zohanisback

Members-

Posts

135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by zohanisback

-

Whoa, it's getting a little too heavy all up in here for me... lol. I don't really feel like chiming in much here. ClassicZ is for stock knowledge and does a good job there with that, ZCar does a great job with all around knowledge, HybridZ aims to take members from each and turn them into more well-rounded, expert mechanics with cutting edge ideas and innovations. I'm not going to use just one, and I post daily on each. That said, ClassicZ is a little more fun to be on because it is more laid back and less uptight. But that's the difference between community college and a competitive private university. You're not forced to be on any one forum. You don't like the Harvard of z car forums, then leave. In all fairness though, HybridZ has one of the WORST search functions I have ever used (I used to admin some large forums, your search needs HELP). At first I thought it was just me until a couple weeks ago. I search for "tire size fender flare" and nothing comes up with a broad forum search. I use Google's boolean: "www.hybridz.org: tire size fender flare" and I get over ten hits with relevant posts right away. I just had a post moved to the tool shed a month ago on the worth of an L28. I wanted recent updates on a changing market, and it got moved. No biggie -- the mod (you know who you are) says to use the search function. Thing is, I had previously searched already and no new posts were present -- AT ALL. Had I used Google search, probably would have been different. POINT IS: You guys are a great community, and I won't ever leave. I'm a little too soft to really fit in with the group and have made some pretty extensive responses to threads which should probably be moved immediately to the Tool Shed. I've had threads moved there, too, but I know my way around cars, and you have high caliber information. But your search function is the worst I've ever seen, and experienced forum users AND management such as myself don't post to be a PITA. We do our homework, but we can't be responsible for low quality IP.Board apps you choose to use. Consider this little digression, as you promote, blunt yet authoritative knowledge and constructive criticism. Finally, members...show some respect. There's enough idiots in the world without you joining the already overpopulated masses of them. If you have a question, pose it politely, and in the correct forum. If you have searched, try to show us somehow and at least pick up the spoon yourselves. If you want someone else to hold your spoon and dinnertime, try the FSM. Management, don't be pompous airheads and get on a power trip with your supposed accumulation of knowledge and authority. Everyone needs to and can indeed learn more about something, including yourselves. Puhleeeeeaaaase...go be a security guard or cop if you want a power trip or prefer putting people down rather than helping them. And don't bite the hand that feeds you. Last thing an admin wants is an airhead mod or fellow admin getting into a verbal pushing match with a contributing member who will then take his story elsewhere. A noob is a noob, a contributing noob holds a bit of weight for future noobs. You're moderators -- a professional representation of a forum. Well, that does it for me. More than I really wanted to say... I'm off for the night, I think. Have tests tomorrow, which means I should probably study some more. Cya all!

-

Dershum, thanks for the suggestions! Looks like you went for the same thing I did with the vertical extensions. I am actually thinking about adding a bar in the middle (spreader bar)... It would make rolling it a little easier as this thing is heavy, lol. I ended up not because from a physics standpoint the stands can't tip over unless the metal kinks on the vertical bar or the whole car end is lifted up. But when I roll it, the lagging stand always follows along reluctantly. Just trying to decide if I wanna spend the cash... :-/ Had my sights on a motorcycle now.

-

Who is running a CLSD and what is your setup?

zohanisback replied to EF Ian's topic in S30 Series - 240z, 260z, 280z

I'm favoring swapping in an R200 and fabbing up a front mount. I don't want to go too far out with my pumpkin choice because of fitment issues. If I can use an R200 and get a CLSD diff and find axles to handle 500 ft lbs of torque, why bother spending extra time with another pumpkin that may require extra fab to fit. That is, unless you are snapping axles. Mack, what stub axles/halfshafts are you using and what HP can they handle? I was reading back somewhere that someone with a V8 swap was snapping axles while dropping the clutch at high rev (drag racing). -

Who is running a CLSD and what is your setup?

zohanisback replied to EF Ian's topic in S30 Series - 240z, 260z, 280z

Not to hijack your thread, and thus I direct the question to the OP (or anyone else), but what made you choose a 1.5 over a 2 way? Just better streetability and corning on engine braking? -

Here's a little update on the rotisserie... It is...Done! Got it done yesterday (my day off from studying). Here are the pics. --------------------------------- Drilled holes for attaching to the bumper mounts. Here is the front stand with the bar attached for testing. The 3/16" plate has to endure 800 pounds of torsion and shear stress. I wish I would have overrated to 1/4", but the solid bead all around should hold it pretty darn good. Ahhhhhhhhhhhhhhhhhhhhhhh. Garage is such a mess I can hardly stand it (I'm a little OCD). Oh yeah....and the car rear is up. Lol, I didn't extend the hoist legs enough (because the engine stand and hoist wouldn't fit there together), and I had to stand on the hoist to keep it from tipping over with the car on it. A rear-end view... A close up (errr....). Notice the stand vertical bar looks bent inward, but in fact the top half I welded on is straight up and down. The bottom half is bent back for better balance with an engine on. $17 worth of mounting hardware... Worth it for the strength. Mildly sketchy, lol. The perils which the hoist and operator hath endured whilst raising the fore of the vehicle shall not be mentioned. But yes, that is a car battery helping to weigh down the hoist, lol. The problem is the hoist legs don't fit under the car with the stand legs... Since the stand can't really move, the hoist has to. Yes, the car is currently being lifted with this hoist... lol Ahh, but the results... And the grande finale: In hindsight, there are a few things I would do differently. I definitely underestimated the physics of a car suspended in the air. I feel everything will hold find, and the material chosen is rated for the weight, but... 1. I'd use 1/4" for mating the plates together, not 3/16" as in the pics 2. I'd upgrade to 6 inch casters. Rolling this thing is still hard, but possible. 3. I would add corner brace supports from the vertical to horizontal leg bars. Not just one in the direction of the load, but for side stress as well. Basically three angles brackets per vertical support. I might still do it, but worried about welding when the car is up. Just some insurance. 4. I'd make both the leg bars 4 feet wide. It's just hard to do when your garage is small and you know you have to break it down eventually

-

If I remember correctly, I am PRETTY sure the guy my brother bought his F150 from had the motor rebuilt by Motor Works. We were in Walla Walla at the time, and the thing ran great. My brother eventually traded it because the transmission was starting to go bad, but the engine never missed a beat. So that said, I'm 99% sure this is the place, and yes, I would recommend them. Though I must confess, their Google reviews are not stellar. Mostly on the warranties they provide.

-

Who is running a CLSD and what is your setup?

zohanisback replied to EF Ian's topic in S30 Series - 240z, 260z, 280z

Holy smokes....almost $2000 in USD. I bet it's amazing, but that's 2/3 the cost for the drivetrain I want. If you do it, get a build thread up, I'd love to see how that thing handles. -

Who is running a CLSD and what is your setup?

zohanisback replied to EF Ian's topic in S30 Series - 240z, 260z, 280z

Yeah, I thought beermanpete was running more HP. I just can't trust the R180 with the amount of power I'm putting in, and I think EF IAN is in the same boat. Sorry I couldn't be of more help, man. I also want to run a CLSD, but you are WAY ahead of me in your project at this point. -

There's probably dozens of these posts, but I thought I would share what I consider to be a unique twist on the rotisserie. Basically, I started with two engine stands, the four wheel kind. I decided I wanted to be able to pull the car around my garage any direction and wanted heavy duty casters. So I said to hell with it -- I have a welder, so why not? I wanted the option to be able to work on the vehicle's interior while on the rotisserie. As in actually climb inside to an extent without risking it tipping over. And so this idea was born. I would widen the front beam of each engine stand and probably add length to the main vertical engine support to allow complete, 360 degree rotation (yes, I pass AWS certified bend tests for butt-end welds). I chopped off the metal casters and non rotating wheels, lengthened the front bar, and welded on the new 330lb caster (engine stand each rated for 1000). I'm in to it: $30 orange engine stand $35 engine stand $100 even (WITH TAX, lol!) 1.5 x 3 x 1/8 inch tube, 2 x 2 x 1/8 inch tube, 3/16 flat stock 18 x 18 inch, 22 ga CR steel sheet for body work. $50 in casters First off is to get rid of these. Here is what I started with if you imagine it under the forward support, lol. Here is what I got. Cheap HF casters. $6 each I should have used my stick welder instead of my cheap $90 HF mig. But not bad welds for a harbor freight tool with no bottle setup. Garage is a mess... :-/

-

Who is running a CLSD and what is your setup?

zohanisback replied to EF Ian's topic in S30 Series - 240z, 260z, 280z

Beermanpete, what kinda of HP are you laying down? Just not too long ago another member was posting about how they were making something near 500HP and dropping the clutch at drag strips was causing snapped axles. What do you presume your setup could handle? The Subaru CLSD sounds rad! -

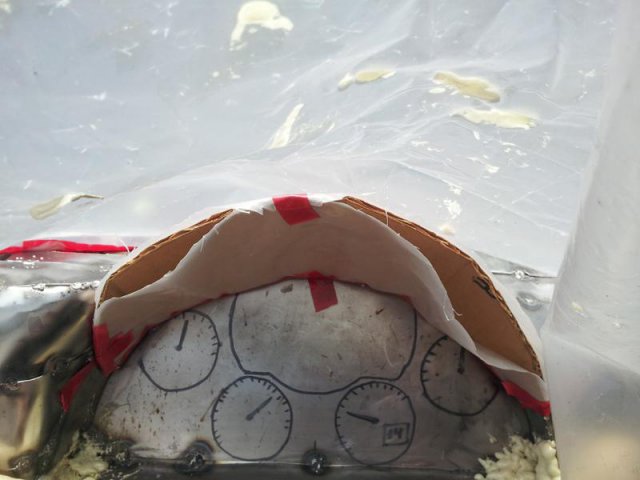

So sorry for the slow updates guys! Medical school is back in full swing, and we're working our butts off again. I didn't get to the dash last weekend, but I WILL be doing more to it tomorrow for SURE! May not be huge steps, but we'll see what I can crank out. I've been building a rotisserie for the datsun, so of course that takes time, too. The main problem we're having is the fact that the dash is technically below the window trim in the center. We wanted a v shaped look to it both from the top and front, which is what we did, but unfortunately now we have to built a small extension running across the dash. It will be a "bar" basically that covers the window seal and finishes off the look of the car. Not to fear, many cars have these, including the RX8 I'm modeling it after. I just didn't think it would be necessary. But...I was wrong. Here is a picture of what one of these bars might look like: And now for the picture "updates." I just basically fit it in the car and finished molding the gauge cluster "shroud." More bondo and the bar work tomorrow.

-

Beautiful fab work. Glad I stumbled across this thread. I am looking at doing more of a extended roll cage into the engine bay for strengthening, but I really like the idea of a lightened front end with fiberglass. Are you going to make the whole front pivot up for service. Like the old hoods? Or are you going to require it to be completely removed for engine service?

-

Changed Fuel Pump and Won't Start

zohanisback replied to RonK's topic in Trouble Shooting / General Engine

Yeah Wes, big red flag when he said the fuel pressure was ok but the car seemed flooded and you could smell gas. Hope he disconnected the line John he blew air through it and you don't have junk in your tank, now. Ether way, definitely get a new mechanic. I could have figure this out in a few minutes... An experienced tech should know better. -

Whoa... Looks like you spent a pretty penny on that, though! I think most of us are a little short on the change needed for THAT kind of job. Looks fantastic though. Power seats, too? That's legit. Pics in the car would be amazing!

-

Changed Fuel Pump and Won't Start

zohanisback replied to RonK's topic in Trouble Shooting / General Engine

This just sounds like a bad situation. The 75 is fuel injected, right? Has he checked the fuel pressure regulator? What pump did he use for the new unit? Is this a Nissan mechanic, or small general shop? Has he pulled an injector for spray pattern? Did he check for spark? The problem is you had a preexisting issue, and now a guy worked on it and you don't know what he did to make it better or worse. At this point, if fuel pressure is appropriate, it's time to start checking all combustion systems. And hope the guy isn't a quack... If he had it running before and now it doesn't, it's on his dime as far as I am concerned. -

Well I suppose it depends purely on your own personal taste. Don't get me wrong I do really value these cars and their interior. They really are very beautiful. The problem is I am making a HybridZ, including body kit, fender flares, roll cage, racing seats, etc. The epitome I always give is TwistedSixx on TunerZine. http://www.tunerzine.com/view-article/twisted-sixx I love original z cars, but I'm not an absolute purist, which is why I am on HybridZ. I like one of a kind custom cars, too. With a car like TwistedSixx, why would you want to keep a 70s dash in it? Not me. But again, this is simply a difference of opinions and I respect, and to a certain degree, understand your love for the original interiors. For my car, I doubt the interior will look anything like a z car when finished. The only thing I don't understand is why you say it will be more dangerous. Granted, the original dash is padded, but it is on a metal frame. My dash will also be somewhat padded, but on fiberglass or carbon fiber. In the end, both are unpadded and have no airbags. Furthermore, with a 6 point roll cage, harnesses, and racing steering wheel, I am not sure how safety is relevant, especially when we're talking about a car that is essentially a death trap to begin with. Lol. For what it's worth, I would definitely consider substituting another material over airbag areas and work in an airbag system. But it obviously would not be endorsed by any safety regulatory entity.

-

Sounds like valve stem seals except usually my experience is that they smoke on cold start. Which plugs are oily? Should only be a couple tops unless you got real unlucky... Let us know. Your build is so awesome, btw.

-

Thanks! I am over here in Loma Linda. Given I am in medical school, it isn't hard to figure out where.

-

Here's the good stuff! Body filler going on last night and tonight (technically also last night since its now past midnight. . .) lol. Second pass sanding the end caps. Still a little tight in the car. Might go down another few mm on each side. More foam added to the top of the hood to shape it better. That's all guys! More updates by this weekend. I'll go back and add some vids to these posts, too.

-

Left side of instrument cluster foamed in. End caps of the dash all foamed. First pass sanding. Final shape on the passenger side pretty much all set. I'm very pleased with the way this turned out. Driver side still needs tons of work. I like the curves from the center dash to the bottom passenger side and will attempt to mirror (though at a higher level) on the driver side. Side views Closeup of the center. Needs some body filler. lol

-

Plastic piece leftover after the pour. The cardboard is what I use to keep the foam from expanding really think, and instead expand vertically. The foam actually exerts quite a lot of pressure, and when pouring this stuff in pontoons, they have to cut relief holes to keep it from damaging the pontoons. A little behind the scenes sneak peek at what the metal work looks like. So glad that is done! A heating technique to preheat the metal, then keep the foam warm for maximum expansion and curing speed. It's amazing the difference heat makes. I wasted so much of this stuff by not knowing how to pour it correctly the first few pours. By the time I got to this part, I was spot on pretty much every time.

-

Hi all! Here are some updates on the dash. I apologize for the delay. I went ahead and have been doing work on the dash without doing updates. Medical school just started again today, so I am stretched for time like crazy now. With my BMW project done and my buddy back from break, we'll try to work hard on it over the weekends. Just not going to happen that much during the week as I need to study. Here's where we are now: I finished foaming the entire thing I shaved and sanded the foam to shape Jon (fellow student) and I started applying bondo and finishing the last shapes We poured a little extra foam over the instrument hood because it was just gonna be too much bondo. And the pictures and videos from what you saw last until tonight: Here is how I shaped the instrument shroud/hood. It works pretty well, but the foam will leak out, so you have to seal it well with electrical tape and hold it in place if it starts to push out. Starting to pour the center part of the dash. This was actually the most fun in my opinion because it transformed the dash so much...

-

PMed you with a triple carb Weber setup 40 DCOE. Price offered is slightly negotiable.

-

Can't believe no one commented on this. This is amazing. Love the two grills together!

-

I, too, am interested as I am planning on doing a complete modernized fit with electronic actuated doors on the system once my fiberglass dash is complete. I'm also planning on designing mine more like a 370z with the three simple knobs at the bottom of the center dash, though. A/c units... darn those complicated things. I plan on just fabricating everything under the dash for my unit custom, as I've shortened the dash space by about 3 inches. Yeah, it's gonna hurt...