-

Posts

208 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 280Z-LS3

-

280Z build w/ LS3 and 2015 Mustang spindles/8.8

280Z-LS3 replied to 280Z-LS3's topic in Gen III & IV Chevy V8Z Tech Board

-

-

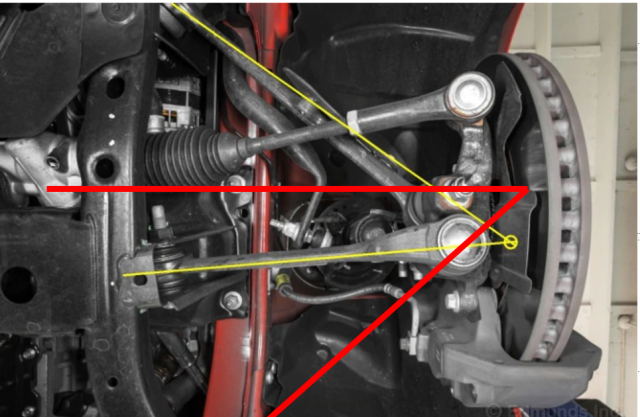

First off would like to say I would never have had the knowledge nor courage to tackle this build without HybridZ and its awesome community so willing to offer advice and share ideas. Purchased my running 1975 280Z almost rust free San Diego area car about 4 years ago with the intent to start the build sooner. With getting two girls off to college then moving to a new home, which included renting for a year while finding the "right" property, let's say the car hobby took a back seat. Sacrilege! The silver lining is all this time afforded plenty of lurking here, other Z sites and Ls1Tech reading, learning, planning then changing the plan a few times. Finally settled on a build which I will get into now. Engine I knew I wanted an LS3 motor because it's powerful, compact, well supported by aftermarket, and affordable. Grabbed a 2008 Corvette LS3 complete pullout. With cam and headers upgrade 450+ rwhp is easy, more than enough for a 2600 lb car being built for the canyons, Autocross and track days. Transmission The F-Body 98-02 T-56 fits the S-30 chassis well, shifter lines up in stock trans tunnel hole almost perfectly. However, these are hard to find and expensive on used market so choosing a new Magnum-F, touted as "direct" replacement for F-Body, makes sense. For the added cost of new over used, you get brand new never beaten on trans with better internals capable of handling more torque and improved shifting. This is a major purchase line item so have been it putting off as long as possible. Time is growing near to get it into the garage... Rear Differential Although my 1995 Z has a stout-as-hell R200, the rest of the stock rear is a mess needing expensive upgrades to handle LS3 torque. A few Mustang 8.8 swap came and went over the years then Vlad, AKA Invincible Extremes, came out with his 2015 Mustang Super 8.8 swap. Watched the whole development thread then pulled the trigger, boom! Insane power handling with easily sourced parts. Ordered up Vlad's "tack welded" kit with his custom axles, purchased an 8.8 Torsen limited slip 3.73 gear diff and some new hubs. Done. Bring on the HP... Suspension Vlad introduced me to Noah (Instagram: @noahdropkin), a young talented mechanical engineer, when I had in depth technical questions about the 2014 Mustang spindle swap. Noah had the 2014 spindle swap at the time and also has the Super 8.8 swap. His main reason for interest in the 2014 swap, as well as mine, was it gave a cheap and strong 5 lug hub to match the rear 5 lug hub of 8.8 swap. There are a few compromises with the 2014 spindle that we discussed at length. Over the course of a few weeks of discussions, Noah decided to grab a 2015 spindle to explore its possibility for swap. Doing some magic with a digital scanner and Solid Works he concluded this could actually work, with some custom parts of course... Hot Damn!!! Noah started in on the heaving lifting of computer modeling and fabrication, he truly is the brains and brawn behind all this, while I peppered him with questions during design phase. When Noah committed to building a swap kit for his car he asked if I would like one also. Ah, Hell Yeah! Noah has test fit the kit posting plenty of good pics on his Instagram page. The end result is the wheel base remains stock, slightly wider tract width, improved scrub radius, good camber and minimal effect on Ackerman. Steering ratio increases due to the shorter steering arms on the 2015 spindle. For Noah's 240 steering rack, the resulting steering ratio is a snappy 10:1 while with my 280 steering rack is close to 11.5:1, a bit more tame but still fast. Off the shelf coil overs are available for Vlad's front and rear swap but Noah and I agreed that good dampeners are in order. Custom strut tubes were fabricated for the Koni 8611-1259 dampeners, arguably the best off the shelf dual adjustable dampeners for S-30 chassis. More details to follow as I dig into this build now that the major parts are here to play with. The last pic is 2015 Mustang with swap concept drawn.

-

How is the ground clearance with Hawk's headers? Or put another way, how far below frame rails do these headers sit? Please mention the engine swap mounts you are using also. I am fabricating some custom puck style mounts to optimize fitment. American Racing Headers is the maker of Hawk's headers. Went to ARH website and learned that they offer a 1 3/4" primary tube and confirmed with a phone call. Hawk's website only has the 1 7/8" option. I was reluctant to use the 1 7/8" on the stock 376 cu.in. displacement LS3 so happy to learn these headers are offered in the smaller 1 3/4".

-

What is the spacing on the John's Cars A/C bracket? Can it be ordered in one of three LS spacings, Corvette, F-Body or Truck?

-

Advice on radiator and fan for LS3 swap

280Z-LS3 replied to 280Z-LS3's topic in Gen III & IV Chevy V8Z Tech Board

Thanks Wildfire490. My car is a 1975. Your comments are exactly what I have been reading about radiators. Chinese radiators like Champion use smaller .626-.75" cores while American made typically use the larger cores. Most C6 and C7 Corvette "upgrade" radiators are two core using 1" or larger cores and the density of cores is higher. What special connections should LS radiators have installed? I believe a nipple for head steam hose. Anything else? Any recommendations on where upper and lower hose locations should be located on the radiator for a N/A motor, seems there are few configurations from which to choose. Sorry for the basic questions, my first LS swap. Off to study OEM LS cooling system design... -

Advice on radiator and fan for LS3 swap

280Z-LS3 posted a topic in Gen III & IV Chevy V8Z Tech Board

While searching around for fans to cool the LS3 swap I came across two good possibilities. C7 Corvette 600w fan with integrated pwm controller 2008 Ford Fusion fan and pwm controller Could not find the exact size/dimensions of these fans so noted the radiator dimensions. Also got to thinking of just swapping the compete Rad/fan setup from either of these cars. C7 Corvette is 17.25x18.5x1 Fusion 17x25.75x1 These are single core radiators! Is it advisable to use a single core in the S30 chassis? Always thought the more cores the better in radiators. How times have changed! CX Racing has a nice 3 core 18.5x25x2.5 for under $200 made for the S30 chassis which very similar in size to the Fusion radiator so it's fan should fit well. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

280Z-LS3 replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Looking good! -

Entertaining making my own mounts only because I will be running a dry sump oil system and long tube headers. Where is the "correct" location to mount the centerline of the engine? Is it dead center of engine bay or off to the passenger or driver side?

-

t56 Magnum vs. t56 Magnum-f

280Z-LS3 replied to WailordUseBodySlam's topic in Gen III & IV Chevy V8Z Tech Board

Ironhead installed the Magnum which put it about 4" forward of stock shifter hole in tunnel. I think the Magnum-F with shifter location 3" father toward the rear compared to Magnum will best match up with stock shifter hole. Have a look at Ironhead's build thread, he has a few good pics of installed Magnum. By the way, I will most likely be using a Magnum-F in my LS build because of the better fitment. I am curious why it is listed at $200 more then the other Magnum models... -

ANOTHER Datsun Z/LS3/T56 Swap Thread

280Z-LS3 replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Forgot to mention that the paint vapors are heavier than air and will sink to the floor level so make sure you have good air movement along the floor. It looks like your air system will provide good air exchange along the floor but check. I used SPI epoxy primer and polyurethane clear. The owner of SPI is readily available to talk tech and I took advantage with a few phones call to him. He paints his cars in his garage with no plastic. His method is to lift garage door about 12" to allow the vapors to flow out and wets down floor, that's it. Looking forward to seeing the finished paint job! -

ANOTHER Datsun Z/LS3/T56 Swap Thread

280Z-LS3 replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

I have painted only one car so take this advice accordingly, lol. I assume you are spraying traditional solvent based paint, not water based so please get good 3M paint respirators and you have a good seal to face, clean shaven. Use a Tyvek suit too. https://multimedia.3m.com/mws/media/103197O/automotive-respirators-and-safety-products.pdf Have you tested movement of air with smoke, like with a cigarette? Great paint jobs have been produced in lesser facilities, i.e. in back yards, literally! Spray gun technique is key and especially in the tight space you have there. I would suggest practice on some fenders. I grabbed some from a body shop dumpster. Sort out properly thinning paint for atmospheric conditions and spray pattern. t's all in the Prep too. Make sure everything is clean by wiping down with quality wax and grease remover., can't be too clean. Oil and wax will give "fish eyes" in paint. I purchased a turbine sprayer because did not want to deal with cleaning compressed air. I can't tell the color of the lighting your have installed. I picked up some cheap 5000K led lights, sun light color, for my shop. Below 5000K light looks yellow and above looks blue. Don't know if color of light will make a difference but I liked the idea of replicating sunlight. -

PM me, I live in Templeton also. Gathering parts for a 280Z build now. Joseph

-

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

Silvermine has a BBK kit using 12.88" rotors up front which is interesting. I believe it uses a 2004 STI rotor with 1.18" wide. I am looking to use a slightly larger diameter hat and rotor 13-13.2" and 1.25" wide to take advantage of all clearance in 17' wheel. Not really trying to reinvent proven systems but just design a system within parameters of my build. If need be will head over to friend's shop to use his Bridgeport to fabricate custom bracket which should allow me to mount almost any appropriately sized caliper/rotor combo up front. The rears are easy because of the 8.8 swap uses 2015 hubs, plenty of off shelf brake options. -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

I have been experimenting with this calculator. https://www.tceperformanceproducts.com/dual-bias-calc/ -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

Any chance different link to Jake's calculator? That one is not working. Also googled Jake Latham's brake calculator with no success -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

I plan on using the stock suspension design modified with coil overs, rod ends, swap bars, camber plates, etc. Don't know if that clarifies the suspension question though. Does eventual shock valving, spring rates, ride height will need to be factored into initial brake system design? If so, that's really starting to look like a "chicken or egg" conundrum lol. I will continue learning about brake bias via piston sizing front and rear calipers and matching rotor sizing, both diameter and width, front to rear. A real world description of how a car was setup would be helpful, I learn best by example. Would like to add learning this stuff is half the fun, maybe more recalling times of frustration while wrenching. The knock back issue has been on my mind. If I recall correctly the AP Racing calipers Essex offers have knock back springs. Will inquire if Wilwood offers knock back springs for calipers that are of interest for my application. -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

I spoke with Wilwood, StopTech and Essex and here is a bit of a review of experience. Wilwood was the most helpful but clearly wanted to steer me to pre-assembled kit only because I mentioned was employing 2015 Mustang Super 8.8 rear and possibly 2018 Mustang front spindles. Felt the tech really wanted to help but I needed to give him more info which is why I started this thread. StopTech did not want to give me the time of day, buy a kit or go away was basically my options. Essex was wanting to be helpful but also said buy a kit because of their "limited stock". He did offer to sell me anything from AP Racing's extensive the Euro catalog, which he emailed over, but I was to be "on my own" choosing parts. I will crack this "black box" lol Thanks for the heads up on Tilton for pedal and M/C. I am hoping to design a system utilizing standard stocked hats from one of three above. I have the rears covered with Wilwood hat 170-14430 but will be locked into using a 12.88" rotor ring which is the smallest diameter offered compatible with 2015 Mustang hat which is machined for 12x8.75 rotor bolt circle. Thinking this should be ok since the 12.88" ring is offered in 0.81", 1" and 1.1" widths. One of these should match well with 13.06"x1.25" front rotor #160-8165 if I can find a hat. I am shying away from the 2014 Mustang spindle swap because it moves the wheel 3/4" forward in wheel well. Arizona Z Car and Techno Toy Tuning both offer 5x4.5" hubs for stock spindles which match the rear 2015 Mustang hub pattern. Hopefully either companies will share the hat off set used in their BBK before I buy a hub set to check hat availability. If not may just gamble by buying a set and hope I can find an off the shelf hat. Or, last resort, have a pair machined by Colman Racing. -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

Thanks Ironhead, these comments are exactly my thinking. So i guess my issue is where to start. Since I have rim size limiting rotor size do I just maximize rotor, say at 12.88" or 13" with 1.25" width for front then choose front caliper size then match rear rotor/caliper accordingly? From what little I understand the larger the piston size the greater the torque for a given pedal effort. Found this little nugget on the web: "All things being the same.... a 1.25" bore FSL generates 2531"lbs of torque at 509psi and 60lbs of leg effort. Moving to a 1.375 FSL- Same effort and same pressure: 3062"lbs of torque. +17% Moving to a 1.625 FSL- Same effort and same pressure: 4278"bls of torque. +40%" FSL is Wilwwod Forged Superlite. How much torque is too much, that's the question. All the rest can fall into place -

Let's talk brake system design

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

Yeah, been poking around seeing what others have done. Will jump over to ZCarGarage to look at StopTech kit to see what I can learn. Getting an understanding of parts choice is what I'm after -

Gathering parts for my 1975 280Z build and time to get the brakes sorted out. Been hunting around the web for brake parts from the major aftermarket players, in particular Wilwood, AP Racing and StopTech. Don't really want to just buy a "kit" from a Z car vendor, purchase parts for custom setup or swap an OEM system without understanding what I am getting and how it will fulfill my requirements and expectations which is performing under road course track duty. I am honestly new to performance brake theory and hope to learn enough to talk intelligently with brake vendors to hone in on a properly designed and balanced brake system. For starters would like to understand how to choose piston sizes in calipers and relation the front calipers piston size have to rear caliper piston size to produce adequate brake torque for S30 chassis. Floating vs bolted rotor ring pros and cons. Proper rotor thickness front and rear, assume starting with 1.25" width up front. Brake pad choice is easy to get into ball park with recommendations. Going to be using a dual M/C to maximize tuning of brake bias. Street legal 275 R17 autocross/track tires are planned. I believe the only item that may need to be custom fab'd are radial caliper mounts which confident I can handle. All other parts should be off shelf from Wilwood, they post extensive product into on their webpage as does AP Racing but they are Euro based thus harder to source. StopTech I have found to be lacking in product description. Hope this is enough info to get the conversation started. Any words of wisdom truly appreciated!

-

Subaru power rack options

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

Thanks for uploading photos! -

Subaru power rack options

280Z-LS3 replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

The pics on your swap thread are out of focus or low resolution making it hard to see detail. I see lower res photos on other sites also and don't know the cause. The "pocketing" of the sub-frame is not a big deal, actually enjoy this type of metal work. Another member here used a newer style JDM RHD rack to convert to a RHD car. That rack has the 2005+ mounting tabs design instead of the older style round and square type mounts. He had to cut off the mount ears to make it work, basically ending up with two round mounts. Not sure why he needed to cut the ears off, maybe it would not clock correctly to have input shaft line up with steering shaft. As you suggested it would be better to fab mount on sub-frame to accommodate the mount ears of newer rack. Good to hear the rack seals are easily replaced.