-

Posts

1384 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rossman

-

I mounted the bus bars with sheet metal screws painted with rust preventative primer. I wet install all sheet metal screws to prevent rust. My differential is at Houston Automatic Transmission awaiting back-ordered parts. Scott is a good guy. I have confidence he will do the job right.

-

Did you get the money order?

-

I snail mailed today. Thanks for your patience!

-

I'm looking for an 3.545 (preferred) or 3.7 R200 ring and Pinion set for a Z31 R200 LSD. I assume that only later R200 ring and pinions will work due to the ring bolt size. Please chime in if I'm wrong. I'd also consider a whole differential if shipping isn't too bad to 77058. Nissan wants $575 for a new ring and pinion.

-

I've used PowerFab before. Jeremy is a good guy. They recommend I take the differential to Houston Automatic Transmissions. Scott at HAT told me that if the bearings are shot there is a good chance the gearset is shot. I'll probably run it by there Friday for an estimate.

-

BFE is relative! Does your guy have experience setting up R200's? Driving to Tomball is cheaper than shipping this beast cross-country!

-

I don't believe my issues are caused by the differential being too weak. It should last a long time if I can get the differential in order. I haven't seen any guys with relatively small displacement turbo engines (e.g. big phil) run into problems with the R200. Also, I don't have any plans to upgrade power-wise past the currrent setup. Frankly, I have lost interest in high-horsepower cars and I have another expensive addiction (cycling) that is more satisfying to me. Besides, the speed and power of this car scares the sh!t out of me even at it's current, poorly tuned 10 lbs of boost state! It's been over 3 years since the differential was rebuilt and I don't trust the guy to do it again. I'm going to let him know what happened and move on...assuming his assembly was the issue. Here is what's going thru my mind...I take the guy a factory set-up differential, have him swap out bearings and seals and he has to install almost 2X the amount of shims. My money is on an incorrect setup.

-

I am hoping to keep the current setup. The 8.8 swap sounds awesome but it's more money/effort than I want to spend right now. I pulled the differential and inspected. The bearings are trashed but the gearset looks good. Ther is scoring and heat damage. The guy who assembled it put a TON of shim on the side bearings. Maybe he shimmed it too tight? I dunno. There is also a bunch of metal shavings inside which I assume contributed or caused to the bearing failure. I need to find the source of the shavings. I did drive it for ~100 miles with considerable clutch chatter. Clutches are coming out this weekend for inspection.

-

Will - Are you planning to produce another round of these kits? I'm very interested.

-

Well, I think I may have trashed my differential. It was the first time I held it to the floor all the way to redline (7500) 1st, 2nd, 3rd, 4th...>60mph then let off due to major pucker factor . I coasted down to <60 mph then hit the gas to maintain speed and heard a howling sound from the rear of the car. I drained the differential when I got home and found LOTS of shavings on the magnet . Gonna pull the diffential tomorrow to see what's going on. Oh, well, I needed a higher ratio anyway . I'm thinking 3.51...any other options that fit a z31 LSD?

-

Thanks Tony! Yeah, I'm still not convinced. I looked at the filter again last night. It's now completely dry. The crud is a fine white powder, almost like gypsum. I'm going to call the station today, I'm sure they will deny it but at least they will know there is an issue if others complain too.

-

After inspecting the filter and thinking this thru *rationally* I believe the fill-up may have been a red herring. The filter is plugged up with very fine, muddy looking particulate. Since I didn't flushed the lines after the install and there very well could have been residue in the lines and tank. Oh well. I bought two 10 micron filters. I'll carry one as a spare in case it happens again.

-

Here are pictures of the fuel system.

-

Thanks for your response. I should have described my fuel system since it is completely custom. I had a sump welded in the tank and professionally refurbished (re-coated) inside and out. The fuel lines are custom bent stainless and earls fuel hose with AN fittings. There is a 100 micron filter on the intake side of the pump and a 10 micron filter just before the fuel rail. I need to flush out the line between the 10 micron filter and the tank. The 100 micron filter is not plugged but has some crap in it. I'm not sure if it can be salvaged (it's stainless mesh) but I'm going to replace it anyway. I automatically assumed the crap came from the Shell station since it happened so soon after I filled up. I guess it's possible that my tank started corroding or something inside it disintegrated but it seems very strange since it was running normal literally minutes before. I don't trust the fuel and I poured it into dirty/oily containers so I'm just going to recycle it. My plan it so blow out the fuel line with water then alcohol and compressed air and slosh water then alcohol in the tank until it runs clear. Anybody got a better idea? Should I flush the pump somehow?

-

So I was cruising around in my Z the other day. The fuel level was getting low so I took her over to a relatively new Shell station in my area and filled up with premium. After about two or three miles I noticed my pump started making more noise. So I started heading home. By the time I got home the pump was buzzing REALLY loud causing the whole floorboard to vibrate. I immediately suspected one or both of the fuel filters were clogged. Today I confirmed it. I can't even blow thru the paper filter filter. I haven't yet checked the pre-filter. My fuel system is practically brand new: new pump, new filters, re-coated tank, new stainless lines, new fittings, new flex lines, etc. I'm thinking it has got to be dirty gas from the Shell station. I drained the tank and out came a little particulate crap and ~17 gallons of waste. So my questions are, how do I flush the system lines to make sure I got all the crap out? What the heck do I do with all the gas? Dump it in the Shell store and set it afire? Thanks! (I am kidding about the fire part )

-

Lookin' good! It would be cool to angle the fuse box cover towards the driver so that gauges mounted in that area are easier to see.

-

I got the car registered and inspected today. The inspector guy was highly annoyed because he couldnt figure out the clutch. He even called it a pos under his breath. What a jerk! Anyway, I got my sticker . The car feels VERY fast and I only have a 5 lbs spring in the wastegate, no boost controller. Baby steps.

-

Problem solved! I remembered today that I had forgotten to connect the Headlight Upgrade Harness that I purchased a while back. I had connected the power but never connected all of the connectors at the headlights. I thought that maybe I could figure out a way to use that harness to feed power to the highbeam light...so I went ahead and installed it. I also modified the grounds and spiced in wire to carry the ground wires all the way back to the battery. Chassis grounds suck on this old of a car. Anyway, I got it all hooked up and tested it. To my amazement, the highbeam light functions properly now! Go figure. If any electrical wizards can shed some light on this, I'm all ears!

-

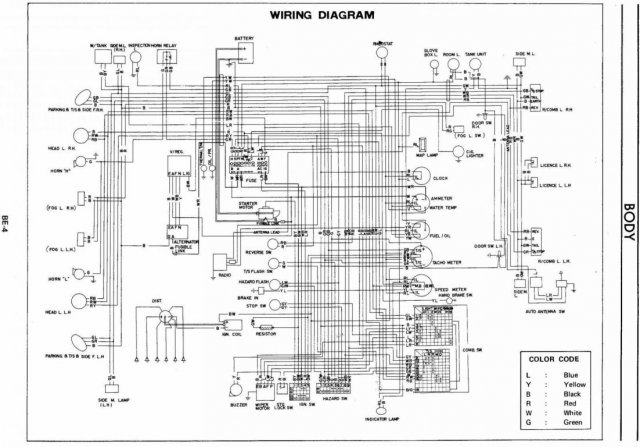

Short version: I'm trying to get the Speedhut GPS speedo highbeam LED to function properly in my 11/72 240z. The problem is that the highbeam LED is illuminated when the headlight switch is set to parking/running (position 1) but works as expected when the headlights are illuminated (headlight switch set to position 2, high/low switch). Thru a bit of testing with the DMM I determined that the switched highbeam ground wire is grounded when it isn't supposed to be (headlights off and headlights in position 1). This is causing the relay that I installed (per KTM's thread, post #18) to activate (close) and illuminate the highbeam LED when it isn’t supposed to. Also, for the record, the stock highbeam indicator was NOT functioning prior to this gauge install. Any ideas? Details below... Extended version: The stock highbeam indicator wiring uses un-switched power from the fuse box (red wire) to the lamp and ground to the same switched ground wire it uses to ground the highbeams and thus power the highbeam lights via the hi/lo beam switch. The problem is that the Speedhut speedo expects +12v and uses its own ground to complete the highbeam LED circuit. So, I wired in a relay (per KTM's post #18) that receives power to its solenoid from the parking/running light switch (grn/wht wire) and is grounded to the same wire (red/wht) that is only grounded when the headlight hi/lo switch is switched to hi, per the FSM wiring diagram. The same parking/running light power wire (grn/wht) is also used to power the Speedhut LED via the relay NO switch (87). In this configuration, when the headlight switch is off, the hi beam LED should be off – no power and no ground to the relay control solenoid. When the headlight switch is set to position 1 (parking/running) the LED should be off – no ground for the relay solenoid. And, when the headlight switch is set to position 2 the LED should be off when the hi/lo beam is set to lo (no ground) and illuminated when its set to hi (grounded). Make sense? That's the way its supposed to work. But I'm getting ground to the solenoid when the headlight switch is off and set to position 2. So, the LED is illuminating when the when headlight switch is set to position 2. I checked continuity from the red/wht wire to chassis ground with a DMM and get the following results: [HL SW, HI/LO SW, reading] off, HI, 0 ohms (grounded) off, LO, 0 ohms (grounded) position 1, HI, 0 ohms (grounded) position 1, LO, 0 ohms (grounded) position 2, HI, 0 ohms (grounded) position 2, LO, OL What confuses the crap out of me is that the high beams function normally, meaning they are ONLY illuminated when the headlight switch is set to position 2 and hi/lo beam switch is set to hi. So why the heck am I getting continuity (ground) on the highbeam grn/wht wire in any other setting other than headlight position 2 and hi/lo switch on hi?

-

I believe the early 5 speeds had two rear mounting ears and the later, close ratio transmissions had one ear.

-

Google is your friend. Look here: http://www.zhome.com/ZCMnL/tech/AandBtranny.htm

-

Thanks for the offer but I verified the size and thread it by installing a new nut.

-

Correct a mundo!