-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

ZG Flares in stamped steel or injection molded plastic

RebekahsZ posted a topic in Body Kits & Paint

Who would be interested in buying screw-on ZG flares in either stamped steel or injection molded plastic? I have purchased ZG flares from 2 different distributors and I have been shocked by what a minimal product I paid big bucks for. These flares look good in photos, but there's really nothing to them when you hold them in your hand then crack them when you install them. Seems like a pretty good product to make either as stamped steel or injection molded plastic (like a milk jug or baby slide). Plus, they are on back order from just about every supplier-there must be just a couple of guys laying them up out of fiber glass for the whole market. We are paying good money for pretty sorry product. I have a buddy who owns several businesses and he has offered to help me with production research. I didn't know this, but he says that injection molding of plastic is pretty expensive and that start up might be pretty tough unless sales were pretty high-volume. But, he knows of a stamping company that is operating below production capacity that might be interested in finding more work. Please sound off with your thoughts on demand for these parts both domestically and abroad (Tony D?). I'm imagining simple screw-on flares of the same profile as is now available that could be painted and screwed on in the usual way... If I think the demand is there, the next item would be patent research. -

I have a NV35oo in my 4.3 S-10. I don't like it. Very noisy. Can't get a quick shift to 3rd without grinding. I would look at a T5.

-

There has been some discussion, which I am certainly not qualified to dispute nor defend, about the appropriate contact length between a belt and a pulley. I guess there's nothing awful that will happen if the belt flies off or slips. Just keep an eye on your temp gauge. If it gives you trouble, just change it, but I wouldn't say that it is the devil, nor would I say that routing is awesome, but it certainly is clean, simple and straight forward.

-

Feeding My Addiction (turbo build)

RebekahsZ replied to Slow78z's topic in Gen III & IV Chevy V8Z Tech Board

Beautiful welding and fab work! You are gonna be smoking those skinny tires like crazy! Better get some wheels and tires else you will only be able to race from a roll. -

Awesome build! Really interested to see how it turns out with that oil pan. If you run out of money, be sure to butter up Mrs. Charlie so that when you are in the money again you can spend like a drunken sailor! Keep up the good work. If you have time, please post a link or a picture of the drive belt configuration you are going to use. The JCI instruction book assumes you will be using a stock L28 water temperature sender and a stock L28 oil pressure sender. If you decide to use aftermarket gauges, be sure to plan to use the senders that go with your gauges. If possible, I recommend using the oil pressure sender location at the back of the intake manifold as opposed to the location down near the oil filter. I put mine down there and it is the only leak on the whole car. I don't know the adapter part number, but it is out there in cyberspace. You were asking me about the low oil level sensor in the side of the pan-I left it in place; there is an aftermarket metal plug available to replace the big plastic piece, but I just left the big plastic plug since the price was right. Also, it looked brittle so I assumed I had an even chance that it would break off and create a parts delay. Its been fine for two years-no associated exhaust clearance issues.

-

I'd like some opinions and experiences on your V8 swaps

RebekahsZ replied to dreco's topic in Non Tech Board

1 tuff z- are you ambydextrious? Cbrit- go put your smoking jacket, ascot, and cigarette holder down and grab a beer! There's a higher place for you in heaven, but in the meantime, I'm raising hell with my v8. Smoke 'em if you got 'em (tires, that is)! -

I'd like some opinions and experiences on your V8 swaps

RebekahsZ replied to dreco's topic in Non Tech Board

Its like more having a young, Spanish wife. ie, high maintenance. Lots of fun, but these old cars are brittle. If you take it to shows and polish it a lot, you will enjoy it without much cost in time. But, if you hit that old chassis with the full capability of the LS motor, you will break stuff. Plan to have a relationship with it. If you treat it like a cheap whore, it will bite back. I love it. Why don't you post some of the other cars you've been driving and I will try to help you with some comparison. -

Lane Culver 256-882-2450. Near Huntsville, Alabama. He does LS swaps and does my LS2 computer tuning. Has a fully equipped shop with a chassis dyno. Fully competent but not talkative. Can't speak to his backlog, but I may ask him to put an LS2 auto kit in my truck.

-

My Dream LS7GTZ.......project underway

RebekahsZ replied to cobramatt's topic in S30 Series - 240z, 260z, 280z

Then the race is on to see who puts the first full sequential in a z-car! I'm just not yet a fan of the 2.437 first gear for my application-probably great for a road race car, but I know an instant gear change would be better for my slack driveline surviveability. Maybe if I geared the heck out of the diff. Looking good, wildman! -

Slicks. What transmission are you running? Go to my YouTube account. Search RebekahsZ. Last year I was hooking then spinning. Hope to fix that with different shocks and bigger slicks. My friends with auto trans and slicks hook better than I do with a manual. Lots of track prep really helps too.

-

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

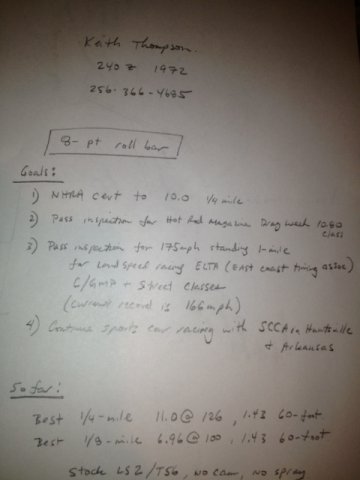

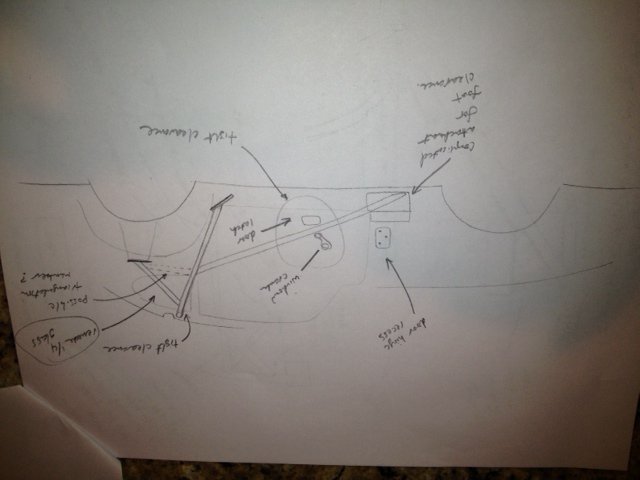

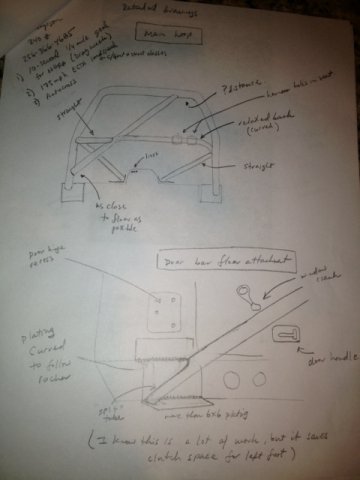

Delivered my car to roll bar fabricator yesterday. Suffering major separation anxiety...... Here are the "final" plans I am dropping off to the fabricator tomorrow. Our discussions at drop-off suggested that I might want to be more specific. I know my fabricator can do the job, it's just his first time with a Datsun and really his first time with a car this slow. He mostly works on 4 and 5-second 1/8'-mile cars. So, this is kind of a minimal job for him. I just hope it pricks his interest and is fun for him. -

That's the way to do it in back. The issue with the webbing is that it is at an angle. If you are a welder, you can get the angle right. If you aren't a welder you are kinda screwed. I have it mocked up and will take it to a welder soon. Will post final pics but it will be a couple weeks. I couldn't find a good place for a simple "bolt-on" solution in front.

-

Roll bar main hoop conflicts with quarter glass screws

RebekahsZ replied to RebekahsZ's topic in Fabrication / Welding

Sorry for double post. -

Roll bar main hoop conflicts with quarter glass screws

RebekahsZ replied to RebekahsZ's topic in Fabrication / Welding

Thank you. I'm gonna run by the ship after work on Monday and pull the quarter windows so they are out of his way. Thanks for the Prozac, johnc. -

Roll bar main hoop conflicts with quarter glass screws

RebekahsZ replied to RebekahsZ's topic in Fabrication / Welding

Thank you. I'm gonna run by the ship after work on Monday and pull the quarter windows so they are out of his way. Thanks for the Prozac, johnc. -

Car is at roll bar shop and I'm freaking out because I almost never ask anyone else work on it. And I'm worried I'm gonna piss off fabricator by micromanaging him. He has the skills and tools that i lack but he isn't a z-guy or a sports car guy. So, I'm gonna piss you guys off instead😊. From the looks of it, the main hoop is going to make at least one, if not both, quarter window mounting screws inaccessible. How do you guys handle that? Special custom screwdriver or do you cut off the quarter window tabs and weld them back on in a different location?

-

Unfortunately for the coilover crowd, the offset for the "group buy" 17x9.5 Rotas was selected for non-coilover cars. So a lot of inboard space is wasted. Ditto for the 17x9s. I'm gonna play this summer with 16x8 with 245/45/16 in front (no flares required) and 275/40/17 in back (BAMF flares). Looking for 315/35/17 A6s for autocross. Will have to enter corners easy but should be able to exit harder. Will keep plenty neg camber in front. I run all used tires. Makes me slower but helps with guilt factor.

-

When I bought my car, it had a cookie sheet on the driver side held in place with a thick layer of bathtub calk. It was fine until I got all self-righteous about it.

-

LS1 or LS2 motor into 240z - Budget wise.

RebekahsZ replied to japanparts999's topic in Gen III & IV Chevy V8Z Tech Board

If you have to have a budget, you need not apply. If you actually go out and drive the car to its potential (which by the way means you will occasionally drive it BEYOND its potential) you will break stuff. It's more like a marriage. If we really counted the cost before getting married, few of us would sign up. But most of the time we are happy that we did. At least on occasion. Once a month. On holidays. -

LS1 or LS2 motor into 240z - Budget wise.

RebekahsZ replied to japanparts999's topic in Gen III & IV Chevy V8Z Tech Board

PLATA, it's time you gave that girl a call. -

Chassis Setup (corner weights)

RebekahsZ replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

I'm watching this thread to learn. Is a bigger rear tire or a lower tire pressure of benefit? I think many of us with big torque zs have the same problems with corner exit oversteer -

LS1 or LS2 motor into 240z - Budget wise.

RebekahsZ replied to japanparts999's topic in Gen III & IV Chevy V8Z Tech Board

In still pissed about the "bought not built comment." The most criticism seems to come from folks with unfinished cars. -

Pleased to be of assistance.