-

Posts

652 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by zeeboost

-

-

Nothing but drawings or artists renderings - not a single picture of a complete/finished car. No "news" since Feb. 08... Looks like it went down the tubes before making it out of the dream stage.

Most likely wasn't helped by the financial meltdown - wonder why they didn't get a bail out? Short of spending $225,000.00, I still have not seen a Sports/GT to match the original Datsun 240Z. Nothing even close...

FWIW,

Carl B.

Base is supposed to be around $42,000 for the 180-190hp engine.

-

Are you referring to the same adapters is in the first post?

-

-

Awesome pics Mr. Chong!

-

I just picked this up, traded in my 03 G35 sedan for it. The G was turning into one of those "oil consumers" So rather than having a 4k paperweight around I traded up to this:

Plenty of power!

Charger SRT8

I like those cars, but my buddy's wife has had enough problems with hers, from overheating to tranny fluid leak - this was at around 50,000 miles or so. Also, IIRC, you get to replace 16 spark plugs every 30,000 miles. He wasn't aware of this, and was detonating pretty bad at 45,000 miles. I never read any consumer reports on it, so maybe they just bought a lemon.

Bummer about the G - I was looking forward to it. Guess I'll stick with a TSX or IS250

-

Stay away from Chrysler, GM/Chevy, and Nissan/Infinity.

The 2006 Mercedes-Benz C-230 is not so bad and doable for $20K.

Why Nissan/Infinity? I ask because I've been looking at buying a G35 coupe...

-

I'd hit it. I think the @ss is very attractive, although I would paint a black strip around the tail lights, to mimic the Z's tail panel.

-

You should watch Zombieland if you haven't:

hint - it's awesome

*edit* found part of the clip

-

You don't think it's a bad ground / loose battery connection or something like that, to where it didn't allow the EFI to work properly, and was too much resistance for the starter? I don't know if I would jump into fluid pouring in the cylinders just yet. You could take the plugs out and see if the engine will spin over. I've had to do that a couple times with flood vehicles, and another guy that added too much oil to his engine and hydrolocked it.

-

Similar story with me:

http://forums.hybridz.org/showthread.php?t=107206&highlight=spec

A lot of other people with lt1 t56-styled transmissions had similar stories as well - I don't know about the other clutches they sell, but I'll never buy from them again.

-

Before he starts swinging away, yeah. I think the dad had plenty of time to do it before the kid started beating on the truck. The dad seems like he should be able to overpower the kid. Just get one firm grip on the bat before the kid has time to react. I hate how they just stand there and watch.

-

Yeah, on the video where he takes the bat to the truck, the parents are just watching him beat it up, while telling him no. Okay, this goes both ways for me. I can see it being fake, because if they take the bat away from him, it's not good entertainment. I can also see it being real, as helping to explain his emotional outbursts. By not enforcing anything, they're allowing this behavior. They don't discipline him, and simply watch him go to town on the truck. It was yesterday that I watched it the video, but I remember one of the parents started to approach him AFTER he began hitting the truck, but made sure the kid got a few hits first before actually interfering with him.

...and then the one with the grandma, I don't know. Next generation at its best, I suppose.

-

Here's one on me

.

.

Have a good one!

-

I, too, would like a recommendation for the DFW area. I'm looking for someone to mold the flares on my widebody, so quality of the bodywork is important...I'm not too worried about the paint.

-

Lol, I actually like that shifter - it's comfy. Guess I'll leave it on for the next owner to complain about.

-

LOL So than how does one get a tag under they're name? hm... Do you guys just randomly stick them on people or what?

~J

Donate you fool!!!

(the more money you send 'em, the cooler your user-title is!!)

-

They finally evaluated the idea with the dowel pins, and decided against it. They told me I can do it myself, but if anything happened to it, they wouldn't warranty any of the damages. They're worried that the cover will be under quite a bit of stress when installed, or when removing it from the bucket, and would most likely crack the paint on the cover, as well as potentially scratch the paint in the bucket (from the dowels when trying to line up the holes). So, I'm trying to think outside the box a little bit and try to figure out a different way to mount them up.

This may sound kind of odd, but I'm thinking I might be able to mount a couple of hinges on the top inside of the bucket (where the bucket to hood area). Then on the opposite corner (inside of the bucket, in the area where it meets the fender) have a couple of dowel pins that drop down into their corresponding holes, trim a part of the dowel to be thinner than the rest (hourglass shape), and use a small curved clip to slide around the thin portion of the dowl and hold it in place while snugging up against the underside of the headlight bucket. So, to get access to the inside of the bucket, just remove the two small clips underneath, and the cover should hinge open (reminds me of a gullwing door, if that helps). Lol, sounds like a really elaborate way to mount up a couple of covers, but I guess that's the price you pay to be different.

Another thing, that I can't quite grasp how exactly it would work, would be to have the dowl pins sticking out from headlight bucket, and have something attached to the cover that could latch around the pin. Also, I don't know if there are any push/release latches out there, so when I push on the cover, it'll latch, push on it again, and it'll release. I know my old pantry had one

, but I don't know if there's anything similar to and smaller than that.

, but I don't know if there's anything similar to and smaller than that. -

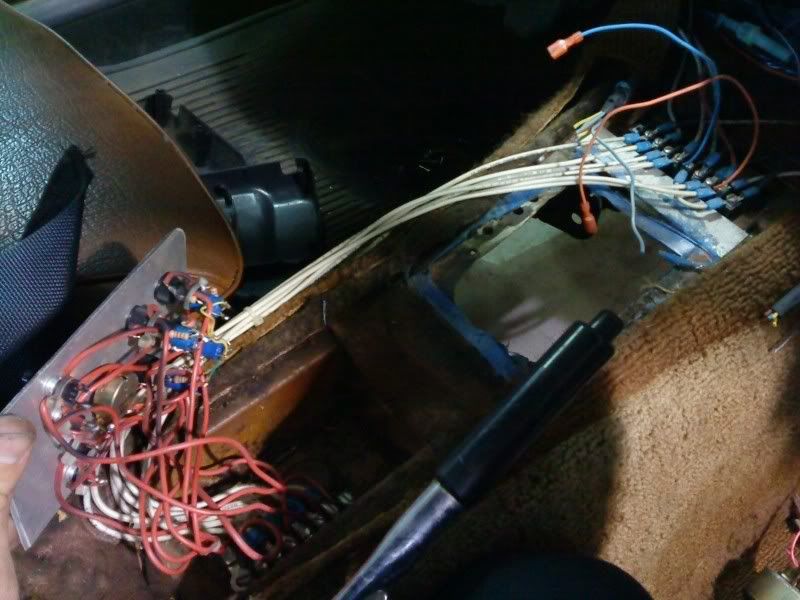

Actually, that's some fine wiring there, and nice terminal board work. I would consider it a pain to restore, but not an abomination. Methinks they did something at some time in the past---nobody goes through that much work to just get switches to light up!

It's got real wires, mounted items, connectors...man that's HEAVEN!

I hope you never have to encounter zip-cord hell, or speaker-cord hell! LOL

You're correct, the wiring did look more professional than most of the other Zs I'd picked up, but it still bothers me that he used house wiring under the hood. If it was better?...I don't know, but it didn't seem right. BTW, the wires pictured ran to two switches that controlled some bulky aftermarked power mirrors on the car. I've already ripped out the illuminated switches. I think the biggest wiring mess in there was a super-fox radar detector, with the main control unit replacing the map light. I bet there were over 20 wires that ran to the back of that thing, scattered from all about inside the car. When I removed the carpet, I noticed several holes drilled throughout misc. places in the trans tunnel to feed other wires through there - no rubber grommets or anything to protect the metal from stripping the wires.

The rat's nest I was referring to, with all the taped electrical connections, was the 280zx:

This was after I had done a bit of "cleaning" from the dash area. I think the worst was under the the hood, though. There were at least a couple of wires resting on the headers, with the insulation already melted. Thankfully they weren't powered, and ran to sending units for a couple of the gauges. This one also had some speaker wires being used to power a few things, like a full-time fuel pump - nothing important though.

-

Here is my N/A L26 with 6-2-1 header and 2 1/2" strait pipe exhaust. Not too loud, but sounds pretty mean.

When I hear Skib's car it sounds pretty loud at idle, but not when he steps on it.

I have just about the same setup as you, except I have tripple webers (thanks Zmanco) and some generic straight through bullet muffler. I thought ours sounded identical, but once I uploaded the video on youtube, I think mine sounds a bit more ricey. Anyways:

-

I stripped out most of the widebody today; here's a glimpse of the wiring with the dummy switches that I was talking about:

-

Hmmmmm......

PO swapped in an L24E block, chopped the pickup tube in half and made it rear sump with flexible rubber hose and two hose clamps.

Cracked (and subsequently repaired with wood) cowl induction fiberglass hood. Really accented the power of that L24E too.

A set of mismatched 3 and 4 screw SU carbs with completely different needles front and rear.

Timing cover held to block with non-metric fasteners. Distributor shaft not even remotely close to being positioned correctly (dizzy was about 180 off). Pieces of lower timing gear floating in oil pan. Piece of front cover floating in oil pan caused by using an oil pan bolt that was too long.

Three 205-75-R14 and one 195-60-R14

2.5" to 1.5" to 2" to muffler to nothing behind the rear half of the car custom exhaust system.

Custom red and black Velour upholstery. T handle shift knob wedged on with duct tape.

That's about all I can think of off the top of my head.

:lmao:

:lmao:Yours takes the cake so far

-

'75 widebody - had several square-shaped switches wired into each other that just lit up, with a rheostat controlling the brightness. No other purpose. Also used house appliance wiring; I'm not sure what the term for it is, but several wires, including the alternator charge wire, were solid copper under the insulation...not braided strands or anything like that. It had the really annoying California mirror that blinded the upper-half of the windshield. There's a lot of quirky stuff with that one, but these are what stand out to me.

'72 240zt - My main complaint is that the PO didn't believe in gaskets, just silicone. At least there was a headgasket on the engine. Couple of switches without wires running to them on the inside, underneath the dash, but I can put a use to those.

'82 280zx - Had several wires behind the dash that had splice connections where the copper was twisted around each other and taped...but the tape came off on a few and would start popping fuses. Had an alarm that was possessed and would go off at random times while driving. The gauges had annoying illuminated blue wire circling the edges...really looked like crap. There was really quite a bit with this one, but I'm not in the mood to type everything out. I'd say this one was probably the worst of all I've owned.

'83 280zx - PO ran the engine without oil for a month which blew a hole in the block, but I bought it afterwards, so I guess that doesn't count. The turbo engine I replaced it with, though, the PO with that car used a pen, a pencil, and something else to plug vacuum holes with...and used speaker wire to run separate wires to the TPS...? Also on the donor car for the turbo engine, the PO used generic acorn lug nuts, instead of the factory ones, which I didn't find out until I had a wheel fly off on the way home

'77 280z had five layers of paint, and the outer-most were the really thick single-stage paints. By different layers, I mean different colors...but I'm also counting primer. It went factory primer, factory brown, primer, red, different colored primer, red. I guess he ran it through Maaco every few years. It also has some mystery switch that does nothing.

'76 280z - I forgot about this until I read flexi's post; all valve lash was adjusted tooooo tight (no gap), and the bolts to the right rear A-arm were about to fall out...actually one did. I was wondering what that popping noise was when I ran over bumps; easy fix, though.

-

-

My LS1 Rx7 :

Sweet mercy! How much and do you accept kidneys? I can get as many as you need. Awesome shots!

280ZX Front Air Dam Mod?

in Body Kits & Paint

Posted

I removed the bumper before doing the bodywork to it, but I know what you mean, I kinda like the bumperless look with the air dam:

The side profile does look a little funky, though, with the headlight buckets sticking out further than the rest of the car: