-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by s30kid

-

I have the MSQ, Data log and tooth log file but when I try and upload the files to this forum it tells me I do not have permission to upload this type of file.. Also, Xnke, When you say to run the sensor ground back to ms sensor ground, you are referring to the wiring harness you get with megasquirt right? Because I do not use the harness, I use the relay board with a db37 connector harness between megasquirt and the relay board and a homemade wiring harness off the relay board to all the injectors/sensors, So where can I run the ground to? The relay board has a power, sqitched power and ground that powers the megasquirt. Can I run the ground to the same ground that megasquirt uses or does it need to be a special sensor ground?

-

I have high impefance supra injectors. And I will change that ground right now. The issue I'm having right now is. I still have sync loss. The trigger wheel is centered The sensor is as close as possible and centered on the #6 tooth ahead of the missing tooth just like on the trigger wheel forum. When I set the timing in megasquirt to 20° and then check with the timing light. The timing light shows 18°. So I tried adjusting the tooth #1 angle. Its set at 50 right Now. But if I adjust it, it should compensate for the unequal timing correct? Because no matter how I adjust it, The timing stays at 18 on the timing light when megadquirt says its at 20. Any ideas on what is going on? Is it just because maybe my timing marks are not centered on the timing cover? And I'm loosing sync because of a bad ground?

-

Well I just sent my crank pulley off the the machine shop to get the trigger wheel centered and welded, I will get it back in about 2-3 weeks. I only had the trigger wheel mounted with the 2 bolts that are supposed to be used to remove the pully and at idle the wheel was a little off center. But when I get the wheel back, If it still does the same thing I will bring this post back up with a coppy of my msq and tooth log.

-

Help with my auto to manual swap

s30kid replied to Viva Datsun's topic in S30 Series - 240z, 260z, 280z

I forgot to add that I did this swap on a 280z, Im sorry, It might be alot different on the 240z, or it might be the same, just take a look under the dash, check the wiring diagrams and speedo gears. -

Help with my auto to manual swap

s30kid replied to Viva Datsun's topic in S30 Series - 240z, 260z, 280z

I did this swap myself a few years back, YES the backing plates are different YES the starters are different, However when I did my swap I used the manual starter, but it went bad so I switched back to my old starter, works fine I still use it today. You will need a clutch master and slave cylinder, the steel line between the two, clutch disc, flywheel, throwout bearing, piolet bearing, pressure plate, clutch pedal and brake pedal. when I did my swap (factory auto) I looked under the dash and there was already a slot for the clutch pedal and a hole in the firewall to mount the slave cylinder, so I removed the auto brake pedal and inserted the clutch and brake pedals, removed the kick down switch on the gas pedal, cut the hole in the trans tunnel to fit the shifter because I was unable to get the car into first, third or fith, so I trimmed the tunnel. And everyting else mounted up just fine, you may need a new speedo gear to get the speedometer to read correctly and you will aslo need to figure out the wiring on the trans for the reverse light. I also believe you need to jumper the two wires for the neutral safety switch, where you cant start the car unless its in P or N, so just crimp, solder, twist tie those wires together so that you can start the car. Other then that it was a really simple swap. Good luck to you. -

dexter72, When I had the car running fuel only with stock ignition I used my wideband and tuned the car really well, 14.7 crusing at all speeds and around 10-11 under 8psi of boost. And now that I have the spark setup the AFRs are even better under boost. My fuel VE table is only set to 100kpa because I just learned that my VE table was not registering boost. So I need to set it up to match my spark table which goes up to 220. madkaw, because i'm using a 36-1 trigger wheel i cannot set my trigger angle, instead i have to adjust my Tooth #1 angle until timing on the engine matches timing on tunerstudio. So what I did was I set my timing to fixed at 10* and checked with the light and everyting lines up, however I cannot set my timing any lower. I tried setting the timing in megasquirt to 0 fixed but the timing light on the engine says 10 and tuner studio says 0. But if I set it to 10* or 15* or 20* it all matches up on the car to the computer. I dont know if thats an issue because My ignition map never goes lower then 18* anyway so i'm not worried about that. At idle my timing is 27* (when running the ignition map not fixed timing) but I cannot get a reading on the engine because my timing marks only go from 0-20 so i set the idle timing to 20 or 10 and made sure it was matched up there as well because with fixed timing the car ran terribly. But now I need to find out why my Car is loosing sync. I do not know why it is doing this. I just remade the mount for my hall sensor and it is rigid. I also re-aligned my trigger wheel on the crankshaft pulley and it looks like it has absolutely no play in it, no wiggle or oscillation, And the hall sensor is mounted as close to the wheel as possible without hitting. But when I drive it megasquirt will loose sync and the car will turn off and on quickly. Just like if I were to turn the key off and on really quick. It'll die but catch itself. I dont know what else to do besides going to a machine shop and having them weld the wheel to the pulley and make a new mount, but i'm afraid that will not fix the problem because the way I have it mounted now, is rigid. And the trigger wheel is mounted and measured to be center. The hall sensor is wired red-12v black- grounded to the sensor mount white- to megasquirt What do you guys think? I'm hoping the guys from DIYAutotune will see this post and chime in as well.

-

Alright UPDATE! I got the car running now. I increased the rpm set screw to hold the idle while I played with the timing. I read a forum(i believe it was extraEFI) that was about the trigger wheel and each gap between the teeth equals 10*. I had my tooth angle 1 set to 70. which would mean 70* before the #1 tooth after the missing tooth. Extra efi also says to set your sensor 6 teeth ahead of tdc for 6 cylinder applications. So I set the car to TDC and counted the gaps between the teeth from tooth #1 to tooth #6 where my hall sensor is and that is 5 gaps or 50*. So I set my tooth angel to 50 and the car ran a whole lot better. I was also having sync loss problems so I tightened the gap on the hall sensor to the trigger wheel. About to go test drive it.

-

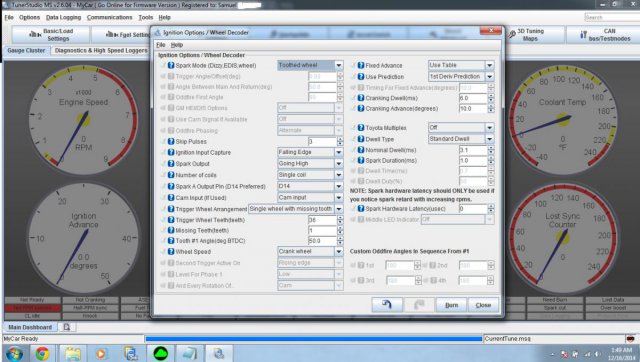

Hey guys it's me.. again.. I finally got all my megasquirt hardware mods sorted out and now i'm in the garage trying to get it started. Its a f54 n47 megasquirt 2 v3.57 direct coil control stock 280z dizzy 36-1 trigger wheel and hall sensor 440cc injectors The car ran great when it was on fuel only with stock ignition Anyway, this is how i have it setup in tunerstudio Spark settings: Toothed wheel skip pulses 6 falling edge going high single coil js10 single wheel with missing tooth 36 1 tooth #1 angle 70 crank speed fixed timing use prediction set to 1st deriv prediction fixed advanced 10* cranking dwell 6 cranking advance 10* standard dwell dwell 3.4 spark duration .5 I can start the car if I hold the throttle open but as soon as I let off the gas it dies. it is running bad and smells terrible I used a spark advanced table from the sticky forum for a standard l28et to get me started. I have not been able to try and set timing to match megasquirt because I cant get the car to idle. What do you guys think. Any help is greatly appreciated

-

I have found the answer to my previous question in another thread sorry for superfluous bumping of this thread, However I will post pictures when finished and let you guys know how she runs

-

It turns out that my megasquirt was not setup for direct coil control and I am currently modding the board with the bip373 mod kit from diyautotune. The only problem im having is I am not sure which directions to use.. Remember the board is the 3.57. So the question is, Do I use the 330ohm resistor or not? This: http://www.msextra.com/doc/general/sparkout-v357.html Or This: (http://www.diyautotune.com/tech_articles/using_bosch_bip373s_with_megasquirt.htm) BIP373s on a MegaSquirt-II V3.0 or V3.57 - Single Coil Hardware mods required: Jumper IGBTOUT to IGN to send to IGBT ignition coil driver signal out of pin 36 on the DB37. (not needed on a V3.57) Cut out R57 if fitted on a V3.0 (This won't be there on my units, though.). Our assembled V3.57 boards, if not fitted for direct coil control, will have a jumper from JS10 to the center hole of Q16. Remove the jumper from the center hole of Q16, and reroute it from JS10 to IGBTIN. Solder a BIP373 into the Q16 slot, using a mica insulator

-

Hey Guys, I have a question about direct coil control with the 3.57 board. I have been reading all over the internet, various websites and megasquirt manuals, but I have not found an answer to the question. Can megasquirt 2 v3.57 control a single coil out of the box or do I need to make hardware mods to the board. Some people said that I need to build the coil driver circuit (BIP373) Others said that I only need to jumper IGBIN to JS10 and IGBOUT to IGN Another forum post said this. "V3.57 should need no mods for what you're doing other then setting the jumpers: http://www.megamanual.com/357/assemble.htm You'll want JP1 2/3 and J1 1/2 jumpered. For a stock distro you probably want to invert the ignition input trigger to get enough trigger angle (~60). 5v to center of Q16 should only be used to drive a transistor ignition module, NOT direct driven coil. " I am really lost here guys. Any help is greatly appreciated. Me setup is: l28et Stock 280z dizzy 36-1 trigger wheel and sensor from diyautotune.com stock replacement IGN coil from autozone Coil + wired to fuel pump on the ms relay board Coil - wired to pin S5 on the ms relay board

-

Okay so I finally got around to working on the car again. I swapped the 12v wire from vref to a good switched 12v source and the car is now synced. I ran 2 wires for the coil. coil - to pin 11 on the relay board (I think its labled s5), and I ran Coil + to the fuel pump pin on the relay board with a 15A fuse inline(I didn't have a 10A). Now Megasquirt sees RPM but the car does not start. The coil has no spark. Is there a setting in tunerstudio that i'm missing? I have spark output set to D14.

-

I didn't see anyone say 240sx seats. I installed a buddy club fixed back seat in my Z but my passenger seat always looked terrible.. Ripped, faded and the foam in the seat was worn down. So i picked up a seat from my friend who was parting out his 240sx. I believe it was a 91. Any way the install was very easy and the fit is perfect. The only tools I used were sockets/ wrenches, pliers/dikes, and a screw gun to drill new holes. Im going to try to explain how I did it because unfortunately I did not take photos at the time.. What I did was I used the stock 280z seat frame. So the bottom half with the hinges attached. I removed the bottom foam and springs. Then I took apart the 240sx seat and removed the bottom foam, and the seat back from the 240sx frame. To mount the 240sx back onto the 280z hinges you need to drill a hole. The hinges have two holes on each side for the seat to mount, one upper and one lower. I mounted the back of the 240sx seat to the 280z frame using the bottom holes on the frame (they match the bottom holes on the 240sx seat back as well). Then I positioned the seat back to the position I wanted and drilled holes for the top bolts. With the seat back in position I then mounted the 240sx seat bottom to the 280z frame using exsisting bolt holes and one custom bracket. And thats pretty much it. It took me about 2 hours to do. The seat is extremely comfortable, and holds you in place when going through the canyon (my girlfriend is very happy about that) Here is a photo of the finished product, please excuse the mess.

-

I have a 3.9 r200 in my turbo 280z with a 5 speed and i'm doing about 4k+ on the freeway. But the acceleration through 1st and 2nd is great, 3rd-5th is kinda of a dog but I blame my tune for that. However I do not regret the swap. Daily driving I fill up about once a week. Just my Input. -Edit- Under 60 mph my speedometer is 10mph fast. So it says 50 but i'm actually going about 40. But over 60mph my readings are way off. If i'm going 90 it says 140 or so.. But I believe that's a problem with my speedo cable.

-

Thanks for the help. My gap is not .040". I read somewhere that the gap had to be smaller then 5mm. I will tighten the gap and run to 12v and see what happens. Now when I made the mounts and installed the wheel, my Efans and intercooler piping were removed but when I put everything back together I found that the fit was very tight. I have also read that the hall sensor is very sensitive to noise. Would my Efan, that is mounted directly in front of the sensor, cause a problem with the hall sensor? Anyway I took some photos of my setup.

-

Oh, and the hall sensor is wired, red to vref on the relay board, white with black stripe to tach on relay board and black is grounded to the block.

-

Hey guys S30Kid here AKA Sam and I am stuck in a rut at the moment. I cant get an RPM signal with my 36-1 trigger wheel/Hall sensor that I purchased from DIYAutotune.com. The motor is a f54 n47 combo. 440cc supra injectors, ported intake manifold, 60mm TB, stock 280z distributor and ignition stock turbo, 2.5" down pipe, Mishimoto FMIC, Megasquirt 3.57 and relay board in fuel only. I found out really quick that if you boost 8psi on 280z stock ignition you will break pistons... So now the motor is freshly rebuilt and my dad had some fun with the head. The head has been de-linerd and port matched to the exhaust manifold with polished combustion chambers. So now I have decided its time to setup the ignition because I do not want to blow the motor again.. I have the wheel and hall sensor mounted. (6 teeth ahead of the sensor) and I will attach a screen shot of my ignition options/wheel decoder. Cranking rpm is set to 300. The plan is to run the 36-1 wheel for my rpm/tdc sig, lock the distributor and fire the coil directly with megasquirt with the distributor only directing the spark. At the moment I cannot get a signal from the hall sensor and I cannot figure out why. If I cant get the ignition to work I might just cut my losses on the wheel and get a 83 distributor. Any help is greatly appreciated

-

So it doesn't matter how I mount the trigger wheel? The missing tooth can be anywhere and megasquirt can compensate?

-

Hey guys I have some questions I cant seem to find answers too. Here is my setup 1977 280z f54 block with a n47 head megasquirt 2 v3.57 with relay board stock injectors (soon to buy 515cc supras, but for now I might just bump the pressure with low boost) 280z distributor and coil stock turbo manifold stock turbo msa 2.5" downpipe Mishimoto 3" intercooler (I don't remember the dimensions but its large) And I am having my intercooler piping built by mckinney next week. all I need now is a trigger wheel and sensor. My first question is can I run the 36-1 tooth wheel from diy autotune mounted to the crank pulley and use megasquirt to fire the coil? From my point of view I don't see a reason why it wont work as long as I disable the mechanical advance. Next question is.. how do I set the timing.. With the 36-1 wheel would the missing tooth be TDC Cylinder #1? I was reading another topic on the subject and he said he was using the 5th tooth but I don't remember.. Thanks for taking the time to read this any help is appreciated

-

I am looking for a crankshaft trigger wheel and sensor for my megasquirt 2 turbo setup. Let me know what you got thanks!

-

Alright so I have come to my senses and realized that when it comes to power/reliability you cant cut corners. So I'm going to pick up a distributor and shaft but im out of money now so the project is on hold. The only parts I need now are dizzy and shaft IC piping and blow off. But I have a question and that is when I switch to the zx distributor do I need to get the ignitor or not? I have read that you need to pick it up when you get the dizzy but when I look up wiring diagrams for megasquirt it does not show the ignitor. Is that because megasquirt has direct coil drive?

-

Im looking for a zx dizzy with the CAS so I can wire my ignition into megasquirt. I also need the dizzy shaft.

-

Well the turbo timer was free and the bleed valve came with the turbo. So far I have only spent about $300 everything else was free or traded. I understand that the way I am going at this is completely different then everyone else but there is a method to my madness. I guess what i'm trying to do is set up everything to "stock" form and go from there. I'm not trying to shoot for high hp out of the gate. I want to slowly build up my car but still get to work every morning. As soon as I get the car running on the turbo ill start sourcing a distributor. The only problem is that I have to pull the whole timing cover off to replace the shaft to match the dizzy and I just dont want to deal with it right now.

-

Alright some time has past since my last post I though I might make an update and ask some questions. In my possession I now have: 280zx turbo manifold stock turbo Oil lines Mishimoto 3 Inch intercooler msa 2.5 downpipe HKS turbo timer screw type boost controller 280zx wastegate All I need to buy now is Intercooler piping, wideband, Blow off valve, intake/exhaust gasket, t3 turbo gasket, boost gauge, and a gasket for the downpipe. I also need to buy a 3/8 npt barb fitting for my return line on the turbo. So I need to drill and tap my pan. After I get all that I can start tearing the motor apart and putting all the turbo goodies on. Here is where I have some questions, I have read a few posts about how some people have boosted 280z on the stock 280z ecu with 5 pounds and the car ran fine but anything higher then 5psi was not enough fuel. Now, Im not saying that I want to use my stock ecu but what I was thinking was stock ecu means stock dizzy. And I also read somewhere that someone had stock ignition and megasquirt fuel and he just retarded the timing on the distributor, ran 91 and said he had no detonation at 5-10 psi. But now for the life of me I cant find the post so I was wondering if anyone has any experience doing this and how to set up the stock dizzy for 5psi. Then eventually ill swap over to the zx distributor. But right now Its not possible. My next question was about intercooler piping. my intercooler is 3" inlet/outlet and the stock turbo has I believe a 2" outlet on the compressor, so would it be okay to just run 2" intercooler piping and just use 2" to 3" couplers at the intercooler and throttle body?

-

Im Looking for a turbo exhaust manifold and a turbo distributor. Please Pm me if you have anything Thankyou