-

Posts

394 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by gnosez

-

Racing G Nose Or Msa Type 3 Spoiler

gnosez replied to ozzinc's topic in Windtunnel Test Results and Analysis

Here are a few pics of the airdam/splitter that Roostmonkey fabbed up for me based on my design. The splitter runs all the way back to the bottom of the radiator, It has since been powder-coated. A radiator air box is next. The headlight covers were added at the same time. The car is stable at 2X the local limit. It would have better (aero-wise) if we had made it wider to cover the front wheels and we will likely address these at some point but the idea was to get something on the car to aid the gnose without drawing too much attention to this add-on part. As many of you already know, Roost is the man.... -

What am I seeing coming out of the back of the car? Gas, smoke, positrons, anti-matter?

-

My late father thought there were only two types of drivers; ones that were so slow you had to get on their back bumper and those idiots that drove too close to your back bumper. His solution to tailgaters was quite simple - he kept a few eggs in each vehicle and when all else failed they got send rearward, or in the case of the open sun roof driver who cut him off while he was driving a semi, down the hatch. When he sold his '69 Volvo it had over 800,000 miles, the original clutch and 4 eggs in the glove box. Loose change works wonders as well, but that is a very aggressive move.

-

AZC rear arms w AZC dog legs

gnosez replied to g00kb0i's topic in Brakes, Wheels, Suspension and Chassis

Not my idea to install a pin first, since it wasn't my car. I'll be putting in a bolt. My street car is inspected at least twice a month or more when I drive it hard so your issue is unrelated to my specific car. The technotoy RCAs weren't available when I was ready to convert my RCAs and I would have gladly purchased them instead, if for no other reason than to save a few dollars. Worst case, I will have the tube and the connecting joints welded or replace it with the techno units. Your unhappiness with these arms are noted.... -

AZC rear arms w AZC dog legs

gnosez replied to g00kb0i's topic in Brakes, Wheels, Suspension and Chassis

I have installed a set of the AZ rear LCAs this winter and am just in the process of getting the car ready to go to the alignment shop. Like g00kb0i I too was concerned about the adjustments and the possibility of the tube to move under hard driving. I also contacted Dave and ended up getting some feedback from a time trial racer out on the West Coast who stated that he started out with the tube arms at or about level and after getting the alignment right drilled a hole and bolted it down. An earlier attempt using a pin resulted in it being seared. A concern for street cars? Not likely.... -

I know the expense of the smaller horns can be a factor, hell I have the cheapest of the two TWM boxes and that was way too much money to spend, but you run the risk with your current set-up of A) not getting the air to flow into the last set of horns and the horns themselves blocking the flow of air. If you don't have a A/F meter installed consider one to protect your engine. It would be interesting to see the numbers with and without the horns.....

-

You should consider making the rear smaller by tapering the box to increase the air flow to the last set of carbs. I would also install much smaller horns (3/8-inch).

-

New stuff, short shift, fidanza, zx trans, OBX, test drive.

gnosez replied to cygnusx1's topic in Miscellaneous Tech

I'd be one to remove that solid mount at the first opportunity and either go back to the stock mount or a Ron Tyler version (as you mentioned in your post). You're likely just a few launches away from a cracked front diff cross member. That snow you (and I'm) getting might have been a sign..... -

I have a very rough 2-piece (fenders and front- split down the middle) that came off a dragster. It had a monster blower style hood that was separate. If you're interested I can find a picture of it. And if you want to come out to the Northeast and get it it's yours.

-

I would like to suggest that it might be in your rack itself. There is a the spring that puts tension on the rack rod that can be adjusted by loosening the large ring nut and then turning the slotted bolt inward (clockwise). BTW, too tight and the steering wheel will not return to center by itself. Very unsettling if you happen to go for a test drive and it occurs.

-

Looking for an aggressive drop - 280Z

gnosez replied to 3demon's topic in Brakes, Wheels, Suspension and Chassis

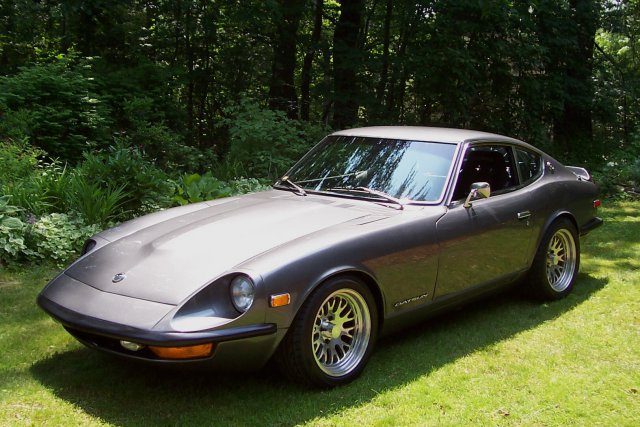

I've attached a second picture of my 240 which shows the wheels a bit more and the rear modified fender lip. My ride height (at the horizontal lip of the rocker) is just under 6-inches in the front and 6.25 at the rear. These measurements were taken after the car was corner balanced and driven. My tires are 23.25-inches in diameter. It is now sans suspension as I refresh the camber plate roller bearings, install the AZ rear LCAs, and install a reman steering rack. I will likely raise the Z just under 0.5-inches once I get it all back together this weekend and see how that effects the car's handling once it stops snowing. -

Looking for an aggressive drop - 280Z

gnosez replied to 3demon's topic in Brakes, Wheels, Suspension and Chassis

My 240 sits on Ground Control coil-overs with 8-inch springs and EMI inner camber plates. Wheels are BBS style 16X8 w/ 245X45s. The rear lips were cut every 1/2-inch (inside) and tapped up then the face was rolled outward to match the slope of the existing fender shape. A flare without looking like a flare. Besides being able to lower the car to the height that please your eye, it also allows you to balance the weight to meet your street or track needs. -

Jon - thanks for taking the time to provide a very useful reply. It made me go back and check all my assumptions and measurements. In particular your first point regarding the stress on the camber plate mono-ball issue was dead on and I went back and took more measurements so that I can line up the strut and CV (fore and aft). The easiest way it seems is to use the inner rear diff carrier and draw a line out. That line on a stock RCA is very close to the center of the bottom of the strut tube and puts the CVs directly in line with the diff. As to your 2nd and 3rd points on center tube angle and track width, this is the very reason I got this type of RCA. None of the others I have seen would give me back that angle or allow some track width adjustment. Worst case I can always go back to the way it was. As you assumed my Z sits quite low and a slight tip of the tube should give me back some of the geometry I am now missing. I could drill the tube and lock it into place if need be. As you stated this raised angle will decrease my track width but I hope to get that back with the 5/8 adjustment in the arm itself. Maybe I can even get a 1/8 more track to allow a bit of insurance room for the ZXT CVs. Once the spindle pins are removed from the old arms tomorrow, I'll install them without springs and go through a complete range of motion experiment before putting it together for real. I'll post pics and my results later this week. Thanks again -

-

I am looking for some initial set-up specs for the Arizona Z Car adjustable rear control arms as I rebuild my 240 suspension. Prior to taking down the entire front and rear struts, control arms and the cross member with the steering rack (replacing with a reman), I rechecked the corner balance numbers, took measurements of the alignment settings (camber, caster, toe), the ride height, and the center to center distances between wheels (found a difference of 5/8 side to side). The AZ RCA allows for several adjustments including: 1) control arm (front to rear) 2) control arm (angle - need to remember to check CV binding issues first) 3) track (width) 4) toe The center to center (tube of the stock RCA to the spindle pin) is 14.5 inches and I was planning on using that as my starting point to set the AZ RCAs but wanted to check and see if anyone here has installed these arms and has some advice they wish to offer. Worst case I'll get it close and trailer it to the alignment shop but I'd like to be able to test drive the car for other reasons prior to the alignment appointment.

-

We make an OEM style replacement set of seat brackets for 240 and 260s if that helps. Our site is: http://www.baddogparts.com and click on "products", then scroll down to Seat Brackets. They're $75/side plus shipping. I have them in my 240 with Cobra seats. Whatever you decide to do make sure you can get at the rear bolts/nuts as they are a real pain to tighten.

-

I didn't see any mention whatsoever of your Z ever being corner balanced, aligned or the many changes you've made recorded so that you know where you started and what effect each change makes, Having a 240 with a 3.2L and running it at just under 6 inches at the rockers I have had no issues similar to the ones you are experiencing. Looking at your Z and what I see is too tall tires and a too low Z. My set-up includes 8-inch GC 275lb springs, Tokico HTSs (mid point setting), cut struts, 3/4-inch poly bump stops, 2.25 neg camber front and 2 rear. I run a 25mm front sway bar and no rear bar. Street tires are 245/45/16 and track are 225/50/15. The 250rwhp go through my Quaife (3:90) and I have run the car hard on the street, AX and track events.

-

Ah, my point exactly. Now which changes to weight distribution provide what specific advantage for a particular track lay-out? For example, Mid-Ohio is primarily a track with lots of off-camber corners, then there are courses with no banking whatsoever, and then there are those with lots of banking (positive). Which direction does one take with a vehicles corner balancing?

-

I ran the program and it says I have the car set right. Now the question is this the right set-up for a Z being driven aggressively. I guess I'll have to wait until April when the snow and salt are gone to find out.

-

Before refreshing my suspension and adding a set of Arizona Z Car's billet rear control arms I put my 1972 240Z on the scales to get a quick picture of where the car was before I dismantled it. The values shown include my weight, a 7/8 tank of gas, full interior, spare tire, tool bag and the usual spare parts, gnose, L28 NA, 82 5-spd, and quaife R200 w/300ZXT CVs and BBS wheels. Total weight - 2688 LF - 653 RF - 640 LR - 707 RR - 689 Left - 1359 (50.6%) Right - 1329 (49.4%) Front - 1292 (48.1%) Rear - 1396 (51.9%) Cross - 1348 (50.1%) Bite - 20 This seems to me to be pretty good and I was more inclined to think it was not this well balanced before I saw the actual numbers. Has someone found a better corner balancing set-up for both street and track usage (with coil-overs and scales this isn't hard to change)?

-

The first is from the Long Beach ZCCA convention and the other is my restored 240 w/Rebello 3.2L, and more mods than my wife knows about. It won the Mr. K Choice award at the '03 ZCCA convention. Third pic is our "club built" race car.

-

Perhaps the best way to insure that there is enough free play in the CVs at full suspension is to trim an 1/8-inch off the MMS companion flanges. They are beefy enough to allow for a slight trim. Once I put my 240 up for the winter I will be doing just that.

-

The problem for me was that the aftermarket CVs were made with the wrong sized shaft. This made one CV too long and looks to be what caused my diff to go bad. Z-Ya can confirm that AutoZone refunded his money for these CVs and even told him that they are NLA because of this issue. I sure hope it WAS the root cause of my diff problem as I plan on driving my 240 to the alignment shop today (40 degrees, sunny and with 2-days of rain maybe no salt on the roads).

-

If you notice on MMS' CV page they mention that lowered Z might have a binding problem. I had discussed this with JohnC and as per his suggestion, I ran the struts through a complete range of motion (w/springs removed) and they didn't bind. A severe squat (bump or launch) could make the rear dip quite a bit. I intend on slowly grinding down the shaft end (1/4) once I get back from overseas. That I hope will resolve the issue once and for all. Oh, I did pick up another 3:90 ring set just in case.

-

The car started making noise about 10 miles from the race track. I didn't use the car that day and on the ride home it got progressively worst. After we cracked open the diff we found that the bearings were gone, the bottom of the diff was filled with fine gray sludge and the pinion was bright (the ring gear was fine). So, yes there was noise, a lot of ugly noise but at that point I was more interested in getting home than ruining my diff. I agree that this seems to be more of a mis-alignment issue but the only thing that was changed in my rear driveline set-up was the addition of the MMS flanges and the CVs. Are the stub axles spacer sleeves different sizes for 240 vs 280? If so a longer sleeve would push the companion flange out that much further. At this point I'm thinking of going back to half-shafts.

-

I've flipped (as per MMS instructions) the aftermarket set, the set I borrowed from Roostmonkey and the set I bought for myself. Been there and done that.......