DuffyMahoney

Donating Members-

Posts

491 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by DuffyMahoney

-

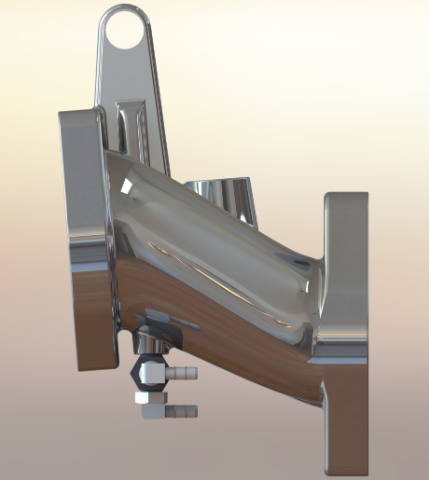

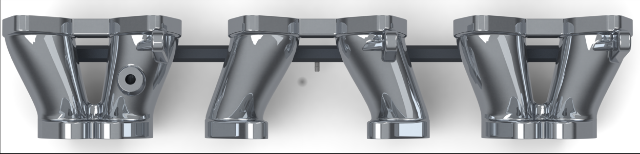

The custom stainless fuel rail is very slick! I can even clock the injectors enough to hide some of the wiring.

-

1 or 5, they are the same price. Slightly less if I buy like 10-20, but not a ton. Since it's all 5 axis time. If it works well, I may try and have it cast.

-

I am a looks and performance person. I am sure it performs well. I just think it would have been sexier for sure.

-

China is cutting this, they picked the material.

-

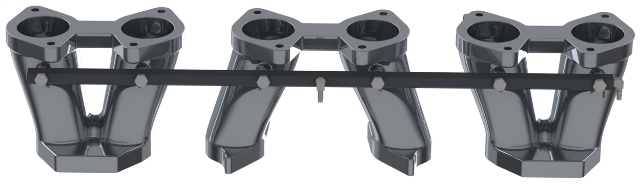

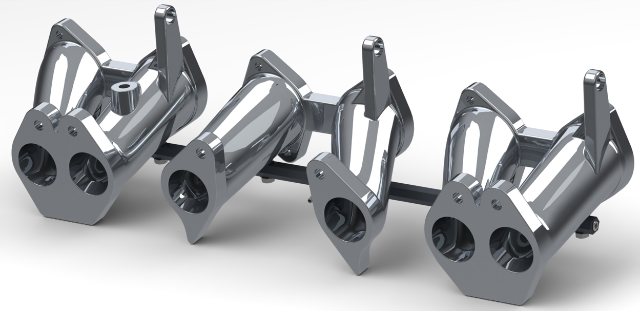

Well the cnc shop missed a program on my first intake and it’s ruined. This is number 2. It’s starting to look amazing.

-

I think the protunerz intake was an opportunity to make something extremely sexy and perform well, but the intake runners look like home depot pipe, then the rest looks fine. But it could have been amazing.

-

Sad, that is 10x better looking then the protunez.

-

Very common on yahoo japan, if you are interested.

-

Version 2 of my 10mm throttle arms are done. I recessed the hardware a little more and added a 5mm allen for safety. Plus designed up a return spring setup to match! I think I’m happy with this aesthetics.

-

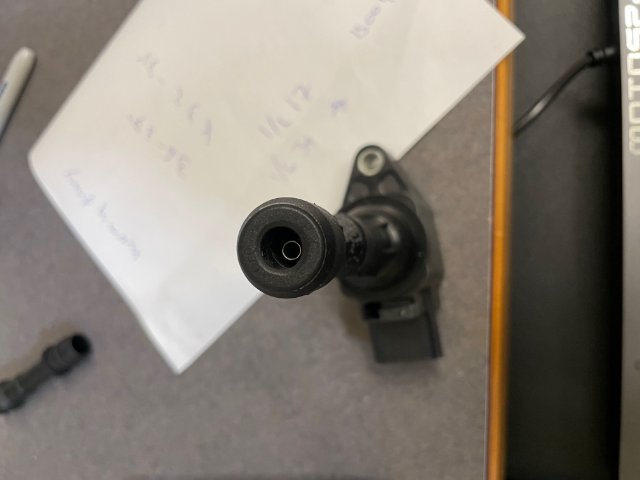

This is Steve from EFI hardwares favorite injector for the L with his ITB, their spray pattern was used in the creation of my intake, with the goal of injecting down the middle of the runner. https://www.efihardware.com/products/2720/Bosch-Injector-347cc-3Bar-12-Height-EV14-E85-Compatible-with-Extended-Nose

-

Something sexy to start the week off with. This is a stainless fuel rail for my ITB setup. Expertly crafted by Michel Vienneau! It features injector safety clip stainless cups, built in AN fittings and polished. I’m hopeful it being smaller will allow me to clock my injectors and hide my wiring a bit. Now I can’t scratch it. Michel is a metal magician!

-

Another thing to note is the car basically ran amazing off low idle (light street) when tuned. I think that poor injector angle isn't a thing, once the engine is sucking enough air/fuel into the motor.

-

I have a ford racing engineer that said the runner shape (sort of S) should have little to no effect air flow in a street car, but honestly I don't know that for sure. Lots of engines have wild air paths to the valve (my 5.0 does 180 at one point). But lots of cars have terrible injector angles. The intake design has 2 big benefits, 1 is it gets the throttle bodies up and away from the header, then 2 is the injector spraying down the middle of the runner. I personally think it looks good. I wished the FET wouldn't have been so poorly made. It would have been a much easier project. One thing I haven't talked about a lot is cold starts, and working with automotive engineers, one theory we have been talking about tough cold starts are from intake walls being cold and my poor injector angels, so higher wall wetting and fuel puddling. Then fuel puddles going into the cylinder, thus causing cold start tuning issues. This is probably my least favorite part of ITB so far. Rough cold starts. I am hopeful that spraying down the middle of the runner helps all of this. But time will tell. Honestly my first intake and throttle setup ran the best (jenvy/ harada). I have also gotten much better at tuning, so I kind of wish I had that setup still to see how I can get it to run. Smartest ITB intake would have been Larrys intake with the injector spraying the valves or the Whitley tune intake. Also haltech is moving away from transient throttle in favor of Map prediction, which I have been told is much much better at cold starts and overall light throttle input tuning. Tuning transient took so much time and I didn't have it perfect.

-

I had an injector at the head intake, but I didn't love the looks of it. I know that is silly, but it's how I feel. About 30 degrees tilted up is also an option for this intake, but not nearly as good for the injector angle. I agree about tilted up looks good, it makes it look mean.

-

What are you doing with it? I am curious, I have one, that I haven't decided on what to do with it.

-

I belong to Classicbroncos.com and to be able to post pictures, you have to pay a small fee. It's not a lot, maybe 5 or 10$ a year. Food for thought. I will donate now.

-

I decided to make my own intake, this is modern version of my FET. I love the angle for the injector and also getting the throttles away from the heat of the header.

-

EFI hardware is saying a Log is bad, a log is what I have done in the past. Its all a ? They want equal length going to a collector. https://www.efihardware.com/products/1963/map-sensor-collector-kit-6-cyl-inc-hose-for-equal-length-connection

-

I have 5 progressive cnc throttle cams for sale. 10mm shaft. Comes with everything in the picture. Gives resolution to ITB and triple carbs. Basically more pedal travel for less throttle travel. Should make street driving more enjoyable. So far a few cars are running around with them. 125$ each shipped Pm me or email me m2racing@bumperlift.com

-

240z SCCA vintage race car, restoration

DuffyMahoney replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I have a few progressive cams left to sell, if anyone is looking. -

Finally nailed down a perfect length, bend with proper spring tension to the spark plug! Now off to Thailand to be made.

-

I have proper spring engagement! Next is 3-5mm longer in the middle section, so the coils push down completely over the spark plug when installed.

.jpg.7066cd2994675c7250cecaf77c2f43ed.jpg)

.jpg.9c6e731fa32a82f7fa3b179754c07d03.jpg)

.jpg.10497f69aac7d3e6b4bf246d99760a55.jpg)

.jpg.45a1493f3b80e99979bf21b5353f09dd.jpg)