diesel pump? 2) What are the visual clues to the diesel pump to identify it as different from the gas? Anyone have pictures?

-

I started with steel nuts but they backed off after the first track day. I thought the issue was due to the exhaust so added a flex pipe right after where a NA header flange would be. I also later added a bracket near there to the tranny. Both seem to have made things better, but obviously I haven't cured the issue. I obviously couldn't see under the hood while on the track, but after about 15 minutes into a 20 minute session had to back off as the water temps were approaching 240 and oil was over 250. But I was being chased by an LS3 Miata and another with Flying Miata turbo (300 whp) and didn't want to slow. Turned out that as soon as I let up for them to pass, both were in the same overheating situation and stayed behind me. We had a good laugh afterward.

-

Thanks, that's exactly what I need. I had searched using the 280zx turbo with no luck and didn't realize the early 300zx used the same turbo. Sweet! I noticed that the corresponding nut is listed at $6.27 each. Are these deformed threads, or something else unique? Otherwise what's so special that they want $25 for the set of 4?

-

Ryan, thanks for the suggestions. I had started looking at Loctite but didn't see any products that could live in that heat range. Same issue for any washers that are spring steel - the heat takes out the "spring". Sorry you couldn't come out to the track - it was a fantastic day as the threat of rain kept the temps somewhat lower (mid 80's) and the rain stay away until 10 minutes after we left the track - total luck! When will you have your car back on the road? And at the risk of hijacking my own thread, here's .

-

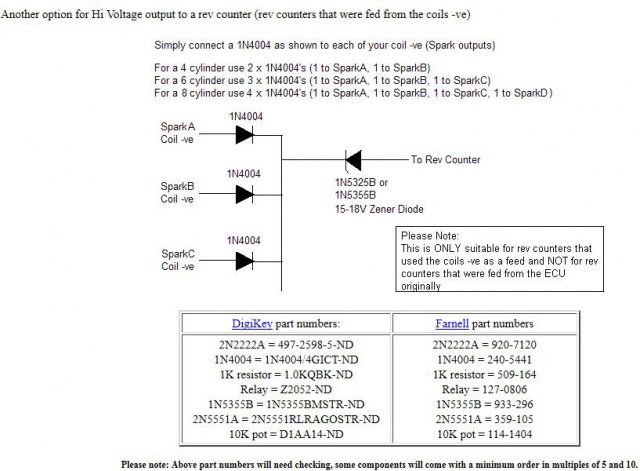

You can create a diode bridge to do this. http://www.msextra.c...re.htm#tachoout That's how I drive the 280Z tach with EDIS. I don't see why you couldn't use the same approach for COP with 6 diodes instead of 3.

-

I've had a recurring problem with the nuts that hold the turbo to the exhaust manifold coming lose on track days. This last attempt I used the deformed thread copper nuts but that just slowed the process down. Due to interfearance issues with the T3/T4 turbo I have to pull the head and remove the manifold to get to the bolts so this is the last time I want to do this. I recall that when I removed the factory T3 turbo that the bolts were secured via a piece of soft metal that was bent up around them. There were 2 of these pieces with each one spanning across 2 studs. I've found it in the FSM but there's no part number. Does anyone know how/where to source these, or perhaps where to get a small sheet of the metal so I can make my own?

-

The point of my post was that the T5 I just put in has about the same 2-3 gap as your setup, and I am NOT having the problem you describe. So as a few of us have suggested, you may want to look at the tune.

-

I just converted my T3/T4 L28 with Isky cam from the 81-83 NA tranny to T5 as the bearings were making bad noises. I do find on the street that I need to delay shifting from 2 to 3 until a few hundred revs higher so the torque fall off in 3rd is not as noticeable, but if I shift at 6500 rpm, there is virtually no delay in getting boost when I get back to WOT in 3rd. I used to run the NA tranny with a 4.11 and now run a 3.54 diff. The result is that the overall gearing for 1st and 2nd are nearly identical and 3-5 are longer. Keep in mind I'm at altitude so that only works against me further, and I'm not seeing this as a problem. FYI, when I ran the stock 4 speed with stock cam NA, the 2-3 gap was very noticeable on the track. To johnc's point, something is wrong with your tune/setup if you're seeing boost fall off shifting at 6500 rpm.

-

current vs Voltage sensing tach

Zmanco replied to Scarab73's topic in Gen I & II Chevy V8 Tech Board

My 73 had a current triggered tach. I think the cutover to voltage triggered was when they changed to electronic ignition which I believe was 74 in the US with the introduction of the 260Z. Perhaps someone with a 260Z can confirm. Z-ya is correct though, it's pretty simple to swap a voltage triggered tach into an earlier housing. I did that after giving up on finding a healthy current triggered tach. FYI, the MSD adapter for current triggered tachs is a poor design that is affected by temperature. I'd avoid it, but if you have to use it, don't mount it in the engine compartment. -

It's hard to say with that setup if you're going to have more front or rear brake bias without a prop valve. If I had to guess, it will be more front, so unless you go to different pad materials front/rear, more than likely you are going to have an adjustable prop valve all the way open. And if that is the case, then you do not want to leave the stock prop valve in as it will mean that the rears are not being fully utilized. But as Nigel said, this is not the time to cheap out. Plus, they are more like $30 to $40 on ebay.

-

I assume you're looking for suggestions for how to make more power. The two main things that are easier with the engine out are 1) bigger turbo and 2) upgraded cam. However, both will likely reduce torque at low revs from your current setup so you have to decide if that's an acceptable tradeoff. Bigger turbo will spool slower at lower revs, and likewise, a bigger cam will trade off less low rpm boost for more at higher revs. I have a similar setup to yours with a T3/4OE turbo and Isky turbo cam. That combo doesn't yield a lot of torque at 2k rpm (although it's plenty for daily driving even though I'm at 5k+ altitude), but 3500 - 7000 rpm is very strong. My 240Z is a few hundred pounds lighter than your ZX, so not sure how much fun that combo would be for you. You could swap to a higher ratio diff (e.g. 3.7 or 3.9) which would help. Of course, I'm assuming that you have a tuneable ECU and are not still running with the stock one, otherwise that would be the first thing I'd address. One more thing - I recently switched back to the stock TB from the 240sx and really improved the driveability. With the bigger TB I could get full boost with less than 50% throttle so it was hard to modulate the power as the boost came on. While the stock TB doesn't feel as responsive, it doesn't feel like I lost any power, at least in terms of my butt dyno.

-

I would be very cautious about going with a Schneider cam. Search and you're going to find many who have had cam failures - I'm one who "did everything right" including using ZDDP religiously. For less money you can have a cam reground by Isky or Delta Cams that is customized for your application. You'll have to source the balance of the parts yourself (it's not a kit), but you'll be using a Nissan blank which has proven to be more reliable than the Schneider. Most tedious task for me was to determine the correct lash pad size and then find them. But I believe Z Car Customs now has them available. Spend some time searching here and then you can make an informed decision about a cam.

-

Thanks NewZed, that make sense. I had been adjusting my clutch pedal height before the swap and now suspect that was the culprit. Ejkej, try adjusting the clutch pedal height - I'm going to raise mine a bit to be sure it doesn't happen again.

-

Please ignore what I wrote - my brain must have been in neutral when I wrote that - of course you have to press the rod into the slave cylinder when you install it, otherwise how would it extend to move the fork? The point I was trying to make is you should check for residual pressure building up in the slave cylinder. This just happened to me when I switched to an aluminum flywheel. First drive the clutch worked perfectly, but later it began to slip under boost. When I opened the bleed valve, a small amount of brake fluid spurted out into the hose due to built up pressure. Since then the clutch hasn't slipped. I know that once the rod fully extends (such as when I remove the slave when changing the tranny) it will not go back in unless I open the bleed valve, leading me to suspect there is a check valve somewhere in the circuit. Perhaps the valve in your system is allowing pressure to build up in the slave thus preventing the throwout bearing from fully releasing. Hopefully there's a clue in this that will solve your issue.

-

There has been a lot of discussion here if the extra power/efficiency gained from raising the CR offsets the loss of power/efficiency when timing has to be retarded due to detonation. I suspect you will not be able to run full advance with 11.5:1 CR on 93 pump gas with an open chamber head such as the N42. The conservative approach would be to get the CR into the 10:1 range, maybe even lower, with your configuration.

-

Exhaust manifolds can crack. Since you've already changed the gasket, take a hose and put one end in your ear, and move the other end around the manifold with the engine idling. You'll know when you've found the leak

-

Do the bearings in an R200 differential need to be greased?

Zmanco replied to RebekahsZ's topic in Drivetrain

Interesting question. When I assembled mine I put a very light coat of assembly grease on the bearing race to keep it in place during final assembly. I figured a small amount of grease in more than a quart of oil wasn't an issue. Sounds like this person got carried away... -

I'm with Leon, it sure sounds like the throwout bearing isn't fully disengaging. You might try removing the hose from the slave cylinder (to eliminate any residual hydraulic pressure) and then remove and reinstall the slave cylinder. You should be able to insert and start the 2 mounting bolts without much pressure from the fork against the slave cylinder's rod. If there is any significant pressure, that's a sign that the throwout bearing isn't fully disengaging.

-

Sounds like an exhaust leak and from your description, probably between the exhaust manifold and the head. Look for carbon deposits to indicate where the exhaust is escaping, but in any event, you'll need to pull the exhaust manifold and the offending cylinder should become obvious when you look at the gasket.

-

Not sure why you're seeing the extra 20 deg from changing the wheel, but TS gives you a tool to deal with this. Go to Tools\Trigger Wizard. With the engine idling measure the timing with a light and then change the Ignition Offset Angle in TS so that the indicated and measured advance are the same.

-

If you're going to change how it triggers, you might want to go EDIS. Timing is rock solid compared to old distributors. Derek has a nice kit too. The only downside I've found is you can't use spark cut alone for rev limit or boost control since the EDIS controller goes into limp home mode and defaults to 10 deg advance. Edit: Scratch that: just remembered you don't need EDIS with MS3, but you might want to consider using Derek's kit for the wheel and sensor on the crank damper.

-

Camber plates with stock struts?

Zmanco replied to emeraldlion's topic in Brakes, Wheels, Suspension and Chassis

The problem with adding more caster is clearance between the outer tire edge and the lip of fender as the wheel is pushed forward in the wheel well. I don't think there is any issue with the length of the TC adjusters. -

Camber plates with stock struts?

Zmanco replied to emeraldlion's topic in Brakes, Wheels, Suspension and Chassis

The top of the stock strut will hit the sides of the tower as soon as you move it a little. Jack the car up and look up into the tower from below to see what I mean. If you want adjustability with the stock strut and springs, you'll need to swap to adjustable TC rod and LCA such as from TechnoToys Tuning. Also, keep in mind that if you want a lot of camber, you may exceed the limits of the thread length for the tie rod ends. Caster will likely be limited by the tire hitting the front of the fender/air dam. FYI, I'm running the TTT TC and LCA with stock struts and have 2.0 deg camber and 3.0 deg caster and that's about the limit without further mods. Edit: my comments are based on my 73 240Z. Just saw another of your posts where you say you have a 280z. I'll let others chime in on where the limits of camber/caster are for the later Zs with adjustable TC and LCA.