-

Posts

779 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Lazeum

-

Weber jets??All who live for their triples please read this

Lazeum replied to datfreak's topic in Nissan L6 Forum

Changing venturis are creating less vacuum at the lowest section. Hence, you need bigger jets to keep the same AFR ratio, so getting a leaner engine with 32mm choke is normal versus 28mm. 32mm vs. 28mm is a big step. 10.8:1 is very rich, you should 2 points higher to be ok. What it could also mean is your engine would not be able to pull enough air to make the 32mm venturi working properly. Somehow I doubt it and you would suffer such behavior only at low rpm. Since I've never tested such combo (only modified engine - I've never touched a stock L-engine ), I cannot prove what I'm writing. If you're using an LM2 unit, you should record some data and post them here. We would be able to spot other problem maybe... Regarding the dizzy, service manual is saying 17° at idle with no emission control (round tops?) to be around 36° total, so your unit is probably ok. Anyhow, I still believe you might have something wrong elsewhere (meaning not at the carbs) but since your description of the problem is vague, it is hard tell anything more -

Weber jets??All who live for their triples please read this

Lazeum replied to datfreak's topic in Nissan L6 Forum

Have you recurved your stock dizzy to get 20° at Idle & 38° total without vacuum? I see Durrag answer and I support his toughts, how do you read AFR? (if it is done with a narrow band, it is useless to talk about anything but +/- 14.7:1) You've talked about kick-in, that could be linked with idle jet eventually if it happens at low rpm. If it is at high rpm (>3500rpm) it would be related to other jets and I don't think you would suffer really bad performance with your setup. -

Nigel, I have reviewed your setup, I thought your VR sensor mount was bolted on the engine block which isn't right. It might work good this way, I trust you. I see you also have a 1 row damper which makes the mount smaller as well. something I don't get is why you've chosen to make a separate support to press the wheel on. Wouldn't it be faster to make a new wheel with the correct bolt pattern to get 1-piece wheel instead? Is it a problem with runout maybe? fabrication issue? I'm gathering parts for now (as well as enjoying my Z while weather is good and the Z in good running condition - which is not so often!) but I might have soon to remove the damper to look more closely about opportunities Your setup might be the way to go for me. I have access to laser cutting option to make parts from some suppliers.

-

Weber jets??All who live for their triples please read this

Lazeum replied to datfreak's topic in Nissan L6 Forum

I think it is odd to not be able to rev freely or have an AFR of 17:1 with such jets. I don't think it is related to jets or venturi. I think you either have to make correction on timing (timing very off could make false AFR reading) or to check fuel level in bowls or to check if needles jets are not damaged or air leaks or loose parts, etc. -

Regarding Derek's solution, it is very clean, it looks fanstatic but the damper I have is not the correct one. So I either have to change it and get Derek's parts or design (since I'm not sure he's still doing some) Nigel, I've been looking at your solution already and this is what I expected to do but the distance between the wheel and the block where I was expecting to mount the VR sensor sensor support is important. I am fearing some vibration issue with such a long arm. So your solution is what I would have done and your feedback is what I'm fearing

-

I'm digging up this topic I'm thinking about going with EDIS also on my setup with Megojolt. I've got questions about the pictures above. The damper currently on my engine is the same unit (2 rows from 280zx apparently) The wheel is on the outer "cage" of the damper. Shouldn't we fear some erratic signal with incorrect timing due to damper movements/action? How are the movements from the damper, by the way? it could be a rotation (bad for timing reading) but it could also be a radial movement (so no impact on timing or very minor but on clearance between VR sensor and wheel). Should we instead consider a wheel to be bolted on the 2 holes available on the damper? Those are M6, would they be sufficient to hold the wheel? Regarding pros & cons of the 2 solutions, the first one seems better from a dimensional stand point (runout of the wheel is probably very good), second would provide more stable reading since wheel would be connected to damper hub directly. However, good wheel position will be difficult to achieve. I'm wondering if I cannot ask my machinist to machine the 2nd row on the damper to make the 36-1 pattern directly on the damper without using a wheel. I should achieve the same results as the wheel pressed on. Akeboshi, would you have a feedback regarding your build since then? Any feedback?

-

I will disappoint you but I got the car back then when I was living in Michigan. When I came back to France 4 years ago, I took the Z with me. I'm driving the Z mostly outside of Paris in the country side where twisty roads are (with no traffic jam). We are quite a small community in France with Z & Datsun and we met quite often. Next meet is a Le Mans Classic where we rent a spot right next to the track witht he help of Nissan France (which will get track cars from the club on display). Marketing manager is fan of Datsuns & Z, that helps! For reaction, Frenchies do not know what is a Datsun (they believe I'm driving a Jag, a Ferrari or an Alfa Romeo) & they don't believe it could perform well. When they hear the sound of the L6 with DCOE, they all ask what under the hood and who build the engine. Forums & technical discussions as deep as the one we have on hbz are not common in France, especially on old cars. Let's forget about wideband controller, MSe, turbos, piston shape, quench, flow and so on. It is also illegal to mod a car, so there's no support for parts in France but we have a least some competent machine shops who know their job. I'll stop the off topic, here's just a picture for fun.

-

Steering Shaft Play in column

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

That's great info. I went as far as removing the snap ring on my previous column but nothing was moving. I did not want to destroy it. I'll give a try and see if I can go further next time and get rid of the little shaft play! Thanks! -

I've just rebuilt my engine this winter with machine work done on crank, pistons, block, etc. It was my first engine! (and not the last, I loved it) So I know a little how it is done, so I appreciate the work done! Mine is now roaring under the hood, it is quite a good feeling

-

Your build looks nice! I love the attention to details! It shows how intensive an engine build could be. It is not as simple as "I change the pistons diameter, I change the rods & the crank & I'm done."

-

Steering Shaft Play in column

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

The u-joints are fine. I've checked them carefully, there's no play in them. It's ironacal but I'm working in automotive steering company and it would be fairly easy to find some u-joint replacements in such case There's definitely something going on inside the column jackets but I have no clue why or how to disassemble the system without destroying it... -

I'm having some steering shaft play in my 240z. It was the case before so I've changed the column and the play is still there with the same exact amount (2-4° maybe) - if you check in the history, you'll find my post to get a replacement. I know it is the column since I've taken it apart. I know it is from the column since I've tested it. I put the yoke that clamps on the coupler on a vice and turned the shaft on the other end with the steering wheel attached. It is hard to feel without steering wheel but it is possible also. What's weird is: 1- That's the 2nd column with the same exact issue I've got. 2- Nobody on this board mentioned such issues (based on my researches) In addition to having some play, it amplifies vibrations in the steering wheel on bumpy roads & the steering feel could be improved. If I could get rid of it, it would be nice. I've tried to disassemble the column to check it out but I wasn't succefull. I believe the splines between the upper shaft & the lower shaft could be damaged. I can only look at splines on the lower shaft that slides out of the assembly easily: everything look like new. I've checked other Z car whenever I had the opportunity. I felt the issue on other cars so I shouldn't be the only one in this situation. What's your feeling about it? Any solution?

-

I wanted to say the same!!! it is quite amazing as well on my side The Z went back in the garage with its own power!

-

You need a tach adapter My weekend was about getting the fuel tank out to recover from the dumbest move I've ever done on the Z. It was 3 years ago when I made an attempt to protect my fuel tank against rust with paint. This is the crap I get off the tank I've already removed most of the stuffs 2 years ago. This stuff made me stop 3 times on the side of the road with no gas going to the engine....

-

Weber jets??All who live for their triples please read this

Lazeum replied to datfreak's topic in Nissan L6 Forum

If you look thru the post, you'll see that I was running 32mm chokes with L28 / N42 + flat tops with mild cam (MSA stage II). The outcome was good even if I was outbreathing a little my carbs. Changing the chokes will cost you some significant amount of money. I would first check if you like the behavior of your current setup (does it rev freely to high rm?). I would try to change main jets to see if it helps. If you're at 10.6 at WOT, definitely drop to 120 instead. Make sure also that your timing are ok, they can foul you. At 10.6, the tip of your exhaust should be very black. On a side note, by increasing the choke size, you'll reduce the vacuum. It will require the carbs to pour more fuel at idle, idle jet would have to be increase, not decreased. It depends of course about how your current setup is. -

The holes on the crank are normal, it is to balance it. Being in the US, I would try to find another one.

-

I used to run a Carter 4070 unit. Very capable but very loud. Some have reported it as being not so noisy so I guess it depends. I now run a Mallory LP4070, same capacity and much quieter (very audible though with engine off). It is also more expensive. For some reasons, my fuel system is not working properly. So I've got some doubts about the Mallory unit that have yet to be demonstrated (it could very be a clogged fuel line). Fuel has never been able to go above 2psi but flow was good (now there's no pressure and no flow) Another alternative could be a Facet Redtop pump that is not so loud. there are other brand also available that would suit your needs. You need to know the power you're expecting, deduct the flow required and choose one.

-

Sure, I care English is not my native language so it is always good to clarify confusion.

-

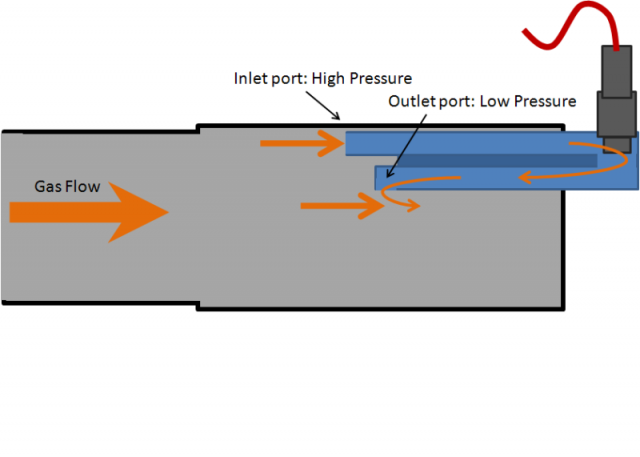

Looks like fun When I was talking about swing, I was talking about variations across rpm range at WOT or during accel event.. If that could be of any help, here's how the Innovate clamp works. Your system is most likely ok for high rpm (> 2000rpm) but not for idle (but who cares since we do not setup idle with a WB anyway Since inlet port is at higher pressure than outlet, Innovate clamp sucks the exhaust gas towards the sensor making the reading much more effective very effective at exhaust tip.

-

Something looks not ok. I would disassemble and check again. The 2 second picture looks quite right, not the first one. I would check proper bearing position (nut should press them tight against shoulder with torque), threads condition on spindle, inner bores of knuckle assembly, etc.

-

Your lash pad seems to be broken... I see the seating face moving while the top isn't. What is the valve clearance on this particular valve? Don't you have a contact between the rocker and the spring seat?

-

I haven't been on the market for LM1 for awhile... they are indeed more expensive than LC1 (quick search made the LC1 with no gauge at $140 vs. $250 for LM1) Regarding LC1, there's a output signal to be recorded but I don't know how that works (do you need a another Innovate tool for that such as LMA3? ) I have swing with my carburated engine. I run 3xDCOE however and my AFR curve is not flat at all. Â

-

I don't understand why you do not get a portative unit as the LM1 or LM2 from Innovate. If cost is an issue, LM1 could be get for cheap nowadays. For your info, LM1 & LM2 units are getting power for cigarette lighter so you should be fine with your setup. Innovate is making a very smart clamp to hold the O2 sensor at the tip of the exhaust. It is not cheap by any mean ($75) but it is clever & doable if you have some welding capabilities. I've purchased it after many months of hesitation, I don't regret it. The best feature you need when you're tuning is recording capabilities since you do not see all variations recorded by the sensor with a gage.

-

People will come back with no "best" but I've asked the same question to Paul when he was building my head. We came to the agreement to use a P79 slightly milled (around 1mm) with stock valves, ported/polished/shrouded + a street rebello cam with assymetrycal profile. Below there's a F54 block with flat top pistons. Clearance between pistons top surface and head is also critical. Only difference with your potential setup is the use of DCOE.

-

It will also help me to believe it is very normal. I'm going for a 300mi road trip weekend, hopefully the engine will remain in one piece