-

Posts

3202 -

Joined

-

Last visited

-

Days Won

18

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Gollum

-

Hmm, looking at the thread again, I think 8.5 @ +4 might be tough to fit up front on a S130. That 4.9" of backspace is going to get you extremely close to the strut tube up front. In the back, that much backspace would be fine, especially with more compact coil overs. So if you're wanting 8.5" instead of 9" or 9.5" you might be better off with the -10, even though that's going to also need rolling if you're pushing a 245 wide tire onto it.

-

FricFrac went with 9.5 all around, but felt 255 was too tight up front, and went with 235 instead for the front, but still on 9.5 up front. The one person who mentions issues in the thread is slownrusty (yasin) who says they're tough to fit on a really low car. On a mild lowering you're likely find, but if you're dropping it a lot then fitment gets really tight. All this is to say that a 8.5" should fit in either a +4 or -10, but I'd err towards the +4 since inward fitment on the S130 wasn't really the tight spot. But let me dig through when Christ and I tested them on my S130 and verify the suspension clearance.

-

9.5 in back, and 9.0 in front, with 255/40 in back and 245/40 in front. Rolling performed.

-

17 x 9 -13 with 255/40/17 tires. Mild rolling performed.

-

Huh? Lots of people ran the group buy wheels on the S130. It's not ideal, as the S130 can stand a bit more backspacing than the S30 stock for stock, but it works fine. You can't maximize the tire though, and need to stay 245 to be safe, but I've seen a few guys pushing 255 on the group buy wheels on the S130. Also, I know rims are always sold in offset figures, but start posting and thinking in backspace measurements. That said, a 17x8.5 +4 is 4.9" of backspace, which should fit quite nicely. You might have some rubbing under full lock, but I'd have to bust out measurement tools be to sure. If you step up to a -10 on a 8.5" wheel that's going to push backspacing down to 4.4" of backspacing, which is LESS than the group buy wheels, which means while it should clear suspension with ease, you're going to be that much more limited on tire size before needing to roll the fender. All this said, the S130 can fit HUGE tires without cutting/rolling if the fitment is right. 275 in the rear isn't unreasonable if done right.

-

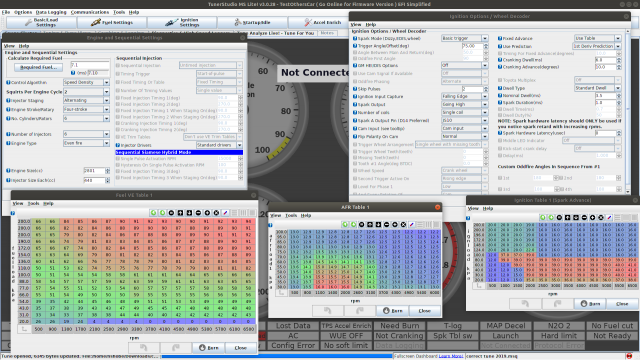

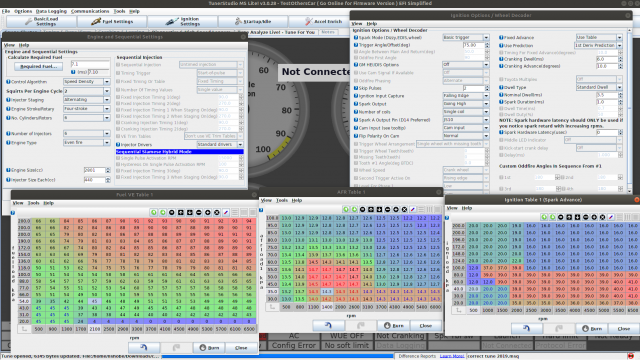

Since it seems the FAQ section can't be posted to, the Map sharing thread is effectively dead to new data. So I guess I'll just keep a running thread log of my tune and config as it changes. I started my tune by taking the "example config" tables, and then adjusting to "ballpark" from what I was seeing in other people's threads. Not many people were running a setup like mine, so it was difficult to get close, so I tried to err on the side of safety for most of my maps and I've slowly been edging them closer. My ignition map was far too aggressive to start with, and in some areas still is, but I've been pretty happy with the performance thus far on this combo, despite everyone's warnings of compression, detonation, and not being "good for boost". My setup: F54 turbo bottom (dish pistons) MN47 Head (factory through and through for now) Factory T3 (likely the first thing getting replaced) running on factory wastegate (6-7 psi depending on how it feels today) NON-Intercooled (one of my defining self-limitations, I'm keeping it this way) Non-EGR N42 Intake manifold DIY Autotune Dizzy Trigger Wheel Bosch Blue 260cc o-ring injectors (Ford T-Bird and others) running sequentially Pallnet Fuel Rail Factory fuel pump Factory fuel regulator Factory fuel filter Factory fuel damper still in place Tuning on CA Pump 91 Flex fuel sensor installed, showing my pump gas indeed is between 9-11% ethanol D585 LS Coils running COP Now, Configs: (I'm only posting windows of which I've altered settings) Basic/Load Settings Fuel Settings Ignition Settings Startup/Idle (I don't think I've changed much here other than WUE) Accel Enrich (lot of work to do here still) Advanced Engine I've also attached my tune file: CurrentTune.msq And the last tuning run logs: 2019-03-02_10.38.01.msl.zip NOTE: The above tune file and tables have been updated since that last log, so if viewing in MegaLogViewer the table data won't align properly. I'll likely be updating this regularly over the next few months as I'm making changes often. In no way do I recommend just copy/pasting any of these settings/values without understanding the risks. I make no guarantees for the validity of this data or lack of harm to your engine.

-

I feel like we've got three or so of these threads rolling around, but this one at least has semi-recent postings. I only trust the scale +/- 20lbs, but my last weigh in was 2280. 1975 280Z Gutted doors (no glass, factory bracing still) No interior other than OEM seats No dash No spare No bumpers MSA Type 1 fiberglass air dam L28ET (no oil cooler) S130 5 speed, I think an '81 R200 diff 3" exhaust, no cat, straight through muffler No AC No HVAC/Blower/anything Hey, I still have wipers! I have another 100lbs easy to remove too, I think. Going to replace the rear glass with plastic eventually, and my whole front end is still steel. Will replace hood eventually, and since I deleted the HVAC I need to get a smooth cowl panel, and might save a few ounces there. I'm also running a common group 53 lead acid battery, so there's 15-20lbs of weight savings there if I wanted to spend the money.

-

I weighed my car this morning and updated my post to reflect that, and also clarified the data source.

-

All the data was there in my first post, though looking at it again I see I could have been more clear. The graph itself states "virtual dyno" right on the top, and I published ALL my data points to show with others what I used. The speedo data isn't used at all by the HP calculation. It's RPM over time. If you know the rate of change, and you know the load, that's all you need. In theory, you could do the same over MPH, but that's now how Virtual Dyno works, that's how GPS based phone app dynos work, and hence their phone-gps-accuracy-dependency that I feel I've just about killed the topic on here. And by the way, I have no speedo in use. Purely using GPS speedo in my car for MPH reference for myself. IMO, the data I posted could have just as easily come from a mechanical dyno, and people would want just as much of an explanation of numbers. In fact, we've done that here more than once... 🙄 I'd expect other veterans here to know from my history that I strive for meaningful, accurate data. And I shared what I have, and what I knew, and have been honest and open about caveats. I've in no way intended to mislead, and feel I've shown that in every post thus far. And at the end of the day let's be honest.... 186whp@5184 is actually damn close to MOST stock L28ET dynos we see.... If I'd had to guess a number ahead of time, I'd have thought it'd be 170-175, about where most L28ET's come in... I mean shoot, drax made 211whp on stock wastegate pressure... Edit: Re weight: I agree, meaningful weight data is important to virtual dyno. But a 200lb reduction that would put me WAY under where I think I am would net me a whopping 10hp loss in the calc. I stated in my first post I plan to weigh my car soon, and would update the data once I had more concrete numbers. For now, I assumed 2400 lbs (car last weighed in at 2540lbs and I've removed a lot since) and my own weight at 230 (which might be more like 235-240 once I take into account all my clothing, jacket, hat, pocket knife, phone, steel toe boots, etc). But Even if we look at how much potentially difference there COULD be... it's less of a HP swing than running dynos back to back on a heat soaked engine.

-

Ahh, to correct myself, the three log pieces virtual Dyno needs is TPS, TIME (not map) and RPM. Everything else is just bonus (like MAP and AFR if you have it). A dynometer only requires the same info. Only the TPS is normally an operator triggering the start of the run manually. The dynometer records its own RPM and time, and only needs vehicle RPM input for axis translation.

-

A bit of looking around and you'll see that it's definitely the most popular software Dyno out there, buy I also admit that's far from a testimony of safety or validity. What does speak to it's validity is the number of tuners who own dynos that admit to using it and finding it useful. The basic premise is no different than any Dyno. Only, a chassis Dyno has a known load on the dynometer side, while virtual Dyno needs you to give it accurate data for the opposite end, the vehicle side. The only logs it needs is TPS(tells it where the WOT run is to log off), MAP/Boost, and RPM. By giving it gear and tire size it knows your MPH and by giving it aero data it can calculate the wind resistance curve. With this data in can you simply plot the power it takes for acelleration at the logged rate, and you have power. This isn't much different than the phone app dynos, except those rely on good GPS data, which honestly is never fast enough. A 10hz GPS is required, though by 2025 that'll be a thing in most phones I think with the new GPS system rolling out. So phone apps might actually end up being more accurate soon anyway. I've had friends with a Dyno that only bought a Dyno to have a fancy paper for certain customers. Thier high end race customers who were competitive didn't care. Results are results. And how did they Dyno? Excel. They used their own custom estimator they built that would generate curves from logs, same as virtual Dyno. And guess what? When they got thier fancy AWD Dyno in the shop, the results were almost identical. They still preferred road dynoing thohgi. Know why? Becuase the results were more realistic to track conditions because it more accurately took into account aero effects on intake, cooling, and intercooling. Just some food for thought.

-

In case anyone needs a small push down the reading/research rabbit hole: https://forums.nasioc.com/forums/showthread.php?t=2278352 and: https://innovativetuning.wordpress.com/our-experiments-with-virtual-dyno/

-

No, I'm using VirtualDyno with the source being megasquirt logs. I actually trust the reality of the numbers LESS than a good GPS and accelerometer based solution, but this has some serious known consistency going for it. I could get MS logs from someone else and as long as I know their vehicle data get very comparable numbers. Arguably more comparable than dynos of the same make/model in different locations. Eventually I'll have a 10htz gps in my car and I'll also have power logs from tunerstudio. The power logs I'm currently getting from shadowdash are.... iffy.... GPS stability is certainly a problem.

-

First rule of dyno numbers: Don't compare different engines on different dynos. That said, I did go through the painful work of validating all my data as much as possible for a reason. I even did my own flow testing of the injectors in my garage because I wanted to know that I was giving megasquirt valid data and that my VE numbers would have some similarity if I switched to another ECU or injector. I think 30hp/tq is well within the realm of error factor. For example, if I overestimated the weight, and my curb is actually closer to 2200 lbs, then that would put me at 177 peak. But let's consider some reasons my engine MIGHT make more power than a stock L28ET, which many might think I have no reason to be far above and I wouldn't disagree/argue with said person. 1) I'm running much hotter spark than factory On that note, I'm also running slightly larger than stock gap, but there just isn't really a comparison here. 2) I'm using an NA cam with the MN47 head. This might not mean much, especially since my torque is still peaking at 3k. But it's something worth noting. 3) I'm at the ragged edge of detonation on CA premium 91 octane E10. As I stated. I need to pull timing still and I'm going in and out of detonation in that range. You won't find an OEM tune anywhere as close to so agressive. 4) The OEM tune is pig rich. Most OEM ECUs are going to land in the 11's during a pull. Nissan ran these engines so pig rich it's rediculous. User stupid_fast was amazed how much more responsive his engine became just taking fuel out. 5) Everything about my combo is minimal. I have minimal vacuum lines/accessories, I have no power steering, no AC. Anything that can be pulled off, has been. Might be worth a few ponies? 6) Sequential fixes all the things! That's a lie. I doubt it adds any power. But the engine happily idles and cruises at 14.7:1 I do plan to add more boost eventually, but I'm getting my tune solid first. But I'm also NOT planning on adding an intercooler. I have a flex fuel sense setup already, so when I get my 91 pump gas tune down, I'll switch to tuning E85. I plan to alcohol-proof my fuel system next winter so I can run E85 for longer periods than just tuning sessions, but I do plan to find out what the limit is for this combo without an intercooler and on E85. I suspect reaching the limits of the turbo are well within reason, and eventually I'll upgrade the turbo. In fact, this one leaks a good amount of oil so I've been debating tossing a cheap ebay T3/T4 on there until I spend the money on a nice turbo. Also, if I happen upon one, I'll buy a F54 flat top bottom end to stick under this head, but I also want to get some basic work done to the head as well. I want to fit it with larger valves long with cleaning up the chamber, and blending the bowl area. If all this aligns before I blow something up, I hope to make more power non-intercooled than I've seen anyone else run. But a number/goal isn't really important, it's about the journey and having done something. Hence my lack of desire to argue about above numbers. It could have been 150 and I wouln't care.

-

We need more activity in this thread, so I'll post my current status as I get my VE table sorted. I need to pull some timing from 3-5k still so power will drop in that region, but hopefully I can get some power back as I clean up the high rpm VE which was obviously off. Just following the rules, force it rich with your assumptions and base maps and sneak up on valid data from the rich end of things. Also, for those curious, the above vehicle data: Weight: 2400 (might be off, hope to get to scales this weekend and update with known valid data) Drag Coefficient: .48 (pulled from windtunnel test data) Frontal Area: 18.5 (pulled from windtunnel test data) Tire Diameter: 23.69 (running 205/60/14's) Gear: 3rd (1.308) Final Gear: 3.545 Dyno Correction Factor: 1 (not emulating dynojet or mustang) SAE Factors: (looked up using local weather data online, might not be exact but should be ballpark of accurate) Barometric Pressure: 30.1 in/hg Air Temp: 48 (I feel like I should use my IAT readings I was getting under cruise since my turbo inlet is in the engine bay, but meh) Oh, I guess I should include: Engine details: Turbo Block untouched (F54 w/dish pistons) MN47 head untouched Stock T3 Turbo Wastegate pressure (6psi) MS3X running sequential and D585 LS coils (full sequential, not wasted spark) Bosch Ford Blue 26lb injectors Factory Manifold Factory turbo elbow Edit: First off, let me apologize. Apparently I wasn't clear that this is a software dyno, based on megasquirt logs using "VirtualDyno" found here: https://barnhill.bitbucket.io/ If you frequent EFI tuner boards you'll find it used regularly, and like all dynos, it's best used as a run-to-run comparison tool, not a bragging right. Edit2: I got my car weighed, and I came in at 2280lbs. Probably light enough to cause as much debate as any dyno graph, but my car is gutted. No door glass, no dash, etc. I can probably get sub 2200 once I go with a fiberglass hood and plexi rear glass. And an AGM battery wouldn't hurt. So here's the same graph as above, but in 4th gear, along with timing and fueling tweaks. I pulled out of it early due to heavy detonation still present after 4k, which is likely also the source of the power loss seen. And as much as I'm thrilled to see the extra power... it's telling me I have work to do, as my target AFR is 12.5 at all RPM under boost. Back to the VE table...

-

Most Suitable Circuit Race 4 Cylinder Turbo Engine

Gollum replied to 260DET's topic in Other Engines

But really, there are countless of people pushing 400+ on factory motors. Many of them indeed put on a 2mm headgasket to lower the compression, and run them like that just fine. Those types of builds I regularly see people street driving 450+whp on 91 octane pump gas (no water/meth, truly just pump fuel). There ARE people running factory compression on pump gas over 400whp. I'd imagine they're probably a bit knock limited in lower RPMs, so your tuning has to be perfect, but that's life with a high tolerance motor. But my guess is that a completely factory unopened motor running E85 could push 600whp forever as long as the tune was good. -

Most Suitable Circuit Race 4 Cylinder Turbo Engine

Gollum replied to 260DET's topic in Other Engines

Those transmissions have done wheel stands in stock form. It'll be fine. -

Most Suitable Circuit Race 4 Cylinder Turbo Engine

Gollum replied to 260DET's topic in Other Engines

While the K is enticing, it's not cheap to build for RWD application. Going F20/2C would save a good chunk of change, and the only benefit of substance the K has over the F is displacement, which again means you're adding costs to the K argument because you're talking about building a Frankenstein engine with a K20 head with a K24 bottom. The S2000 transmission is just fine, and the stock internals will do 400whp well within any stress margins (I've seen much higher than that on factory internals). But due to the relatively high compression ratio, you won't be running cheap pump gas at those power levels. But that's the same as any motor. The F motor would likely cost a bit more to build than a SR, but it should make for a vastly superior race motor since it'll make considerably more power per psi of boost. Would be an ideal use case for the new garrett G660 in my opinion. Spools like a T28, but has enough flow to shame any T3/T4 you've ever seen. Would easily keep up with the F motor up to 400whp, and likely be making minimum boost bellow 3k in any gear. -

Beauty can go have her love fest without me, because I seem sworn to forsake all sense of revel in the goddess's embrace.

-

F54 block, stock turbo bottom end (dish pistons) MN47 head (high compression penut chamber) Non-intercooled Factory T3 D585 LS coils MS3X Ford 260cc injectors DIYautotune in-dizzy Nissan trigger disk Factory fuel pump Pallnet rail Factory FPR Any other details feel free to ask

-

Syncing the engine to MS: Use the "fixed advance" pull down in your ignition settings, and set to 20 degrees. Check engine with timing light and get to 20 degrees or as close as you can. Lock down distributor. Now you can switch off of fixed advanced back to table, and generally never worry about syncing again. If you're already done this at 12 degrees and felt like you had good results, then leave it be. Once you've done that sync, feel free to adjust the table to your hearts design, just err on the conservative and keep timing lower in the load regions to avoid detonation until you're ready to tackle that. For reference, here's my tune (which is far from perfect, so don't treat it as gospel, plus it's not a factory combo)

-

Also, look at your AFR table, It goes from 13.5 to 16:1 AFR at 30pka from 800 to 1100 rpm. That's an intense step, and will get extrapolated everywhere above idle. That 16:1 target is insanely lean imo. You wouldn't touch it stabbing the throttle wish pushes the map up, but that's still crazy close to idle range imo. That's also ASKING for detonation if you're pulling away from a slow roll in 2nd gear (like if you came up to a light turned green before you came to a stop).

-

Several points: Make a huge "idle area" for advance, that will save you piles of headache while you get up and running to get things running nice. I'd recommend using the L28ET factory setting of 20 degrees. Your VE table is also VERY low in the idle region. That might be fine for some engines, and some injectors, but don't be afraid of running 50+ in that region. I'd also flatten out the AFR table for the high vacuum, low PSI area until you have a known solid VE table. Never give your ECU a chance to "miss" an AFR calculation by 2 points because your VE is off and swing from 16:1 to 18:1. It's much better to push the AFR table rich everywhere, and then lean out the table once VE is known as close/reliable. Making the suggested changes, might look something like this:

-

In your tunerstudio projects folder you should have a "currenttune.msq" file you can add to a post by the "drag files here to attach or choose files..." feature of the forum posting window.

-

Any chance you can share your tune and log file(s)? If you mean it leaned out as it sat at idle and warmed up, I'd suspect you're still to lean on the VE table and WUE is to blame for the rich to lean transition. If you mean it leans out as you rev it, that could be AE being not aggressive enough (mine was WAY too mild from the base tune), or if even bringing up rev slowly causes a lean condition then either your VE table needs adjustment in those areas as well, or your Req fuel might just be really out of whack. Start by sharing tune data and some logs, and we can go from there.