-

Posts

658 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AkumaNoZeta

-

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

It would be a one time fabrication thing. The whole car has been a one time fabricaton thing. In fact today I had a conversation with myself, telling me that I need to stop over-complicating everything. It's bad enough I have to completely fab up the rear suspension, at this rate I'll never get to drive the car. At least I still have most of the provisions for the front. Plus, I'm not a race car driver so I'd probably never notice a differance anyways, and like you said I can always change it up later. On a side note, has anyone ever thought about Johnny Joints by Currie Enterprises? I was looking for an alternative to rod ends and came across them. They look real promising, albeit quite bulky, but I haven't came across anything negative about them through Google. In fact one guy on an off roading forum said he has something like 70,000 miles on his lifted truck (both trail riding and daily driving) and none have developed any slack yet. They have weld in ones and bolt in ones, but it seems they don't came with threads smaller than 3/4"-16 which would be alright if you don't mind bulky control arms. -

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

I may be officially overthinking this now. I just had the idea of making a bracket to attach to the bottom of the S30 spindle that relocates the ball joint outside the unit, towards the center of the car. Seperating it from the steering arm allows the possibilty easily swapping out different arms to try different set-ups, and the relocation of the balljoint should allow a lot more ackerman without having to put the tie rod inside the brake rotor. I spent a little time looking at the front hub of the Z and can't see why no one just throws a slip on rotor hat over the wheel studs. With a 1.25" thick rotor, I don't see why it would need to be more than a 2" offset and Wilwood has pretty much any size you could need. Eliminate 4 bolts in the process, so less weight there. I also don't see why not just fab a bracket coming off the strut tube/knuckle joint for bolt on style struts. All this should equate to ample more inside wheel clearance as well with the strut bracket and ball joint bracket both moving the hub outwards. Ya'll can tell me to shut up at any time. lol -

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

Or, maybe working of a Mustang knuckle would be better? https://www.stangnet.com/mustang-forums/attachments/94-95vs96-98spindle-jpg.153405/ They're already front-steer cars, tapered bearing hubs with slip-on rotors, and still uses bolt-on strut allowing access to bottom knobs on double/triple adjustable struts. Edit: I guess the later model, the one with better geometry, actually uses a barrel style bearing so there's go that advantage. -

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

Well, mine's not going to be a race car anyways. More like an overkilled daily driver. I don't think I'd ever run tires soft or sticky enough to run into pre-mature bearing failure like that. I've been planning to run 245/50/16 tires, I got one mocked up on a 16X8 0 offset wheel and I like how it looks. Like I said before too, I already tied my strut towers together so I rather keep with the strut design. I did that before the full extent of the rust was revealed. If I knew ahead of time that nothing was usable, I would have just built a tubed chassis and make a fiberglass copy off the body. Probably would be done by now if I did that. -

Idea for front knuckles.

AkumaNoZeta replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

You do bring up some good points. Not only is there the less leverage with the shorter arms, but I think scrub radius would make a bigger effect on slow speed steering effort and that would be an unknown factor, especially since it also changes with tire height and wheel offset. I also have an 260Z model and I believe they have a 17 or 18:1 ratio vs. the earlier 15:1 so that would probably help negate some of the effort. I wouldn't use the rest of the 240SX suspension, for all I know the knuckle may already fit on the Z's balljoint, I doubt it though. I'd want to keep the flange to flange distance the same so making control arms to transition between Z and SX would be better, but depending on the inclination of the SX knuckle that could result in a shorter arm which means bigger camber changes through the suspension travel. Another thing that worries me is since it's a dropped knuckle, would it require an unusually long coilover to get proper ride height? I wish I knew how to use CADD so I could make a digital model before finding out everything is a waste of money, haha. I'll be making a new crossmember for my car anyways, the factory one looks wierd on it now so I need to make one out of square tubing to match the rest of the car considering I don't have any of the stock sub-frames or crossmembers anymore. I even thought about going ahead and making it a rear steer, but when I swapped the Z knuckles side to side and eyeballed it, it didn't look like it would have sufficient clearance from the oil pan. -

I came across these on the interwebs https://www.gktech-usa.com/v3-super-lock-s-chassis-front-drop-knuckles.html and I if you look at their image of the steering arm placement, it looks to be pretty much in line with the balljoint. Making me think they can be swapped sides and be able to run with the front steer of an S30, versus the 240SX's rear steer. Maybe move the rack forward to add a little more ackerman. Control is nothing, just build one with a 240SX balljoint on one end and a heim on the other. I'm thinking the main advantage would be serviceability. Now more having to remove the wheel bearing to change out rotors, be able to adjust the bottom knob on those fancy coil-overs without disassembling anything, and I personally like replacing sealed bearings more than having to repack individual pieces with grease. Plus, looks how strong the aftermarket is for 240SX, and I'm sure it will only get stronger so you don't have to worry as much about certain things becoming obsolete in the future. Speaking of the future, I'm hoping to be working on finally getting my car to be able to sit on it's own wheels one day in the near future so I've been exploring my options. I don't want to re-design for double A-arms since I already tied in my strut towers to the cowl and I feel that would be a waste of time if I don't retain the strut design. Tell me what you think.

-

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

Thank you. Been working on it since 2010, it's a little behind schedule. Haha. -

Stronger motor mounts

AkumaNoZeta replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

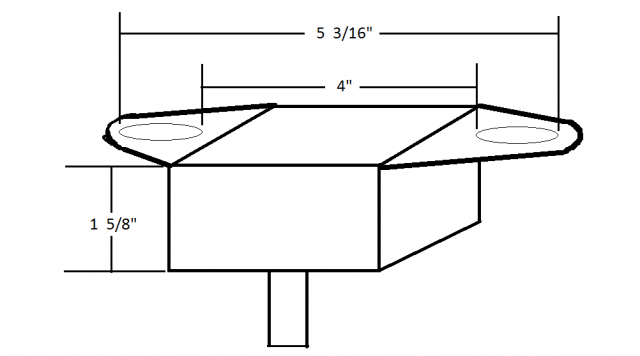

I don't have a stock motor mount anymore to compare to, but I am using poly Jeep motor mounts to hold a 7M-GE in my Z. I took some measurements off it, if it helps. The bottom stud is centered pretty good and about 1/2" diameter. And the slots are for 3/8" bolts. This is the mount I have. https://www.summitracing.com/parts/ens-2-1102r/overview/ When I got them I knew I was making my own parts so I literally just went through the entire list of motor mounts and picked the ones that I felt would allow the easiest disassembly. I wanted to make the car easy to work on, which is why I built a bracket to use a poly GM transmission mount on the back of the R154 transmission. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

-

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I've got the room for sure so I was actually doing a V-mount intercooler set-up. I'll definitely see what I can get away with, I just keep my expectations low so it's easier to be happy. That's assuming gas is still available when/if the car is ever done. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I have seen some crossover alternatives on the interwebs, mainly people replacing them with braided hose, but I prefer ARZ's solution with using bigger tubing. I heard about the pick up being too short as well, seeing as I was planning on adding kickouts and trap doors, that's already something that would have to be checked. I also heard about welding up oil squirting holes in the connecting rods to prevent pressure loss, or using aftermarket ones without the holes. I figure any motor is going to have it's own problems that needs addressing, nothing is perfect. I have to admit, when I first received the engine my plan was completely different. I was originally thinking of a high-revving N/A motor with DCOEs and custom valve covers to make it look more like a flipped image of an OS Giken/S20 hybrid. I've never had a power-adder before and I figure after you get used to it you'll just be craving more power. So with the turbo I can start out with 5lbs, then when that gets boring I can go to 10, and so on and so on. Back when I bought the GTX35, mathematically it should max out around 25lbs and still be in the 'efficient' range. I've been thinking up to 15lbs on pump gas, then go up to the 25 mark with pump gas and meth injection. Always been a firm believer that street cars don't use race gas. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I think it's getting out of hand and starting the de-evolution of man. From what I've seen, the amount of people who are capable of thinking is getting smaller. Sometimes I wonder if that's the intention, stupid people are easier to control. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I'm interested in seeing what I come up with too, haha. I have a couple plans in mind, but I've learned that plans end up changing along the way. I need to go to a local machine shop and see if they can make me a couple pieces of 3/8" steel with the holes cut for the Dodge hub so I can have something to work with. People are always needing something on my days off though, leaving little room for myself. I highly doubt I can make anything as light as Nissan, I just hope I don't make anything too excessively heavy. I'm 27 now and never came across a situation where I wish I had a smartphone. When gas stations stop selling maps, I might find one useful, haha. When my laptop from 2007 died 1.5 years ago, I got an 11" tablet with keyboard for half the price of a new laptop. I can't stand the touch screen stuff, very hard to control. Even the 2015 Tacoma I bought has a bunch of fancy stuff I can't find a use for. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

What kind of issues have you had with them? I only really chose the motor on 4 accounts: It's still an inline 6, the exhaust is on the passenger side (more room for turbo), at 3.0 litrs it's a really like a big motor in a small package, and it's cheap. This is all I have done motor-wise so far. I started on the exhaust manifold one day when I couldn't afford parts. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

It's a 4" pipe with a 3.5" opening and I'll be using 3" exhaust so as long as I can get the bends right it will have 1/4" all around it and I will add a bracket close to it to prevent rattling. I set the 7M-GE as low as possible and the R154 transmission was bigger than I expected, so I'm trying my best to make sure the exhaust isn't going to be dragging on the ground too much. I'm planning on adding a Y under the driveshaft where it will become two 2" pipes so they'll tuck up under the sides of the 8.8" better, and then cross-over to a Z432 style muffler. -

Getting back to it. Working on the Z again.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I'm actually not that concerned about adding weight, it's going to be more for daily driving and cross country. Placement is more of my concern. The car was so ate up with rust that it really shouldn't have been attempted, and modifying is a lot easier to factory restoration. That small section of the stock subframes you see there by the rear wheel wells was pretty much the only salvable section, and I even had to patch the bottom corner of those. It's got all new tubing from very front to very back, even the section below the tail lights because of some rear end job that someone from decades past had filled 3 inches of bondo in. I've cut out a surprising amount of weight too. You know those threaded holes for the top of the doglegs for the rear suspension? Did you know Nissan tapped those threads into fairly large pieces of what seemed like 3/8" thick steel that spanned over both holes? That's pretty good engineering because those were the only bolts that didn't break off on me, haha. I was shocked at the weight of it though when I cut it off, there were quite a few areas like that. Jan. 74' if it matters. As for suspension, I'm actually quite fond of Nissan's lightweight design so I'm not really deviating too far from it. I want to make my own uprights using 2001 Intrepid hubs and instead of one big bolt on the bottom, I want to make it two smaller ones bolted in double shear. I also like JMortensen's design for the rear control arm in this topic. http://forums.hybridz.org/topic/122993-adjustable-rear-lca/ and I'll probably end up using Arizona Z car coil overs with their front control arms too. Yeah, I'm still old school. I use a $5 flip phone that doesn't download anything except for mono-tone ringtones. I have 270 photos of my progress on my Facebook page, just keeping an online record incase I have computer problems. I feel records are important. -

I have taken a very long hiatus, longer than I care to admit, but I finally overcame my laziness and got back in the garage. I thought I'd share some of my progress, especially since this site has slown down WAY more than I could have imagined over the years. Remember when there were so many new posts being made that you could read for hours and hours and hours and never make it to the second page of results? Those were the days. I'm going to stop reminensing and post some photos of what I've done lately.

-

I just came across this video and though of this post. The results were surprising to me.

-

Car update with advice need on roof approach.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I couldn't cut up a donor car like that, especially knowing that car is likely to have been a lot better shell to start with. I've always wanted to learn how to use an English wheel, it's just been too slow at work to justify getting one. For the time being I went back to working on the bottom of the car again. -

Car update with advice need on roof approach.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

Where do you even get one? -

Car update with advice need on roof approach.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

So far I'm thinking about blowing the dust off my oxy-acetylene torch, getting some mild steel rods, and using that to weld in new pieces that I'll make. I have some scrap that I can practice on. Then I can use my new hammer and dolly set to planish and stretch the beads out, that is if the slapper will fit between the roof skin and sub-frames. -

Car update with advice need on roof approach.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I should also note that I made sure to have a complete new "frame" from to back before putting it on the rotisserie. I didn't want it to bow. And sorry about the photos, I have the cheapest digital camera you could get from Walmart 3 years ago, but if you see the marker marks, I circled the rust and put "L"s in the low spots. -

Car update with advice need on roof approach.

AkumaNoZeta replied to AkumaNoZeta's topic in Fabrication / Welding

I was pretty anal about it. Took me 3 days to get the twist out of it, and brace it up, before doing any cutting, and everything I put in is straight and square with exception to the the factory front crossmember I welded back on. It's an 1/4" out of square from it being 1/8" off from left to right, but it doesn't match anything anymore so down the line I'm going to cut it back off and make a new one for heimed control arms and modified rack mounting. The hatch itself open closes fine, I bolted it back on last night actually, and has a perfect gap down the passenger side and across the top until it get to that big, holey dent. And the driver's side gap narrows in the center with the corner of the quarter being 1/8" shorter than the corner of the hatch. I'm just assuming the damage is related, probably happened before I was born so it may be from seperate accidents. Maybe I should try CarFaxing it. Haha. The good news, I'm 80% sure the fenders and hood have already been replaced with new ones because there's no signs rust or dents by looking on the back sides. -

Well, I'll start off by saying I haven't been on here for YEARS so none of you probably don't know anything about how it's been going. Well I'm happy to say it's finally on a rotisserie, has been for the last few months. When I bought it, it was a clean looking early 260Z with an L28 and 4 speed. I drove it around one day and I couldn't get it running, never did until I put a E12-80 distributor and 390 Holley on it. After a few months I starting nit picking, literally picking at bubbles in the paint and finding lots of bondo and quite a few holes. Drove it for 2 years with no wipers and having to jerry-rid the front torque boxes to keep the T/C rod from bouncing off the pavement when you hit the brakes. After I got another car to drive I started tearing the Z down to the nitty gritty with everyone I know telling me I'll never get it done, which made me work harder on it. Well it turned out that there are no floors, what was there was nothing more than tin foil held in place with screws. There is no outer rocker, and only half the inner rocker was salvagable. Someone has fill in the cavities with expanding foam with duraglass over it, and finally the bondo and paint. I have to give it to them, whoever did the body work before was damn good at shaping bondo. I think I'll just let the pictures do the rest of the talking. At the end I'll show my concerns about the roof and would love to get any tips or advice. Here's the roof. This is BAD, but not my main concern. I should note, on the back of the car there was 3 inches of bondo where at some point in the car's life it was rear-ended, Hard. This shows how far the damage traveled. This is my main concern. It's got heavy surface rust, big pits but no holes yet. From the passenger side there's a 24" long strip of it, the a 2" clean spot, 4" of rust, 8" of clean, and another 3" of light surface rust on the driver's side. I'm thinking I'm best off replacing the entire roofline there, but I'm afraid of messing something up and the windsheild not fitting right anymore. Plus in my opinion any blemish across the hood and roof will stick out like a sore thumb. So, anyone have any input?

-

I've always wanted like a 71 or 72 Celica liftback, but with a V8 in it since it has the classic muscle car lines.