-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

Emergency Electrical Power Shutoff Location

RebekahsZ replied to RebekahsZ's topic in Ignition and Electrical

http://www.allfordmustangs.com/forums/5-0l-tech/246271-battery-relocation-w-4-post-kill-switch-install-w-pics.html This switch from a Mustang sight refers to interrupting the voltage from the alternator exciter wire....I wonder if that would let me avoid running another heavy gauge wire? I may just have to start the car and start yanking wires... -

Emergency Electrical Power Shutoff Location

RebekahsZ replied to RebekahsZ's topic in Ignition and Electrical

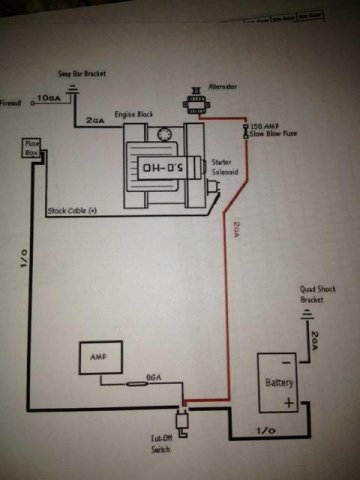

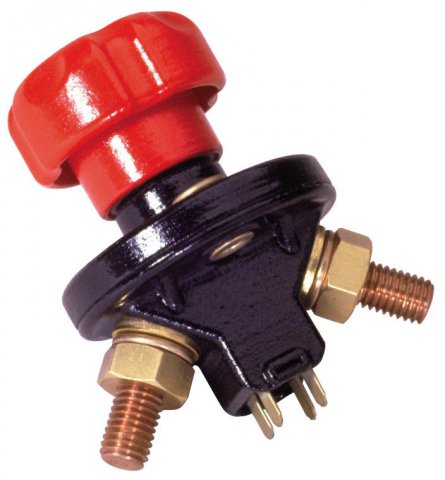

Thanks for replying! Can you show me how you wired that? I have several folks telling me that I don't need a dedicated alternator lug, but rather to just run a second heavy cable from the alternator back to the switch and to have the battery cable and the alternator cable share a lug on one side of the switch, rather than getting the switch with more than 2 lugs. I posted this same question on LS1tech.com and got the attached wiring diagram. Funny that the motor shown is not an LS1. It looks like that push-and-twist switch from Flaming River doesn't offer any advantages for coil-on-plug motors; it doesn't really kill the alternator, rather it shuts down the coil. I'm gonna be looking for a switch like the one above, but one that has an extra long threaded section so I can pass it thru both layers of the taillight panel. Lots of the switches don't seem to have the little off/on label, so I may have to buy the switch, then if no label is included, then go and find that. -

I just had a hamburger. I wonder how that will effect my ETs?

-

RT Diff Mount - Necessary to notch lower diff mount?

RebekahsZ replied to The Woj's topic in Drivetrain

We do need to keep our eyes out for some kind of different bushing for the RT mount. I think the way we have to "notch" it to fit over the snout on the diff weakens it a good bit. I should have posted pictures but the metal inside the bushing wore thru on mine and was metal to metal rubbing on the diff. I have been pretty hard on it.... -

The first time I did a stub axle I thought "never want to do that again!" I've done it 3 times now and it isn't so bad. I now own a 3' breaker and a 300# torque wrench. Now, I still never want to do another spindle pin...even though I own a puller.

-

Cool. I try to follow thru when I ask somebody for advice. Thanks for yours!

-

It was when I was having a driveshaft loop made that the cracked paint was found. The driveshaft went in the mail back to JCI on Wednesday. I'll call on Monday and see if they received it and what they think. Honestly the construction on that driveshaft look like good quality-I have no complaints. In the letter I enclosed, I welcomed them to go up to 3", thicker wall tubing or aluminum. Because the engine sits to one side a good bit, the front yoke is very close to the passenger side of the tranny tunnel, plus, the way my fabricator welded in my driveshaft loop makes things even more crowded. I think I need to keep my u-joints and yoke the same size as they were, but just find a tougher tube. It is pretty tight in there-and I still don't even have it filled up with exhaust!

-

Seeking reviews of harbor freight port-a-band

RebekahsZ replied to RebekahsZ's topic in Fabrication / Welding

-

Emergency Electrical Power Shutoff Location

RebekahsZ replied to RebekahsZ's topic in Ignition and Electrical

-

E-Rod LS3 vs. GM BW 5 speed transmission

RebekahsZ replied to Mike Mileski's topic in Gen III & IV Chevy V8Z Tech Board

Start a membership on ls1tech.com. You will find a lot of answers (some more educated than others) there when it comes to the Ls platform and parts interchange. Remember at the end of the day this is a Datsun site and we mostly know Datsun stuff. For most of us, the Ls is new to us too! -

how far foward does your ls sit

RebekahsZ replied to ls280z's topic in Gen III & IV Chevy V8Z Tech Board

Some guys have all the luck! -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Spring rubbers arrived to help me play with stiffening the rear springs without having to totally disassemble the rear suspension to change spring rates. Sanderson LS1 headers arrived. Gonna get those installed in order to figure out how to modify them to improve fit and adapt them to v-bands. -

My xenon urethane rubs-so cut away!

-

Its that thing that money goes into slowly, but comes out of instantaneously and brings pretty little boxes with labels like Summit, Jegs, Speedway, Racerparts Wholesale, Discount Tires, JTR, JCI and the likes. When it is full, everyday is Christmas-when it is empty its like a long slow burn with endless days of looking at a lonely car on jackstands. For the surfers out there, a full checkbook is like Santa Cruz in January and an empty checkbook is like the North Shore in July-a good time for fishing and snorkling.

-

Balanced my checkbook-OUCH!

-

Actually not bad because they toss the noise out the side. wfritts911 had his headers pointing straight out the top of the hood and it wasn't awful (he let me drive his car). I think you get the most noise when the exhaust dumps underneath the car with the sound trapped between the street and your butt. wfritts911 made his own long tube headers and he hasnt finished the whole exhaust (hopefully he's too busy boxing up a bunch of beef jerky for me, or doing well in college), but he said his car was louder with the exhaust under the floor board than it was dumping out the top of the hood.

-

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

I wish I could have figured out a location that was farther outboard on the front LCA. I'm also curious to see how much the nylon straps stretch. More photos after straps arrive. Got delayed a day cause they didn't have all same brand/color in stock. Told them to send any color they had. -

Cool. They sure do sound good.

-

duragg-you are such a kick-ass guy that I'm wondering how long it will be before you put a V8 in that thing? You need to think about it-you deserve more....

-

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Dropped driveshaft-actually pried it out. Somewhere between my original build and changing the clutch and changing the diff the dimensions have changed, although it was a tight fit before. Sending driveshaft back to JCI to have it made 5/8" shorter and to have them look at a new driveshaft that has same size yokes but a bigger and thicker tube. Going out to make box and get it labeled. Of course the new driveshaft loop made this a bigger job than it used to be. Dreading having an exhaust system, but I want to autocross and I know the exhaust needs to exit behind the driver. And the SCCA club in Little Rock is pretty picky (at least they used to be 10 years ago). All good things must come to an end. -

Seeking reviews of harbor freight port-a-band

RebekahsZ replied to RebekahsZ's topic in Fabrication / Welding

Just used my Milwaukee Model 6232-21 portaband to cut some cast iron. Used a 18 tpi blade, although I bought a 24 tpi blade too for the stainless jobs. Blade install was super easy-cut like butter. That would have been a big job with a hand saw and a messy job with a disk. Turned a 30 minute job into 5 minutes. Used the slowest speed on the variable speed setting. Swag table is ordered yesterday and shipped today. It was a PITA putting the item I was working on in a vice, then using the heavy portaband at an odd angle. The Swag table should solve that. Thanks again for helping me make my decision. -

Strut Tower Brace and Camber Plates - How?

RebekahsZ replied to 240zip's topic in Brakes, Wheels, Suspension and Chassis

Is the firewall really stuff enough to do any good in the absence of a brace on the other side from the knee bar of a roll cage? I can't believe how much my firewall flexes from my clutch pedal. I'm balancing weight against performance value. I just put MYSELF on a diet to offset the weight of my new exhaust system. Gonna try to look like a skinny assed jockey by summer!