-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

MS II has a correction factor for altitude that effectively increases the VE (richens the mixture) as the car goes up to higher elevations. The theory is that at higher elevations there will be less exhaust back pressure resulting in improved (higher) volumetric efficiency. I live in Colorado and recently took a driving trip in the Z to California. My MS setup has the second MAP sensor so the system can monitor and adjust for changing barometric pressure on the fly. As I descended from the Lake Tahoe area (6000 feet) on highway 80 and got below 3000 feet, I noticed that my mixtures were going pretty lean. By sea level I was so lean that the O2 correction (limited to +/- 10%) was pegged and not able to fix it. As a stop gap I used the Barometric Correction of MS II Extra to add 20% at sea level (100 kPa) and that got me in the ball park. While in the Bay area I read up on the built in barometric correction algorithm and found how I could change it. Keep in mind that the default algorithm was in effect leaning things out as I went down to sea level, my experience said I needed to go the other way and increase the VE values. I bring this up to the group here because I'm wondering how other non-MS EFI systems handle the issue of correcting VE as altitude changes? So far I have been quite impressed with the design of the MS systems - obviously there are some pretty smart people developing them. But this issue, at least from my one data point, suggests they were completely going in the wrong direction on barometric correction. So to those of you with experience with other EFI systems, what algorithms are used to correct for VE as altitude changes? PS: I averaged 26.9 mpg for the trip typically running between 75 and 85 mph. Not bad for a 4.11 diff!

-

Not exactly sure what you mean by "grind on" (pictures will help), but I've been using resurfaced rockers as well as a reground cam from Delta Cams with no issues.

-

What a handful! It looks like he's struggling to turn the wheel with both hands, even at speed. BTW, when I watched it full screen I saw that the silver "blob" on the steering wheel is a mechanical stop watch taped to it. Ha! Old Skool just like the rest of the car. I love it!

-

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

Like I said above, it sounds like the MC is leaking and needs to be replaced or rebuilt. Might be a good time to upgrade to a 15/16" while you're at it... -

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

Is the pedal firm, but sinks down with continued pressure? If so, that sounds like a failing MC (fluid leaking around the seals). Otherwise, if it was firm but then became mushy again without you doing anything, I'm not sure I have any good ideas. -

Thanks for the extra inputs guys. It may be that the right solution is to pull it out and change the clutch stack, but before I do that I'm thinking that a thicker oil might be enough. The only time it's an issue from a handling point of view is when the diff is hot. If it's cold or even just warm (driven easily on a 75 degree day), the amount of lockup feels fine. It's when it's a hot day (85+) and it's been driven hard (high speed running or lots of city driving with lots of turns) that it's troublesome with the agressiveness of the lockup. My thinking is that that 75w90 oil is thinning out and not providing as much lubrication between the clutch plates. No one has said that running a heavier weight is going to cause damage to the ring and pinion so I'm thinking I'll try switching to some 75w140. It's a lot less work than messing with the clutch stack and might calm the lockup enough when hot.

-

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

Let me start over: your previous reply sounded like you now have a firm brake pedal and I was just explaining why I didn't think the difficulty you encountered was due to the speed bleeders. Once the brake pedal is firm then the calipers are whetted inside (bubbles are gone) and in the future I wouldn't expect you to have this problem unless the reservoir runs dry. You still have a MC that is a bit on the small side which is why your pedal has a longer throw before the brakes engage. I doubt that it's a safety issue and have seen others who stay with it, but if you don't like it, then upgrading to a 15/16" MC is your next step. That's what I did. -

Eliminating the chattering is one issue, but I'd also prefer it to not grip as hard when hot - in other words, allow more slip. The lockup isn't an issue when cold or even warm, only when hot. Could I try a thicker oil such as 75w140 without damaging the gears?

-

I have a Powerbrute CLSD in a 4.11 R180 with 75w90 Royal Purple synthetic gear oil and when it's warm it chatters around just about any street corner-type turn. Also, in 1st and second, and sometimes even in third, I can feel the direction of the car in a turn affected when I let up on the throttle as the clutches disengage. Usually it's no big deal, but sometimes it's pretty significant and it even makes a clunk loud enough to hear. My guess is that the CLSD is locking up more aggressively than I need. Can I switch to a heavier oil? My thinking is that it would effectively give a lower breakaway torque when the diff is warm. In particular, what about using a 75w140? Normally I'd just run a trial with it, but I don't want to take a chance at damaging my ring and pinion gears with too thick of an oil. Thoughts?

-

Thoughts on this Aluminum Radiator

Zmanco replied to Zmanco's topic in S30 Series - 240z, 260z, 280z

FWIW, everything I've read suggests that puller fans are more efficient (move more air for a given fan/motor combination) than pushers. But that only matters when the car is stopped/moving slowly. Once the car is at speed the fans are no longer affecting the system's cooling capacity and the radiator and air flow determine how much heat can be dissipated. On your comment about removing the AC condenser, do you think the main issue was that the radiator was plugged? I wouldn't expect that removing the condenser would make a difference if the radiator already had issues. -

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

I had the exact same issue with mine when I first installed them and then have had no issues since. As I mentioned earlier in this thread, I suspect that some air bubbles get trapped on the surfaces inside the caliper when brake fluid is first added and the surface isn't yet whetted (sp). I don't think it has anything to do with speed bleeders because I've seen others with stock nipples have this same issue. -

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

I think you're saying that the pedal moves easily most of the way, and then gets firm very quickly without much more movement? To me, that's the sign of a well prepared brake system. Only if it still feels a bit mushy as the pressure builds would I think there was still air in it. -

MSII Extra DOES have closed loop O2 control. There are now 3 choices for the algorithm used to control it.

-

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

So after you finished bleeding the rears things felt good? Did this occur (pedal squishy and going to the floor) ONLY when the bleed valve is open? Otherwise, what changed from the situation above? Two things: 1) it sounds like you still have air in the system somewhere. 2) with a 7/8" MC you are going to have a longer pedal than with 15/16" unit. When I did my swap I initially left the stock 7/8" MC in but didn't like the longer pedal travel. It wasn't so long that it was unsafe, I just didn't like it. But in general, once you have the system sorted out, you should have brake feel similar to what you describe for the Evo. -

-

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

FWIW, when I installed my 240sx calipers in the rear, the only way I could get all the air out was to unbolt them and shake them and then bleed them. I suspect some air bubbles were trapped/stuck around the piston. Once all the air is out, bleeding is easy. It's just getting it out the first time Good luck! -

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

The prop valve is on the firewall on my 73, but I'm not sure where it is on a 77. It shouldn't be too hard to follow the rear brake lines to find it. It sounds like there is air trapped in the front calipers. I hope you don't mind me making a very basic suggestion, but double check to be sure you have the calipers on the proper sides. A while ago a guy had the same issue and had them swapped resulting the air collecting above the nipples. No amount of bleeding was going to solve that. -

Naviathan, I've read the same thing although to read the Megasquirt documentation one would think that they both follow the same concept of calculating the required PW based on the ideal gas law. Hence you'd expect the tables to be pretty similar, yet they weren't in any way related. It really isn't a big deal except that I had expected the swap to only take an hour or so. That was my mistake.

-

S12+8 and 240sx brake issue

Zmanco replied to WizardBlack's topic in Brakes, Wheels, Suspension and Chassis

The master cylinder should be bench bled before installation. If you try riverz' suggestion and it still doesn't solve it, then that's probably your next step. It was for me BTW, with 4 wheel discs, the factory prop valve is not going to help your braking performance. As for adding an adjustable prop valve, it's likely with your setup that you'll find that the fronts still lock up first without one. I had to go to a rear pad with higher coefficient of friction in order to be able to get a good front/rear balance. Lastly, make sure you have the correct toyota 4x4 calipers for the solid rotors. You probably do, but if you had the vented ones, then even a 15/16" MC isn't going to solve the issue of the pads not hitting the rotor. -

I switched to it at the same time as I switched to the MSII processor and it was almost like starting over. None of my VE tables were worth anything. The good news is that the higher power of the ms II processor seems to give a much more stable idle, and the idle control algo is better than with MS I. Also the O2 correction is much more sophisticated and offers 3 approaches. I'm running NA so haven't bothered to try launch control as I really don't need it. All in all it's a much better solution, but I was not expecting it to be so much different from MS I extra. Still, the tuning process went a A LOT faster the second time since I was much more experienced with the whole tuning process.

-

I've been datalogging and then using megalogviewer to modify the VE table and with MSII Extra I've had really good success getting a very drivable tune. At this point what I can NOT do on the street is a) safely tune for WOT and determine the best spark advance and VE at WOT for max power. That's what I hope to accomplish on the dyno. Again, thank you all for the advice - this is good stuff! I'm thinking I'll rent the dyno for self-tune and do it myself.

-

Pulling on the knob opens a flap that allows air to flow onto your feet when the car is moving.

-

Another option for compressor is to use one from a 280zx. Get one from a JY along with the bracket. It mounts on the driver side in place of the air pump (if you still have it). Make sure to get the belt tension adjuster too. I'm running that on my 73 with the dealer installed system and it works reasonably well. I'm pretty sure the limiting factor of the system is no longer the compressor.

-

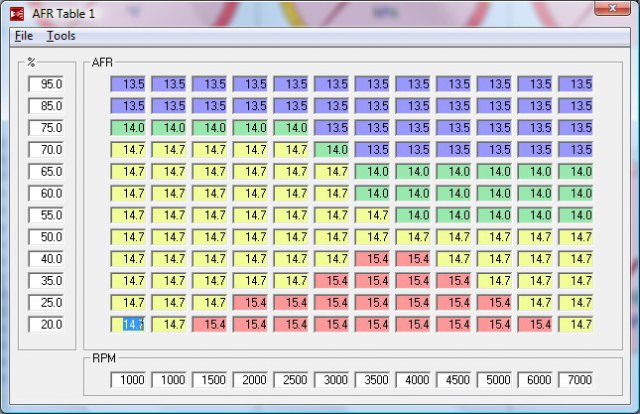

I don't mind shifting the discussion to tuning turbos, but before we leave NA behind, to summarize what I've learned so far: 1) Get a good tune on the street using target AFRs at WOT of around 12.7 and timing of 36 degrees. 2) Assuming it's an inertia dyno, experiment to find the optimum AFR at WOT (find best lean and then richen a little). 3) Then experiment to find best timing advance. 4) Go back and verify best AFR hasn't changed. All of the above is focused on getting the most power/torque at WOT. Tony D, you mentioned tuning for economy. I wasn't going to spend any time on the dyno on that, but you bring up a good point that it could pay for itself quickly. But it wasn't clear to me how to approach that if it's an inertia dyno. Can you be a bit more specific? And thanks for the inputs so far guys - this is exactly the kind of inputs I was hoping for!

-

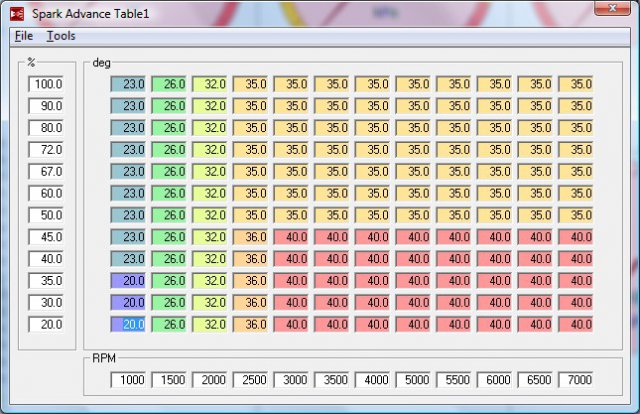

I've finished swapping the P90 shaved head onto my NA L28 and have the megasquirt tune pretty well dialed in for street driving as well as on the track. I figure it's now time to take it to a dyno and need some advice on the best approach to take. The main things I'd like to learn/accomplish are: 1) What's the optimum timing for max power at WOT for my combination of head and cam? 2) What are the optimum AFRs for max power at WOT? 3) and of course, how much power/torque am I making? I've found a shop not too far from me with a Dynojet that is available for $105 per hour for self tuning and $175 per hour if they do it. I'm pretty familiar with my megasquirt set up (it's also controlling ignition) as well as datalogging, so am leaning towards doing it myself. My questions are: a) What's the best approach to achieving #1 and #2 in the shortest amount of time? Should I start with a baseline pull and then work on timing first, and then play with AFRs? Am I being naive and thinking that I can do this myself? Should I instead just let them do it with me watching? Again, my current tune is very driveable and has served me well on recent track days. My goal is to make sure I'm getting the most out of this combination, not solve problems. I'm attaching my current timing and AFR target tables in case any of the NA experts have any advice to add.