tube80z

-

Posts

1383 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by tube80z

-

-

On 2/2/2023 at 6:18 AM, clarkspeed said:

Another new shop toy. Bought a cheap fuel injector cleaner/tester. So far so good. I wired a few dropping resistors to test the old Bosch low impedance stuff. Pulled a pile of old injectors out of storage and to my surprise most all fired. I will polish them up and sell the best flow checked results.

Did you get the machine with an ultrasonic cleaner? I've been thinking about these for a while but it isn't high on my list at the moment.

-

18 hours ago, jhm said:

On the topic of data logging tools, has anyone had any first- or second-hand experience with the Racebox Pro? (I didn't know this, but it's produced in Bulgaria.)

Seems to have a lot of organic features not inherent in many other data devices. The biggest weak point I've come across is the app apparently, but the company seems to be improving it and releasing new updates regularly. Overall, looks like a lot of capability for the money ($279 on Amazon).

I'd personally avoid this one as the software doesn't provide a desktop app. Solostorm is probably a much better option and if you have any engine data from a swap then you'd possibly want to use an AIM solo DL or the racecapture logger. It depends on what you need from it. If you want something basic and lap timing Harry's laptimer is probably about as good as this.

Cary

-

On 1/13/2023 at 4:22 AM, AydinZ71 said:

Sorry for hijacking your post Clark! Looking forward to your next update.

@tube80z ah yes! This brings back memories of a previous discussion. I recall you mentioning you got a Z down to ~1800lbs, and one way you did so was through clever selection of wheels and tires.

My car was 1850 with 5 gallons of fuel in the cell and had an easy 100 pounds that I could have removed. I had to run that much fuel as the cell wasn't installed properly and it would have fuel starvation. I dropped a bunch of weight from the front hubs/brakes when I redid them to lose much lighter Wilwood calipers. Someone had spent hours grinding the 4-piston Toyotas down to the size of a Wilwood Dynalites. Hubs were steel and couldn't have been changed to Aluminum. Car had a steel driveshaft, R200 diff, and all the stock crossmembers. I had a super-heavy Optima deep cell battery (65 pounds) because I had alternator problems until I switched to a modern Kubota tractor version. All in all I thought there was an easy 100 pounds of weight I could have removed getting the car into the 1750 range. I've seen other Z's that low so mine isn't an outlier, just not a normal compared to most.

Wheels, tires, brakes, clutch/flywheels, transmissions, subframe braces, all are hidden weight that really adds up. Even too much MIG welding. I started to look more and more at modern panel bond techniques as a way to save weight. Riveting brackets that didn't need to be unbolted, etc.

-

My guess is that the spammers are using ChatGPT or something similar to make comments. As long as the profile looks reasonable and the posts don't look too odd for the forum I've been letting them slide. I think this is only going to get more difficult in the future and will need some kind of tool to upfront check to verify that someone isn't a bot or spammer.

Cary

-

22 hours ago, rturbo 930 said:

I imagine there's some additional security measures that could be put in place in the account creation process. Classiczcars, which has the same software, doesn't have this problem.

Dan would have to answer but we're missing the spam plugin. It appears this software has a license fee that isn't trivial that Dan has been paying. I'm not sure how much the spam plugin costs but there may be other reasons it stopped working I don't know about.

-

14 hours ago, NewZed said:

This one at least has a Z in the web link. Maybe the AI is learning. No posts, just a sign up and a web link.

Also removed. I try to make sure I check the site a couple of times a day but it doesn't always work out that way. I appreciate the extra help in getting rid of these.

-

23 hours ago, NewZed said:

There has to be a better way to screen these scammers out. They're just signing up to get their web links on the site. Not really clear where things are supposed to go from there.

https://forums.hybridz.org/profile/58772-slotgacor02/

https://forums.hybridz.org/profile/58771-daftarratuslot88/

https://forums.hybridz.org/profile/58770-coeducation/

https://forums.hybridz.org/profile/58773-1sboslot030/

https://forums.hybridz.org/profile/58776-petir33slot/

https://forums.hybridz.org/profile/58777-lienanhtuan1986/

These are all flagged as spammers.

-

On 1/9/2023 at 2:13 PM, AydinZ71 said:

Ah! hey, that's helpful Cary! Silly question, why the 13" wheels?

The main reason was weight. Moving to 15 inch wheels in the combo I was using added almost a hundred pounds to the car. This was an autox/hillclimb car and not a road racer. I wouldn't have used 13s on those.

-

If you like I can add these as an FAQ. I'm going to link to these for now from your other message.

Cary

-

Thanks NewZed. Those and a bunch of others have been flagged as spammers. I've also removed from bot posts and topics from the forums. I've been away for a few days and unable to do my daily patrolling. We seem to have a lot more spam activity lately and it will take the village to fight them.

Thanks for all the help,

Cary

-

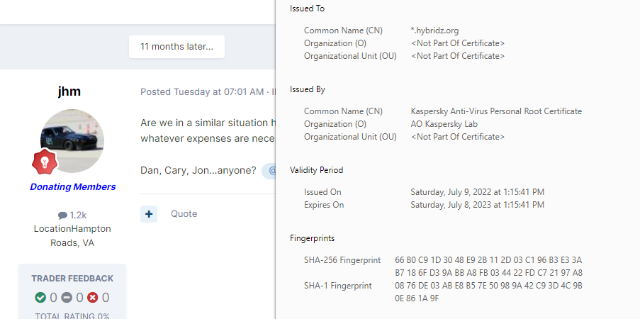

Hi JHM,

I'm not sure why you are seeing this. When I look I see an updated certificate. The only issue I think might be an issue is if your browser doesn't consider Kaspersky to be a safe certificate authority. What do you see for the certificate details?

Thanks,

Cary

-

I sent Dan a DM to look into this. I don't have access to these functions. Sorry, I'm not more help.

Cary

-

2 minutes ago, JMortensen said:

I thought about welding a clevis to the rear of the upright and then being able to adjust roll center with spacers. I think you had brought that up years ago. I like the "fix it at the top" idea though, I think that's going to be simpler, won't have to mess with the CVs, etc, so that's the plan for now. Just need to disassemble so that I can get the camber plate shape and then work backwards to make an offset spacer. Was thinking of drilling and tapping the spacer so that I could move the camber plate to the stock position and then 1" back, and running studs in the top to bolt to the chassis and bolting the camber plate to the bottom. Might be a little tricky getting the plate to move far enough without the strut top hitting anything, but I suppose I've reinforced enough in there that I can hack some metal away without affecting things too greatly.

It sounds easy from the office chair...All in on sounds easy from the office chair

I don't think I'd make a spacer myself but just move the entire plate over and weld up the old holes. That way you can still check on things easily and, if needed, doe some basic adjusting. And since you are rebuilding think about making an end stop that would allow you to easily measure or drop spacers for pre-aligned camber.

I don't think I'd make a spacer myself but just move the entire plate over and weld up the old holes. That way you can still check on things easily and, if needed, doe some basic adjusting. And since you are rebuilding think about making an end stop that would allow you to easily measure or drop spacers for pre-aligned camber.

-

On 12/28/2022 at 9:11 PM, AydinZ71 said:

So I don’t actually know of a caliper adapter for an S30 to S130 brakes. Greg said he “brazed” his on. Maybe silicone bronze? I was literally going to put the rotor on, caliper on (with some clamping force applied) then weld a bracket to the existing caliper mount. If he brazed, I’m thinking the cast strut material is forged and hardened as you said, and hence difficult or unadvisable to weld to?

You can weld to it fine. Greg most likely was worried about distortion. What I found when doing my brakes (remember 13 inch wheels) is that the original ears the caliper bolted to will interfere with the new caliper as you try and bolt it up. So you need to remove some section of these in order for everything to align.

As Clarke mentioned this is some really tough steel. I milled one side of the bracket and it took a few days of working on it in the evenings and ruined a couple of cutters. Next side was sliced off using a fire axe (cutting torch) and then ground smooth. New bracket was welded to the old base.

-

On 12/28/2022 at 12:09 PM, JMortensen said:

Question: I have some 1 1/8" x .120" DOM mild tubing. Looking around, most tubing ends are 1" so that works fine. Could also do some 1 1/8 x .058" wall chromoly. I'm not very proficient with my tig welder yet, but that would be another option. When I dyno'd the car they tied it down with the control arms and it didn't want to start spinning the drum, car was bouncing all over. Not sure I'd feel confident with .058 in that scenario.

The 0.120 DOM is going to be stronger than the the rest of the components you are bolting into. If you every get a large lateral hit (curb/pothole) what is the fuse that will blow?

On 12/28/2022 at 12:09 PM, JMortensen said:Slight revisions I'm considering, would appreciate feedback:

1. Using a monoball holder instead of an outer rod end in the rear

2. Welding in 5/8" studs into the strut upright rather than using a long bolt3. spacing the rod ends away from the strut a little bit. Monoball holder does this automatically, if I did a rod end again would probably use a rod end spacer like so:

I'm not sure how you are welding studs to the strut but I'd personally weld on brackets that allow me to bolt to the strut using a much smaller (shorter and smaller diameter) bolt that is in the same orientation as the strut tube. These can the connect to a monoball or the rod end as needed. Another variation is to weld the monoball cup to the strut tube and use a clevis on the control arm to bolt to the strut.

-

1

1

-

-

These accounts have all been flagged as spammers and I have removed the posts that were made. I allowed one to stay that was indicated as a bot but have sent them an email asking them to respond on why they are not a bot and should be banned.

Thanks for all the help everyone,

Cary

-

19 minutes ago, NewZed said:

I have been very aggressive at banning accounts and hiding posts/threads from spammers. It's possible this is related to me but when I look at the post I don't see the info mentioned. Another mod may have already deleted it. Thanks for reporting, I can't get them all.

Cary

-

Link works fine for me.

13 hours ago, xreho said:I see that when I access the link, an unusual warning pops up. What is it about.

Link works fine for me.

-

19 hours ago, clarkspeed said:

To answer the first questions, yes and yes. You will need another joint and a intermediate shaft support. Do you also have clearance around the engine? When I mocked up mine using a similar rack with the L-series block I had a small interference with the lower corner. I had to slide the entire rack to the driver's side to clear. The shorter V8 block didn't have that issue.

-

Cool additions. I was looking at some similar models too then a friend bought some and I wonder how often I'll do this versus stop by his shop. If you don't mind my asking what drove the purchase decision in your case?

-

22 hours ago, clarkspeed said:

Does anyone have experience with floating rotors? They really do float. Both axially and radially. I can see why the bolts require lockwire. So how do I check runout with these? Seems like I need to somehow lock down the float first?

Yes, on my old F2000 and a friends FA car. What kind of floater are you using? Is the floater also sprung or is that mounted solidly and only the disk floats? If you're using bobbins those should allow for a little of each. There's also the t-nut style and fancier stuff when you go up in dollars. I've had both bobbins and t-nuts and on each they were torqued to spec and not safety wired. Did any spec come with the new hardware? I can give you my advice but since it's 25 to 30 years old I'm not sure you'd want to trust it

Prepare to Win claims 0.002 to 0.004 radially and 0.006 to 0.008 axially. When putting these together I'd check the hub, then with hat mounted, and finally with the disk mounted. The floater to floater plate will wear over time and you need to make sure none of the floaters get too loose. That's about all I remember except for having to crack open PTW for actual numbers.

Hope that helps,

Cary

-

I was going to do a lot of replies but I'll just distill my relationship with data and how I've found it useful or not useful if that's the case. I mostly autox and hillclimb, but I help friends at circuits and have been exposed to really high levels of DA through my professional work. I've taken a ton of data classes over the years like Claude Roulle's optimumG training, John Block's excellent data courses, a number of race engineering vehicle dynamics seminars, etc. I also have an excellent collection of well-used books into what's needed. For me this is something I like and enjoy learning more about and digging into. For a lot of people this is considered too technical and all they want to do is drive and have fun. If you fall into the latter category you can quit reading :-). Please keep in mind this reply is for people with older cars that don't have CAN/ODBII.

The single most important thing you can do is to keep records. At the minimum you want to record the course, lap times, basic weather info (warm dry vs wet cold) time of day/date and what needs to be fixed so you could drive better or make the car faster. If you have an event or option to do practice or fun runs you can use those to make changes and then see if that helps or not. How to make easy adjustments to your car to figure things out could be its own thread. It also important to get pictures from the event where you can see your car loaded up in a corner as well as those that are faster than you or in the same class. There's a lot that can be learned from these photos. And ideally have someone take video of the same cars and if possible use a tripod so you can tell what are and are not trying to see if the car is hopping or the camera operator(phone owner) had too many lattes. These days almost everyone has a camera and most of these also capture video and those get shared on social media, which makes it easy to collect this info.

One really cool trend that I think helps is the emergence of many packages that merge data and video. There are now packages that exist that let you use nothing more than a GoPro camera as a data logger and you can get some very basic info. As @Ben280 mentioned for autox there's solostorm, garmin's catalyst, Aim's solo, Apex Pro, phone apps, etc. There's no right answer for what is right for you. I would say it helps if you have the same thing as other people and you have a way to sync the data to video. The latter is extremely important if you want to know why a run was better or worse. The hard part is getting feedback on what you need to do to improve/go faster. For autox it's impossible to read a dash on most courses, but a green or red graphic or LEDs is something you can see if this is important to you. I can also tell you that many apps that use GPS as the main source of data often fail when hillclimbing. Here in the PNW a number of events are remote (no phone service) and have full growth over the road so no GPS.

Circuit lapping (HPDE, races, time attack, etc.) is often where you'll see the mid-range systems used. It's still possible to use a number of the same autox systems they usually don't capture enough data. These are where you normally see the squiggly lines that make some people so excited. The good news is the low end has been pushing the middle tier options to include more video capabilities. My experience here is mostly with Aim systems and some of the older Race Technology systems (like the one @clarkspeed has that @JMortensen should buy :-)) If you're just looking to get better and do HPDE then the garmin catalyst and similar competitors will be helpful.

With any of these systems the challenge is how to use the data to get better. In autox you don't have much time between runs so any analysis has to be fast, which a few of these systems are better at. For circuit racing if you're a one-man show then you often have a lot of prep between runs and data still needs to be quick but you will have a little bit more data to you should look at like engine/car health. And above these are truly fancy systems that often have a single person looking after them and helping with the analysis. I'm not going to mention these as there are probably 5 people that would be interested.

So if you're still hanging in there here's what I think will be the most helpful.

Starting out and I want to get better (most basic system)

1. Video pointing out of car that captures run and the main driver controls

2. Second video source capturing feet on pedals (or the BS on being flat in that corner show)

3. Speed captured against distance travelled (not time). This is important for comparisons.

4. Lateral & longitudinal acceleration.

Consider adding steering, and brakes to the above list. On the brakes side it can be done one of two ways. You can look at the pedal movement and/or you can add in brake pressures. If you go for pressure make sure you are measuring caliper pressures and not master cylinders if you use a proportioning valve. This will give you a system you can use to learn to go faster. If you are thinking about doing any of this it pays to educate yourself on youtube or take a class about the system you have. A few of the companies offer webinars and paying a couple hundred for a course can put you years down the road from what you'd learn on your own. Unless you have a friend that is into this and can help.

Being this is hybridZ there's still one important topic we need to discuss. @Ben280 mentioned additional sensors and the costs associated. I have some great news. You can use stuff from a JY for a lot of this and it's just a matter of calibration that you need to do. Here's a handy list. For distance (shock pots, steering, throttle, brakes -- you can use a throttle position sensor. When using with shocks, steering, or other linear source you will need to create a linkage that rotates the sensor. RC parts often are very useful. For pressures you can use JY sensors (Bosch) from any of the newer cars that have ABS. There are a lot of cars using these today. You can also get another cool part called an IMU. These are often used as part of the vehicle stability systems that all new cars are required to have. Time to stop until there's more interest.

More later ...

-

4 hours ago, AydinZ71 said:

It is a 5.5" with two disks. True story, I told Greg Ira I planned to run the 9lb flywheel and asked for his advice on a clutch. He laughed at me, and said "you are kidding, right?" and shipped me his identical spec (he just added +qty 1 to his order). I want to say it was around $1200. I could ask him the details, but I think he was pretty protective (at the time) about disclosing too much. As he said to me "you know how long it took me to settle on this setup?". On-track he said it would last two seasons as long as you are rev-matching and baby-it in first gear.

My friend has an EP car and they raced a dual-disk Tilton all year and we measured the disks and floaters after a couple of events and they had hardly any wear. It raced all year and had some wear on the floaters but was still in spec to be used. He then moved to a 4.75 triple disk. It's really cool to hear an L6 rev like a superbike.

The EP car did have a dog box in case that matters and it's driven like Jon mentions using small stabs to get moving from a stand still. Quickest way to kill it is try and drive it into the trailer. I've seen that done a few times.

-

On your button clutch are you using the rally disks? I converted my 3-disk quartertilton (yes mix and match parts) to a 2-disk rally version. We have a local CP guy using one behind a 377 LS with a dog box and he's been driving on it for a year and a half at autocrosses and hillclimbs. I think Jon may have a similar setup or perhaps the grabbier metallic disk version.

Csc delete possible?

in Nissan V6 Forum

Posted

and now gone