-

Posts

3183 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Gollum

-

I'll be curious to see how these new projects pan out for them. I know the S30 market in Japan has gotten to be American-Mustang levels of insanity, with six figures being the norm for what a clean restoration can go for. But where does "purity" end with those builders and buyers? Is it perfectly fine to do a twin cam head when it's 4x the cost? Will they see any return on value for that? Will commissioning customers be interesting and foot the bill? Will they sell enough to be worth while? I have a feeling they won't come close to approaching the value Derek has, but I also wonder how many potential buyers there would be if someone like JCM just simply imported castings and finished them. Either way, more product options on the market are generally good, and tend to help the community as a whole. So, yay!

-

I took the time and got the reverse alignment info here for posterity. An engine should sit about 1" towards the passenger measuring at the steering rack. If your engine sits further forward you might want the crank snout a bit proud of a inch left (looking towards the rear) and if your engine is super short maybe a hair shy of an inch. The larger point though is that if you perfectly center the engine in the engine bay, and point your transmission at the pinion exactly in line with the centerline of the pinion, you'll actually be introducing non-parallelism between the engine and transmission centerlines. If you add that on top of any unmatched angle between your engine tilt back/down and the pinion tilt up. The diff sits about 5 degrees nose up to begin with, so if you mount your engine level, it's not just the 5 degrees of difference you've added (which is a lot) but also likely some horizontal angle difference as well. Did several tests and measurements to ensure this was square: And then measured both directions from the steering rack bushings (could also easily see the offset from above)

-

Before the last time I pulled the engine I was getting an idea for how aligned I was and square to the pinion centerline and chassis. Its "easy" to get your transmission aiming at the diff center, but that doesn't mean the diff would be pointing at a centerline that intersects the crank snout. So I measured the transmission output and the engine front as square to the rockers as a ball park idea to make sure I wasn't too far away from where I wanted to be. My results: Probably not perfect measurement methods, but I was surprised how close it all seemed to be without much fuss. Will measure it all again as I get ready to tack mounts.

-

The good news about running a bit more engine angle and getting the engine up higher and all the way back, is that I can move the engine mount attachment points on the chassis side down and away from the top side of the frame rail box. So I cut off the tack welds and I'm making new sections to attach down on the side of the frame rail box and the TC rod attachment point. Once the mounts or made and I'm ready to weld these fully I'll box them in in a few areas.

-

More fiddling, I think I'm going to actually end up with the engine tail down around 3 degrees. Everything just ends up fitting better. I can't get the engine as slammed back, but I can run it higher up (solving not just pan, but also exhaust clearance issues). It had been a while since I'd refreshed my memory, but my pinion is sitting at 4.6 degrees nose up already. I planned on making an RT style mount, but seeing that again highlighted just how important that will be in order to keep angles in check. I'm sure engine down 3, diff up 4.6 wouldn't be a huge deal on cruise, but we all know how much the nose of the diff wants to rise under accel, and that's a level that's getting to be concerning. So I'll add that to the endless todo list.

-

'82 280zx Turbo max boost without an intercooler

Gollum replied to cpan's topic in S130 Series - 280ZX

I think a bit part of the problem with detonation on L heads is that the overall chamber is "lazy" compared to any modern chamber. There's virtually zero swirl going on. The spark plug is not ideally placed. The pistons aren't do anything to "help" either. Even if you used flap top pistons for added quench, you're still just putting band aids on upstream problems. And I'm not knocking 2V head designs. But look at how far GM has come: That chamber is just cleaned up, not worked. Note the plug angle. Note that it's quenching on both sides and that they're "pointing" different directions. There's also very little valve shrouding. Also, find me an EFI engine designed from scratch in the last 3 decades with round intake ports (to a single valve). Also, what are the average valve angles? Nissan more than once chose valve angles wider than they should have, and only realized it in hindsight. And engines like the L series which were initially carbureted and converted to EFI suffer from old assumptions. By using oval or other elongated entries you're encouraging the airflow to maintain better velocity averages across the lift and RPM range, and promotes swirl to excite atomization. Injectors are also worlds better than they used to be. If you pay attention, most people who de-cap injectors to get more flow might be able to make more power, but idle and cruise quality suffers. Ben talked about some great stuff in this podcast, and it's well worth the listen: https://www.hpacademy.com/blog/089-pushing-the-limits-of-nissans-forgotten-turbo-4-cylinder-podcast/ But something to ponder that he brings up, is that on meth they were running down to lamba 0.50 in order to keep the engine from detonating, that's gasoline equivalent of 7.3:1 btw... Absolutely insane amounts of fuel, and adding intercooling capacity wasn't helpful, and in some cases detrimental as they had an _even harder time_ atomizing fuel when there was less heat in the charge. And this is with the measurably better FJ head which had a lot more Nissan engineering prowess behind it's inception. So to think we're going to magically get a L series head to not fight detonation with some magic bullet? Nope. It's the reality we live with. We can do what we can to make the results predictable and live within those confines. I would say definitely add a huge intercooler, as a rule. If you're going to push past the 300whp mark, definitely do the head cooling mod. If you've ever got the head off, do Jeff's block/head cooling upgrades and use his head gasket. If I was still playing with L engines, I would also definitely go with an electric water pump, and probably reverse flow the engine. I would also never run non-premium pump gas, and ideally would just run E85 all the time. I had a MN47 with the intentions of making "high compression" turbo engine and doing all the above and more. But time and life lead me down different paths. The L engine can do amazing things if you put in the time and energy. But in a factory arrangement, you're almost always going to be fighting detonation as you raise the boost. Also, side note. I'd ditch the distributor/dizzy as anything other than an oil pump and potentially a cam sync. Put a wheel directly on the crank and you'll get FAR better timing accuracy. Even if your shaft has near-perfect lash (which any old used shaft won't) then you still have shaft flex/vibration issues to deal with, and your timing could be as much as 3 degrees off just from deflection. In my case with the added lash I was getting as much as a 8 degree timing error. Great way to grenade an engine. -

'82 280zx Turbo max boost without an intercooler

Gollum replied to cpan's topic in S130 Series - 280ZX

@AydinZ71 And I'm perfectly content to agree to disagree. My experience and point is that HEAT is what destroys rings, and that inlet temperatures have almost zero bearing on heat produced in combustion. The normal factory combustion within the engine at factory boost is going to be somewhere in the neighborhood of 800-1200C at point of ignition. Exhaust gasses once COOLED OFF during the power stroke will still be well over 400F at the manifold. Being concerned about 100F inlet or 160F inlet is irrelevant compared to these temperatures. That's my point. Now, if your lack of IC is causing you to be on the edge of detonation and getting into some sporadic light detonation here and there, I can see that eating through rings quickly too. The guys out there running 2k+HP on meth powered big blocks still chew through rings like a consumable, and their inlet temps at the valve itself are likely well below ambient. Inlet temps are only a small fraction of overall heat generated within the chamber and thus expanding the rings and causing them to work. -

'82 280zx Turbo max boost without an intercooler

Gollum replied to cpan's topic in S130 Series - 280ZX

First thing to set straight here is that lack of IC might lead to being harder on piston rings. This simply isn't true. Yes heat is what will kill your rings, and without enough ring gap then heating up the rings enough to the point of them touching will crack a ring land on the piston, just about every time (true for all engines, not just L engines). But that will be caused by BMEP over time far more than inlet temps. Heat produced is going to be a product of how much fuel is burned. Cold air makes for denser air makes for more fuel makes for more heat generation. An extra 3psi of air (at valve) will cause far more BMEP than 50 extra degrees fahrenheit on the inlet air. All THAT said the largest problem with hot air and raising the boost to the limits of the factory turbo, is that you WILL be seeing inlet temps over 200 degrees (been there, done it). At those temps your MBT or required timing is going to be a VERY narrow window. Retard the timing to be "safe" you'll be leaving a lot of power on the table. Be too aggressive and detonation is almost guaranteed since the mixture is so volatile. The factory compression is low, but the head is also super inefficient at mixing the charge, so you'll be bound to have rich and lean spots within each chamber, and running under load with that hot of air long enough, get heat soaked into that head and it will be detonation prone. So, if you want to spend a full day on a dyno with someone who knows what they're doing, you can likely get well over 200whp without an intercooler. But the tuning would have to be exact, and you'll only see that power figure on a cold run. If it's tuned well then each sequential run as it gets hotter and hotter the peak power will go down as inlet temps rise. Run an intercooler, or run E85. Or run both. Both take work. And if you want "bolt on" parts, I hate to say it: buy a different car. Any car that's outside of mainstream is going to take a good bit of work to modify. Personally, I'd go with a generic intercooler and generic piping kit. Get a larger same side in/out to make routing easier inside the engine bay, and while you're at it make sure the inlet to the turbo is in front of the radiator outside the engine bay like factory. It's worth it. If you upgrade your rubber fuel lines, injectors and pump to run E85 you'll have all the cooling you'll need to reach the limits of the factory bottom end if you put enough turbo on it. Hope that helps. -

Didn't snap pictures, but got the engine back in again after some firewall massaging and it's definitely sitting a bit better. I still feels like I'm hitting somewhere and it's not quite sitting where I want, but it's close. Also opened up the shifter opening width a touch which will definitely be required to fit the MGW shifter.

-

I'd be interested in a black hoodie if we make a run. Also, if it saves effort I think Nick might still have a vector drawing of the logo around, which he drew up for the Norcal BBQ back in 2008. I'm digging around on my fileserver to see if I have a copy of the file, but I'm not sure he ever sent it to me as he was doing the shirt prints on his own.

-

This is about as level as I can hope for, measuring several points around the car, I think the car is about 0.5 degrees tail up, so I'm probably within half a degree difference between the engine angle and the chassis. Positioning isn't perfectly square, and I'd like this to go back another 1/2", but it's close: Will definitely clear the hood at this height. Next time I'm out in the garage (hopefully tonight) I'm going to swap the sump support with another scissor jack so I can get a bit more precise on the height. Might weld some extra supports on a jack to give it a larger footprint and be less tippy (will still shim with wood for softness but would like it to not want to lean more than a few degrees. In this position, The shifter would just barely make it into the OEM opening, but definitely sticking up a bit proud. Overall this is definitely close to where it needs to be, but I would prefer being up another half inch or so, and another half inch back, but I think I might already be making contact in the tunnel somewhere. Going to investigate that, along with looking at what exhaust manifold clearance looks like in this spot.

-

Tim is a legend. I wish I could hand him a 10k check for _all the carbon_ for my car, but sadly I'm just not there yet. Maybe some day. There's quite a few people on the facebook groups with some of his carbon parts. Seems to be a much better parts distributor/manufacture experience than some others have dealt with in the Z community.

-

Oh, also potentially of interest, I don't see my having mentioned it before. I did this weight almost a dozen times, and this was the heaviest reading. If I had to guess, I think on an accurate crane setup (easier to omit balancing issues), I think actual weight would come in around 123lbs. Considering what a T56 weighs, and that these are "generally" okay up to 500whp, and still shift decently up to around 7k, it's not a bad "little" transmission. A pretty good weight-conscious way to get into a 6 speed transmission. In a perfect world, I'd love to have a TKX 5 speed, as they shift great at high RPM, and are fairly bullet proof, and have some really great ratio options. But for what I paid, and that this thing was less than 2 years old with less than 30k miles on it... I'm not upset.

-

It looks like the pictures died... again. No idea what's going on. Here's the bushing I'm using (attached). I probably could have gone with smaller bushings for the transmission mount but it seemed to make sense to just make four of the same due to challenges finding the appropriate interference fit. These seem to work out nicely, so I figured I'll continue with them, despite being oversized for the trans,

-

I'm not dead, promise. Finally doing engine fitting work again, it became apparent that the transmission mount support definitely needed to come out, so I did. Definitely will have to come back with the MIG and patch it up, but it's at least out of the way now. Just need to massage the firewall a bit at the top of the transmission and I can refit for the umpteenth time. The "good news" is that I think I can get the engine far enough back and up as to not be too worried about ground clearance and still git it under the factory hood, and also have enough space to fabricate exhaust manifolds/headers. The engine/transmission was much easier to fit with the engine lower, but the exhaust ports are just inches away from the "frame rails" in the engine bay. I'd be looking for something tighter than a 2" radius to make the turn. Even logs would be horrendous to make work. Ground clearance was also a serious concern. I've got an aftermarket Moroso pan which even comes with a pickup tube spacer because it's so deep. But even if that's 2" (which is not), if I removed the spacer and cut the oil pan down, I would still be hanging the sump as one of the lowest parts of the car. Getting the engine up higher starts to solve all this, but the transmission starts to get impossibly tight at the rear. The MT82 is nice and fat where the shifter attaches, but I'll see if I can get some better pictures in the next fittment.

-

Serious lack of updates: I moved. Long story but I'm now in New Hampshire. Took about a year and a half to find/buy a house out here, car was in a storage unit during that time. Just got a welding machine and some welding gear. Will be starting back up on this shortly.

-

Yeah, I found some examples of S197's running 15's all around specifically for drag racing, with slicks in the back and skinnies up front, and those 15's where even clearing the larger GT brakes, but using spacers. Lots of talk of mild grinding of the caliper to fit. I'm still not sure that it's not the less expensive way to go, even with expensive aftermarket brakes to fit 15" wheels, because the alternatives are just as expensive for fancy brakes, and you still end up with many aspects that are proprietary to Z cars. If you convert to the S197 spindle at least then you're using "mustang market" parts which get volume discount. All that said, when I went looking for "compact" brake packages from willwood and others, the only compact stuff I found are specifically "drag pack" brakes which are far less braking potential than OEM for usage like road racing. They're designed for one hard stop at the end of a straight, not a 30 minute heat on a road course. I'll keep looking though. Realistically I'm probably another year out. Rough order of operations before we get to front spindles: 1. Finish engine mounts 2. Fabricate trans mount 3. Fabricate exhaust manifolds 4. Purchase flywheel 5. Attempt to find a clutch combo that works with said flywheel 6. Find driveline shop that can make me a custom shaft with the sliding section required (bolted on both sides) ( Then the fun begins ) 7. Determine if I want to move forward with the R200 just to have the car back on the road, or reach out to Vlad and start a super 8.8 swap and only have the driveshaft made once, instead of twice.... Also, in the midst of all those very mechanical/logistical aspects of the swap I'll be wiring an engine loom, potentially switching from MS3x to something else, we'll see. Then there's the triage of either route. If 1-6 take a full calendar year from now, expect to get a DM from me around April 2024 @Invincibleextremes

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

I've been digging around and can't seem to find good info, probably because everyone is doing the opposite, but what's the smallest brake package you can fit on these S197 spindles? Trying to figure out how to plan to keep to a 15" wheel if I'm converting to 5x114.3 all around. I'm attempting to keep wet curb weight relatively low (sub 2300lbs is the goal, with V8 and 6 speed), and would rather not escalate to the taller/larger wheels. There's still a few good options for 15's left that the market hasn't completely dried up on.

- 90 replies

-

- suspension

- 240z

- (and 5 more)

-

DOM tube is .120 wall, and the plate I'm using is 1/8th". So as long as I engineer the gussets to support the tube properly it should be okay. I'm also going to engineer the chassis side of the shackle bushing receiver to be a box u-shape so that in a bushing failure mode the chassis will catch the engine mount preventing it from falling more than a quarter inch.

-

Should be fixed now. Seems like hybridz is having some issues with copy/pasting images directly into posts. Now they're just links to google photos urls that seem to render properly. This size bushing is about the same size turbo yoda uses on the cars he makes mounts for (skid factory youtube) and is on the larger end of what shackle bushings are readily available. It might feel like solid mounts, and I'm okay with that. I was actually pretty close to just fabbing solid mounts... You gotta remember, this car doesn't have glass, interior, a dash, etc. It's perfectly fine if it's a bit rough on the NVH, but I'll be sure to report back. Regarding durability, these bushings are intended to hold the weight of a jeep across four of them, with constant change in angular deflection on where the internal pin is pushing as the suspension moves up and down. If four of these can handle holding up the rear half of a jeep, I think four of them can handle my engine and transmission. And the nice thing, is that it's a "standard" part that's now easily replaceable, and I can carry a set of spares that would work for either the transmission or engine.

-

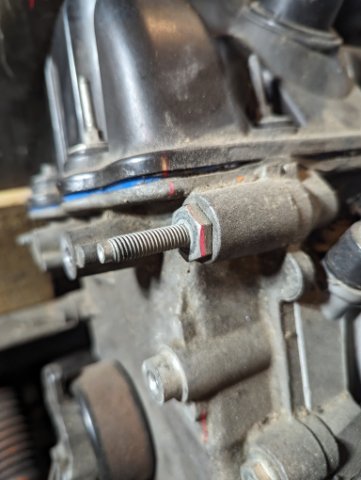

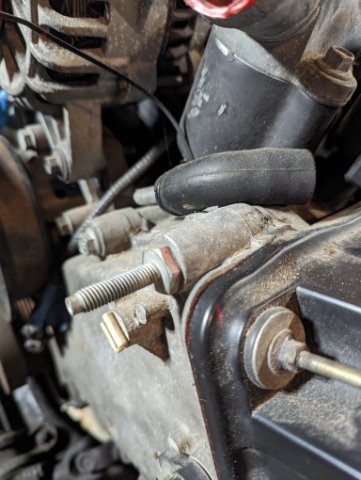

Since I couldn't find information I needed, I figured I'd post here once I'd answered my question. "How much clearance or interference should you run on polyurethane bushings?" Well, it's quite difficult to figure out from looking at the cross reference chart on energy suspension's website what size tube is expected to be used. Well, my first guess turned out perfect, so it's at least one data point. I bought an energy suspension 2.2120(R) which has an OD of 1.265". I bought DOM tube that's 1.5" OD and .120 wall, so 1.260 ID. So 0.005 interference. At first attempt the bushing seemed just a touch tight to get in but I went ahead and cut my length (about 2.5" for this bushing) and cleaned up the cuts. Added some grease, and it all assembled with minimal effort but nice and solid (light tapping with the dead blow to get the pin in). So there you have it. Data. By my guess, for 1-2" bushing diameters, you probably want at least .001 interference, and probably not more than .008. I'm sure if it were 0.010 I'd have had a hell of a time ever pulling it apart once assembled. Caption: I just had to know as soon as it all arrived Assembled: Using a 2.5" cut I've got about 1/16th of an inch or less of a gap between the two halves. And about 1/32 of poke out you can see in the picture on each side. Some might feel the need to "compress" the bushings and make the tube a touch longer so that when the bolt is tightened it puts some compression force on the bushing. While that's likely not a bad idea, this will be for engine and transmission mounts, already way overkill, and that would just cause faster wear in my mind. I figure let it run a touch loose so that any violent engine movements don't just want to sheer my mounts off the chassis. Or maybe I'm wrong. We'll see.

-

Looks like I was talking about engine coupling ideas about 9 years ago. Go figure. I've REALLY been wanting to build a multi-bike engine thing for a while now. No reason it can't be done. Multi-engine options abound, but most automotive engines are quite heavy once adding two or three, and offer minimal performance impact over other options. Example: Why run two V6's when good V12's exist with similar displacement? Why run two engines for more power when cheap force induction is attainable? The benefit of multiple bike engines is that bike engines have an extremely high power to package weight and size ratio, so they fit anywhere and don't weigh much. But their clutch package and transmission don't like pushing more than 1,000lbs around, especially with boost. So add more to increase capacity. And two GSXR motors still weigh less than most automotive engines. And if you look at the definitive engine weights thread, you quickly reailze that an iron V8 with an auto weights about three or four bike engines/trans packages worth....

-

A 350whp L28ET is a sub $5k endevor, and most of that is spent making it perform nicely versus just getting to the number. You can get to the number with an ebay turbo and a junkyard engine. Getting to 600whp is probably a $20k endeavor realistically. JeffP has thrown away more blocks because of not meeting his specs/needs than I've probably owned datsuns... You need a good block, it needs heavy cooling mods, careful attention to detail when building, good headwork by someone familiar with the platform, and then all the right supporting mods on the turbo and induction system. That said, I bet I could do about 700whp for pretty cheap if it was just a drag racing motor. Concrete and nitro does wonders...

- 25 replies

-

- turbo

- twin turbo

-

(and 2 more)

Tagged with:

-

I promise I've making progress. Not a whole lot going on that's worth noting imo, just typical engine fitting stuff. I did finally come up against something worth sharing though... If you're using the MT82, unless you can get the motor REALLY LOW, you're almost certainly going to have to massage or cut the transmission tunnel just forward of the factory opening. The MT82 top shift linkage mounting point fouls. Otherwise, I cut the factory ears out, the MIGHT clear but it's tight enough I decided just to ditch them. If you can get the engine block basically up against the firewall (would have to remake and reroute brake lines, ditch the vacuum booster, etc) then you MIGHT be able to get that part into the factory opening, but you'll also then have issues fitting an over the counter shifter in front of the back of the opening. So it's a problem to be dealt with. Now, for the record, I'm at 2.9 degrees transmission tail down (compared to the rocker being "level") and the diff is 3.3 degrees nose up (compared to rocker being "level). Technically, I need to bring the transmission "down" a touch, but I'm already in the ballpark of workable dimensions. The struggle I'm facing right now, is that my pan is LOW, and I still have some space in the front of the engine to come down a little (about an inch). As it is, I'm likely going to need to make a skidplate, and it'll need to land about .75-1.00 inch lower than the OEM "frame rails" on the floor to bring it lower than the oil pan. The pan can likely be chopped and welded, but I'd rather not do that right this moment ,especially as the pan will be relatively easy to remove down the road with how little of it sits over the cross member. At any rate, it's getting really close to fitting in order for me to start welding mounts. And hey, the hood fits, right? Technically.... Yeah... If the front drops down that inch, that will get me close... but then I'll likely need to drop the rear at least another quarter inch. In theory if I welded it as-is there might be enough sag to be "safe" but then any motor rock will bump the hood. So better to get it just a touch lower.