-

Posts

497 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by strotter

-

FJ 280z wrote: It's always amazes me when someone says something stupid, then compounds it by saying something else stupid in defense of the first statement. This site has standards, and I'm afraid you're not meeting them. One of the things we respect here is, well, respect for others. "pull that stick out of your tailpipe" kind of thing just doesn't cut it. "I'm sorry, it was a joke, my bad" might have shown you to be a mature, grown up guy. Instead, you went for the "pissy prick" option. BTW, Mr. Soileau has that many posts because he asks a lot of questions, gives a lot of answers, and is widely respected; his assistance is often requested and always well appreciated. He's spent countless hours helping people who need it - as has every one of the old-timers on the board. For those guys, it isn't about post count or popularity points, it's about being a decent person, an inspiring teacher, and a worthwhile member of a community.

-

Ralph Nader first made his name known to the public by writing a book about the Corvair, "Unsafe at Any Speed". The main point: the wretched bastiches in Detroit conspired to foist an unsafe car on the American public - a car which, because of its' faulty rear engine position, would spin out on corners if entered too quickly. This "over steer" was uncontrollable by humans, and thus invariably lethal. Corvairs, possibly the most forward thinking car fielded by Detroit in decades, was effectively killed by this bad press. To be fair, the thing *would* transition to oversteer on a moments' notice, mostly due to the miserable wet-surface behavior of tires in those days. Also to be fair, many many front-engine / rear-drive cars of the period understeered to the point of plowing along in a perfectly straight line under similar conditions. It is an interesting aside to note that Volkswagen and Porsche sales were skyrocketing at roughly the same time. The convertible version of the vehicle pictured is one of the prettiest cars of the 60's - possibly one of the prettiest convertibles ever produced.

-

You know what's sad? What's sad is that I was really into the story. I'm reading, and I'm kind of muttering to myself "So what's he going to do with the - hey, is that a new carb on that motor, or the old one... wait ... Oh, I see! Hmm, he's going to have to do something with the self-propel system ... Oh, cool! That's cool! ... "

-

Tuner Cat info for LT1's...what I've found...

strotter replied to 80LS1T's topic in Gen I & II Chevy V8 Tech Board

You know, of course, that you'll never "finish" your tune, don't you? It's a never-ending quest. Eventually, you'll get tired of fiddling, or it'll be Good Enough, but there will always be some little things that'll bug you and you'll get out your tuning gear and fiddle with it just a little more. I've spent three years tuning my '7730, and before that my '7747, and I just keep coming up with more things I want to try. I actually ended up writing an ALDL monitor program of my own, because there were things that the other programs just didn't do. FYI, there's a great deal of tuning info on thirdgen.org in the DIY-PROM forum, as well as some very useful FAQs. Once you get past setting your BLMs and have a rough timing curve, you're going to need to fool with things like tip-in, throttle follower behavior, transition behavior, so on and so on. Excellent fun and food for plenty of deep thought. -

Introducing myself and my 240...

strotter replied to Mr.Woof's72z's topic in S30 Series - 240z, 260z, 280z

Well let me be the first to welcome you to HybridZ! I also have a '72 which, if I may say, is one of the finest years available. The car has excellently low miles, and appears to be in nice shape. I'm curious: do those "Rocky mountain" cars experience a lot of rust? -

Strange squealing from engine.

strotter replied to cygnusx1's topic in Trouble Shooting / General Engine

Thank goodness it was a gasket noise! I was dreading opening this thread this morning ... when you described the noise early in the thread, I had that cold-in-the-gut feeling you get when some huge problem looms - and the "chirp chirp" thing reminded me so much of bad noises I've heard under my own hood. Glad I was wrong about the bearing! -

modifiying returnless fuel system..? can anyone help me with this.?

strotter replied to crazyFaizy's topic in Other Engines

Perhaps you should find a Honda forum? Perhaps you should learn to spell? -

Strange squealing from engine.

strotter replied to cygnusx1's topic in Trouble Shooting / General Engine

You know, rod bearings make a chirp-chirp-chirp sound before they completely fail... -

My original swap was set up virtually identically to yours, including both a 327 and the WC T-5. Everything looks very similar, and just fine. The small diameter balancer is positioned similarly to mine, and as stated above no problem. The shifter is also similarly positioned. I aligned the driveshaft straight, then modified the tunnel opening to fit the shifter, cutting it on the driver's side to provide plenty of clearance. I used the donor car's rubber shifter boot, which was twice the size of the Datsun one, along with its' mounting hold-down plate, with short little sheetmetal screws to hold it in place. With regards to the shifter itself, I cut it off so that it was about 4 inches long, then ran a die I had laying around over it so that I could put the original knob on it. The die didn't match the threads on the shaft (I gave it a shot!) so I disassembled the whole thing, heated it red-hot with a torch, and shoved the knob into place. The shorter shifter fits more appropriately in the cockpit, and makes for nice short throws.

-

Any tips for removing a v8(what to save?)

strotter replied to a topic in Gen I & II Chevy V8 Tech Board

Keep the donor vehicle as long as possible. There are many items you may not think you need, but may change your mind about during the swap. When you're done with the swap, throw the l6 and tranny in the bed and sell it as "pickup with 6-cylinder, needs work". -

For those pondering swapping carb to EFI on SBC

strotter replied to BLKMGK's topic in Gen I & II Chevy V8 Tech Board

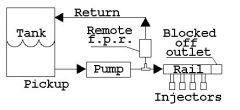

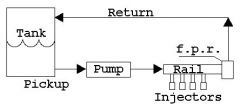

I was thinking about a non-return efi fuel delivery system. Here's a sketch of a conventional efi fuel circuit: Now my idea is this: The idea being that the pump and remote regulator (one of which I already have, and aren't that expensive) goes in back by the tank, and only the one line goes forward to the engine compartment. Everything between the pump and the regulator is at high pressure, including the "T" and the delivery line. Heck, you could probably use the stock line if the engine isn't a real fire-breather. Thoughts? -

What Cygnus said works fine. I built one some years ago, but getting it hooked up to my manifold was a pain - and it died after a few uses. Cost was "none", though. I finally bit the bullet and bought an inexpensive single-stage pump (Mastercool model 90059) for less than $140. Much faster and quieter than a venturi pump, and pulls down to 50 microns. FYI, venturi pumps won't pull vacuum deep enough to boil out the water in the system unless unless it's quite warm outside (over 85 degrees, I think).

-

Sure, I don't see why not. Your low-pressure pump will be flowing at its' free-flow rate (in your case 255 liters/hour, or about a gallon a minute), and that's going to be true all the time regardless of the demand from the motor. A similarly rated pump might be pushing about 200 liters/hour against 40 psi.

-

BLKMGK wrote: you just gotta tell me about this.

-

This is clearly an electrical malfunction of some kind. Don't thermo-sensors (thermistors) work by increasing resistance with temperature? So there's supposed to be less voltage getting to the gauge with higher readings. Your headlights come on, the gauge sees less voltage - or less voltage difference. I don't know a great deal about electricity, but I would suspect that there's either: 1) a short between the gauge circuit and the headlight circuit, reducing the voltage on the hot side of the circuit when the headlights come on (that is the temp gauge circuit is driving the headlights), *or* 2) the headlight circuit is changing the ground the gauge sees when there's a load on it, that is the ground side of the circuit could be "pulling up". You could be grounding the gauge through a circuit that is going hot when the headlights come on. No matter the problem, you're going to have to identify the bad leg of the circuit. Try this: unplug/disconnect the old wires in the existing circuit, both at the gauge and the thermistor. Get out a few feet of wire and build a new circuit for the gauge from scratch "in parallel" with the existing wiring. See if it works by dropping the thermistor in a pot of hot (boiling hot if possible) water. Headlights on, headlights off. If it works correctly, you've eliminate the thermistor and gauge as problems. Then, reconnect one of the original wires at a time, redo the test for each one. There are only a few wires involved, it shouldn't take too much time (other than the "digging around in the dash" time!) to figure out where the problem is.

-

Careless wrote: Well, nothing will eliminate air getting in, I suppose, but minimizing the chance that it will is as good as you can hope for. If the high-pressure system is pulling out more fuel than the low-pressure system is pushing in, the internal pressure will drop below ambient pressure and air will enter the system via the low-pressure return line, assuming the return is exposed to air in the tank - which I believe it is in the original Z tanks. Putting the pickup at the bottom of the surge tank is going to be the "best case" design, whether you pick the fuel up via tube or hole in the bottom. Careless wrote: Remember, the low-pressure pump is only going to see, well, low pressure. Likely only 1 or 2 psi, depending on friction losses. As far as that pump's concerned, it's just shooting fuel around a short loop of hose and then back to the tank, so it's going to be moving a lot of fuel. The high-pressure pump, however, will be pushing against the pressure regulator up front, so will see whatever pressure the regulator is set to, somewhere between 40 and 50 psi, and will therefore pump only some fraction of its' maximum capacity.

-

Careless wrote: I don't see why not. It just seemed easier to me to tap the bottom, but whatever works!

-

Check these threads and others found with a quick search.

-

BLKMGK, that looks like a good solution. However, I noted that the upper fitting appears to be set into a boss at the top, leading me to wonder what the wall thickness is on the unit. You're going to have to tap two more fittings into the top, aren't you? I wouldn't be comfortable unless there were at least a couple of threads worth of aluminum there... Careless, I think BLKMGK is talking about air bubbles "mixed" with the fuel so that it enters the high-pressure pickup at the bottom, where it'll get sent out to the injectors. You don't really need to separate the air out - any air that finds itself at the top of the reservoir is going to "go with the flow" back to the tank via the low-pressure return anyway: you just need to keep it away from the bottom of the tank. It's a concern, especially with a reservoir like this one, 'cause there's a torrent of fuel being squirted into the reservoir from the high-pressure return at the top, straight down, ensuring that if there's an air-pocket at the top it'll shoot a stream of bubbles all the way to the bottom where they'll get picked up by the high-pressure inlet. To a lesser extent that'll be true of the low-pressure pump as well. This will be especially true at idle, when the return-line is flowing at its' maximum. At full demand, the high-pressure return will be flowing just a trickle (because all the fuel will be exiting via the injectors and not returning to the reservoir, assuming the high-pressure pump isn't radically oversized for your engine). I think the best solution is to guarantee that an air gap never forms at the top of the reservoir. The only way *that* can happen is if the mass-flow out exceeds the mass-flow in. Hey, let's make an equation! (Lo=Low pressure system, Hi=High Pressure system, "in" & "out" means in & out of the reservoir) MassFlowIn >= MassFlowOut MassLowIn + MassHiIn >= MassLowOut + MassHiOut but ... MassHiIn = MassHiOut - MassInjectorFlow (at max demand) so we substitute that in and we get... MassLowIn + MassHiOut - MassInjectorflow >= MassLowOut + MassHiOut and let's cancel MassHiOut on both sides, MassLowIn - MassInjectorflow >= MassLowOut and then let's move some things around, MassLowIn - MassLowOut >= MassInjectorFlow and then if we say that MassLowOut can = "0" at max demand, MassLowIn >= MassInjectorFlow. Which means that so long as the low-pressure pump can keep up with the max demand of the injectors, you'll never form an air bubble on the top of the reservoir, and therefore never have aeration.

-

So what was wrong with the car?

-

A 305 will move your car around nicely. No, it won't be maximum fast, but "amazingly slow" it won't be. If a 305 is what you have, and you're ready to go, do it; later on, if you want, you can drop in a 350. After all, actually putting the engine in place is one of the simpler aspects of a swap, it's all the other "stuff" that takes the time. Replacing one V8 with another identically sized one will seem like child's play after you complete all the other details of the swap.

-

Building a scale windtunnel

strotter replied to rudypoochris's topic in Windtunnel Test Results and Analysis

Yeah, I got my BSME quite a long time ago. Still looking at my "Compressible Flow" book, slow going and it's mostly transonic/supersonic material. Trying to remember my differential equations... -

Glad we got the high pressure/low pressure thing figured out. Careless, the metal disk can stay, but any desiccant pellets and filter or bag has to go. The disk is there to restrain the desiccant and filter, so you'll find them "under" it. And of course the whole thing needs a thorough rinsing with something voluble that'll put the a/c lubricant into suspension. I used mineral spirits then acetone, not for any chemical reason but 'cause I ran out of mineral spirits. If you have a good sniffer you can smell the esther lubricant, even over the other smells. As for fittings, you're only limited by what will fit. I ended up using 3/8 i.d. for everything, though note that there are different threads available for the same i.d.; the smallest I could find at OSH was 1/2" npt.