-

Posts

637 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ozconnection

-

notching/beveling/butterfly l24 block for valve clearance

ozconnection replied to rossman's topic in Nissan L6 Forum

Be aware that when you notch your block, you dont grind/file too far down the bore. Measure the distance from the top deck surface of the piston down to the top of the first compression ring land. When you have measured this distance, subtract a value of .040' or 1 mm (because of component stretching and flexing at high rpm's) and transfer this distance from the top of the cylinder down the bore and don't grind below this point or you might damage your top ring when you run finally the engine again. As for your unshrouding issue, you could use the locator dowels placed into the cylinder head. Get an L24 headgasket and lay it on your P90. If you can, push open your valves and see where they hang up on the gasket. If your careful, you can grind away the gasket until the valves open without tagging the gasket. A very slow process but it will work. Place the modified gasket onto your L24 block and you can now mark the block where the gasket doesn't completely cover the bores. This is what you need to grind. Oh, and dont forget to use your locator dowels in the block when your doing this...it needs to be accurate. Then, before you cut /grind your block, grab your L28 headgasket that you'll be using and see if it will be undercut anywhere. Like the boys already said, don't grind too wide or too deep. Cheers. -

Tony is in love with that E32 manifold! I must admit, if I could find a cheaper one than the one we saw, it would be mine already and when I'm done with it , I'd sell it to him for only twice as much . (The value of the Australian dollar on the international scene at the moment means that finding anything 'cheaply' isn't going to happen for quite some time methinks....buggar!) The two barrel intake manifold that is mentioned here is a later version of the E30 and P30 intakes seen on Cedrics, Glorias, Skylines et al , both JDM and other markets such as Australia. The P45 intake is designed for L24's with smaller internal passageways than the larger P53 manifold which was on L28's. Runner diameters were 30 and 32mm's respectively. However, with some mods and matchporting (to 35mm's), this manifold (P53) could be used to produce good power. I modified a P53 to accept a two and then a four barrel Holley carburettor with one then two adapter plates from Lynx. I used a rotary burr connected to a hand drill to smooth and streamline the internal passageways. I guess the only problem with this setup is the height factor. The darn thing wouldn't fit under the hoodline of a stock Z with two adapter plates and a Holley 4bbl. You could, if prepared, cut a small hole in the bonnet and add a scoop. I never had this problem fortunately because my car has a much higher hoodline than the Z. (I'm lucky I guess! ) But for a Weber or Holley/Motorcraft 2 barrel, it's not a bad setup if you're after something a little different and want it all sitting under the hood.

-

I just bought an N42 block and head the other day. The head looks like an N42 until I had a closer look and noticed that the intakes weren't notched and the head not drilled and tapped for EFI. Has anyone seen this and can anyone suggest why this N42 isn't like all the others I've seen? Cheers people.

-

Interest in custom distributor trigger?

ozconnection replied to Hotrodpez's topic in Nissan L6 Forum

Isn't this the reason why we move altogether away from timing anything off the dizzy spindle? My understanding of the situation is that to obtain the most accurate timing for anything, it was to be obtained from a crank angle sensor. Isn't it to do with gear mesh, the required clearances and backlash as the drive spindle rides up and down and back and forth especially at rpm, like Woldson said? As the parts wear, wouldn't the timing become less accurate? Would that happen with a crankfire setup? -

One of the many reasons people get into photography A lot has to do with light casting and camera settings!! Enjoy.

-

I made a strange L motor on sunday from spare parts.

ozconnection replied to Austin240Z's topic in Nissan L6 Forum

Dyno 2000...I have this too. How 'accurate' do you think this program is or is it good for Chevs Mopars and Ford V8 type engines only? Whats your experience? How close does it come when working with L Series engines? -

Can a head an manifold be overworked

ozconnection replied to smokingwheels's topic in Nissan L6 Forum

Um, er, yeah, maybe. Please help us to understand what's your aim and how we can help. At the moment, I'm lost on all this and it seems a shame because I can see that you're fairly passionate about something...it's just I'm not sure what it is yet... Cheers mate -

Gawd, that is lovely, how much is the washing machine? And then add this to the top of that eaton look alike (or is it?)

-

Yeah, I couldn't figure out whether that guy uses the carb as a throttle only or what? I can't really see the carb working at all properly mounted at that angle?! Perhaps he's using LPG or fuel injectors somewhere? Dunno. Custom built manifold designed to keep everything under the bonnet by the look of things, hence the angle. Still, it runs but I haven't seen any more vids of this machine. Love to see it down the 1/4 though! And the sound.

-

Something like this you mean? http://uk.youtube.com/watch?v=YBwWXD_Rq7Y

-

Oz delivered 240k's never came with 4 barrel manifolds. This ones gotta be jap spec only IMO.

-

I guess when your motoring along at 130+ mph, you could afford to try your luck with a little 'free' supercharging (Ram air tuning!). Great idea you guys had and one very few of us will ever get to worry about! It made sense when you said Andy richened the mixtures and the thing went harder at the top end. You'd never see this happen on the dyno and for obvious reasons. My searching around for 4 barrel intakes for the L Series came across the E32. A factory 4 barrel intake manifold and one very similar to the 'candelabra' two barrel manifolds (E30 and later P30's) found on 1970's Cedrics and probably some others. Rumour has it was used on an S30, but I can't prove or deny this. I do like the almost complete separation of this design and have often thought that if the manifold was built with 35mm runners instead of the P30's 32mm or the E30's 30mm ones, it might go a long way to minimizing charge robbing, especially compared to the Cliffords 1/2 and 5/6 cylinder runner configurations. The bends on the Nissan runners have a generous radius unlike the Cliffords runners. I have looked at the Offenhausers dual port offerings for the L4 engines. Why didn't they make one for the L6??? Doesn't make any sense to me at all. I do like the theory behind these manifolds and how good they'd be for street engines where superior low speed torque would be complimented by great top end power. Your thoughts? Now if you could blend these two ideas together, then you'd have a very good 4 barrel manifold IMO. There is probably something fundamental that I've overlooked but on the surface I like it. There is nothing like the consistancy offered by fuel injection. I hear you Tony. That's the reason I bought that throttle body. At 1000 cfm flow potential and without the restrictions imposed by venturis, I might get lucky with this one. Cheers

-

ITB's vs. Intake manifold in an N/A application

ozconnection replied to olie05's topic in Nissan L6 Forum

Can we use the terms 'Helmholts resonance' and 'organ pipe tuning'? From here on in it gets pretty heavy so I'm going to let the 'scientific' types chime in and explain this to everyone, including me, please! . It's for this reason why for any degree of accuracy in designing a 'good' plenum chamber, a computer software program is needed. But there are always going to be some compromises with a plenum type intake manifold. Why? Because the waves that are generated to assist with cylinder filling run in and out of tune as engine speed varies. Now you know the reasons why some manufacturers design and use variable intake manifolds, to keep this 'tune' in tune for more of the rev range. Couple this to variable cam timing and presto.....superb performance everywhere!! If built for max power, theoretically a plenum intake will beat an ITB setup. Most are not and are built as compromises or worse, as 'educated' guesses. A lot of written literature relates to the performance of Chev and Ford V8 engines. It's from this that the idea exists that ITB's can be restrictive. In these engines, cylinders are larger than 600 cu cms. Nissan cylinders are considerably smaller than this so there isn't the same flow restrictions placed on ITB's when used on our engines. In other words, there is minimal flow restriction as long as the runners and throttle body bores are of sufficient size and volume, which they often are, to feed the cylinder. Unfortunately, this style of intake cannot rely on plenum pressure wave tuning to assist in cylinder filling. However some tuning of ITB's can be achieved with altering manifold length, volume, taper and trumpet size and shape. -

Thanks Tony for your insight. I'm curious how you managed to get a predator carb under your bonnet line with some sort of air cleaner attached? I guess its probably a combination of low air speed in the Cliffords plenum along with the induction pulse 'soup' that's created that can either enhance or detract from performance. I also found a large degree of idle insensitivity on my holley ie a weak signal. I did manage to overcome this somewhat with a combination of altered low speed air bleeds and a shortened transition slot(s) for off idle tractability. As far as the rest of the induction system is concerned, I'm reasonably confident that there is an optimal port and cam profile combination that'll work very well. I doubt if anyone is motivated enough to try though, you and I included. Shame. I may decide to try the 4 barrel throttle body on my car to see how much it improves drivablility. But it would be a fairly expensive upgrade to a fairly sedate 'daily driver' even though it doesn't serve as one anymore. I bought it to use as a blow through setup on my 240C coupe that's being built as we speak. I have thought about buying an engine management computer that has the ability of storing multiple maps. I could use one map for the 330 and another one or two for the 230, the logic is that I can't drive both cars at once but I would need two 4 barrel throttle bodies. Buggar. A good security device though. I found that when I had the L20A in my car whilst the L28 was being rebuilt, I kept the turbo cam in it. It was a factory L20A ET engine. I ran it in N/A form at that time. The thing would buzz easily to 7.5k rpm with a very linear power delivery. When I put the L28 back into the 330, I decided to give the L20A cam a try. WOW, what a difference. A completely different car to drive, lots of torque down low, excellent if fact, but it hit a brick wall at anything above 4.5K rpm. Compression ratio, rod ratio, port and valve size etc aside, I guess the point I'm making is that you don't always know what to expect from a new combo until you give it a try. :burnout:All I need to do now is to take my own advice!! Cheers.

-

Do you think it was a deficiency in the carbs that you were using or the design of the manifold that was causing the top end power loss? How much time did you guys spend attempting to optimize those carbs? I have a 4 barrel throttle body with 4 injectors that I was seriously thinking of running (on either manifold) to improve on one variable if it was deemed the carby to be the biggest problem area?!. Are you sure you cant have a little look around for some dyno sheets or pictures for all of us (me in particular) to see please? Cheers.

-

Turbo Exhaust Manifoild Gasket ...Sealant?

ozconnection replied to Zraced...'s topic in Nissan L6 Forum

Have you established the reason why it's leaking? Sealer isn't normally used at this junction and I don't really think that it would solve the problem. It's time to take your manifolds off and run a straight edge over your exhaust manifold to see if the mounting face is true. It could also be that the manifold gasket was too old and just failed or that the nuts holding it on there loosened up or one of the studs into the head gave out. A few things to check and do. Don't use any sealer. Cheers. -

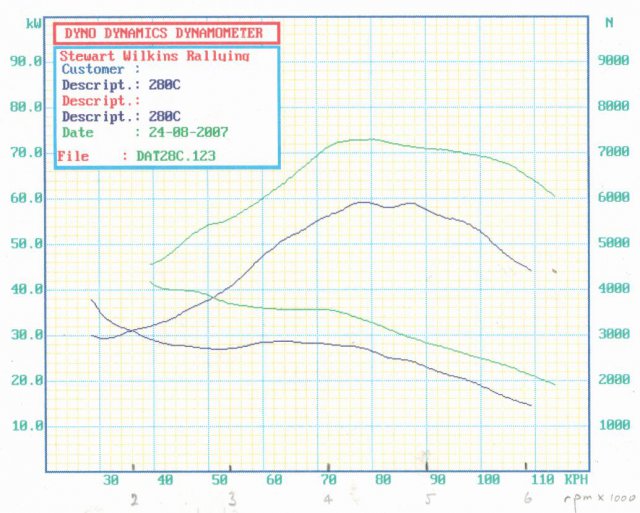

Tony, you mention the Mercedes 4 barrel manifold as a design done well. I have done some internet searching and discovered that the SOHC 2.8 inline six that was in the W114 had dual two barrel Zenith 35/40 INAT carbs. I also found mention of the Zenith 4A1 4 barrel carburetor(from an M110), so obviously there was a 4 barrel manifold but I cannot find a picture of it that shows it to good advantage. Do you have any photos/schematics/ web sites that can show me what they look like? So, without having seen one yet, why are they better than what's been designed for the L series sixes? Your comments about the Clifford 6=8 manifold is what I also found on the dyno. It has this ability because of the 'single plane' nature of its design, a large open plenum under the carb which unfortunately drops gas velocity and drops some fuel out of suspension along the way. As a redeeming point, it does have a large water heated floor to re-introduce fuel back into the airstream. Cold or hot, the engine first needed a good stab on the throttle to get the thing to start though! Power was good with an annular discharge list 9002 600 vac, but throttle response was better with a vac 650 reverse idle spreadbore Holley with just as much top end as the 600! A four hole spacer under the carb helped with the transition into the plenum but it wasn't until I built an aluminium divider for the Clifford that response returned. I'd changed the single plane Clifford into a dual plane! I bought an Arizona manifold for that reason, a dual plane manifold straight from the shop! A much smaller plenum helped heaps with throttle response but the top end was very limited compared to the Clifford (all else being the same). Reversion was a big issue with the Arizona and I had to have a list 4548 Holley custom calibrated to account for this phenomenon. But I would have to say that the Arizona is a great low speed torque booster if set up correctly. For the STREET, it's a good choice. (BTW, the greater curve on the dyno graph uses the Arizona manifold with a list 1848 465 Holley, headers and a 2.5 inch system. Compare it to the stock L28S and you can see the low speed torque increases for yourself). Thanks for any light you can shed on the Mercedes manifold.

-

Try these guys for your headgaskets. http://www.zccjdm.com/catalog.php/azcarbum/dt43033/pd858312/KAMEARI_L6_METAL_HEAD_GASKETS_

-

Yeah I agree, this manifold is far from perfect! I've seen these things pop up on ebay from time to time and some of them are not too bad, with the base of the manifold water heated (like the one you have) and what appears to be 'cast'. Also of note is that the plenum chamber is quite large on yours, so gas velocity will drop off quite a bit after exiting the carb, undoing all the good work done by the small venturi's in the Holley. Some of the better versions I've seen have a divider in it to separate the front three cylinders from the rear three. This really wakes up the bottom end of the rev range and is akin to the V8 boys' term "dual plane" manifold. So if you're keen, you could fabricate a simple divider and have a go. However, the carb will require tuning though, as the pulses that effect flow through the carb will alter the fuel curve requirements significantly. Jetting will get you close but often a Holley needs more work than this and it revolves around boosters, emulsion tubes and transition circuits. Not impossible, but I've had to make these changes to get my engine running exactly how I wanted it. This is often why guys who try and run Holleys throw them out....they fail to get the tune spot on by really understanding what's required, the problem with attempting to adapt a V8 carb to a small capacity six. Still, have a play with what you've got mate. I hope I didn't put you off though.

-

Thanks for the advice Tony.

-

Tony, I really look forward to reading your posts on hybridz. You obviously know a great deal about all things automotive and Nissan/Datsun specifically and its this knowledge that I appreciate from you. I cannot provide z-spec with all the answers that he's seeking. I simply do not have that sort of experience. As much as I would like to own several race cars and race them around the world, I am but mere mortal so it remains a pipe dream only. I do enjoy reading and have gathered quite a library of automotive literature that allows me to further investigate some of the thoughts and ideas that people bring up. So when a question is posted, it should be fairly obvious that as much relevant information be provided to allow for a timely, accurate response by the readers and responders. I do not have the time nor interest to be reading what other people did for breakfast last week or even for next week. That's all. Country of origin is irrelevant. Number of languages spoken well that's also irrelevant. Why should that make any difference to anyone? I stand by what I said earlier to Z-car, get to the point. Thanks.

-

A good question. Consider that the MQ? is a heavy beast. Very heavy. I'm absolutely certain that you could get that thing to hoot along very well with a turbo/V8 or a 2jz. But you used the words "L28". If you're seriously going to keep this engine, check the dyno graph. My car is very heavy too. I wanted what you wanted, but I didn't want to spend the earth trying to achieve it. (Mortgage,kids' school fees and the rest limits my spending money these days). So look at the graph, then really look at it. Get the pen, paper and a calculator out and look at what torque increses I obtained with, what is, essentially a stock L28 with some bolt on stuff. Hear it and see it on the dyno on youtube. Type in Datsun 280c and see for yourself. If you want to know more, PM me and we can talk some more. Cheers.

-

Don't you love the way that we're given 'extra' information after half a dozen posts or so!!? Why don't you give everyone a chance to answer your questions properly with everything that you know your going to do to the engine at the beginning!!!! And how much power do you expect to be making? If you had looked around on this forum first, you would see that many people are making more than 400rwhp. I think the L series block is pretty tough...tough enough to be making this sort of power. Sorry if I sound 'narky' but its this type of open ended question with dribbles of information supplied by you that gets under my skin.....get to the point

-

I have an L26 block (83 mms) bored out 100 thou (2.5mm's). I didn't do it but received the block from a friend with it already done. I think that its important to realize that there is a limit to the amount of overbore that still renders the whole thing as reliable. If you're going to build a race engine, cylinder temps and pressures are much higher than stock as well as the redline. The chance of splitting the block as a result are greater and you'll be searching for another block or sleeving that one in a hurry. One or one and a half mm's will give you a capacity increase without the potential headaches associated with extreme overbores. You can if you wanted too add heaps of capacity via a diesel crank to the engine if you must have an L24 block. Fantastic mid range punch would be the benefit of that combination, compared to the standard L24. Even the L26/28 crank will make a bigger engine than the one you already have. So many options!!! Good luck with your project. Cheers.

-

If you have the time and resources, why don't you try both cams? You'll be asking yourself forever "I wonder how the other cam will work with my engine combination?' otherwise. Put your car on the dyno for each cam and drive each one on your favourite piece of road and track. Then you'll have some idea of which cam is better suited to your driving style. Only YOU can decide this. Some guys will just tell you to use the biggest cam you can and for a dual purpose machine this might'nt be your best option. I read in a book once very famous to us Datsun guys, "Don't overcam your engine and don't break it either". Have fun!!