-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

Coolant is clean, oil is clean too. Reading my post again, I dawned on me that this is the first time I've run 10w30 oil in warm weather. I wouldn't think going from 10w40 to 10w30 would make that much of a difference, but tonight I changed the oil to castrol 20w50 as a test. I'll take it out tomorrow and see if there is a difference with how much advance I can run.

-

I've got a few issues right now that I fear may be related and need advice. Here's the background: Rebuilt N42 with flat tops (.030 over) 15k miles ago N42 head that was "cleaned up" including new valve seals (probably stock) Reground cam 284/284 Initially ran with triple webers after the rebuild Last summer converted to megasquirt fuel-only, recently added spark Issue 1: when I had webers on it, I was able to run with 32-35 degrees of advance without detonation. Since converting to megasquirt, the max I can run between 4k and 5k rpm is 21 degrees. Above 5k rpm I can't hear detonation if I add more advance, but I'm not sure since the other noises are so loud. I can richen the mixture to ridiculous levels in that range, but can't go over 21 degrees. And this is on mild days (70 degrees F). Issue 2: A few weeks ago I checked the oil and found it was down 2 quarts. This was only 1200 miles after I had changed it. Last weekend I was down 1.5 quarts after another 600 miiles. Granted, a few hundred miles ago I upgraded megasquirt so those last few miles have seen a lot of idling as well as pulls to redline. Still, the most I had ever lost prior was less than a quart from a 100+ mile track day. Issue 3: Take a look at the spark plugs. A few look too white to my eyes. But I am used to tuning carbs, not FI, so maybe I'm just not used to clean plugs In any event, you can see there's oil on the threads on all. The area around the plugs on the head is clean on all but #6 (mild seepage from the valve cover gasket which I'll replace if/when I do the head swap). There are no visible leaks. The exhaust does not have any tinge of blue when idling or blipping the throttle with the car stationary. In the last year I have noticed at times that after a high rev down shift, when I first got on the gas I could see some smoke out the rear view mirror. Also, on group drives, people said sometimes they saw a puff of blue smoke, but all said it was no big deal. The oil in the engine right now is 10w30. Last summer and before I ran 10w40. Today I ran a compression test on the engine (hot) and all were within 5 psi of 165. I figure there could be any combination of the following issues going on: a) With the N42 head and flat tops I'm at 10.3 CR which is probably too high. However, with the bigger cam and the fact that I'm at altitude (never below 5k feet), and the fact that I didn't have detonation with the webers, I figure that I shoud be able to run at least 30 degrees with megasquirt. If oil is getting into the combustion chamber (it must be, right?) then that would explain why I can't run the full advance like I used to with the webers. In other words, it has nothing to do with carbs vs. FI, it's due to the oil consumption. c) I figure the valve seals are probably in need of replacement, but given it doesn't smoke after a hot restart, I figure they can't be too bad. d) I have a P90 head I picked up on ebay that I'd like to shave etc, but before I do anything, I feel I should understand the oil consumption issue. Of course, I'd change the valve seals before installing it. Questions: 1) Is it plausible to see that much oil consumption from leaking valve seals? Or should I be suspecting the rings? But then why wouldn't the compression test have worse numbers? 2) If I ignore the oil consumption for a moment, does it make sense that I have detonation only between 4k and 5k regardless of how rich it is? Why would the detonation stop instead of remain at higher revs? Is that normal? It's not what used to happen when I had too much advance. 3) Could it be that I just need to run a heavier oil? Seems to me that going from 10w40 to 10w30 shouldn't result in this much consumption if the engine is otherwise healthy. Ok, that's enough, I'll stop now and take a breath If you're still with me, thanks for reading all of this and I'd appreciate your thoughts and advice.

-

UPDATE: Matt from diyautotune.com figured it out. The soft rev limiter was at 100 rpm with a Soft Limit Absolute Timing of -10. As soon as the engine started (actually, while cranking) the rev limiter kicked in. Raising the soft rev limit to 7k solved everything. I hadn't changed those values so figured they were the defaults. Just goes to show with MS that you have to check everything. Thanks Matt!

-

Thanks Moby, turns out Matt from diyautotune.com just figured it out. The soft rev limiter was at 100 rpm with a Soft Limit Absolute Timing of -10. I had never set or changed that page, so assumed that those values were the default when you didn't want a soft rev limit. As the saying goes, that's what I get for assuming ... In the end, I went ahead and bought the MSII processor upgrade as it appears the MSII extra code is more sophisticated for controlling idle - the MSI code is hard to get right across a broad range of conditions.

-

Backgrould: I recently added spark control to my MS1 v3 set up using the 280zx dizzy but cannot get the spark tables to affect timing. http://www.msextra.com/viewtopic.php?f=4&t=28645 http://forums.hybridz.org/showthread.php?t=135184 I took the board out today and went over it again and cannot see anything wrong, nor can I even come up with an explanation how a hardware issue would cause this. Question: Has anyone else been able to get spark to work with MS1 Extra V3 non-turbo? My current theory is that a bug in the MS1 Extra code is preventing it from actually reading the spark tables while the engine is running. Either that, or there's something else unique about my situation that's escaping me. I'm about ready to buy the MS2 daughter board so I can switch to an entirely different piece of code. But it's a shame to do that since the MS1 solution fits my needs perfectly (except for this bug of course!). Thoughts and experiences?

-

Xander suggestion gave me the idea that perhaps I had a software/firmware compatibility issue so I reloaded megatune as well as the ms firmware (029y4). Megatune is now listed as 2.25 P3 vs. just 2.25 on the previous version. The firmware finished the download without errors, but listed the installed version as 029y3. I don't remember if it reported that when I did the original install. I know MS runs a little loose with its rev control, but still wonder if this is this normal? In any event, even after the updates the problem remains. Other ideas?

-

Good idea Xander, but unfortunately it didn't work for me this time. I also tried using the number pad to input -10 with no success. I'm wondering if there is some other setting or combination of settings that results in this issue. The MS is triggered by a 280zx turbo distributor that I just installed.

-

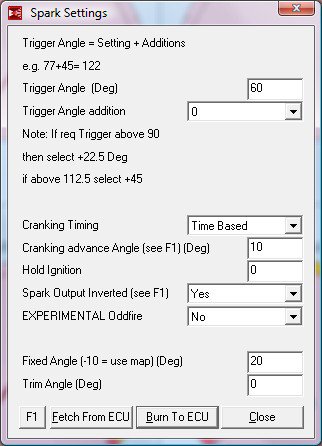

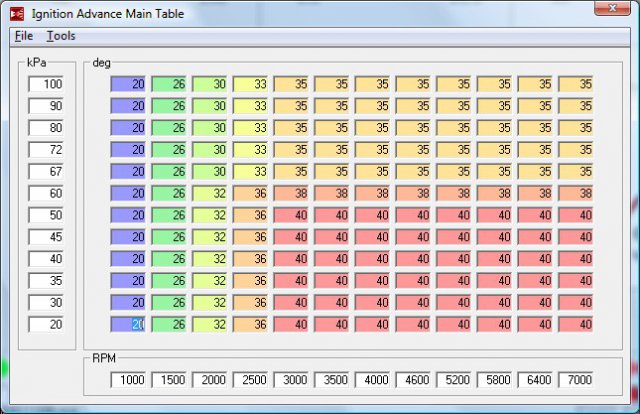

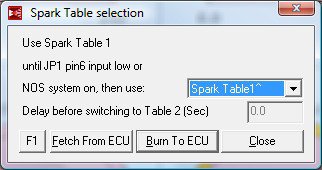

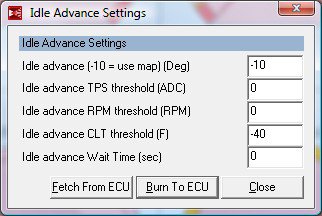

I've recently added spark control using MS1 v3 and MSnS and an MSD 6AL. I've got everything working except one important thing: when I set Fixed Angle = -10 on the spark setting, the timing goes to 10 ATDC instead of reading the spark table. If I change the Fixed Angle setting, the timing changes as it should. Changing values in the spark table has no effect regardless of the value in the Fixed Angle field. When the spark table is displayed, the bin being used is highlighted and moves around as it should according to rpm and MAP. However, the timing light shows that the timing isn't changing. I've tried resetting the MS, restarting megatune, and also rebooting the laptop, but nothing makes a difference. Also, although I don't need to use it, Trim Angle has no affect on the measured timing either. Attached are some screenshots. I'm sure I'm missing something obvious, but I've gone over all the settings multiple times and am out of things to try. megasquirt200806111006.zip

-

The way the part is recommended for just about every Z car ever built makes me wonder which car they really fit. If you go this route, please let us know if they are correct. FYI, when I did my swap, I went with Raybestos PG discs at all 4 corners. I've had them out on multiple track days so far, including Pueblo's track where there's a good hard brake from about 120 to 70 at the end of the straight. I have never had any fade, nor do the discs show any discoloration. I understand that you would prefer the brembos, but in case you can't find any, at least you know you have a decent alternative.

-

If the head is completely fubar, then you might try a pipe wrench. But it won't be pretty, and once you start with that, there's no going back to anything else as you'll completely destroy the head. FWIW, that's how I finally got the filler plug out of my old diff.

-

http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&sspagename=ADME%3AB%3ASS%3AUS%3A1123&viewitem=&item=260222028387 This one claims "only 1 hole to drill" and I've seen others that say no holes need to be drilled. It seems to me that it would take a few holes at least to securely mount these. I don't see an lips or other edges to help hold the cover in place. While I'm not a fan of the way they look (just my opinion on the early Zs), they appeared to make a measurable difference "at speed" on the windtunnel tests hence I'm beginning to consider them. So what am I missing?

-

My 73 reads "empty" at 12 gallons as well. As an experiment, I took my spare gas can with me and drove until the car ran out of gas. It took 15 3/4 gallons to refill (2.5 gallons from the can, the rest at the gas station). It turns out that true empty on my car doesn't occur until the needle is pointing towards the left corner of the bottom of the "E". That's a long way (4 gallons!) after it hits the left-most side of the scale.

-

I had my flywheel turned on a lathe down to 16.5 lbs (from 23 lbs stock), but in order to take any more off the machinist was going to have to switch to a mill (taking material off between the dowels and threaded holes). He thought he might be able to take off as much as another 2-3 lbs, but he didn't like the idea much as he felt it would become too weak. I figured he was turning down additional money for what would otherwise be a simple job and hence I listened to his advice. For me, I would not use a steel flywheel that had been reduced to 11 lbs. That's quite different compared to using one that is aluminum with a steel surface and was designed to be 11 lb from the start.

-

Along with Common Sense 101...

-

There's a guy on ebay who uses a large tupperware plastic box. It looks to be big enough to fit the tranny inside, and then he fills it with padding. FWIW, my used tranny came in a big box via UPS. The box was in surprisingly good condition and the tranny in fine shape. Still, I wouldn't recommend that approach for obvious reasons.

-

What were they thinking? http://www.yeah-oops.com/?p=5390

-

Where are you all meeting up? I'm in Castle Rock - might be able to come down in the am. Send me a PM if you don't want to put an address in a post.

-

BRAAP, I think you nailed it in the title: the answer is usually just laziness. This is a huge pet peave of mine. If you can't take the minute or so to read the post before launching it, why should the rest of us spend any time answering? When I ask people I haven't even met to help me solve my problem, the least I can do is make it easier for them to understand what I'm asking! Seems like common sense to me, but I can't help but wonder what those who make incomprehensible posts are thinking. But I fear that those who are the biggest offenders haven't read even this far. Sigh...

-

Jon, this is the only thing I've been able to find for "American Cams": All American Cams 810 Ashmore Drive Charlotte, NC (North Carolina) 28212-6111 Phone: (704) 567-0069 It's Sunday so I can't call them, but does this look like the guys you were referring to? I can't find a website for them either.

-

A few years ago when all lightweight flywheels were in $450 range I had my stock L28 turned down. Turns out there are 2 steps. First the machinist starts with a lathe to remove material. This means he can only take it off where the "extra" is continuous and nothing (such as a threaded hole or dowel) is in the way. (Visualize the flywheel on the lathe with a cutting tool taking material off and I think you'll get the picture.) I had him do that and he got my weight down to around 16 lbs. That cost around $100 IIRC. (The only shop I could find that would still do this work in Colorado was in Co. Springs, so probably not the cheapest.) The next step would be to use a mill and remove additional material. He felt he might get another 1 -3 lbs removed but no more without leaving it too weak, and the milling time was more expensive on a per lb removed basis. So I stopped there. I still had to get it balanced which meant a different shop for about $30 IIRC. In the end, I was happy with how it turned out. If I was to do it today, I'd just buy the Fidanza here: http://cgi.ebay.com/ebaymotors/Fidanza-flywheel-Nissan-240Z-260Z-280Z-280ZX-Pickup_W0QQcmdZViewItemQQcategoryZ33732QQihZ021QQitemZ310027563006QQrdZ1QQsspagenameZWDVW It's a bit more, but most of the material removed from mine came from the around the middle, but not at the outer edge. Because of the dowels and threaded holes, the lathe couldn't take much off at the outer radius of the flywheel. (That's why you'd need to use the mill.) Keep in mind that what matters most is NOT the total weight of the flywheel, but its rotational inertia. The same amount of weight at the outer edge will have more rotational inertia than if it's closer to the center. The Fidanze not only weighs less, but I'm sure has much less weight at the outer edge.

-

Jon, by bigger, do you mean more duration, or more lift? How much?

-

Thanks again everyone for the further feedback. Just to clarify, I already have a reground cam that is spec'd at 284/.480". I've been very happy with its driveability too. I just got off the phone with Delta Cams and they have another profile they call 325R and describe as a "hot street cam". It's 250/250 at 0.050" and .475" lift. They don't have any profiles with more lift than that. This is pretty appealing to me from a cost point of view because I want to pull the head anyway to try porting, and the extra cost to do the grind and resurface rockers is only around $150. He thinks it's likely that I could use the same lash pads and could continue to use my stock springs since the lift isn't any greater than what I have in there now. As I said above, I don't want to go down that slippery slope of "just doing a little more" and find myself with another $1k or more in the engine. (If I buy a new cam with more lift, new springs, rockers, lash pads, I think I'm going to be bumping up agains $1k by the time it's all done.) But this seems like a reasonable approach that would net me more power up top, give me a chance to begin to learn to port, and still keep the engine streetable. My question to you is you think this cam is still reasonable for a car driven mostly on the street? (Remember, I have an 81-83 5 speed and 4.11 diff, so keeping the revs up is easy).

-

Weber jets??All who live for their triples please read this

Zmanco replied to datfreak's topic in Nissan L6 Forum

I found that my triple webers idled best with lots of advance. That's why many swap to the later 81-83 ZX distributors - they provide less mechanical advance which allows you start with more advance at idle without ending up with too much total advance. Did that make sense? -

Thanks everyone for the feedback. What I'm hearing is that the best way for me to gain power is to go to a more aggressive cam. It sounds like just doing the mild porting/polishing won't make much difference by itself (which was my original plan). As I said up front, I have a feeling that eventually I'm going to replace the L6 with an LS1. At our altitude I think that's going to be more cost effective way to gain power vs. continuing to work the L6. (No offense to the turbo guys here, but that just isn't going to do it for me on road courses.) So now I have to decide if I spend "just a little more" on this engine, or just stay where I am until I can make the big jump. I'm just a little afraid of that slippery slope of doing "just a little". It never is

-

Jon, thanks, I follow your reasoning. A few follow-up questions: 1. Wouldn't a bigger cam move the torque curve higher up the RPM scale? My current cam is still good on the street, but not a lot is happening below 3k. 2. Maybe I should qualify what a "bigger cam" means. If I went with one with more lift (and of course new valve springs) but kept the same duration, then would the shape of the torque curve change much? Seems to me that it would remain about the same with just an overall increase across the rev range due to better flow at all rpms. 3. Since I'd have to pull the head anyway, wouldn't it make sense to at least unshroud the valves? Assuming my personal time is "free", there's no extra cost. It might drop the CR more than required when combined with the bigger cam, so would the extra flow offset the reduction from a slightly lower CR? I guess I'm looking to understand the trade offs of CR vs. ignition timing. I hope I'm not getting to far off into the muck with these questions. I've seen a lot of discussion about how each of these changes can improve performance, but not much about the relative benefits and tradeoffs.