-

Posts

551 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by HS30-H

-

I said "wow" to myself when I read that too, but probably not for the same reason as you. Where does this story come from? It sounds completely apocryphal to me. Maybe something 'lost in translation'...? Nissan was selling the MK63-20S caliper as a 'Race/Sports Option' part for other cars in their range before the S30-series Z debuted in 1969, so they were already in public circulation. Their original source - as a stock part for the top of the range Nissan President limousine - meant that they could be sourced elsewhere anyway. Why would Nissan want, let alone need to ask teams to give them back after using them? What a bizarre story. I'm also not sure why you are making the narrower, unvented - solid disc - type MK63 caliper sound like it's something cooler than the wider - vented disc - type? It was always easier - and cheaper - to find the unvented type, and it was the more expensive vented type that was more difficult to source. The upshot was that people started machining up spacers for the unvented type calipers to make them fit over a vented disc, leading to all sorts of caliper flexing problems. The reason they wanted to convert to vented discs was the fact that its so easy to overheat the stock - unvented - disc, with sudden fade (just when you didn't want it...) and pad glazing being the result. So the unvented type are fine up to a point, but the weak link is the disc. I would always recommend the vented type over the unvented type. I run MK63-20S calipers on 4 S30-series Zs and a KPGC10, and all of them with vented discs. I would not bother with the solid disc type.

-

Nissan's #116 'Grand Prix Maroon' is most definitely not "wine red metallic". It's a solid, non-metallic, dark chestnut brown. The 'Maroon' name might make people think it's more red than brown, but it's not a maroon shade at all. The name of the colour was one of those Lost In Translation mistakes, and it was meant to be 'Marron' (French for Chestnut...). OP - You can get really close to it if you search through 1980s Opel colour charts. There's also a modern Ford Europe colour (used on Fiestas) that's pretty close. It's just a case of distinguishing who knows what they are talking about, and who doesn't.

-

Thanks! I just sent him a PM with my e-mail address.

-

Well I've been down to the beach, but no Message In a Bottle has washed up yet. In fact it seems I haven't received a PM since 2013. Not even a nasty one. Nobody cares any more... Airtime262 I'm always happy to talk HS30s. I'm sure we'll get there somehow!

-

Historic Rally Car Restoration

HS30-H replied to Evandavis73's topic in S30 Series - 240z, 260z, 280z

It's an R200, but it's almost certainly got an LSD unit inside. Possibly an *interesting* ratio too? -

Historic Rally Car Restoration

HS30-H replied to Evandavis73's topic in S30 Series - 240z, 260z, 280z

Yes, designed and fabricated in Japan. The Works 240Zs were all built in Japan. They arrived in their countries of use fully built and ready to go. Only relatively minor fettling was carried out away from base before international events, but cars required servicing/preparation/refurbishment between events and this was carried out at local bases (like O.W.S.S. in the UK). The more you look into the Works cars the more you realise just how thoroughly they were prepped and put together. The level of detail is amazing. -

Historic Rally Car Restoration

HS30-H replied to Evandavis73's topic in S30 Series - 240z, 260z, 280z

Well spotted John. The Works sump guard brace killed two birds with one stone, in that it formed the middle mount for the sump guards (of which there were several different materials and several different shapes, depending on event and year...) but also spread load and beefed up the engine mount crossmember/inner TCA mounts. It was a heavy piece of steel plate, bent and welded. Beefy! Apologies for the poor photos, but it's rare to see these parts off a car... -

Historic Rally Car Restoration

HS30-H replied to Evandavis73's topic in S30 Series - 240z, 260z, 280z

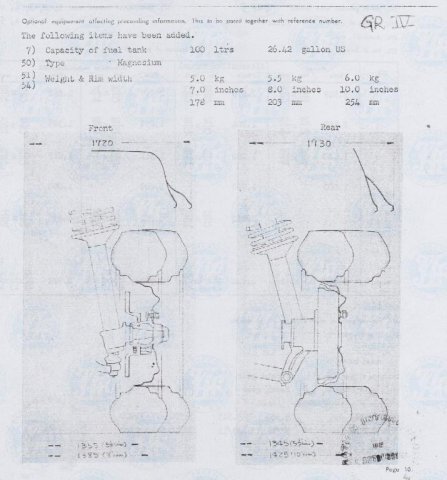

Here's what the original struts on the '71 East African Safari Rally winning car look like. Notice the fixed spring platforms, long strut tubes, the Halda drive cable tubes in the front tubes (they go right through the spindles) and the big nut which holds the complete strut tube and damper into the rear hub, which allowed the Works team to change complete damper, spring and top mount units without having to remove driveshafts, brake line & cable and complete rear hub. Quick change and serviceability quite an important factor in stage rallying. -

Historic Rally Car Restoration

HS30-H replied to Evandavis73's topic in S30 Series - 240z, 260z, 280z

"The real deal" might take some defining. Nissan entered teams of factory 'Works' 240Z rally cars in the 1971, 1972 & 1973 East African Safari Rallies, winning overall in 1971 and 1973. They used different designs/makes of strut in all three years. If you're talking about the 1971 winning car, it used long-tube, fixed spring platform gas-filled struts manufactured by Tokico. This exact type were never made available to the general public as new parts (like many of the true Works parts...) and are quite distinctive, so pretty easy to identify. The rear strut tubes were actually bolted to the bottom of the rear hub casting, and both right and left fronts had integral Halda drive cable tubes installed through the spindle forging, and these were braced to the strut tubes. As I say, they are quite distinctive. Can illustrate with some photos if you are interested. I think it's more likely that you have the E7220 Nissan 'Rally Option' long-tube gas-filled struts, which were sold to the general public through Nissan's 'Sports Option' lists and the likes of Datsun Competition in north America. These can be rebuilt, but it's a tricky process and involves installing a fill valve on the strut tube. I have a set and to be honest they are more of a conversation piece than anything else. Building a set of Bilstein monotube struts would be a good choice for serious off-road use today. Your strut tubes should have part numbers on the tubes if you want to identify them more conclusively. Good luck with your project. Looks like an interesting car with some nice history. -

Twin cam head for the L6 from Derek at Datsunworks

HS30-H replied to Derek's topic in Nissan L6 Forum

Actually, production S20 cam covers were low pressure diecast. See photo of underside with splash cover removed. I like the cosmetic 'defects'. I could have repaired/improved them, but chose not to. They suit the period, age and character of the car, I think. Something to think about, perhaps? -

Twin cam head for the L6 from Derek at Datsunworks

HS30-H replied to Derek's topic in Nissan L6 Forum

'Nissan' logo on one of my S20s: -

"Some guy" huh? The truth is that the original diagram was made by me, using a scan from one of the Nissan factory 'Service Shuho' booklets which covered the HS30-H Fairlady 240ZG model. I posted it first here, on HybridZ.... I took the measurements from my original 1971 Fairlady 240ZG, but - as the mirrors were already mounted on the car (by Nissan, in Japan...) I didn't want to remove them simply to measure to the centre of the holes. So I measured to the EDGES OF THE BASES, and made this quite clear in the original post. What has been happening since then is that people have taken the original diagram out of context and posted it elsewhere. Copies of copies of copies have turned up, and context - as well as the points made in the original post - is lost. Typical internet. The fact is that there was always more than one set of measurements. Nissan moved the mirror mounting positions at least twice during the 1969~1974 period. And if you're fitting C10, 510 or generic aftermarket mirrors on an S30 - as the great majority of fender-mirror installers using the diagrams are - then it's pretty much academic anyway. They have different length stalks mounted at a different angle than the original S30-series mirrors anyway, so they are not going to look the same or work the same... Bottom line: Mount them where you want.

-

Actually, the 'best' (the closest match to the period factory parts) are made by Marugen Shokai (or 'Marugen Shoukai' if you can't type a macron on the letter 'o', as on HybridZ): http://home.att.ne.jp/sky/FairladyZ/ RHD Japan can act as middlemen in sourcing them for you.

-

100% not Nissan / Nissan works / Nissan Sports Option. They never used anything like that on S30-series race or rally cars. Likely to have been a local fabrication in USA.

-

Twin cam head for the L6 from Derek at Datsunworks

HS30-H replied to Derek's topic in Nissan L6 Forum

Quite a few actually. Just off the top of my head I can cite aftermarket performance 'heads for MGs, Austin Healeys, Aston Martins, Jaguars, ALFAs, even Abarths. All commercial propositions, and usually - to be expected - not 'cheap'... -

Actually the rear sway bar / anti roll bar was part of the original design and engineering of the whole S30-series Z range at launch. It was only the north American market HLS30-U models that were not fitted with them. The rest of the world (European HLS30, UK, Aus. and NZ HS30 and Japanese Fairlady Z/Z-L/432/432-R) had them as stock equipment from the beginning of production in 1969.

-

Brake Booster Is Much Smaller Than Factory

HS30-H replied to 12doplumbing's topic in Brakes, Wheels, Suspension and Chassis

I might look big to you, but actually I'm regular size. It's just that I'm up here on my high horse and you're really, really, really weeny. Here's a tip: Show member Xnke a little more respect. He's one of the people here who know what they are talking about. And that's why you came here, isn't it? Here's another tip: Factories usually are pretty big. Bigger than most brake boosters, anyway... -

Brake Booster Is Much Smaller Than Factory

HS30-H replied to 12doplumbing's topic in Brakes, Wheels, Suspension and Chassis

There was. He did. You just didn't notice, or ignored it. Alan T. (laughing at wannabe drifters since 1989). -

Twin cam head for the L6 from Derek at Datsunworks

HS30-H replied to Derek's topic in Nissan L6 Forum

Carbs like it better if they are mounted roughly level (floats etc) but some of that can be achieved through the inlet manifold shape as long as it does not become too much of a compromise. I would imagine some proportion of your potential customer base would like to run with carbs, and it seems to me that it would be worth catering for them. Stock L-gata, LY and S20 were not tilted for oil draining reasons. On stock L-gata it was mostly about packaging (and not forgetting - as some Z specialist websites seem to - that the L-6 was designed and engineered to be used in more than one platform) and the need to fit in both RHD and LHD vehicles. LY was originally designed to be used with individual throttle-bodied injection, but also catered for carbs. A lot of the 'tilt' was about packaging, and again in both RHD and LHD form. S20 was designed and engineered pretty much solely for RHD use, and was designed, engineered and packaged accordingly. Yes, you can move things around with different bellhousings and engine mounts as Xnke has pointed out, but that will have an impact on inlet and exhaust manifold shapes and I would think a 'one size fits all' approach might help to make your head a more accessible proposition cost-wise? -

Twin cam head for the L6 from Derek at Datsunworks

HS30-H replied to Derek's topic in Nissan L6 Forum

Not sure if this has been covered in previous posts, so apologies if it has - but, does the design of this head make any concession to the canting of the L-series engine block in the chassis? On the LY 'Crossflow' head conversion, Nissan canted the block over to the induction side (ie, induction side of head was higher than the exhaust side) by using a completely different LY-specific bellhousing and engine mounts. Different sump and oil pick-up arrangement too. On the S20 twin-cam engined cars the cylinder bock is canted in a similar way; High on the induction side and low on the exhaust side. S20-specific bellhousings (for A type and later B type transmissions) were used, and engine crossmember is specific to S20-engined models. I'm presuming that this custom-made head uses the stock cant of the L-gata block in non-crossflow configuration? With that being the case, does this impact the design and engineering of the oil system, and what knock-on will there be on inlet design (presuming that the inlet side will be lower than the exhaust side)? -

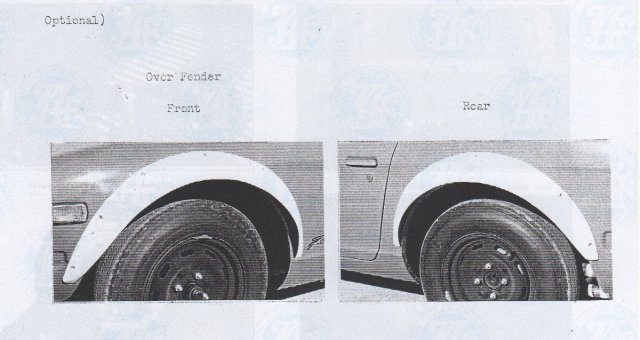

'Factory Correct' for the HS30-H model 'Fairlady 240ZG' model's overfender attachment was wide-headed Pop rivets....

-

New S30 D Brinkworth flare kit (New Installed Pics)

HS30-H replied to JPN_Garage's topic in Body Kits & Paint

Hideous. -

Mail link is on his blog: http://www.geocities.jp/kuni_s30z/ ....but you'll need to write in Japanese.

-

I'm sorry to say that - in my experience, and that's based only on what I have seen and held in my own hands - the MSA overfenders are really not the same as the OEM 240ZG overfenders in weight, thickness, shape, fit or finish. I'm sure they are perfectly serviceable for what they are, but in comparison with 'The Real Thing' they are not equal. The Marugen Shokai 'Special SP' ZG-type overfenders are the best replicas of the OEM Nissan Fairlady 240ZG overfenders on the market today. So if that's what you want, I'd recommend them. In my first post on this topic, the DARK GREY/GRAPHITE overfender in the photos is an NOS genuine, OEM, Fairlady 240ZG overfender. The WHITE overfender in the photos is an NOS genuine, OEM, Fairlady Z432-R Sports/Race Option overfender. Please don't get confused between the different types.

-

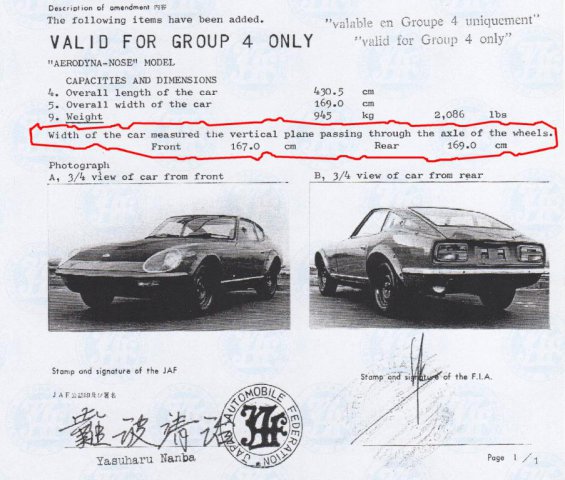

I think the best way for me to answer part of that is with some photos/diagrams. However, please remember that the 'Type A' and 'Type B' descriptions of the Nissan works overfenders are vernacular names given to them in retrospect. In period, Nissan only ever referred to them by their part numbers. The original parts have been copied and plagiarised, and in turn those copies themselves copied, so that we end up 40-odd years down the line not really knowing what is what. The factory race cars themselves gradually used evolutions of the originally-homologated parts, so it makes it even more difficult to pin down what's what from old photos. I don't have any firm dimensions for 'Type A' and 'Type B' overall widths. I could measure the original parts I have, but I don't think it will mean much. Probably better to ask any supplier/manufacturer for the dimensions of the parts they are selling, as that's what you will end up with. Here are dimensions for the 432-R type overfenders (the very first overfenders made and homologated for the S30-series Z) and the 240ZG type overfenders, both from the original homologation papers: