-

Posts

282 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Ben's Z

-

This

-

.012 feeler on the center exhaust ports, it fits. Accuracy of Stanley level?

-

Ok. Took back to second machine shop and they took .012 off of the top. They did say it was uneven. I get the head home and set on top of the block, alignment dowels in and ARP head studs in the block. This cam is still not spinning like it should. I set the towers on with the bolts finger tight and put the cam in, tapped and torqued in different and multiple sequences. I have the suspicion now that the head is bent like a banana with the center exhaust ports being the inside apex. Like this looking from the sprocket "(" I believe this because when I was getting ready to put the cam in to the last tower it simply does not slide home and is offset from the tower hole. I walked around the back of the motor and looked at the back of the cam as it was about to enter the tower and it is clear as day that the cam is not going in on center. I tried my other cams and it is the same case. All of the cams go in my old head and towers bolted to my old block like butter. My question is why would my head fit down on the alignment dowels if it has this curve to it? I believe now I have over $300 bucks in a large alumnum paper weight. I even tried an extra rear tower I had, it was worse. I also tried retorquing the head to the block and took it up to 60 ft lbs. Unlike before it never got tighter to turn the cam as the torque load increased, no better no worse. Ok I just thought about this again and then went out and checked my thoughts. The head is actually curved in the middle with inside apex being the center exhaust ports. I once again put my Stanley level across the intake surface on the head and indeed their is a gap at the center exhaust ports.

-

My Fel Pro's were chrome faced on the top compression ring and Moly only for the bottom. Those should be ok.

-

Sorry I misread Peter's statement about the "bar going through the towers" and thought boring. I took the head to another shop. I said I don't want it back until the top and the bottom of the head are straight. Gave them the cam and towers to check for binding. With all the frustration it is pretty cool learning the intricacies of engines. Knowing these engines were designed (or any engines for that matter) before the advent of computer aid. Hats off to the pioneers. I have not shared any pictures of my work with my car with anyone. I am freshening up the engine bay too. Here are some before and after pictures of the engine bay.

-

I never said it was acceptable. I am looking for errors from the first machine shop. This is my first ever experience with an engine rebuild and a machine shop. I don't run the Penske race shop for my job. I hope to begin the process of rectifying this issue tomorrow with a new shop. From what Peter at PMC is saying, if the head is straight (highly doubtful) not all shops possess the equipment to align bore these heads. I also want to clear the air that I did not actively seek out the cheapest machine shop. I asked around from guys I know. I am in the automotive aftermarket and work for a parts manufacturer and deal with parts distributors and professional shops on a daily basis. I was recommended this first shop by more than one individual. I think the errors are not limited to one thing. Inexperience with seeing these engine, and a lot of sloppiness on their part. I mean they lost one of my cylinder head alignment dowels and bushing inserts for the lash adjusters. They corrected the wrong exhaust valves, but they should have put the right ones in to begin with. Do these guys probably do a good job with BBC and SBC, probably, with OHC L6 Datsuns? Isn't looking too good. On to the next shop.

-

All good information. I think the next step is to dissemble completely and check both the top and bottom of head again for straightness. Seeing as it got worse when I torqued the head to the block leaves me to believe this head just isn't there yet, and certainly not there on the top. I was out in the garage again last night and the cam does spin much easier with #3 tower out. My Stanley level could be wrong but if I can get .008 feeler between the level and where the #3 tower mates, we problem.

-

Thanks my man. That is the next move. Will keep you posted.

-

Did a little more looking. I took all my cam towers off and used my potentially not perfectly straight Stanley 18" level and found that a .010 feeler gauge has a little drag under where the center cam tower would bolt down. I put in 1,2,4,5 cam towers and torqued to spec, and it really didn't seem to make a difference. Odd.

-

Well I tried a few things this morning. 1) I took my NA cam out of my P90 and put it back in my NA head which is still on the block to get an idea of how free the cam should spin. Knowing that I took it back out. 2) I installed my P90 head with the head gasket with the theory that perhaps with the head torqued the cam might spin easier. Sort of a reverse torque plate theory when machine shops bore cylinders. I put the cam towers on loose and put the cam in. I did the torque sequence checking the cam for spin after each sequence. I torqued it to 20 ft lbs first go around and then tightened the cam towers to 14 ft lbs. The cam was even tighter than my bench top spin. Went once more around to 40 ft lbs., no change. Still too tight, I stopped there. My question is this. When Nissan align bored the cam towers at the factory did they torque the head to spec first? I believe they did straighten the head but if they didn't resurface the top the I am pissing in to a 100mph head wind and torquing the head made it worse. I am going to take it to a shop and have them plane the top. Is there anyway they should simulate the head being torqued to the block when they do this?

-

Ok ok. Find another shop and insist they mill the top too? It's not that it's that tight. When I put the cam gear on yesterday it seemed to spin but about 20% of the rotation was tighter regardless of cam. I wish nothing more than to find a machine shop here in Houston that has nothing but L series Datsun blocks and heads waiting for machine work. I may show Doug at Awesome z and get his input. This really has been hell.

-

Took it to another machine shop. They agreed with my presumption that they did not mill the top either. They thought that the cam would be fine once the motor is warm. I suggested torquing the head to the block and checking to see how it spins with it torqued properly. Any other thoughts?

-

Damn. I ain't there. Call me crazy with this thought. Could one use valve lapping compound to get that cam to spin a little easier? I will use the dead blow hammer a few more times and see if I can get it to spin a little better.

-

Gary Busey is that you?

-

I have seen posts that say "spin with 2 fingers". "Spins freely" leaves a lot of room for error. My cam turns over by hand but its not like it keeps spinning or snot on a glass door knob. Thoughts?

-

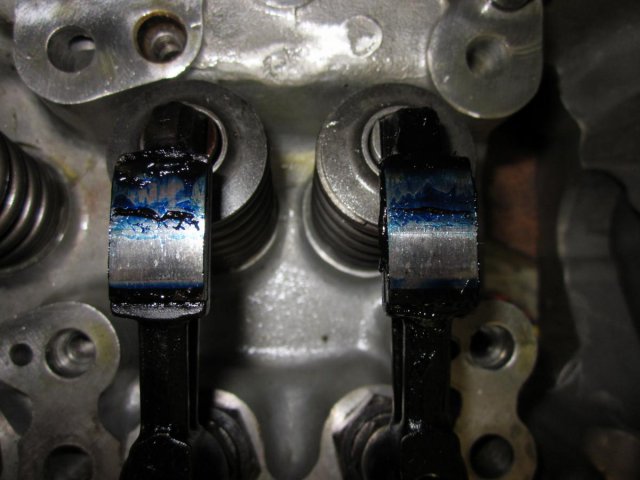

Only 1 thing startled me. I had the ball pivot much higher than the others on the intake valve on the last cylinder. Pictures are from back of the head to the cam sprocket. I think I smudged a few after I backed the pivots back down and lifted the cam off with the towers still on the cam. I tried to lift the cam straight off as best I could. I don't know what I am looking at, but it seems I am little close to the rocker tip side.

-

I put blue marker all over the pad, and there is marker left on the pad, you can just tell that is favoring one side. I just ran to the garage. I am going to coat the rockers again tonight and spin it over a few times.

-

Ok guys I did some wipe pattern checks. I am favoring the the valve side of the pad. Thicker pads correct? Question is how much thicker do I need to go? For all I know all the valves could be totally different but thus far I have checked 3 exhaust valves and the wipe pattern is about equally favoring the same spot towards the valves. 1 size bigger 2 sizes bigger?

-

I left my head "complete", cam in, rockers in, when I dropped it off so they could see how there was no lash

-

Got my head back. Amazing how much more lash you get when the correct exhaust valves are in there. I don't think I could have cam tower shimmed my way to 2mm of clearance. I wonder if these guys put the rockers back in the right position?

-

Well I dropped it off. Owner says .015 shims give you .030 in adjustment? Beyond my knowledge. I can see where he is coming from to a degree, but why do the intake valves adjust, just fine? I originally took them the original P90A head, and spare N47 for parts. The P90A had electrolysis holes so it was junk and and I took them a bare P90. Now I am questioning if they put the N47 valves in the P90. I say this because when I took them both heads in the beginning they rebuilt the N47 parts head, and I told them "wrong head buddy." need the bigger combustion chamber for the turbo. I took my extra valves from all of this and gave them back to them. They are going to take out the exhaust valves and measure it against the length of the valves in the parts box. If they have the correct valves in there and they wipe their hands of this, I will put in .015 tower shims. Once I check the wipe pattern, if I need thicker lash pads how do I go about knowing what size I need without buying a big assortment of thicknesses? When I use to dabble in Ford SHO's a shop sold a valve shims for the shim in bucket Yamaha engine and when you used the shims you needed you sent back what was left and paid for only what you used. Someone should do that around here.

-

Do not, pulled them from my N47, my original motor. The rockers, and cam came from my original engine. Cam towers are the originals to the P90. However, I did use some other lash pad from another N47 and here is why. My old engine upon inspecting the lash pads was wearing the lash pads unevenly across the pad, but only on some of the pads. It was wearing a trapezoid shape, but the wider side of the trapezoid wear pattern would be towards the front of the engine. On top of that they had like small chunks of metal or pitting removed from where the rocker meets the lash pad. I didn't use those even though my old motor ran fine except for some oil use, which I blame on the valve seals. Basically I went through and use the best of all the original lash pads I had.

-

Thanks for the input. I will haul this back to the machine shop and let them handle it. To me, to save face, they ought to do the cam and rocker set up themselves now. This shop was recommended by two different guys I know. I can't believe they have been in business for something like 60 years doing crap work, but perhaps they are getting sloppy.

-

Tony, cannot tell what the height was before hand. I am starting to distrust these hayseeds who run this outfit. With no exhaust adjustment should I go steeper than .015 on the shims?

-

My god, can this build can any worse. So I got my Heli Coil in today with my cam towers and my N47 cam spun great on the P90. Reused the rockers from the N47 and kept them in order. I put permanent marker on all the rockers arms in prep to check the wipe pattern. Anyhow, I got all the rockers in and start setting the lash. I quickly found out even on base circle I couldn't get ANY feeler gauge on the rocker arm on ANY of the exhaust valves. The adjusters are all the way down. I was able to adjust all the intake valves and usually had about 1/2 to 1 full thread sticking out on the ball pivot past the jam nut. I spoke to a knowledgeable forum member who thinks the shop cut the exhaust valve seat too deep. .0015 was taken off the head by this shop and they felt as much as .0010 was taken off in a previous life. Holy crap I am getting weary of this... If they cut the seat too deep can they still use my valves and take some off of the stem or will that make the lash pad compress the spring retainer and not the stem itself? Are we look at custom valves on the exhaust side at the very least? It should be said they reused the valves (all but 1) out of my bad P90A head in this P90.