mainboyd

Members-

Posts

83 -

Joined

-

Last visited

-

Days Won

1

mainboyd's Achievements

-

I don’t mind the extra material for strength but if it’s going to cause complications in using them and the extra material was just for a huge safety factor then I personally think it’s overkill and not necessary. Which is why I machined 4mm off of my adapters before even checking to see if they would fit first. I'm with you about how you feel about welding adapters. However, it’s definitely not because of the welds breaking. It’s how true everything will be when it comes to everything being centered.

-

The flanges I bought were from silvermine motors and I made them the same thickness as the flange from the CV axles. Which went from 12mm to 8mm. I figured if the Nissan engineers believed 8mm thick flange would be strong enough then why not the adapter flange… I probably didn’t need to grind the little stub off but I did just for safe measure. I have pictures of the before and after machining the flange adapters and a side by side pic of them next to the flange end of the CV axle in my IG page @ideation_z if you want to get a better idea of how they look like. They look very similar to the post I said I followed. The only difference is that the silvermine motors adapter is completely round, which I don’t know why they weren’t made like that in the first place because that less machining which means cost less. Anyways, like I said, it seemed to fit just fine for me. Wasn’t too long or too short and I installed them while the suspension was hanging at its lowest. I haven’t dropped the car yet but I can follow up on this thread and confirm if there were any problems or not.

-

I literally just finished installing the CLSD and CV axles from the Z31 turbo into my 1972 240z this morning. All I did was flip both cages and grinding the extra threads sticking out of the stub axle after the nut. Everything seemed to fit just fine and this was when the suspension was just hanging from the top hats. I’m just wondering how do I know if there will be no binding? It rotates fine when the suspension is hanging. I am going to jack the suspension up as much as possible to then see if it will still rotate. But if there was binding then what are the symptoms? Will it not rotate? Or making a clunking sound? I followed every step from here:

-

@mtnickel or whoever else can help me. Bringing this back because I have the Z31 turbo cv axels and the CLSD diff that I would like to swap in a 72 240z? Would following all the necessary steps provided still be ok if I were to also have the finned CLSD diff installed too? Assuming the diff is larger and wider than the others.

-

I was actually going to go with an idea similar to yours. I think they call it a hydro brake. Super simple set up and a lot cheaper than buying two parking brake calipers. But I decided to go the mechanical rout because I feel safer that it is independent of the main brake lines. Makes me “feel” a little safer on the road. Also, in wonderful California, not sure about everywhere else, requires that you have a mechanical (cable) parking brake. Maybe controlled (on/off) electronically but still using a cable. Don’t quote me on this because I only did a single search to find this out.

-

The wilwood will fit the smaller wheels. I’m not sure about the rear Brembo’s. I guess it all depends on the diameter of your rotors. My rotors are 13 inch front and rear. The front Brembo calipers barely won’t clear the smaller wheels. Maybe if I had smaller rotors and design the brackets a little shorter they might. Pictures of my custom front and rear setup are on this thread.

-

Oh yea that’s a really good point. I’m glad you mentioned that.

-

Man I really do wish I could see this in person or at least see some pictures. So the first spark plug (front one) was aligned with the front axle. So you were super close to making it a legit front mid engine Z. I think another 6 inches then that would make it possible? Not sure on the exact measurements because I’m just eyeballing it. That’s actually why I’m interested because I want to do the same. I want to just make sure I know what I’m getting myself into. I have some machining and welding experience for fabricating things. But for the things I know I will run into is the transmission tunnel clearance, ground clearance for oil pan and figuring out how to still switch gears in a manual transmission. If I’m going to move forward on this then I’ll start a new build thread but I would still like to see if anyone can provide any pictures and information on this topic.

-

Just lowered and not moved back? what made you want to drop it 20mm?

-

I guess it makes sense why I see highly modified cars have a fuel pump switch to have the pump running constantly before starting the engine.

-

I purchased the kit just last month from summit racing. So far I don’t see any leaks on the ground or any kind of smell in the garage. Hopefully I dodged a bullet. thanks for the heads up.

-

I’m very curious to how that build went. Like the placement of the shifter or transmission tunnel clearance (was there clearance for the transmission because it was lowered 2”) or how the firewall was fabricated or, what was already mentioned, clearance from the ground for the oil pan. I have so many questions. I wish there were pics of at least the final stage of it.

-

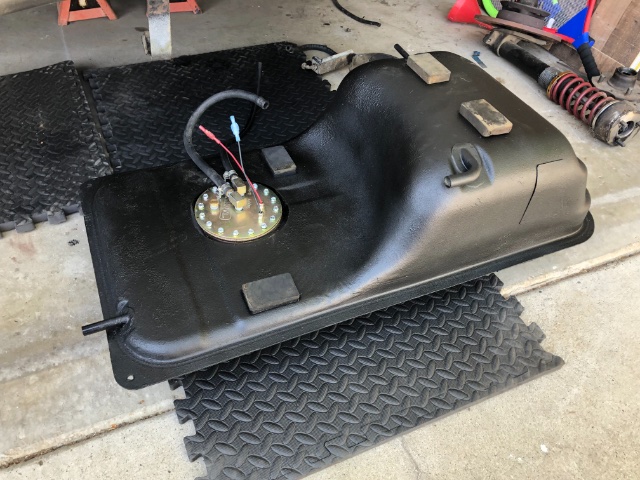

That’s how mine is currently. I haven’t really tested it yet because I’m in the process of changing out the old fuel rail and injectors. Reason why I went this route was because I was going to cut out an access hole in the spare tire section so that I can get to the fuel pump if needed rather than dropping the tank. Also, the cut out hole will not be seen since it’s in the spare tire area. The hole cut out from the spare tire section is not left open. I can close it back up with screws just like the same concept of how now the fuel pump system is mounted on the gas tank. Also, while it was all out I used POR15 to clean and seal the inside of the tank. This is also on my IG @ideation_z along with other mods I have done to the z. In the pictures, I intentionally have the fuel pump in that angle because the fuel strainer is also slightly angled. So with how the fuel pump is angled, the fuel strainer is now sitting parallel with the tray. Also, it avoids creating a 90 degree bend on the supply hose from the fuel pump. Warning!! I’m not sure if you will have an easy time finding that type of strainer. I contacted Walbro and they don’t offer it anymore. I was lucky enough to find what the guy suggested in the YouTube clip as a secondary at Napa Auto Parts (local auto parts store) but they only had one and it was at their main warehouse and I also found another one on ebay.

-

Ok NewZed, that was a really good and clear explanation from that link! Nice find and thank you very much for sharing that. I guess the aftermarket FPR are another component in your build that you can use for fine tuning if necessary? Back to the drawing board and back to the OP. To answer the OP: Long story short, I should be fine with the 11/16” ID fuel rail. As long as I have adequate fuel pressure in the fuel rails. Which is mostly determined by the fuel pump and a good FPR. Second question, what’s a good FPR?: Basically, it’s a personal preference but can possibly be based on the build. If you want a FPR to hold pressure for longer than a few seconds or possibly a few days when the fuel pump is not running then a factory FPR is the way to go. A aftermarket engine management system will also help with the air:fuel ratio adjustment. I guess that sums it up for the thread? Unless we can share what FPR are out there that would work best for the L-series engine with various hp ranges? Maybe that’s another new thread or something that has already been discussed in another thread. I can at least now go ahead and machine the fuel rail extrusion and start assembling.

-

You make a good point about not needing a FPR if I already have a aftermarket engine management. But how would the management system (I have MS2) regulate the fuel pressure on its own if the factory FPR is not adjustable? If I were to turn up the boost in the future then how would I make sure I have the ratio I am needing and know the factory FPR is not restricting my flow? I’m being honest here, I am no expert in this exact field of work.