-

Posts

163 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chris Duncan

-

I'm building a new house with a high ceiling garage so I can put a lift so I'm about a year out from getting back to this project.

-

Yes it's correct, I got some from Belmetric https://www.belmetric.com/standard-height-left-c-3_273_1642/nl14x15-left-hand-nut-p-2822.html?zenid=slnpddj6fn4u2v4a7i23evepk1

-

Looking for a 5th gear set for a 1983 ZX 5 speed, tooth count 26-44 Or a complete 5 speed from any ZX (if you're in the PNW)

-

Broken Extended Wheel Studs

Chris Duncan replied to Bartman's topic in Brakes, Wheels, Suspension and Chassis

5/8" wheel spacers? 90 ft-lbs is a little high, the FSM for a '76 280Z shows 58 to 65 ft/lbs. Typically a 12mm lug stud can be torqued to 75 ft/lbs. 80 ft/lbs max. -

Broken Extended Wheel Studs

Chris Duncan replied to Bartman's topic in Brakes, Wheels, Suspension and Chassis

Do a visual inspection of the other studs, you can also feel if they are necked down from overtorque, the diameter will be smaller at the place where they are stretched. If you find some other ones stretched then you have your answer. Visually you may see more space between the stretched threads. The one in the pic almost looks damaged, the break is really jagged. Have you had it in a shop where they took the wheels off for some reason? I've seen techs take a test drive with the lugs loose and it will cause damage. what is your offset and are you running spacers would be the other questions? -

Update on this diff in our Chumpcar endurance racer 280Z with the J30A1 swap. Still going strong after six races of 7 and 8 hour duration. Oregon Raceway Park, Sept 2016, Sat 5th, Sun 1st Laguna Seca, Nov 2016, Thur 21st (blown clutch), Fri 1st Sonoma (Infineon), Feb 2017, Sat 3rd, Sun 1st.

-

Any metallurgists on here? Input about breakage

Chris Duncan replied to BluDestiny's topic in Miscellaneous Tech

Looks like the design is flawed, the material is weak and possible manufacturing problems this piece should be an off the shelf rod end, one on the stronger more expensive end of the range. Probably a 5/8" dia thread at least. It looks like a fabricated piece and it's too long so it has too much leverage. If you use a rod end threaded straight into the end of the arm then it's hard to adjust so it looks like they made this one with opposite threads to ease adjustment. Normally this is done with a opposite threaded sleeve and regular rod end so it doesn't have too much length and thus leverage. -

Rebuilding engine and want to hear your opinion on rods.

Chris Duncan replied to grillhands's topic in Nissan L6 Forum

Just make sure they are a matched set from the same engine because they are balanced from the factory. -

that looks usable to me PM'd

-

Here's a reman for $243.00 http://www.zcarsource.com/crankshaft-240z-260z-280z-280zx-300zx_8_55202.html they general don't show any wear until after 150K So guessing like $300 to $400 for a new one

-

Looking for a 5th gear set for a FS5W71B from a ZX, the short tailshaft trans? The 0.745 ratio 5th Broke some teeth and don't want to buy a whole trans.

-

J-SWAP SUCCESS!!! Week before track day first start up. Huge vacuum leak from the EGR passages, apparently when you flip the lower intake it opens up the passage, had to tap the plenum and put a pipe plug. The EGR will be re routed externally. A bad main EFI relay from the 200K mile parts car kept the fuel pump from running at first. Night before the track day, drove it for the first time, no windshield or hood at 10pm (wearing goggles) (the dash wiring is easier with the windshield out). Only minor problems, a seeping brake line from where they were re-routed and a rad hose seep. The RPM Systems modded stock ECU works normal with no limp mode (big sigh of relief). Drove 1.5 hrs to the track, did a track day and drove back, no problems. It's not an LS1 but it's still scary fast and seems to be less nose heavy than the stock setup. Wider powerband, way more torque, better gas mileage due to the VTEC. Pulls hard all the way to the rev limiter (which will take some getting used to). Haven't had time to set up an electric fan, it got up to 200F but didn't overheat in stop and go traffic up a long hill (low 90's ambient). It seems to cool a lot better maybe due to the aluminum block. About 8 months working part time and approx $1500 Don't know if I'll ever do a kit, it would take another year or so of development. May just write up the plans and a how-to. Will do a more complete post and parts list when there's time. It's already tempting to step up to the J32 and that might be more desirable as a kit. The J30 was just chosen because of the race series the car runs. The J30's are down to $100 at some wrecking yards. Now I have to name the thing. Datsun J30Z? Datsun 300HZ? Datsun V-TEC-Z?

-

Did a track day at the Ridge Motorsport Park with this diff installed. No more one tire spinning. Consistently faster coming out of the slow tight corners, especially the hairpin. No noise from this thing, didn't even know it was there aside from the lack of any wheel spin. Ran the Redline 75-W-140-NS

-

They make straps now with a sliding D ring on one end so you can loop the strap around whatever and connect that way

-

Which car would you buy to upgrade from your Z?

Chris Duncan replied to afbrian13's topic in Non Tech Board

In no particular order S2000 FRS BRZ (w turbo or super charger) Z06 Vette with LS7 R32 Skyline (imported from Canada) Z32 twin turbo -

Coilover Leveling Issues

Chris Duncan replied to ~KnuckleDuster~'s topic in Brakes, Wheels, Suspension and Chassis

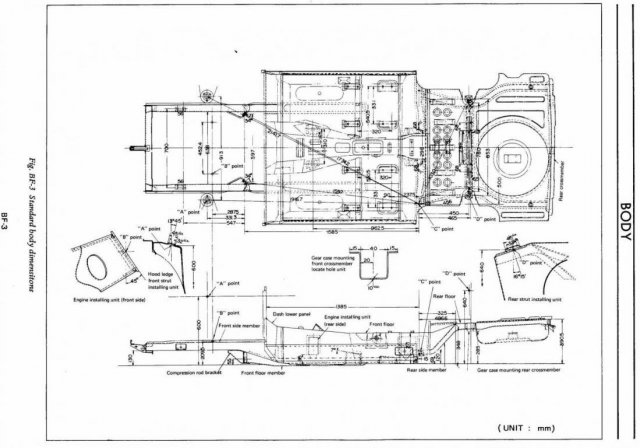

Best guess is your upper strut mounts are not straight. The easiest way to check short of paying a frame shop would be with a Bosch laser level. About $100. You could get away with a string level but it's very tedious/ time consuming and not as accurate. First level the car using probably the jack points, then check the level (height) of the A and D points in this chassis spec sheet. You don't need to get an exact measurement like the diagram you are just comparing right to left to see if it's level. To level the jack points you would set the laser up underneath and measure upwards. To level / measure the upper A, D strut points you would measure down from above with the laser projecting from a ladder or similar item. The other suspect area would be the struts although you say it was like that before with different struts on all four corners? The different front springs is a pretty good sign it was like that before. -

From MFactory FAQ's Maintenance: Oil: Regular 75w90 Synthetic Oil for Street/Spirited use. Heavier 75w140 for Race Applications. Recommended brands include Torco SGO and Redline NS. Limited-slip Friction Modifier must NOT be used, as Torsen (helical) style LSD's rely on friction in order to function.

-

Found the answer in TeamM Factory FAQ. Taiwan is pretty good, and still better than China. MFactory® Helical LSD™: Availability - since 2008 Country of R&D - USA Country of Manufacture – Taiwan (In-house) Quality Control – ISO Regulated Metallurgy – Housings are open-die forged from SAE4320 steel. Internals are cold-forged from SAE9310 steel Origin of Barstock - Japan Heat-Treatment – Double Tempered, Super Sub-Zero (Deep Cryogenic), Micro-Peened Surface Bias Ratio (Max Torque Transfer): 75% Warranty: Lifetime, Globally Transferable Guarantee: 30day Money Back MSRP (LSD only): $999.95 MSRP (Reconditioned Pumpkin): from $1499.95

-

The cleaner pair for $250 (3 screw top) Bought on Ebay, unknown year The pair for $150 (4 screw top) Bought local off a 1970 Z

-

they both have manifold and linkages

-

I have a marginal set for $150, pretty corroded, WILL need overhaul and a fair set for $250, may need overhaul plus shipping from Seattle

-

installing motor/transmission - lost my bolts

Chris Duncan replied to Ctweber01's topic in S30 Series - 240z, 260z, 280z

The two big bolts that hold the trans crossmember to the chassis are 12 x 1.25 x 80 with nuts to fit The four bolts that hold the engine brackets to the rubber isolators in the front are 8 x 1.25 x 20, should have captive nuts on the isolators the one nut that holds the trans crossmember to the rear trans rubber isolator is 10 x 1.25 A good hardware store might have these, although 12 x 1.25 is sort of rare. You could substitute a 12 x 1.5 x 80 which is a (more common) coarser thread, because you need bolts and nuts anyway. All sizes in MM. -

Found a socket that fit in the two washers very close and got them lined up to each other and the axle bore. Got the runnout and backlash down to .001" variance. Ended up with the same shims as the old carrier. 2.30 driver, 2.15 pass. and the tooth contact is good. So back together and back in the car, should be on track in another month. So all's well that ends well.

-

The runnout I measured was on the carrier. I called TeamMFactory in Califa and talked to a David. He said look down in the axle bore and see if the two washers are aligned. Sure enough they are not. He said un-bolt the nine 8mm allen bolts to loosen the carrier case and re-align the two washers. He also gave the choice of shipping to them and they could do it. I mentioned the warranty being void if the case was opened, and he said there would be a record of our conversation and the warranty would still apply because they told me I could open the carrier. He had me send some pics and confirmed that was probably the problem. So I loosened all the bolts, but left two of them tight to within a couple threads so the case did not come completely apart but was loose enough to move the washers. Aligned the washers by eye with a screwdriver and tightened all the allen bolts back up. The carrier is now at .0015" runnout and the backlash variance is about .0015" also. The shims sizes also changed to 2.30 driver, 2.10 pass. I do note that although the two washers are now aligned to each other they are a little bit off center to the axle bore, was thinking about making a jig tool to center the washers to themselves and the axle bore. The next check is the contact pattern, a whole other can of worms if it's off and it probably is. Just waiting for the Prussian blue to come in at Napa. I also asked David where the diff was manufactured. He said he wasn't sure exactly but it was "somewhere overseas".

-

Got the thinner shims in and it looks like either two 2.10's or a 2.05 and a 2.15 are going to work. Sort of near the thin end of the selection but it will work. Measuring backlash and got it to .007" with a 2.15 shim on the driver side and 2.05 on the passenger. Then started measuring the backlash at different points by turning the gears. Getting a varied measurement from .007" to .014" . What is causing this? Measure the radial runnout of the carrier, getting .007". Just a preliminary because I'm not sure where this is coming from but it's not good. Because it's not going to be able to set within specs. It's probably the carrier. The only other possibility would be the bearing and I measured the inside bore where the stub axles run and that's almost zero, so it must be the carrier. One question, the TeamM Factory box the carrier came in says "designed and engineered in the USA". But it doesn't say where it's made?