-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

An N42 head with flat top pistons will likely have detonation on pump gas. When I first put that combination (N42 head and flat top pistons) together BRAAP warned me that it was likely to have detonation and that the benefit of the higher compression would be more than offset by the loss due to retarding the timing. Even with bigger cam I had to retard timing to around 20 degrees. I could feel the torque fall off as the engine RPMs pulled through the band where I had the timing pulled back. Is there something wrong with the P79 head that causes you to want to switch to the N42? Otherwise, why not put it back together with a Felpro gasket (1 mm)? That will yield a CR of 8.7 and you can run with full advance.

-

Weird Idle, RICH spikes. MAPdot threshold not working?(datalog)

Zmanco replied to cygnusx1's topic in MegaSquirt

Yes, IIRC, it's 8 without vacuum connected. -

I think you should focus on what's causing the noise on your battery line into the MS. The CAS signal may have its own issues, but I don't think that would cause the noise on battery voltage and doubt it would cause the flash data in the CPU to be erased, at least not all by itself. I had an issue with random resets and in the end traced it to EMI from the spark plug wires. I switched to Magnecor wires (#6524) and that solved it. (Magnecor claims to have the best EMI suppression.) I only mention this because when dealing with noise, the sources aren't always obvious. I'd suggest turning everything that is not essential off for a while and see if the problem persists. BTW, how is the wiring to your fuel pump? A big pump can have a large inductive load and might cause this kind of noise if a connection was loose/intermittent. I suppose it could also be the regulator, but unless you are seeing other signs that point to it, I'd look elsewhere first.

-

Weird Idle, RICH spikes. MAPdot threshold not working?(datalog)

Zmanco replied to cygnusx1's topic in MegaSquirt

The spec for the stock L24 is only 8 deg. Just curious what's different with the later motors that there is such a big change? I wouldn't think that switching to electronic ignition and FI would by themselves cause such a large change. BTW, I have my current L28 idling with 20 degrees and tuned more towards lean than stoich (the actual AFR varies a lot based on temp and who knows what else). It seems to recover from sudden loads like efans and AC better when lean vs. rich. -

I'm hoping to get a local drive together in the next few weeks that will go up into the high country, probably at least 8500 feet. Of course, we'll have to hope that weather is clear that day I'll post the datalog here and on msextra.com.

-

You're right six shooter, my bad. I was thinking of the 280zx damper pulley I had swapped (which is larger than the stock 240). Of course that's irrelevant to this discussion - sorry for the confusion. Still, I'm pretty sure I did use a 280zx pulley which, after grinding the bushing/washer, fit ok.

-

No Dave, I'm NA. I too think it would be different. Isn't the main resistance to exhaust flow on a turbo from the turbo itself and and its plumbing? Seems like that would be far more significant than the backpressure of a low restriction NA exhaust.

-

IIRC I swapped a pulley from a 280zx alternator over to the Maxima alt as it's a little larger than the 240z pulley which helps the output at idle with the lights on etc. I also had to grind the spacer/bushing a little to get things to clear. I wasn't thrilled with it, but it's been on for more than 5k miles and all is still well. I definitely had more than 1 thread engaged. Perhaps someone here has a pulley off of a dead alt they can send?

-

Based on my experience, there was an 8-10% difference between sea level and 6k feet so I'd suggest 57 / 43. This will effectively not change anything at sea level and give you an 8.6% reduction at 80 kPa barometric pressure which is typically what I see at 6k feet. Here's a simple spead sheet I built to help work this out. The middle scenario is unique for me in that I had already tuned my VE tables for a barometric pressure of 80 kPa and didn't want to retune them, hence the different offset value (Total Vacuum in MS2/E). I think in theory that's correct, but if the table isn't perfect (and it never is) then it's possible that even with +/- 15% control there may not be enough range to fully correct. Also, I found that if the VE map is too far off, then the O2 correction is constantly changing and since it's always missing and then over correcting it feels like a lean/surge at steady light throttle such as when cruising.Barometric correction calculations.zip

-

Weird Idle, RICH spikes. MAPdot threshold not working?(datalog)

Zmanco replied to cygnusx1's topic in MegaSquirt

If you're using Megalogviewer to tune, it's tempting to just leave AE on as MLV says it ignores records where AE is active. But the WB O2 sensor delay (slider between 0 and 4) is only accurate at a particular rpm range so by definition it's a compromise and not accurate at other rpms/loads. So what you're doing here is getting your VE tables as good as possible BEFORE adding in AE. Once I adopted this approach I found I was using much less AE and things just worked better. BTW, another thing to check since it just happened to me the other day is if the processor is well-seated on the circuit board. I was trouble shooting an intermittent lead to the MAT sensor and all of a sudden was getting all sorts of triggers of AE even when the log showed that neither the MAPdot or TPSdot was triggering. Eventually I tried reseating the processor (just because I couldn't think of anything else to try) and the problem went away and hasn't come back. And what's weird is that it was physically already well seated, but I guess pulling it out and reinserting it solved whatever was causing the problem. Just something else for you to try. -

It's the exhaust fumes

-

The equation is correct - perhaps you read the "*" as "+"? Make sure you solve within the parenthesis first In any event, the main issue I see is that the -47 value determines the slope of the function. In practical terms, that means that the default settings increase VE as barometric pressure is reduced. My own experience says this is wrong and that VE should be reduced as barometric pressure is reduced (opposite slope). As I think I said earlier here (or was it on msextra.com?) this doesn't appear to affect very many people so I won't obsess over it, but I did want to make others aware that if they do drive across a wide variety of altitudes, my own experience suggests that the default correction in MS2/E is incorrect and needs to be changed significantly.

-

I've been discussing this on msextra.com and it was recommended by one of the developers to use % Baro for the fuel algorithm instead of speed/density. I've since made the switch and find that I now have the full range of the AFR table as well as VE table to use (before I only used about 80% of the table). Also, in theory, as I go down (or up) the richening that we all add to the VE table as we approach WOT will scale according to the ambient barometer setting. So far I only have one test run (weather needs to clear up before I go out again) but at this point I would recommend this approach for anyone who drives across a variety of altitudes. This option is also available for Ignition. For my NA engine I've decided to leave that controlled by MAP since I found I had to back timing off more at sea level than at altitude all else being equal. For a turbo motor I'm not sure which would be the best approach. Still unanswered is how the other FI systems handle correcting for changing altitude (my original question in this thread). In the next few weeks I hope to take a drive that will see me going up above 10k feet which will give me some good data to see if the change I made to Barometric Compensation helped.

-

Ha, I was thinking the same thing Open up any issue of Car and Driver and look at how few street cars can run 12's and how much they cost. Pretty awesome that 12 is where you're starting out!

-

With regard to your question about oil and water temps, here's a thread I started about aluminum radiators that morphed into an oil cooler discussion. See post #25 for the results of adding the oil cooler. http://forums.hybridz.org/showthread.php?t=136714 Also, I was glad to read John C's comments that 215 F water temps are normal on the track.

-

z-ya, I have a similar set up to you only my surge tank is mounted in the rear right near the 2 fuel pumps. FWIW I don't have any issues with the fuel pressure changing even on hot track days. And I'm still using the stock fuel rail and FPR. The gauge I'm using is a liquid filled unit that I purchased from diyautotune when I bought my megasquirt kit - not sure of the brand. If it's not too much effort, might be worth moving the surge tank out of the engine compartment.

-

Racing pads for Toyota S12W calipers

Zmanco replied to jgkurz's topic in Brakes, Wheels, Suspension and Chassis

You might want to consider Hawk HP+ pads. I use them on the rear with 240sx calipers and I think they were about $75 IIRC. For the fronts with S12W calipers, you can use '84 300zx pads as long as you are willing to cut off a tab. (This is only for the calipers that have 2 large pistons. They will not fit for the caliper that has 1 large and 1 small piston.) That gives you a lot more choices for pads and I think (don't know for sure) that you can get the HP+ there too. BUT ... a heads up, I have the same setup as you and found that when I run the same pad material front and rear that I don't have enough rear braking. I run a pad with a lower coefficient of friction in the front so that I can use the prop valve to fine tune F/R balance. Also, with the exception of last weekend where I used pads with very little material left, I have not had any fade issues yet. In hind site, I should have replaced them before the track event. -

Update: I decided to try switching to 75w140 Mobil 1 and added a tube of LSD additive as well. I had a track day this weekend and even in the paddock just after a session the diff remained smooth without any clunking even when making sharp turns to park. When I had the 75w90 + LSD additive it would get noisy and clunk when the diff was hot. But before I declare "victory" I'll have to wait until next summer: the temps last Saturday stayed in the 70s vs. the 90s in the middle of the summer.

-

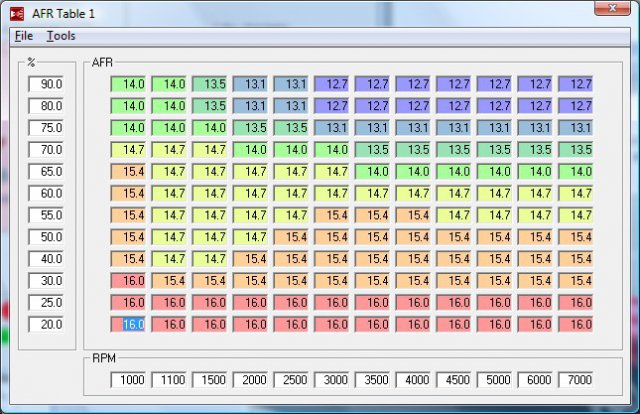

Here are the key tables for my N/A setup using MSII v3 and: - MS2/Extra v2.0.1 - L28 w/flat top pistons - Shaved P90 head w/mild port - 284/284 0.450" cam - 280zx intake manifold port matched to head - MSA Header - 280zx turbo injectors - 280zx turbo distributor (MS controls ignition) My driving is all above 5000 feet so the VE values above 80 kPa are only a guess and SHOULD NOT TO BE TRUSTED. Also, keep in mind that the VE table is tuned to the AFR and Ignition tables. If your AFR targets and/or ignition advance is different, then your VE table will be different as well.

-

No, I hadn't posted there as I was waiting until I installed the P90 head and had some time to sort the tune out. I'll update that thread as well.

-

MS II v3 on an L28 w/flat top pistons, P90 shaved with mild port, stage III cam etc. I think you really need the AFR targets and timing table for it to be useful as those will directly affect the VE table.

-

Last weekend I installed a centerforce II clutch (pp and disc) in my L28 NA. I also swapped a different ZX 5 speed with better syncros. Since then I've noticed that there's a vibration that is not from the tires. It comes and goes at various speeds as well as rpms. For example, one minute the vibration will be at 3000 rpm, and the next it's gone and moved to some other rpm range. In other words, it's not consistently reproduceable. It almost feels like one or more cylinders aren't getting enough fuel. But I've done nothing with the engine and this started from the moment I drove it out of the garage with the new clutch. I'm wondering if the ring of weights that are outside of the pressure plate fingers is moving around? You can see the weights in this picture. The vibration isn't bad enough that I think it will cause any damage, and it's more annoying than anything else. Still, after swapping to the P90 head where I cc'd the chambers to get to a constant volume, the engine had been so much smoother. Has anyone else with a CFII had this issue?

-

Z distributor caps have 2 plastic tabs on the inside designed so that (in theory) there is only 1 way to install the cap. When it's properly installed you won't be able to twist it, and it won't rock side to side. I suspect that either the old or the new cap wasn't properly seated (cap was rotated away from the proper orientation) and hence your timing is now off. I'd start by reinstalling the new cap and making sure that it is properly seated. Once you're sure about that, you may then have to retime it as naviathan suggests. But that's only if the old cap wasn't properly seated. BTW, it's really hard to get the clips on when the cap isn't seated properly. That's a good clue to stop and reseat it

-

So what you're saying is that at a given combination of MAP and RPM, the engine's volumetric efficiency is greater at lower elevations than at high. That's what my intuition says too and my experience bears out. But here's what bothers me about this: the higher barometric pressure at sea level only exists upstream of the throttle plate. It seems to me that at sea level I wouldn't have to open the throttle up as much for a given MAP for the reason you just gave (supercharger effect of extra barometric pressure). But from the cylinder's perspective, why would it be more volumetrically efficient at any given MAP and RPM at sea level? I'm not seeing any good reason for it. BTW, I'm just trying to understand what's going on here - not trying to argue that VE doesn't go up at lower elevations. Also, does anyone know how this is handled by non-MS EFI systems? Is the correction a linear function as megasquirt models it?

-

I dropped the washer for the cam bolt once (completely brain-dead moment!) and was able to fish it out of the sump with a magnet attached to a telescoping rod (like an older antenna). You can get them at Lowes and Home Depot for less than $5. It only took a few minutes. I might have been lucky, but it's definitely worth spending some more time with a magnet before dropping the oil pan - that's not fun with the engine in the car.