-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Naptown Dave

-

Progress report and advice

Naptown Dave replied to CrayZ's topic in Gen III & IV Chevy V8Z Tech Board

Sunny, it was the 10mm straight thread I was worried about, it's the inlet and outlet for walbros. -

Progress report and advice

Naptown Dave replied to CrayZ's topic in Gen III & IV Chevy V8Z Tech Board

I just looked at my Speedway Motors order and realized I ordered the 26" x 19" radiator part# 917340-26 . Anyone want to guess how wide the subframe is at the core support? 26" I doesn't matter cars are stupid anyway I'm gonna sell all this bs and take up knitting (bad car day). I'll let you know about the fit and quality on Wednesday -

Progress report and advice

Naptown Dave replied to CrayZ's topic in Gen III & IV Chevy V8Z Tech Board

Brakes, fuel system and intake look awesome! What fittings did you use for the pumps? I used some Russell 10mm x 8an but the 10mm side is not a tapered thread like a NPT. I just teflon taped the crap out of them and screwed em in as far as I could. Hopefully they won't leak, is that what you are running? I don't have any experiance (yet) on the radiator or cai. I did just order a LS swap radiator from Speedway. I'll be watching! -

LSx s30 Longtube group buy thread

Naptown Dave replied to 1 tuff z's topic in Gen III & IV Chevy V8Z Tech Board

Cheechq, Speedway motors makes a metal plug for that sensor port for $20. I don't know how tall it is I just bought one yesterday and should be here tuesday -

Finished the primaries on the passengers side last night and the drivers side tonight. I had to put a miter in the primary closest to the mount on each side, I'm debating trying to bend a short piece of tube at work next week. It would look better for the pictures but since I'm going to have to wrap them it probably doesn't matter. The first one on the drivers side sticks out a little more than I like but my steering shaft won't let me tighten it up any more. I'll get the primaries on the drivers side cut to length tomorrow. The drivers side was a little easier than I expected, mostly becaues I offset the engine to the passengers side a pretty fair amount. Looks like I may have to rethink my 5" ride height! I think I have about 12-14 hours into these right now and probably another 6 to 8 to complete.

-

I love it when I find dumb s**t I miss, I changed the oil pump in my 70 Camaro years ago and was about to refill with oil when I found the pan gasket laying on the cowl! When you go turbo you should sell me that LS6

-

I thought it looked familiar! That car came up for sale about two months after I bought mine and it sold before I saw it. I was pissed that I missed it. I bought a thousand dollar basket case (its not that bad) and your car looked like a really good start towards where I wanted to be for less than I could build it, and about an hour from my house! Send me some or post some pics of your mounts maybe even with a tape measure to show size & location. I wouldnt mind selling some economy versions of the stainless longtube thread headers.

-

CrayZ , yeah I built my own mounts. They are about 3" at the widest point. I don't know what the JCI mounts look like send me a couple pics with an overhead and profile view. I have my engine with the heads about 2 1/2" from the firewall and offset 3/4" to the passengers side. Let me know where your engine is placed. Did your car come out of Indiana?

-

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Matt, If I can break even on costs and you get rid of some parts your not using I'll be in. You can add a little cash to the turbo fund! I know your car dosent have a bumper thats why that big chrome anchor would look so sweet, just think of the extra traction you'd get! Sunny, I did a little research on bearing vs bushing and it seemed to be about a 50/50 split on what guys ran. I just decided to run with what the factory installed. If anyone has any strong opinions I'd love to hear them, I have to pull the engine at least once more to get my headers in. -

Made a little progress last night. I need to grab a tig machine from work for the weekend and hopefully finish. I don't think I will have to worry about my starter getting cold, there is about 5/8" clearance from the back two tubes. I hadn't planned on wrapping these but I think it's going to have to happen. Before you ask that is nascar certified header fit up tape, you can get it at Lowes for about five bucks. The toughest part of this is trying to hold the tubes while measuring or tacking, I need to come up with some kind of magnetic clamp or something. 2013-07-10_22-09-07_885.pdf 2013-07-10_22-09-28_515.pdf 2013-07-10_22-10-10_754.pdf

-

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

I hear ya Matt, really all I have left to do is everything. It seems like the clock spins a lot faster as soon as I hit the garage. I think I'm gonna shelf my wide body mods until winter and just do what I need to get it looking decent. I have yet to double check my driveshaft length to make sure yours won't work for me. I was thinking if the price was right I might want to get it from you and just have a local shop shorten it for me. I have a sweet almost rust free '75 rear bumper I may be willing to trade lol! -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

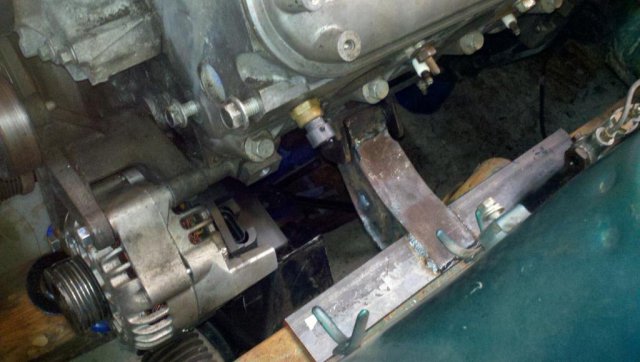

I haven't updated for a little bit buy have been making slow progress. Recieved my diff output bearings and completed the OBX installation. I put the diff in the freezer for a while to shrink it a little to help get the bearings on and then heated the bearings with a heat gun until they were hot to the touch (with bare hands). Two light taps with a 12oz hammer and a socket that fit the inner race and they dropped right on. I had a little more work setting the backlash, the new diff was really tight getting in and only had about .001" backlash. I measured the right and left shims and found they were about .006" different so I swapped the sides and carefully sanded the now left hand side, this resulted in .008" backlash at the tip of the ring gear just a little more than the .006" the open diff had. The OBX preload ended up at the max tolerance, I assume that will wear in a little.. I pulled the engine back out to weld in the mounts and clean up and paint the bay and make a new battery box. I realized that I had pulled out the steering rod before placing the mounts so of course it was hitting the drivers side mount! I spent a little time grinding the mount to fit the rod in and then reinforced the mount with some .75" pipe and .125" steel, back in business! With the motor out I installed new clutch and brake masters and replaced the brake booster. I'll route the brake lines once I get my headers built. I got a pilot bearing for the T56 from Summit that listed the LS1 as an application. It turned out the bearing was for an LS3 and wouldn't allow my tranny to mate with the bell all the way. This is my first time assembling a clutch by the way. I did stop before I broke anything and did some research to figure out the problem. I read on a vette forum that a guys builder had the same problem but "fixed" it by getting longer bellhousing bolts and cranking it together. They couldn't get it to turn over so they figured they had a problem. It took out the crank thrust bearing and reluctor wheel in his new engine. Got the engine and trans back in, had to dress it out a little and I think it's looking sick! Finished up my fuel tank and coated it with Red Kote, mounted my regulator and started piping to the engine. I built some 280zx rear disc adapters at work, they still need a little tweaking but are gonna work out. Today I rattle canned the beautiful gold off the Rota D2's I practically stole from a guy while in Georgia. I'm gonna focus this weekend on finishing my headers and getting some rubber under this thing, I'm getting really excited! If you more experianced guys see any red flags please let me know. 2013-06-25_21-07-09_896.pdf 2013-07-01_00-00-02_354.pdf 2013-07-01_00-00-32_370.pdf 2013-07-02_00-10-17_864.pdf 2013-07-02_00-26-00_801.pdf 2013-07-04_00-59-23_976.pdf 2013-07-04_00-59-44_31.pdf 2013-07-10_11-03-50_207.pdf -

I got to a point where I can get started on my headers. I wanted to have all day Sunday to fit the passengers side so I could take them into work to tig weld this week but the wife and the lawn intervened. I started on the passengers side because I thought it would be best to do the easiest side. I spent about an hour figuring out a plan of attack and then started to cut the flange ends of the individual pipes to allow me to at least place then close to their final position. It looks like I will have to lengthen (vertically) the back two about .75" to clear the starter and lengthen the front two 2.75" to clear the back two. Three of the four will have to be miter cut at the bends to clear either the starter or motor mount. Other than that it looks like they will work, and the drivers side is starting to look possible as well. This is anything but a bolt in operation but for $200 with bolts, gaskets and O2 bungs I think the labor may pay off. 2013-07-02_00-16-57_317.pdf 2013-07-02_02-10-47_403.pdf 2013-07-07_21-05-07_102.pdf

-

Tokico woes.....

Naptown Dave replied to 2eighTZ4me's topic in Brakes, Wheels, Suspension and Chassis

Anyone have any updates on Tokico avaliability? -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Looks like 19 7/8" but I'll verify that by the end of the week when I get the drivetrain back in. -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

On the u joints? Of course I pulled the motor /trans yesterday to weld in my mounts and clean up the engine bay...I'll take a look tomorrow, I'm sure I can figure out what the spacing is. What would you be looking for for the shaft and cv's? -

The heat index in Georgia the day before I left was 120, it was like hell's sauna! You'll still be driving your Z when I have a couple inches of snow/ice on the roads though.

-

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Looks like 25 3/8" from the end of the tailshaft to the input flange. PM me if you think it would work. -

Getting hot down in Texas?

-

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Yeah I may be interested, I'll measure from the tailshaft housing to the input flange on the diff. -

Finally got back home from Georgia and got started. Started with the front suspension, painting and replacing worn/damaged parts and installing Toyota calipers and repacked the bearings. There is a mess 'o stuff in my garage I wanted to get my suspension back in so I could move the car a little to help have more clearance for the engine hoist so I started on the HLSD. I took my open diff to a trans shop to see if they could pull the bearings without damaging them, they gave it half a try and told me they couldn't do it with out damaging the cages, so off to Harbor Fright for a bearing puller. I got the passengers side of with no problem and started on the drivers side, it started off so to I ran the OBX unit inside to put in the freezer to try to help with reinstallation. The puller must have slipped and damaged the cage when I was away. New bearings ordered, 5 days out. I neglected to get the clutch bleeder from speedway so I just bolted the engine and trans together. I'm going to have to pull the engine after any way to clean up the heads and install the cam so the engine will be on a stand Installed the front crossmember and built a lifting bar for the engine and transmission. The lifting bar worked out pretty well, turned one way it hung the engine and trans at a good angle to slip into the bay and then turned 180 degrees it lifted it level. Placed the engine/trans in the car and spent a fair amount of time aligning the engine to the diff, I had string lines, levels,. I used the old trans mount from the Datsun, cutting it in half and boxing it in with 2 X 1/8" flat. I got started on the trans crossmember and should finish that today. I'll have to throw the shifter and drivers seat it and make some engine noises and bang out some speed shifts. I think I may have a cracked oil pan, will pull it and check it and weld it up at work tomorrow if needed.

-

Tri-Y header fab. The really hard way.

Naptown Dave replied to peej410's topic in Gen I & II Chevy V8 Tech Board

I had to bookmark that article, way too much info for me to digest in one sitting! Thanks! -

Tri-Y header fab. The really hard way.

Naptown Dave replied to peej410's topic in Gen I & II Chevy V8 Tech Board

Have you seen the Magnaflow X pipe muffler? I'm kind of interested in it myself. I would think you could add two small mufflers or resonators out back and still have a reasonable volume level. Headers look great! I hope to tackle my own pretty soon.