-

Posts

551 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by HS30-H

-

'S31' prefix didn't start until 1976 production year. Separate reversing lamp style rear ( "260Z style" ) started very late in 1973 and ran right through to the end of production in 1978 for the Japanese market models. 'S30-109459' chassis number indicates a January 1974 production car.

-

DOHC L6, Was somebody looking for the Goerz-Paeco DOHC L6 Head ?

HS30-H replied to Vintageracecar's topic in Nissan L6 Forum

-

Well, don't get distracted trying to replicate what the factory did or being some kind of idealist. I like the trick factory parts - perhaps more than most - but it's more forensic and carchaeological than anything else these days. If you want to run with the big boys you will need to match their free time, their budgets and their pragmatic interpretation of the rules ( read: cheating ), as well as the fact that the manufacturers of their chosen cars did a better job of homologation 40-odd years ago. If you want to be competitive you'd probably find that your time and money was better spent in maximising basic setup and ( especially ) in some intensive driver tuition.

-

Yes, they are all photos / scans that I have put on HybridZ in the past, including the scan of the FIA homologation page for the LY head. Nissan 'ECGI' ( Electronically Controlled Gas Injection ) systems were allowed under FIA Groups 4 and 5, and also as a special dispensation in Group 3 in certain FIA sanctioned rally events. These parts didn't need to be specifically homologated, but the cylinder heads they were designed to be used on ( the E4621 'Safari' / 'FIA' head and the 'LY' / 'Crossflow' head ) did, and were. The Lucas-based mechanical ( sliding throttle ) fuel injection seen on the S20 engines in the first post ( both on works KPGC10 race cars, incidentally ) were used in JAF sanctioned Touring Car races, and in certain JAF GT and Prototype classes ( in the 432R, for example ). Sometimes these races were run under JAF-tweaked international FIA rules, so a little bit of a fudge in scrutineering. So, ECGI technically FIA legal ( although strict conformation would require use of the original type analogue control box / 'computer' ) in some classes / periods, and Lucas-derived / similar mechanical injection FIA illegal.... except in classes where the car would doubtless be uncompetitive anyway.

-

Nissan didn't make cars according to "Year Model". I think you'll find that's mainly an American obsession, based on the activities of American automakers. These cars are Japanese. The S130-series started production and was sold to the general public in 1978, so a 1978 Fairlady 280Z is just that; A 1978 S130-series Fairlady 280Z. I think the problem there would be that you asked for the wrong thing, and/or in the wrong way...... You should try ordering parts by their ( correct ) part numbers. Nissan and their suppliers made them according to the specific model they were designed to fit, not just some vernacular local idea of "year model".

-

Wrong. Japanese market never got the 'X' suffix on the S130-series Zs.

-

Manufacturer = Kotobuki. Application = Nissan OEM.

-

'S130-008634' would be 1980 build year, not 1979. And very likely late in 1980 too.

-

Euro market S130 FSM and EFI Service Manual scans:

-

It's like Sanford & Son sometimes. You're the Redd Fox character and I'm the Demond Wilson one ( younger & better looking, natch ). We should go into business together. Chapter 11 within a few months.....

-

I've got two sets with the Fairlady 240ZGs still attached to them...

-

Yes, that's a set of OEM overfenders for the 'HS30-H' model Fairlady 240ZG. NOS sets change hands for relatively high figures in Japan. If you've got a genuine 240ZG and you happen to damage a corner, you'll probably be willing to stump up for the OEM item....

-

.....and so do Spirit Garage, City Auto, RS Start and any number of other Japanese businesses. The stainless version on the Bingo Sports car in your link was made by Spirit Garage.

-

That's not what he wrote, is it? You might have the nous to read between the lines and pull out the greater truth, but he was linking the KEW Twin Idler ( and the electric water pump ) to a ( big! ) power loss. I can't speak with any authority on the water pump issue, but I do know what I'm talking about when it comes to the Twin Idler and I know it would not normally cause any such power loss. Mixing all this up with a distributor change ( likely the main culprit for the described power loss ) is at best bad writing and at worst an attempt to damn a decent product. I've seen him do the latter before, so guess what I think? Since you ask me a direct question, I'll try to give you a direct answer: These little seeds of untruth sometimes grow into great forests of lies, so I try to nip them in the bud whenever I see them. Quite often a waste of time, I admit. There's just so much bullsh*t floating around out there about these cars that it's a wonder we don't all drown in it. If anything it's actually getting worse. But as I said before, this shouldn't be about me. The guy is scathing about what I think is a decent product that does the job it was designed to do. It had plenty of mud thrown at it when it was first introduced ( that "...geetar string.." comment was a memorable one ), and very little - if any - of it stuck. PMC doesn't like the Twin Idler, but that seems more to be about 'Not Made Here' syndrome than anything more solid. Fair enough if he doesn't want to use it or doesn't recommend it, but I object to him falsely linking it to a big power loss.

-

As a matter of fact, I don't use ANY Kameari Engine Works parts on any of my engines. Ironic, isn't it? But I've known Mr Mori and KEW for many years, respect him and his products, and have listened intently whilst he explained and demonstrated the reasons for developing the Twin Idler cam tensioner system some years ago. I know many people who use the Twin Idler, they have been used in endurance racing and rallying ( including the classic East African Safari Rally ) and I've yet to hear a bad word about them from anyone who's opinion is worth listening to. I've got no problem with you saying that you would prefer not to use the Twin Idler ( build them any way you want.... ) but linking it to a power loss - as you did above - and calling it a "waste of money" sounds like politics to me. Kameari don't have a presence on this forum to defend themselves, so I'll do it for them.

-

As is quite often the case, what you write doesn't really add up. In what way could the Kameari Twin Idler cam chain tensioner be responsible for any of what you describe above? It's not a power adder ( it was not designed to be ) but by the same token I don't think I've heard any stories where people fitted one to an engine and then found they had less power than before ( unless they messed up their cam timing whilst fitting it.... ). It sounds to me like the Kameari Twin Idler kit is suffering from 'Not Made Here' syndrome when it goes through the doors of your 'shop. From what you describe above, the most likely candidate to point the finger at for your power difference is the distributor. No surprise to find that "our" distributor is superior ( funny that.... ). Unless of course the big secret with these engines turns out to be the genuine OEM water pumps.....

-

Purely for accuracy's sake: All those 1:1 5th gear 'Direct Drive' ( ie, not 'Overdrive' ) 'boxes are actually F5C71-B type code, and the N3130 and N3030 are FS5C71-B type code ( not FS5W71-B ).

-

I'm confused - Can someone tell me more about this car?

HS30-H replied to jacob80's topic in Nissan L6 Forum

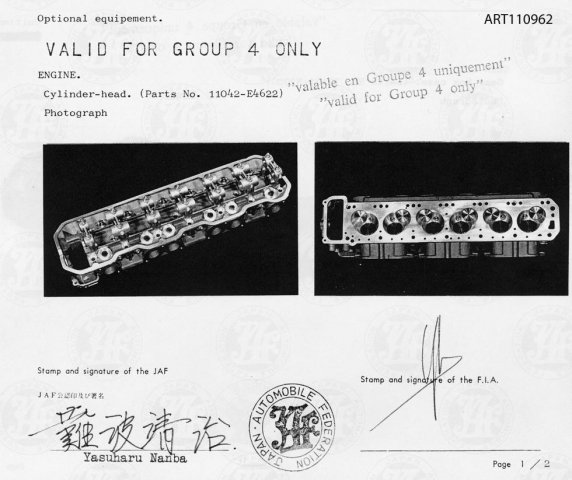

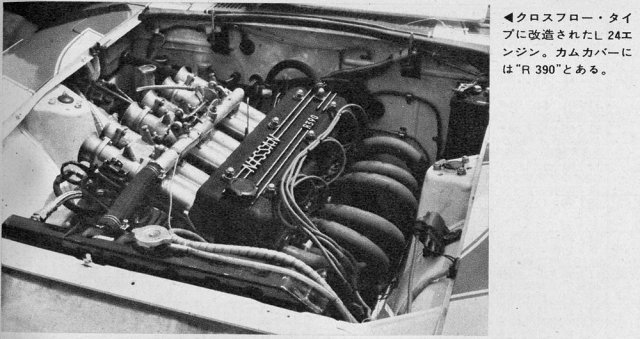

For reference: FIA / JAF homologation amendment for the E4622 'LY' crossflow head, Works 240Z rally car with ECGI injected LY head on L24 block, pictured prior to the 1973 RAC Rally, Works 240ZR race car with 'R390' injected crossflow engine in Japan, 1973. -

I'm confused - Can someone tell me more about this car?

HS30-H replied to jacob80's topic in Nissan L6 Forum

Just to clarify: The engine pictured is using a genuine Nissan 11041-N3175 'LY' / 'Crossflow' cylinder head. A two-valve, semi-hemi chambered design using a single camshaft with twin rocker shafts and diagonally acting 'finger' type rockers. The first 'LY' heads were seen on factory race cars in Japan in late 1972, and were being used in competition by the Works team in early 1973. The LY was designed to be used with Nissan's own ECGI ( Electronic Control Gas Injection ) 'computer' injection system, and by the end of 1973 just such a setup ( LY with ECGI ) was being used on L24s mounted in factory Works rally cars competing in the World Rally Championship. The factory called these complete engines 'LR24', and sometimes LY24-R'. Later, bigger, versions used in circuit racing in Japan were also nicknamed 'L390' - in a tip of the hat to Nissan's defunct R380 / R381 / R382 / R383 sports-racing cars. The owner of the red car pictured has been developing his engine for a long time, and as it now stands he is running a twin turbo conversion on his LY head. This is something that the factory never did with the LY, although Janspeed here in Europe campaigned a turboed LY28-engined car in European races in the late 1970s. Beware of bad information about the LY ( or any other rare period Factory parts ) and be especially wary of dimwits who confuse them with recent RB20E-based lookalikes..... -

I'm confused - Can someone tell me more about this car?

HS30-H replied to jacob80's topic in Nissan L6 Forum

You know, it's really hard to take you seriously with some of the billy bullshit you come out with sometimes. Do you honestly think Nissan designed, built, developed and homologated the 'LY' all for "the look"? Nissan's own published figures for the full LY28 ( ie, the type sold to privateer racers in Japan ) tell their own story: This was recommended as a package, and not just a cylinder head to drop onto a stock or stockish bottom end. At 2870cc, with an 11.7:1 compression ratio, on three 50PHH Mikunis and with factory CDI, they quoted a nice round 300ps @ 7,600 rpm and 32kg/mm @ 6,400 rpm. Max recommended revs were 8,000 rpm. Block was a 'specially selected' N42, but with additional processing and with Wills ring type head gasket sealing. There was a dedicated CM40 crank with narrow rod journals, special ( narrow journal ) rods, pistons and flywheel. It required the dedicated bellhousing and engine mounts too, as it canted the block over on the opposite side to stock. Factory 'Works' circuit race versions of the LY ( some of them internally nicknamed the 'R390' engine ) on ECGI injection and with dry sump were giving well in excess of the figures quoted for the privateer versions. Trouble is, people look at the LY and they don't understand it. They don't understand what it was designed to do, they don't understand what type of racing it was designed to be used in, and they don't understand what it was homologated to do. Nissan was not playing a game of 'Top Trumps'. -

How about trying that with HLS30-00001 and S30-00001...? Alternatively, HLS30-00030 and PS30-00030...? HLS30-00800 and S30-00800..? Might surprise a few people.

-

HybridZ Windtunnel Test Video Clips

HS30-H replied to Mikelly's topic in Windtunnel Test Results and Analysis

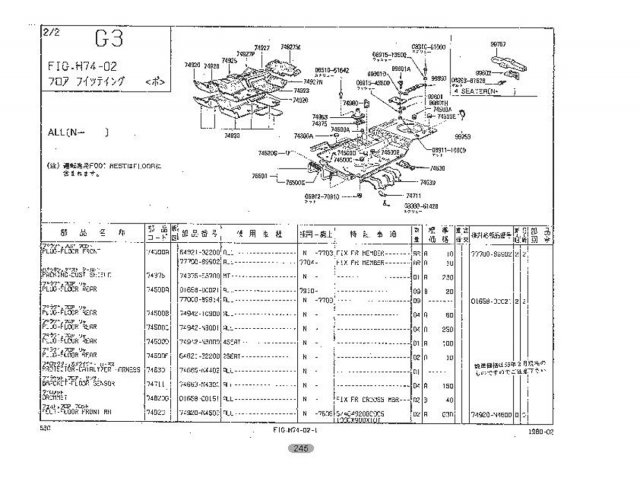

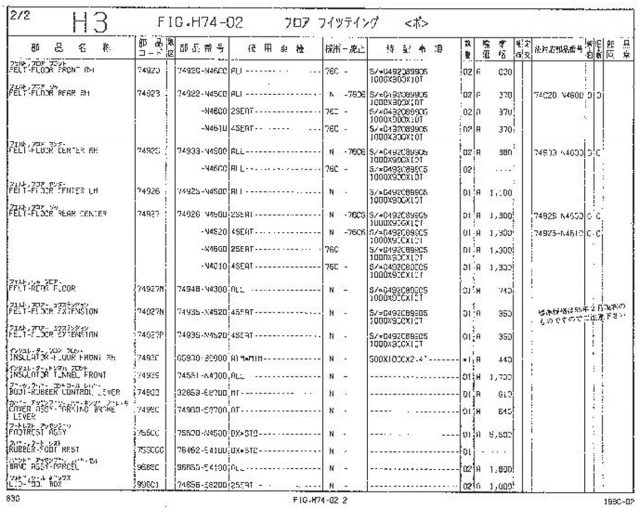

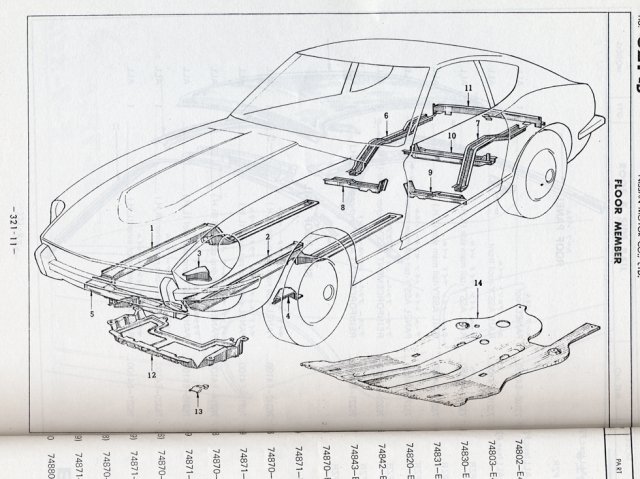

Congrats on the S31 purchase, Clive. I think the panel you see under the car is actually a heat shield rather than an aerodynamics-related device. The S31s had a LOT of extra add-on equipment, and were equipped with catalytic converters which left a lot of heat under the floor, and Nissan made a big effort to counteract this. Here's a couple of relevant pages from the S31 factory parts fiche. Sorry about the quality ( the original PDF is a bit better than my scanned images ) but the part I'm pointing at is numbered 74939, and is the 74661-N4300 Insulator - Tunnel Front. Cheers, Alan T. -

HybridZ Windtunnel Test Video Clips

HS30-H replied to Mikelly's topic in Windtunnel Test Results and Analysis

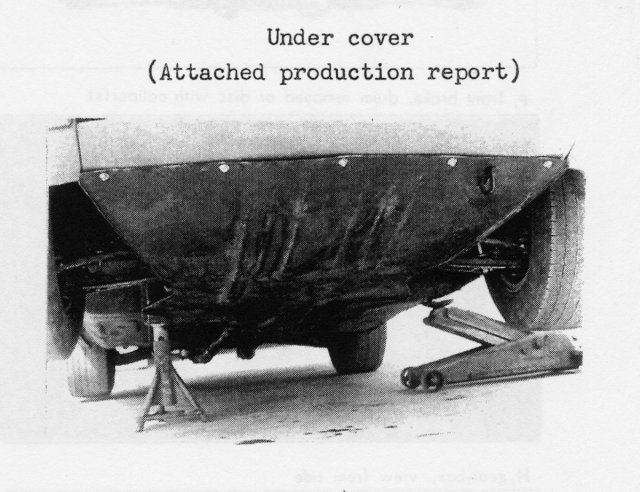

Not the kind of image that's easy to find, really. Here's the best I can do for now. It's from the JAF homologation papers for the 432. Remember that this was not a stock part for the 432, but was a stock part on the homologation special 432-R model: -

HybridZ Windtunnel Test Video Clips

HS30-H replied to Mikelly's topic in Windtunnel Test Results and Analysis

-

HybridZ Windtunnel Test Video Clips

HS30-H replied to Mikelly's topic in Windtunnel Test Results and Analysis

Tony, The 'HS30-H' model Fairlady 240ZG homologation special - as sold to the general public - had exactly the same splash tray / under cover as the other L-gata engined models sold alongside it. You may be thinking of the FRP engine & trans under cover of the PS30-SB Fairlady Z432-R, which extended from the front valance ( which was made from FRP on the 432-R, and stepped to accommodate the under cover ) all the way back to the trans - splitting in two to cover the gap at the sides. It was initially part number 98200-E7200 on the 432-R in 1969, but later versions - tailored to the L-gata engined cars and rather more fancy - were seen in the Sports Option catalogues. The works race team of course used quite complicated and comprehensive ducting and spoilers in conjunction with the G-noses on their factory 240ZR race cars. The Fairlady 240ZG that was sold to the general public was essentially a base to build from....