-

Posts

779 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Lazeum

-

I don't understand the benefit of those portable blasters Don't you need to have a compressor also behind? the gun looks very similar to the one I use to blast my part in a cabinet. So I do not see any benefit besides the tank to store the media.

-

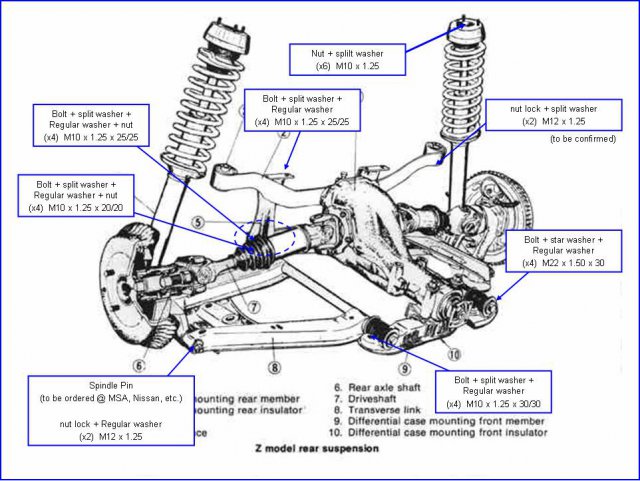

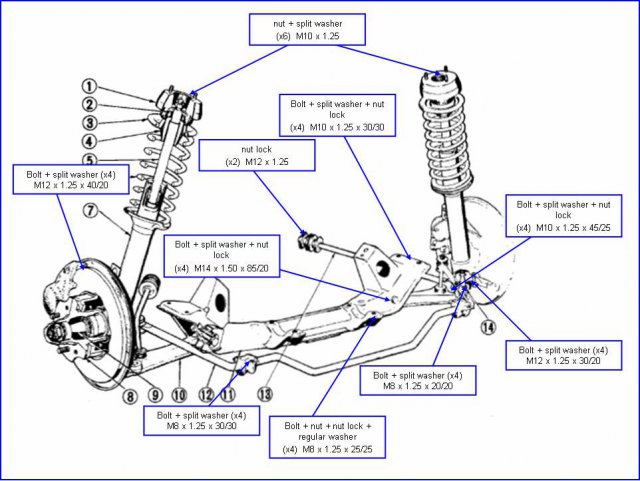

Suspension Bolts - Inventory

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

-

Burning oil in #2, looking for suggestions as to why...

Lazeum replied to BrandenZ's topic in Nissan L6 Forum

No problem... I've mixed Carl and Andy. I'm buying too many things and I'm mixing up names... (Andy is the tool guy selling me Chicago Pneumatics tools in UK ) Carl (since it is his real name this time) received some orders from me on Monday, parts were at my place on Friday on the other side of the world Shipping is usually quick! -

Burning oil in #2, looking for suggestions as to why...

Lazeum replied to BrandenZ's topic in Nissan L6 Forum

No problem to share the email here since it is the one you can find in the contact info on the website. info@clarksdiscountautoparts.com Please, tell him you're coming from me: Mathieu in France. He did a good job so I believe it is good for him to know that happy customers spread the news about it -

Burning oil in #2, looking for suggestions as to why...

Lazeum replied to BrandenZ's topic in Nissan L6 Forum

I had very good experience with Andy Carl from www.clarksdiscount.com even if I was in France. His service was spotless, quick & very responsive. Not sure thought he would have cast rings alone. You would need to check. Since he's carrying ITM pistons with cast rings, you might find what you're looking for. [edit]: found this on the site -

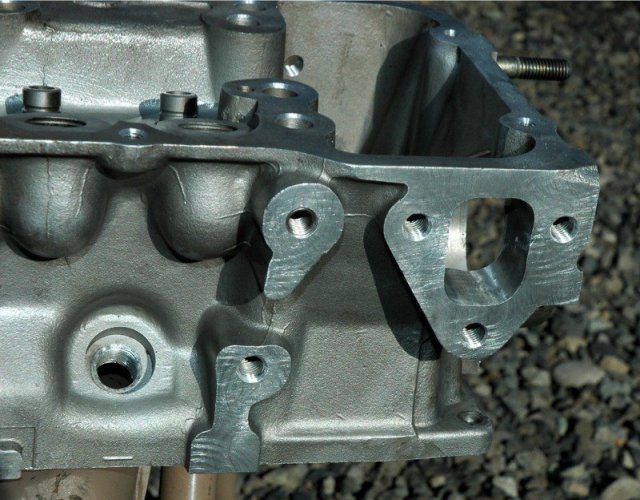

I would try to blast them with baking soda if you already have tools to blast. Regarding glass bead, you have sharp ones and ball type ones. the sharp one will make your part clean, the other one with bring you a nice finish Here's my intake manifold, before/after. On your trottle body, I would not do this way if you cannot be 100% sure cleaning would be done fine.

-

We've managed to contact all the Datsun teams including Brad We'll try to schedule a dinner within the Datsun group in Reims We might also have Nissan France part of the trip with us. Last year, they came with a GTR, we had a dinner also and they've enjoyed it.

-

It needs to be tuned, lowered a bit, cleaned up and it should be a fun car. We should see the car at SPA Classic, Le Mans Classic and other classic races in Europe.

-

I don't think what you've stated is right: those studs (like rod studs & head bolts) should never be stretched past elastic/yield strength. If you tighten them past elastic mode, there're going to snap them under load & inertia from pistons since there're going to be in plastic mode. So those bolts are reusable since you should never go beyond critical stress on those. However, I come to the same conclusion as you do: it is cheap insurance. I did not do it however on my rebuild, I only did rods (notorious from being the weakest link in the bottom end) & head studs.

-

I've just seen your post The owner is not on this board but I know him. Setup as far as I know is: F54/P90, Sprintex supercharger @ 6psi, Emerald ECU with EDIS. It is an original Sumo ZX which apparently used to race in the UK. And if you'd like to see more pictures of the engine bay =>280ZX Sumo on Datsun-France

-

Since I'm the "quench story" as well. I believe it is important to tell that head gasket thickness should be checked. My personal experience shows me stock (Ishino) or Felpro are having a quite similar thickness.

-

best wheel option for orange 260

Lazeum replied to camilo's topic in Brakes, Wheels, Suspension and Chassis

or Minilite in black? -

A friend of mine tried with an arc welder. In 20 minutes, you might be ok but I'm not responsible for any conequences that may occured

-

Then you definitely need to find a good tuner Good timing solution would also help to get better mileage at part throttle. Good luck with your project!

-

-

To give you some more motivation, here's the result of last weekend: front bumper brackets after 5h sitting in electrolytic bath and 20s literally with wire wheel (not the small one on the picture) to clean up the residues, paint included.

-

Machinist has been fair with me. They've already proposed to fix everything at no cost, except piston since I'm the one sourcing them. I agree they should pay for them but they believe it is acceptable to have one piston lower by 0.2mm versus the rest and have the remaining piston machined. I disagree since I want the piston to be ok so they've proposed to machine for free 3 more pistons: 1 to get better clearance than current piston #1, 1 new to fix the bad piston & 1 to machine the forgotten one. All and all, it is going to cost me 100€ to fix this situation. I'm probably too nice but 100€ won't change much my budget to restart this engine. On European engine, "quench distance" at 0.3mm is acceptable and they believe I would be also on my engine. So far I'm trusting HBZ more than my machinist so I stay with original plan and 0.022" min clearance (0.6mm). Regarding part marking, they've done it but before and after. Since one piston was missed, there was no in between marking "after" was already there I know: Lame!

-

Since it is never going the way things should go, I have a new situation L Machinist mixed up pistons and as a result, he forgot to machine one piston and machined 1 piston twice. One f the remaining pistons is a little out versus the good ones. Outcome is: - 3 pistons are protruding over deck surface at 0.20mm (0.008â€) which is perfect with Felpro gasket - Piston #1 is 0.13mm (0.005â€) over the deck. I call this one acceptable - Piston #2 is untouched, it protrudes at 0.49mm over deck surface – easy to fix - Piston #4 is exactly at 0.00mm over deck surface, which is not good. I’m concerned I cannot use piston #4 as is since compression ratio is out, weight is not OK, quench (= mix rate) is out compared to other pistons. What would you do? please consider I’m in Europe, - Will 0.2mm height difference on 1 piston change anything, could I leave everything the way it is without being bother? is it safe? - Remachine all pistons to 0mm deck height – quench distance would be 0.9mm (0.035â€) – quite high I’m going to lose engine efficiency and quench benefit - Order one new piston to redo the “bad†one - Leave the engine the way it is – it is even possible??? - Should I worry about piston #1 at 0.13mm? I believe if I order a new piston, I could order a second one to fix piston #1 (maybe!) I need to take a decision. So far, I’m leaning toward ordering new pistons. What’s your call?

-

Burning oil in #2, looking for suggestions as to why...

Lazeum replied to BrandenZ's topic in Nissan L6 Forum

I know it costs money & time but you should check everything such as cylinder bores, honing condition on bores, piston clearance, etc. or problem might come back soon. If you replace the rings, make sure your pistons are well clean otherwise you have some more problems in the near future. I had issue with my engine and I'm currently rebuilding it, it is a very demanding process but I encourage you to do it right. Since you've removed pistons, I would also change rod bearings at least with new ones -

Despite risk of damaging pistons & pins during teardown, we've decided with the machinist to give it a try (new pistons would have been as expensive as a new gasket anyhow). They did it carefully with no damage So pistons have finally been milled down by 0.3 / 0.4mm, I'll pick them up tomorrow. Hopefully engine will be built very soon with no more road block... I'll let you know the outcome. They even gave me a rebate from the initial quotation @ 130€.

-

I've called the machinist. Cost would be 15€ per piston for milling and 14€ per piston for pin removal & install. I end up with a total cost of 174€, not worth the hassle of ordering new head gasket. I'll drop everything tomorrow

-

To check rods is very doable. I see no reason not to check them so it will be done. and... happy new year to you guys and thanks for insights on my rebuild, it is always appreciated

-

crankshaft journals have only been polished, no machining on them so everything should be as new - meaning as it was when it went out of the factory, not perfect. Rods haven't been touched, they are stock rods with no work done on them. So Only pistons are not stock on the bottom end. Block wasn't straight so it has been decked (hence the troubles with the head gasket) I'm not building a F1 engine that goes over 10k rpm so I call it a day. The "while I'm at it" syndrom is very true - that's why all parts have been derusted, galvanized/painted/polished or shot blasted, front & rear suspension torn down, bushings have been changed, wheel bearings also, same goes for ball joints, steering has also been reworked, suspension bolts are all brand new, etc. all of this is due to a bad oil pump

-

For your info, I've measured up to 0.1mm between pistons. However, I don't know where it is coming from: crankshaft rod shaft center lines? rods length? pistons geometry? pin differences? block deck not fully flat? Measurement error? I believe at some points, I have to ignore this variation. It is a street engine. I try to do it cheap (if I can say so... ) but especially right but it hasn't have to be perfect at all cost if it not worth it. 0.1mm variations of stack between multiple machined parts sounds very acceptable to me. I will however ask the machinist to remove the same amount of material between pistons so variation will remain.

-

...or the new Felpro gasket I still have in stock