-

Posts

3202 -

Joined

-

Last visited

-

Days Won

18

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Gollum

-

No doubt it will fit, but feels like a huge milestone. Still posting on youtube weekly and hope to get to installing this driveshaft asap. I was very concerned about the cost of a shaft with a splined mid section, but came out to a very reasonable $647.02. Granted, I guess when you only paid $800 for the engine and $800 for the transmission, that seems like a lot. But this is also one of the main custom pieces not off the shelf available nor that I can make, so I'm happy it wasn't more than $1k.

-

My K swap isn't done yet, but under 4k isn't impossible if you score the right deals. Done with a "lazy wallet" 6k is overspending but not impossible. Go price out JUST a TR6060 locally, or a new T56 Magnum + flywheel, clutch, etc. Doing a RWD K swap is definitely more work than a LS swap, even if you had off the shelf mounts. Tuning the ECU isn't open source/cheap like it can be with the GM stuff. You have to do something about the intake manifold which can cascade into other choices. There's less documentation about exhaust manifolds/headers that fit. By contrast, you can buy a truck LS for $800-1200 depending on what gen you want, and toss an auto box behind it, and have a whole swap done for under $3k if you're pinching pennies, and most of the parts "just work" or at least are known quantities. Much less time fiddling solutions together. But you want a manual transmission, right? The only budget LS option is Muncie 4 speed, which I'd argue isn't a terrible idea. When I pulled the trigger on doing K24, the cheapest TR6060 within a day's drive of me was over 3k. The cheapest T56's in "ran good in my 250k mile F body" that have been passed around like a peace pipe, was still over $2500. I've seen some deals since, but I was hunting for 4 months with NOTHING interesting enough in price to jump on. By contrast there's SEVERAL AP1 transmissions I've seen go for under $1k. The AP2 transmissions are going for more, but there's little documented about them that's definitely better/stronger, and the ratios aren't much different if I'm honest. The transmission is really what kills the LS as a comparable swap to proper "budget" swaps. If you're fine with a 4 speed, sure it's a great budget option. But realistically I think I'd rather have a VQ35DE with CD009 than a LS3 with a Muncie, and I don't love the VQ. Now as for power. It depends on what you want to do. A K series should be nearly 200whp stock if we assuming you've got a decent base tune with basic bolt-ons (needed as part of the swap anyway). Even if we under rate that and say 180whp... that's still what a stock L28ET puts out, and that's a fun car still. By contrast, a LS3 or similar Gen4 6.2 LSx with JUST A CAM, is going to be potentially a 450+whp car. The stickiest tires that fit under a stock fender well are still going to be easy to overpower at will. So unless you do a bit of work with throttle tuning and/or enjoy babying the throttle, you're going to find yourself eating through tires, and depending on experience maybe investing in diapers. The latter is what leads many to the escalation path of upsizing tires and adding flares. Well now with a 315+ rear tire you're bound to start breaking driveline parts (like stub axles). So now you're looking at rear end swaps with beefier axle options. But of course it's going to understeer like a pig, so you also have to start working on the front. And will all this escalation you're going to add bigger brakes right? Before you know it, you've got a 2800+lb Z car, and yes, it's FAST. But is that what you were setting out to build? For me, that's not what I'm after. Before K swapping, my L28ET powered 280Z was at 2280lbs, and I hope to get as close to 2k as I can eventually. I want as raw and connected of a street driving experience as I can get. I don't want/need the ability to do burnouts in 3rd gear. I want the limit of my vehicle to remain attainable and the overall street driving manners to be fun, not terrifying. Once could always add a turbo to the K series though. No reason an unopened K24 don't do 450whp same as a NA LS...

-

A musician's therapist (The $300 Z)

Gollum replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

If I was going to buy an off the shelf kit, that's what I'd get. And as most spec miata guys will tell you, compound matters far more than just about anything. And for autox (read: not long periods of repeating heat ups back to back), thermal mass is almost irrelevant. Most people's perceived "weak braking" is lack of pressure at the pad and/or poor bad choice. And in that regard, the Micro BBK gives you in practice more than double the usable thermal mass, and also much better pad options. All in all I'll be waiting to hear your thoughts once some miles are put on them. -

Just updating for others, I reached out and Tom said it's sold.

-

In case anyone's not paying attention, I'm up to Episode 5 published now. And in the backlog to be released weekly, the engine mounts are done, and I'm working on the transmission mount. I've got my digital whiteboard forming and will transfer to a common cardboard punch list soon. Definitely making progress!

-

The plan is to gusset the 1.5" tube on multiple planes so that the plate isn't supporting the weight just around the diameter of the tube. Depending on how I feel about it I might do more to reinforce it, even maybe boxing sections in.

-

Not the most impressive thing. But officially marks being further along than I was with the Ford. Somehow that marker makes this feel far more "real" of a swap now. Like, I can get any engine and just put it into the engine bay. But actually having a mount made? That's something. Also, I'll be posted progress as I go on Youtube. Not trying to make some huge successful channel, just attempting to catalog what I'm doing and share some of the info and kinds of info I wished I could find more easily in the past. Sections of the swap and work on the car will be broken down into sections with their own playlist and grouping of episodes.

-

No pictures, but got the driver's side plate made for the engine mounts. Kind of "fun" since each bolt is on a different plane, but just takes some fiddling around. I ended up moving the engine towards the drivers side to generate more clearance for the exhaust. This whole powertrain is so much more lithe than the Ford engine it's comical, so it appears as though I should be able to keep the engine/trans parallel to the diff even with the offset. And since there's only the intake on the driver's side, clearance on that side so far looks great. I'm not even close to anything touching the steering.

-

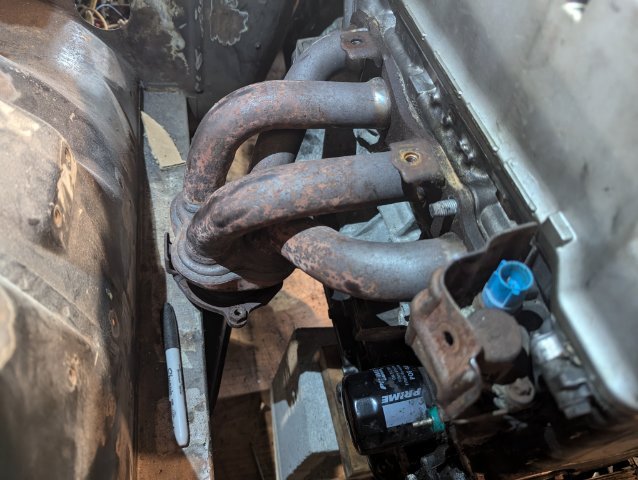

Well it's far from exactly where it needs to be, but getting a picture for how it will fit and come together. SEMA ready! But in all seriousness, plenty of room for the rear sensors and water neck + cap Hood should clear by a mile in this position (since the center sits fairly proud of the inner fender seam). I think this would leave enough space for pulling the pan without pulling the engine as well as plenty of space for getting belts on. I thought for sure this would sit further forward leaving so much room behind the engine at the firewall. So, that leads us to the real challenge, making the OEM exhaust manifold fit: Now, I already planned on putting a v-band on that so the OEM bracket can come off anyway. So I'll need to take some measurements of the ID/OD at various points, and see if I'd have to put on a 4" v-band then maybe transition to a neck down to a 3" to get it cut far enough up to work. Alternatively I could cut the runners up by the head and add some angle up there (could just cut them 90% through, close the gap and weld them easily enough). This would definitely tuck the manifold in closer to the block, though either way there's still the planned cutting at the other end for a v-band. Just might give me more room and options. And in all that, I need to also figure out fitting the mounts around the manifolds. The intake side should be "easy" because the manifold doesn't want to occupy the same space as the mount, but the steering shaft does. So there's that. I might mock up the intake manifold this weekend simply for some aesthetic motivation. Edit: Oh, and the oil pan is sitting about 3/4" below the cross member. Still well above where the floors sit, but I have the space. Might be worth it raising the whole thing up that much since I have that clearance (and more) above the transmission currently. Won't entirely solve the exhaust manifold fitment, but might make it a touch better.

-

Engine + Transmission Also added from the previous minimum weight of the engine is an aftermarket aluminum rear coolant housing. Edit: Also includes adding the starter back in since it helps hold the adapter plate on. Not including: - Flywheel - Clutch - Intake Manifold - Exhaust Manifold - Alternator - PS/AC

-

No updates, sorry y'all. Dealt with the passing of my father (unexpected) this June. So spent a month away which as many might know doesn't just kill momentum but also motivation. I'll be back at it eventually, but might not get back in the garage until later this autumn.

-

Got my AP1 trans on the scale. Didn't zero tare weight but that's sub 0.5lb from my previous measurements. Weight is wet, with shifter. 104.87 or call it 104 if you want to over-weigh the strap. These only take a very small amount of fluid, so very similar dry vs wet weight (1.4qt iirc off the top of my head)

-

Another reference. This took me a while as two of my flex plate bolts weren't happy to be removed from their home.

-

This is fantastic information. I also need to get some dowels but I have that information assuming it's correct: Dowel Pins 4x 15.25mm (Length) x 12.70mm (Diameter) And yeah, I ordered the upper coolant housing version that had the fill neck. I don't have a hood latch, so I wasn't worried about colliding there. As far as mounts, my factory perches are already cut off anyway. And I also already have metal materials and bushings from the Ford swap attempt that I plan to reuse. Luckily mounting is a small piece of the time pie, so it's not a huge expenditure. I wasn't sure yet on a swivel neck housing for the t-stat, and I wasn't sure I liked the idea of tossing parts at something when the OEM parts might work. And yeah, I'm definitely keeping the internal tstat bypass. I'm aware of how bad that would be to entirely eliminate for the pump life, though my research suggests it's probably better to cap off my heater line (since I won't be running a heater) versus routing that in as a second internal bypass. I'm also not adverse to hammering/cutting the transmission tunnel. I already have the reinforcement box that the stock ears are welded to. I'm also not adverse to having the oil pan a touch under the stock L series location, as the stock L series pan actually sits ABOVE the bottom of the floor pan and the lowest point of the radiator from factory. I don't plan to drag the oil pan, but I do plan to eventually build a belly pan and expect to run my engine as low as I can realistically get to that pan. Sounds like your clutch setup will be pretty trick and I'm sure it'll be wonderful. I'm rolling the dice, and going with the ebay xtd option. It might be crap. We'll see. In other news, some goodies have arrived: The MAP sensor on the TB was damaged in shipping, but not a huge deal since I wasn't planning on using it anyway. Intake came with K2F intake adapter and hardware and all looks to be in good shape. Now to just get my two stuck flex plate bolts out (it's been fun). Then I can get manifolds attached and lay the engine in for initial look of how things will lay out. Then onto transmission fitting and planning out the engine mounts.

-

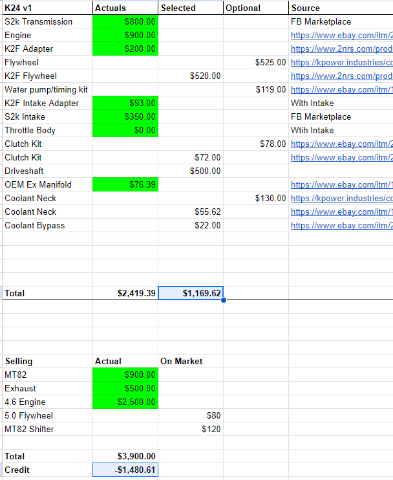

Also just for openness, this is my current budget states. Intake an exhaust manifolds are en route. A had a lofty soft goal of doing the swap for $4k or less. Still unlikely. But not impossible.

-

Spent some of my lunch break today in the garage. Front engine mount (now front, RWD orientation): 2.8 lbs Driver's side engine mount bracket: 2 lbs Cylinder head rear coolant bypass (plus a solenoid I likely need to put back on at some point): 2.9 lbs Power Steering Pump bracket: 1.1 lbs (boy did I think that was going to be heavier since it looked like a chunk of iron)

-

Since the reply button/box is MIA in the general engine/trans weight thread, I figured I'd just start a new topic and let an admin move the post if they wanted. I recently picked up a K24A2. It's an early TSX engine with a RBB-2 head, not the later TSX K24A2. I picked up crane scale that's (in my opinion) accurate enough for what we're working with. It has a limit of 660lbs and is supposed to be accurate +/- 0.1%. I started with the engine as delivered and pulled off parts at a time cataloging the weights as I went. My "linkage" weight was 0.31lbs, but I still tared it out. The engine as it sits in our starting point has known to be REMOVED: exhaust manifold, up pipe post throttle to air box, exhaust side engine mount (is there one?) The engine as it sits in our start point still HAS: Flex plate (auto trans car), AC/PS, Alt, Water Pump, intake manifold, DBW Throttle, Wiring Harness, Starter, and Oil (yes, came wet). It didn't gush any coolant, but considering it had oil I'm sure it would probably leak some coolant if I tipped it on an engine stand. First for removal was the power steering pump (and belt): That puts the PS pump at 6.4 lbs Next was the AC Compressor: That puts the AC compressor at a chunky 13.7 lbs Next was the tensioner: Puts the tensioner at 2.4 lbs Next was the wiring harness: Puts the wiring at 5.5lbs Next up was the alternator: Puts the alternator at 12.3 lbs Next up was a bunch of rubber hoses (vacuum and coolant) that were basically just in the way. Figured I'd include them as a step as to not throw off the weight of the next part: Puts us around 0.9lbs in hoses Next up was the DBW throttle (bolts were put back onto the intake manifold, this is just the dbw throttle): Puts us at 2.9lbs for the throttle body Next up was the "upper" intake (which I find ironic since it's physically lower) manifold half: Puts us a 6.8lbs for the upper intake manifold Next up is the starter (and some wiring attached that goes from the alternator and starter to the main fuse/relay section of the chassis wiring I guess): Puts us at 8.2 lbs for starter and wiring Next up is fuel rail and injectors: Puts us at 1.1 lbs for injectors and wiring (one tip stayed in the manifold, sorry. probably not much weight there) Next up was the lower intake manifold: Puts us at 9lbs for the lower intake manifold Next up is the oil still in the pan: Puts us at 6.2 lbs of oil I removed, which equates to around 3.4 quarts, so since these are generally around a 5-5.5 quart engine you could add another 5lbs to the initial wet weight to make it more accurate for a full wet weight. So what's still on the engine: Flex Plate Front engine mount Intake side engine Mount There's a bracket for the PS I haven't removed Water Pump Thermostat Housing Rear head coolant block Various Sensors/Solenoids (VTEC, VTC and more for example) Coils Spark Plugs Balancer A few random brackets There's probably another 5lbs of stuff from above that has yet to come off that is unlikely to go back on, though not everything that's going back on I can guarantee will be lighter than the OEM parts that came off. As such I'll likely weight again once it's ready to run. And thus there you go. What does a K24 weight? Somewhere between 240 and 320 based upon what the hell you're talking about.

-

-

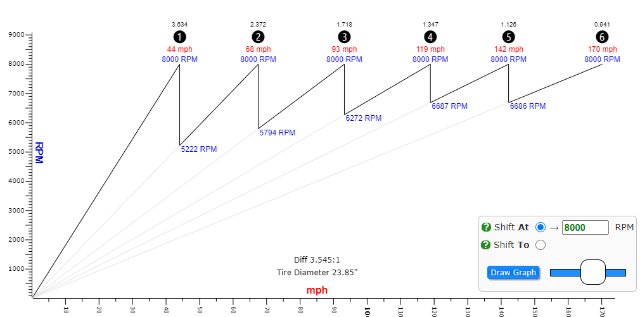

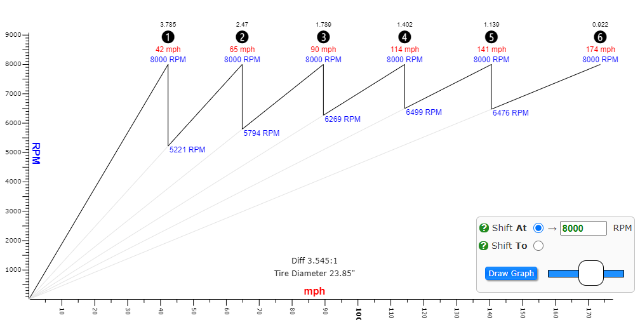

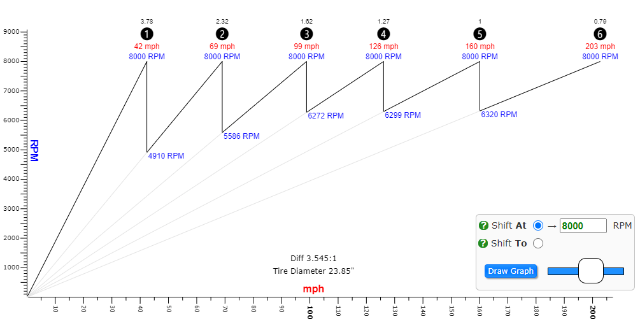

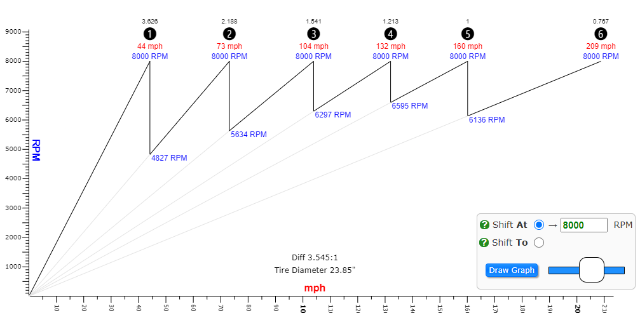

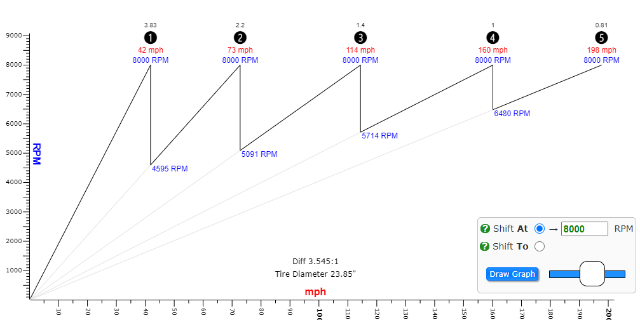

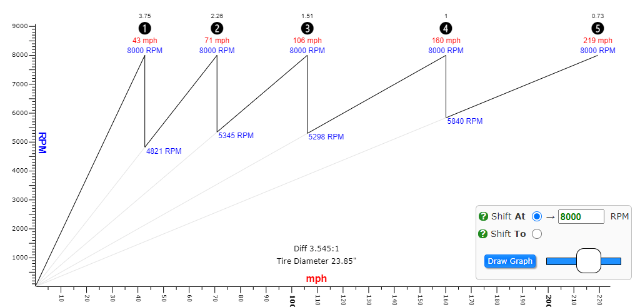

Yeah, I've never been a huge fan of 4 cylinders in a S30. It's one of those "sure, it's okay for you, but it's not for me" kind of things. But the K series is definitely more interesting the more I learn about it. My trans I picked up is definitely an AP1, and I'm aware they're slightly less desirable than the AP2, I haven't found any good indication that they're weaker. (note the 'AP1' as the 4-6 characters) AP1 bellhousing with internal slave cylinder conversion (will likely try to source parts to convert back to external slave) As for placement, yes it's a long transmission, but the design would lend itself decently well to modification if necessary, as the shift rod is of a single rod design and already travels a long distance to the interface with the forks. That said, it's looking like it will work "as is" for at least a first iteration: The engine might sit further back than this, but probably not much. Which puts the shifter here: If I put the tranmission back to where that shifter is just touching the back edge, then the bellhousing face is definitely behind the plane of the firewall. So I think it'll work without fuss. And for those playing at home: AP1 Net ratios (has internal reduction) 3.634 2.372 1.718 1.347 1.126 0.941 AP2 Net ratios (same 1-4 but different 5-6 and reduction gears) 3.785 2.470 1.789 1.402 1.139 0.922 And with a 3.545 R200 on 23.85" tall wheels: AP1 AP2 You can see that 6th in particular sits quite a bit further out, increasing overall spread of the AP2, but the added reduction makes 1-4 end quite a bit sooner, while giving relatively identical RPM drops as the AP1. The AP1 by contrast, gives you slightly longer legs 1-4 but 5th and 6th stay a bit tighter with smaller RPM drops as compared to the AP2 for 5th and 6th. Either way, the fact both transmissions have internal gear reduction and yet are geared surprisingly narrow, makes this a good fit for a higher revving engine in a chassis that isn't running super high ratio differentials. In a perfect world I think I'd still opt for at least a 3.7 diff, if not maybe as high as a 4.10, but let's compare this to something like the CD009. CD009 Notice that the RPM drops between gears are much larger, and the overall spread is much wider. This would certainly work well for a VQ which has a much broader torque range and falls off a bit on the top end, yielding a wider HP curve. But for a K24 where you want to stay up on VTEC to have fun, the CD009 trans would suit something like a 4.44 final ratio much better. The BRZ/FRS transmission for reference, has a pretty sizable drop 1-2, but stays decently tight 2-5 and a big drop into 6th which is fantastic if you want to run a super high ratio diff but still want a good highway cruise RPM. BRZ/FRS Now, another common option for K series transmissions would be the BMW E30/E36/46 transmissions, so we might as well add those to the comparisons (since I have dozens of these transmission ratios saved anyway). The BMW 6 speed: The BMW (E30) 5 speed: The BMW (E36) 5 speed: The BMW E46 also had a 5 speed option for a bit, and is relatively close/similar to the E36 5 speed. The ZF 5 speeds all end with a 1:1 5th gear, which ends up being pretty awkward so the better suited option would be the ZF 6 speed, but even that one has an awkward "rising" spread shift, or gets tighter and tighter. This might be good for a lot of driving situations, but my goal is making a car that's fun on the street, as well as fun doing HPDE/Autox events. I want as narrow of a spready as I can get 1-3 if not as narrow as possible 1-4. To that end, the AP1 or AP2 are both stand out options. Also, just because, here's the AR5 Would suit a V8 torque range nicely... Shifting a 6500 drops you to 3900, 4300, 4300, 4700 rpms. Very wide 5 speed, with decently spaced gears, though maybe a slightly close 1-2 shift. Not so idea for something super high revving, but I can see why a lot of LS people use it.

-

So a bit of an update. The engine is up for sale. Already sold the transmission as well as exhaust/cats I had. Why? Because every time I fit the engine I was faced with the reality that either I needed to change the oil pan, intake, throttle elbow out, and then buy several manifolds to see what fits, or make custom manifolds. I'd resigned to the reality that I'd just have to make manifolds. But I just don't have the time to sit down and hammer that out. It might be a 40 hour job if I could just hunker down and do it, after buying $500 worth of supplies. No big deal right? Except I simply don't get chunks of time like that (currently). I want to just finish a swap and drive the thing. So I was entirely ready to just go LS instead. Over the counter swap parts are available, so it was just budgeting the money and doing it. Selling everything would be the necessary shot in the arm to raise the capitol to just make it happen. ...excpet... ...HOLY T56 PRICES PEOPLE! I kept an eye out for over two months. Facebook marketplace. Craigslist. Ebay. I now know most of the T56/TR6060 ratio sets by heart, and I definitely had some preferences, but I had in my mind what a "good deal" would look like for various sets and nothing was ever close. If I was just tossing money at problems I'd just get a new T56 Magnum and be on my way. But that's $3600, before a flywheel, clutch, master cylinder, slave cylinder, etc. Then I realized that converting a K series wasn't actually as expensive as I thought it was. Started pricing everything out, and realized I could do nearly the entire swap for the price of just a new T56 Magnum. At first I was thinking I'd used the cheap and very plentiful BRZ/FRS transmission, but so many horror stories of them being wrecked. The strange thing is that so many things indicate it should be a strong transmission, and some people drift them (one of the hardest modes of abuse for driveline parts) at 500+hp without issue. I wonder if it's just a shift fork design issue. Who knows. So I shifted and started researching AP1/AP2 transmissions. Kept an eye out, and score! Paid $800. Not 100% known to be good yet, I'll have to do some inspecting before assuming, but the guy was pretty up front about his experience. He was running 700+whp and had been through several transmissions, and this was his third. It held until he did his E30 transmission swap, and then later sold the car. He said when pulled it was still shifting great and not making any noise. It then sat outside for a year (in a bag he claimed) so fingers crossed I'm not replacing bearings or synchros. The bearing prices for this aren't bad. I can get all bearings and orings/seals for under $300 shipped to my door. But the synchros add up. The 1-2 synchro is like $266 on it's own iirc. (comes as a whole assembly with the hub gear, shift ring, etc). But it gets better. The seller was also very strapped for space and trying to see what else he could toss at me, and threw this in for free: The tag was long gone, so it took me a bit to figure out what it is. It's a Precision 6262 with the Gen2 ball bearing cartridge. It has some mild turbine denting, but the housings look unscathed. Bearings have zero play (might be able to measure with a dial indicator, but can't feel it by hand) so I could probably run this as-is. But that said, I'm going to get this swap done NA first for several reasons (cost being one). Once I decide to go turbo, I can just swap in a new wheel (found a rebuild parts supplier with new wheels for $120), and voila a solid turbo pairing for this engine. Speaking of engines, I haven't gotten one yet. I had a line on one, but due to issues with the seller we couldn't meet up. He's about 2 hours from me, so not sure when I'll get the opportunity to reconnect and see if I can get a motor. But I did find this and picked it up locally yesterday: Hard to read, but that says "K to F Adapter". There are a few companies making these, ranging from $240-300 depending on manufacture and reseller, but I picked this one up for $200 and it seems like I'll have to source my own bolts and dowels. I might be able to keep that under $20 so this still feels like a deal (though I'd still have the ship the above new prices, so maybe it's not bad no matter what). I'm tracking all the parts in a spreadsheet (which I normally do anyway) and it's looking like the budget is landing around $3600. Now, there's some hand waiving in that others should be aware of. 1. I'm going to use the existing Megasquirt MS3X box I have. Getting hondata/k-tuner would easily add $600+ to this. 2. I plan to use the OEM exhaust manifold. I simply don't see any good reason not to. I don't care if I'm losing 10 or even 20 horsepower. It's worth it to me to save time and cost to just drive the thing. 3. I already had steel and bushings in stock for doing engine mounts for the 4.6. Would easily add another $50-100 that I'm saving. 4. I have no clue what the driveshaft will cost. The AP1 transmission is a fixed flange, not a sliding splined output, so I'll need to find a shop familiar with making a shaft that can give me that half in of compliance or so necessary. Also, I'll likely need to find a converter flange to go from the AP1 output to a u-joint to cancel out the vibrations from the rear R200 ujoint. As of now I've got $500 for the driveshaft solution, and that could easily go up. 5. I'm also planning to save a few buckets by using 2NRS's K to F intake flange adapter, to use a S2000 intake. The "better" alternative is the Skunk2 Ultra Street manifold which has a reversible plenum. It's $550 and then you're still needing your throttle body, fuel rail, etc. Some of these might be source able or mix-match able with OEM parts, but for $120 I can get an adapter to use a full intake/throttle pull off out of a S2000 and that solves the problem soup to nuts. And considering some people have made well over 250whp NA on the S2000 intake I'm going to say it's "good enough" for me. 6. I'm also not buying into the "use this oil pump, use this water pump, remove balance shafts" internet myth ethos. I understand why people do that, and suggest that. But a lot of people are making changes with very little implications as to the reality of the why. These are $900-1100 motors, all day long. They might go up like B series have, eventually. But for right now, they're still dirt cheap. When people like Richard Holdner go and dyno a completely stock K24A2 with balance shafts up over 8700rpm, 280+hp NA, and 600+hp boosted, you have to wonder where the failures are. And if you go looking, and find one, let me know. I know MotoIQ, 4Pistons, Drag Cartel and other big names all say the same thing. And I'm sure if I was building a 10k motor, I'd also go with a better oil pump, remove the balance shafts, and gain oil capacity as well as ground clearance at the same time. ...or I can just buy a spare motor to store in my garage. So stay tuned. I hope to have an engine in the next few weeks and start mocking things up.

-

I'll be curious to see how these new projects pan out for them. I know the S30 market in Japan has gotten to be American-Mustang levels of insanity, with six figures being the norm for what a clean restoration can go for. But where does "purity" end with those builders and buyers? Is it perfectly fine to do a twin cam head when it's 4x the cost? Will they see any return on value for that? Will commissioning customers be interesting and foot the bill? Will they sell enough to be worth while? I have a feeling they won't come close to approaching the value Derek has, but I also wonder how many potential buyers there would be if someone like JCM just simply imported castings and finished them. Either way, more product options on the market are generally good, and tend to help the community as a whole. So, yay!

-

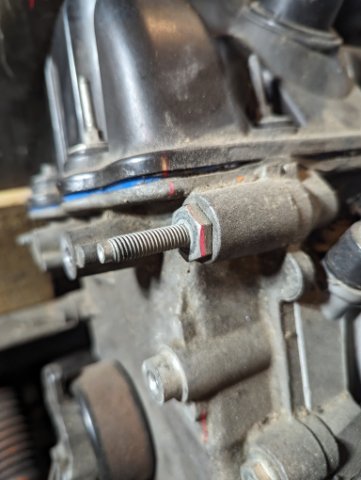

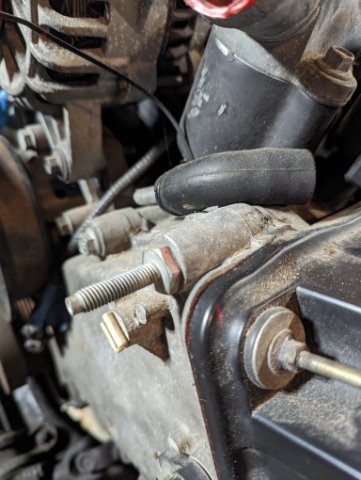

I took the time and got the reverse alignment info here for posterity. An engine should sit about 1" towards the passenger measuring at the steering rack. If your engine sits further forward you might want the crank snout a bit proud of a inch left (looking towards the rear) and if your engine is super short maybe a hair shy of an inch. The larger point though is that if you perfectly center the engine in the engine bay, and point your transmission at the pinion exactly in line with the centerline of the pinion, you'll actually be introducing non-parallelism between the engine and transmission centerlines. If you add that on top of any unmatched angle between your engine tilt back/down and the pinion tilt up. The diff sits about 5 degrees nose up to begin with, so if you mount your engine level, it's not just the 5 degrees of difference you've added (which is a lot) but also likely some horizontal angle difference as well. Did several tests and measurements to ensure this was square: And then measured both directions from the steering rack bushings (could also easily see the offset from above)

-

Before the last time I pulled the engine I was getting an idea for how aligned I was and square to the pinion centerline and chassis. Its "easy" to get your transmission aiming at the diff center, but that doesn't mean the diff would be pointing at a centerline that intersects the crank snout. So I measured the transmission output and the engine front as square to the rockers as a ball park idea to make sure I wasn't too far away from where I wanted to be. My results: Probably not perfect measurement methods, but I was surprised how close it all seemed to be without much fuss. Will measure it all again as I get ready to tack mounts.

-

The good news about running a bit more engine angle and getting the engine up higher and all the way back, is that I can move the engine mount attachment points on the chassis side down and away from the top side of the frame rail box. So I cut off the tack welds and I'm making new sections to attach down on the side of the frame rail box and the TC rod attachment point. Once the mounts or made and I'm ready to weld these fully I'll box them in in a few areas.