-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

That's what I'm thinking is going on. I guess I'll have to drive over there tomorrow to see first hand. BTW, in re-reading some posts on shaving the P90 head 0.080", it's not clear if it's necessary to put shims under the valve springs. I'm planning to use the earlier (longer) valves to hopefully not need to change lash pads. Given that Nissan uses the same spring for both valves, is it desirable and/or necessary to shim up the valves? Obviously I need to get this figured out before going any further with valve seals.

-

Looks like Felpro has a set that is specific to the L6 part # SS27415. http://www.autozone.com/R,APP21617/vehicleId,1218502/initialAction,partProductDetail/store,834/partType,00013/shopping/partProductDetail.htm The picture is too small to tell what the material is. Does anyone know if it's Viton?

-

After reading the sticky on the alternate Felpro seals SS72686 http://forums.hybridz.org/showthread.php?t=90825 I decided to use them on my P90 head rebuild. The machine shop just called and said that they have a problem with the seals. As he described it, as soon as they push down on the valve, the seal's spring pops off. He thinks they are for a smaller diameter valve stem. The shop is pretty far from me so I haven't gone over to see it for myself yet. Any suggestions? I'd rather not go with the stock seals, although I guess I could as I've been running this reground cam on another head with stock seals with no problem. But I liked what I read in the thread about the better longevity of the Viton seals, and on top of that, they were cheaper too. Thoughts and suggestions?

-

Unless someone rewired it, I'm pretty sure on the 280z the factory tach is triggered off the coil. And I assume you have the coil fired by MS? That would suggest, like you're thinking, that the spark is indeed really dropping out and it's not just a s/w processing issue for the megatune tach gauge. Do you notice any change in the engine when this happens? Or is it too brief to notice? Are you sure it's not a reset?

-

I follow that thinking, but I would imagine that there is a spec (perhaps generic one for this vintage system) for the range of acceptable values for the high and low side pressures. I'm a noob with measuring AC and while I've watched it done, I don't remember what the target values were.

-

I'm running the dealer installed AC on my 73 with a 81-83 compressor and Freeze 12 refrigerant. I recently picked up a Harbor Freight AC manifold gauge set http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=92649 and need to know the specs for pressure on both sides when the system is filled properly. I've searched using just about every combination of words I can think of, but so far nothing. Can anyone help me out? Also, assuming I need to add some more refrigerant, what is the proper procedure to do that? The manifold has a fitting to allow this, but is there a specific sequence? And just to confirm, is it added to the low pressure side? Any other words of advice and/or cautions from those who know AC systems? I know the theory of how they operate, but am without much practical knowledge.

-

I don't think I'd say that. For me, the issue was that there wasn't any good space left in the engine compartment to mount the relay board. Also, the 37 pin connector is pretty large and it's not likely you have a hole in your firewall that's big enough to fit it through and I didn't want to make one that large. So I was going to have to pull wiring into the passenger compartment anyway. I ended up mounting the main MS unit along with the relay board on piece of masonite which sits underneath the passenger seat. I also mounted several screw strips for various power connections and the calibration switch for the O2 sensor. What I'm leading up to is that you'll likely have to create a mounting board anyway, and once you have that, you don't necessarily need the relay board. Does that help?

-

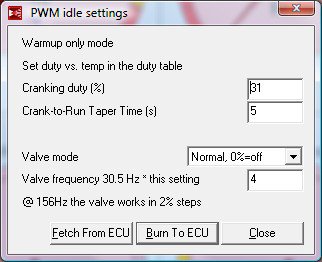

MSII Extra is supposed to have a feature shown in this screen capture where you can set the cranking PW for the IAC and then set how many seconds will be used to taper it down to the normal idle setting. But for me, it doesn't matter what value I enter in that field: within about 1 second after the engine starts, the idle just drops. It turns out that on a cold start, this isn't an issue, but for a warm start, the engine stumbles for a second or two until the PID takes over. Is anyone successfully using this feature?

-

I agree with the other comments about the relay board. Even though I went with one, if I was to do it again, I'd do like cygnusx1 did. By the time I was finished, I had used very little of the relay board.

-

I think you're right. Overall the engine runs so much smoother and is more consistent in its behavior, even when I don't have a particular portion of the map fully tuned yet. I think the MS1 processor running the MS I Extra code didn't have enough power to keep up.

-

I know you're kidding Ryan, but I hope I didn't come across as suggesting there was something wrong with MS I. I don't think there is. If I wasn't controlling idle, I think I could have stayed on MS I and been quite happy My point was that if I was starting from scratch today, I'd go straight to MS II.

-

I've recently finished upgrading megasquirt from the early MS I processor to the more powerful MS II and thought I'd share some lessons learned for those who have yet to go down this path. First, a little background on my application: L28 N/A N42 head Reground cam 284/284 .480" Header Stock EFI intake and fuel rail 280ZX turbo injectors Bosch 3 wire IAC valve 280ZX turbo distributor (installed when I upgraded to MSII) In the beginning I wanted to get the megasquirt installed without spending a lot (sound familiar?) so I went with the MS I processor. I wanted to be able to control idle so ran the MSnS (MS I extra) code. Lesson 1: The MS I Extra idle code is pretty crude. They say this up front, and they are correct. I spent a lot of time experimenting to be able to get it to hold a steady idle and to deal with the e-fan kicking in without having the engine stall. And even then it didn't work all that well. Lesson 2: The algorithms that determine fuel from the VE tables are quite different between MSI and MSII. I had expected that I would just import my VE tables and be on my way. In fact, I had to start over from scratch. All the time I spent tuning on MS I was thrown out, with the exception that I'm more experienced and hence better at it the second time around. Lesson 3: The MS II Extra idle code is pretty good. If you plan to use MS to control idle or think you will in the future, go directly to MS II Extra. Lesson 4: If you can swing adding spark control into your plan, do it. I am quite pleased with how MS handles spark. It's so easy to create custom spark curves that vary not only with rpm, but also with MAP - think of MAP as the opposite of vacuum if you haven't crossed over to MS yet If you hear any detonation, you can dial the timing back from the driver's seat (parked of course!) by as little as 1 degree. And unlike with a mechanical distributor, you can pick a narrow range of RPM and/or MAP to reduce the timing and then let it go back to normal for the rest. Lesson 5: When you begin tuning, follow the advice in the MS documentation and start off with no accel enrichment, O2 correction, over run cutoff, etc. All those add-ons make it hard to tune the VE table properly. The first time around I didn't listen. This time I did, and was pleasantly surprised how well the tuning software, MegaLog Viewer, works without all those other systems running. And with a good VE tune, those other systems, especially Accel Enrichment, will require much smaller values. Too often, people try to fix poor VE tables with excessive Accel Enrich values. At this point the driveability is excellent, nearly as good as an OEM system. It starts cold just by turning the key - no pedal pumping or holding a high idle for a few minutes is required. Power is good, but in fairness was good with MS I and even the triple webers I had on originally. Mileage is great - if I keep my foot out of it, I see mid to upper 20's. The best I EVER saw with my triples was 19, and that was on a long highway cruise. I do have a huge issue of detonation in the 3.5k - 5.5k rpm range that no amount of richening will solve. But I'm in the process of prepping a shaved P90 head and I'm expecting that will allow me to run full advance. So if you're thinking of going with MS, I'd strongly recommend you start with MS II. The extra cost (~$70) is really quite small in the overall scheme of what you'll spend, especially if you include the price of gas consumed while tuning. I'm attaching my msq file for anyone who may find it helpful. megasquirt200807080859.zip

-

http://cgi.ebay.com/ebaymotors/DATSUN-Z-240-260-280Z-3-1L-Base-ENGINE-MOTOR_W0QQcmdZViewItemQQcategoryZ6763QQihZ006QQitemZ160256934734QQrdZ1QQsspagenameZWDVW Not mine, just tripped across it.

-

FWIW, I had a similar situation with the toyota in front and 240SX in the rears. While I would prefer the dual master setup, my budget didn't allow it. In the end I experimented with different pads in the rear and found that with Hawk HP+ in the rear and Axxis metal masters in the front, I get lock up in the rear first with the prop valve all the way open. I know the metal masters don't have the best reputation, but for me, I've had no issues with them and have never had any fade even at Pueblo where I was seeing 120 at the end of the straight before braking hard to about 70. And once I had them balanced I was quite surprised how much later I could brake. I had always thought of the rears as just going along for the ride. Obviously they don't do as much work as the fronts, but the benefit of having them do as much as they can (before lockup) was surprising to me.

-

I'm nearly finished with unshrouding the valves and will be taking the head in tomorrow to have it shaved, the valve job done and some of the valve guides replaced. A few are clearly too loose - I don't need any measurements with a gauge to tell me that I'm hoping the machinist can help me make a decision on a few that feel borderline.

-

Thanks Tony, I should have thought about the FSM. Here's the relevant page. page 9.pdf

-

I have the head off the car and torn down. To determine if a valve guide needs replacing, is it as simple as inserting a valve and trying to wiggle it while it's off the valve seat? I'd guess any play at all is bad. Or is there a more precise method?

-

The P79 has a larger combustion chamber than the E88 so you will lower your compression ratio. Is there something wrong with your current setup? If not, then there's nothing to be gained by swapping to the P79.

-

Great! Then I should have no issues with my 2.8l at .80". But this has me wondering: what is the trade off for a closed chamber head design such as a P90? Did Nissan not understand these benefits when the original heads (E31, E88, N42) were designed? Otherwise, why wouldn't they have gone this route from the beginning? Perhaps emissions?

-

I'm in the middle of switching to a P90 for my L28 NA and have a similar situation in that one of the towers on the head is cracked. My plan is to swap all the towers from a donor N42 head. I looked at the towers from the P90 and my donor N42 and the only difference I can see is that the there is only 1 oil hole on the bearing surface on the P90 at 6 oclock while there is a second at 9 oclock (facing the front of the head) on the N42. Also, given the N42 is externally oiled, there are the machined surfaces and holes for the oiling tube to be attached. I did notice that on the side of each tower near the base there is a two digit number. Does anyone know what it represents? If you search here you will find two sets of opinions on the importance (or lack thereof) in keeping the towers in place. Some claim it's no big deal to remove them as long as you are careful to ensure the cam doesn't bind when reinstalling. Others say the towers were line bored and should never be touched. I haven't seen anything definitive posted. In about two weeks I'll have mine together and will know more.

-

Maybe another way to ask my question is to ask those who have done this (shaved P90 head on a NA L28) what CR are you running and can you run full advance of 35* without detonation on pump gas?

-

Good point Z-ya. I've measured the chambers (after unshrouding valves but before polishing) and they are all 54.0 or 54.5 cc. To determine how the volume changes with shaving I traced the outline of the chamber on graph paper and added up all the squares. The surface area is 49 sq cm. That means a 2 mm shave removes 9.8 cc and a 1.6 mm shave removes 7.8 cc. Daeron, in my case, a 2 mm shave would result in 44.2 - 44.7 cc chambers. The CRs I mentioned in the original post were all calculated using my measurements. See screen shots attached.

-

I've begun porting the P90 head and need to decide how much to shave it for my NA L28. I know most of the write ups suggest taking off .080", but LEngine says that for me (.030 over bore with flat top pistons) that will give me a CR of around 10.3. That's what I currently have with an N42 head and reground cam (advertised as 284/284 .480" lift) and I have to retard timing to no more than 24 degrees to avoid detonation. This is in Colorado where we're always at least 5k elevation. Again, I'm NA, no turbo. I know the P90's combustion chamber prevents detonation better than the N42, but is it possible to go as high as 10.3 on pump gas (91 is the best we have) and not get detonation? If I only shave 1.6 mm (.063") that yields a CR just under 10.0. I'd rather trade a little CR for ignition advance, but don't want to give up any CR if it isn't necessary.

-

Timing was verified with a timing light. (Note: it's pretty sweet to be able to create a custom advance curve based on rpm and MAP any way I want!) I found that the max advance I can run and not hear any detonation at all at any rpm is 26 degrees. It's less than I'd like, but as I said earlier, not surprising given the flat tops and open chamber head. Time to get going on the P90 project ... I drove a lot around town today along with a bunch of pulls to redline on the highway. Total of about 75 miles with ambient temp pushing 90. So far I can't see any drop in the oil level. This is with Castrol 20w50. Plugs are gapped to 0.050. I figured that with the MSD box and blaster coil, I could open it up some. Glad to hear you think they're ok. I'm going to assume the main problem was the 10w30 oil. The brand was Mobil Clean 5000 (chosen because it was on sale). When I put it in towards the end of the winter, I figured that any brand name oil would be ok since they all meet the SAE standards and the weather wasn't right for any hard driving and track days. Perhaps it was mis-labeled and wasn't really a 10w30? In any event, I'll be a lot more careful about which oil I choose from now on.

-

I had a chance to go out this morning (ambient is already above 70) and the detonation issue is better. I can run up to 28 degrees now before I begin to hear a little detonation. I suspect that may be the best I can hope for with the open chamber N42 head and flat top pistons. Only time will tell on the oil consumption. But I would never have guessed that running 10w30 would make that much of a difference. Has anyone else experienced this when running the thinner weight oils?