All Activity

- Past hour

-

Can't separate oil pan / bottom block on 1981 280zx

toolman replied to adsdsasdasdasda's topic in S130 Series - 280ZX

Have you tried industrial Heat Gun (capable of heating the area to 200degrees)? This method usually works but be carefully not melt anything near by. Try on a small area first. - Today

-

Can't separate oil pan / bottom block on 1981 280zx

NewZed replied to adsdsasdasdasda's topic in S130 Series - 280ZX

Not clear what this means. There is no "upper pan". This is a 280Z but it's the same engine. You posted Sunday so probably already got it done. Good luck. https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-block -

Can't separate oil pan / bottom block on 1981 280zx

Zetsaz replied to adsdsasdasdasda's topic in S130 Series - 280ZX

It should only be the bolts that hold it to the block. No extra secret hidden bolts. Have you tried tapping it with a rubber mallet? if someone used gasket adhesive on both sides it would be pretty well stuck. I had to use a rubber mallet to knock mine loose. If it's really stuck with something like permatex ultra black instead of a stock style gasket have you tried running fishing line through it? Could cut through easier than a blade without damaging the metal. -

My rollpan is almost ready to ship as well. I got it from Chop Suey Hot Rod Shop, he is filling in the exhaust cut out for me. It bolts on to the rear.

-

dropped off my new hatch from resurrected classics, my grille, and my 240 taillight outer panels at R&S Powdercoating for a coat of gloss black powdercoat. I had the hood sandblasted and found damage, so I ordered a new hood for Resurrect Classics, and will make my cut out and then have it powder coated gloss black as well. The car will be light metallic blue, with black hood, hatch, flares and rear spoiler/Air Dam. here is the inspiration for my change in direction: (Just picture the light metallic blue instead of red)

-

Yep that is there forever home. I can cover them if needed, but this is an around town hotrod only. no wipers, my version of a cooler AC Corbra.

-

stock brakes Sir. of the two "blocks" I assume you are talking about the one with the electrical probe on there. Rather than try to figure it out, I knew I was going to run stock brakes so just copied how Nissan built it. (shrug)

- Yesterday

-

You don't really need the brake line differential pressure warning switch. It does function as a decent junction block. You are also likely to want an adjustable proportioning valve instead of the stock unit unless you plan to run stock brakes.

-

I believe you are referring to the Proportioning Valve and the Brake Line Pressure Differential Warning Switch. Is the switch still functional (I couldn't see any wiring from those photos)? Did you decide to relocate them to the fender well for a cleaner look under-hood? If that's going to be their permanent position, I would fabricate some kind of metal shielding to protect them from road debris damage....the stock plastic inner fender liners are probably not sufficient. Good tip on the "Finishing Lines"...will check it out for sure! 👍

-

jpndave started following A COMPLETE EARLY MODEL 240Z BODY may be available soon

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

IMPORTANT MESSAGE-CONCERNING NEW COMPLETE 240Z BODY ASSEMBLIES FOR SALE I just posted information concerning new complete early model 240z bodies assemblies that may be available in the near future. It is posted on the BODY KITS AND PAINT SECTION of Hyprid Z Forums on Monday. There are a lot of pics and text discussing their construction and quality. Information about the manufacturer is also listed. There was a lot of interest in their line of reproduction vehicles( Toyota Land Cruisers,Toyota A86, Ford Bronco bodies). Also, I also will post text and pics of ALL ALUMINUM BODY PANELS FOR 240Z MANUFACTURED IN JAPAN. Weigh savings are about 20 to 30 percent and very corrosion resistant. The workmanship was excellent and looked beautiful. This is a limited production run so if you are interested, I would put your order in. Star Road in Japan is handling the sales of this product. I will also start posting pics and text of other cars and products that I found at the SEMA SHOW 2025. This will posted in my usual Hybridz Forum site at V8 ZForums-Gen III & IV Chevy V8z site soon. - Last week

-

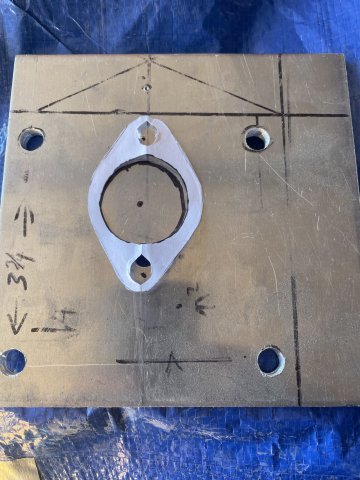

I had a couple hours this morning, so I went ahead and worked some more on the layout for my brake master cylinder backing plate, and then installed my brake "parts", that divert fluid to all 4 wheels (I don't know what to call them). I used Finishing Lines for the hoses. These hoses are the new PFTE hoses that do not swell, etc. Guys are completely running brake lines in whole cars with these and they work great! I will be doing a combo of hard lines and this. Everything past the firewall back is the stock stuff. www.finishing-lines.com. They advertise a lot of Honda stuff, but they DO have our 10mm fittings etc. Great people to work with. I then went ahead and pulled the back window as part of gutting the rusty hatch out and then installing my new hatch I got form Resurrected Classics. My hood is at the sandblasters right now, should pick it up tomorrow, and then I can cut the hole and repair the spear with all metal filler a tad, as I can see some mud in it. Seriously thinking about having the hood and the deck lid powder coated gloss black to contrast the light blue metallic. Black spoiler and air dam also (they are already black, I can put a coat or two of 2K clear on them), I have glossy black flares........I will attach a pic that a guy did this with..... but the car is red.....it is giving me these ideas. Pics follow, Cheers!

-

just barely screwed them on and took a pic.

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Good list, I went with the track Attack kit And a 370Z diff (R200). I went with the Bull Dog Frame rails as they can go over the existing frame rails. They are still in the box though, I’ll install those after I install the rear suspension. -

Those struts look really long. How much can they be shortened and still maintain sufficient travel?

-

When I installed my small block Ford in my car there wasn't a kit available to mount the engine and transmission. So, like you, I had to figure it out on my own. A particular challenge with these cars is that they are small and you will end up with a very short drive shaft. Because of that we have to pay particularly close attention to driveshaft angles. We need the axis of the engine to be parallel to the pinion axis, and to keep the u-joint angles as low as possible. If you don't do these things you will have drive line vibration that will make the car very unpleasant to drive at high speed.

-

Fast Floridian's 240Z Track Build

Mitchel0407 replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

What did you get, the Pro Touring kit? I do like how the Apex suspension looks and I heard a lot of good things about them. I also picked up some parts for myself to try out. Modified S30 Z’s are rare in Europe and once with anything more the coilovers even more so I’ve never seen the Apex suspension myself. I will eventually move down the new Retro Mod line as I want to keep the stock drivetrain and R200 diff but for now I just got some nice upgrades that give me the adjustability I need. - Front fender brace - Frame rails - Rear strut brace - Front control arms - Steering knuckles - Front crossmember - Upper steering rack clamps - Rear control arms -

Today my fiberglass smooth cowl I bought from Jhousa Ramos arrived and I got my caliper / lower strut assemblies back from welding. The cowl is really a nice clean part. JP Fiber Shop – The world of your car

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Thanks. I ordered a can, I’ll see where I can squeeze some in. Also Apex rear suspension got here today, going to get to started on that this weekend. 🤗 -

It is as firm as a rock.

-

How many of you have played around with Crossmember plates/shims, hammering a trans tunnel in a bit, engine height, trans height and driveshaft angle? I am now stepping into this new realm. I have my Vortec 4200 in, now for the trans. If you plate the crossmember you give up ground clearance, and the more you plate the more fender wheel well gap you will have, so you raise one, then adjust the coilovers to take it out, but coilovers only have so much adjustment......using aluminum plates, I can get it to where I may have to actually take the plates in to a machine shop to mill them to a precise measurement. I have some megan racing coilovers being welded on to my spindles right now. Not interested in messing with the motor mounts and like my engine riding high, so I guess we shall see!

-

Fast Floridian's 240Z Track Build

jhm replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Yeah, getting rid of that crappy worthless "undercoating" is very satisfying and worthwhile....as well as all that 50-year old dirt, gravel, and grease! Looking good! P.S. While you've got it stripped down, this is a great product for protecting your frame rails and other hard-to-reach areas on the chassis: https://www.eastwood.com/eastwood-internal-frame-coating-14oz-aerosol.html -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Hydraulic Clutch Pedal Modifications- I enlarged the Clutch Master to Shift to move about 1" to the Left. Interior Side of Clutch Master Mounting Bracket checking Push Rod Clearance Measuring Master Cylinder Piston Depth then adjusting Booster Clearance to 3MM. Modified Clutch Pedal by moving the Clutch Pedal Push Rod over about 3/4" to the Left. This small movement of the Clutch Push Rod Pin Mounting Bracket should allow even Larger Clutch Master, in case of Installation of a Larger Clutch Assembly. Finished Installation Next-ROAD TEST -

Did you grab the engine and see if it moves? That's all I was suggesting. Trust (your ideas). But verify (that they work). “Give me a lever long enough and a fulcrum on which to place it, and I shall move the world. ” ― Archimedes

-

it is the angle of the pic. Look at the one right above this. It is clear of any obstruction.

-

well, the factory motor mount for the L series six is a solid design with a rubber pad on the bottom. I have poly bushings where the engine mounts attach to the arms coming from the crossmember. The arms are made of 3/16" steel, very thick and heavy and professionally welded. In short they won't break, and they won't bend. Twisting forces, I guess that could be an issue down the road, but if it is present, then regardless of what style is used it would be present. the style used is one that is currently used by a ton of guys running LS powered cars. If you can grab this engine at the top and pull on it, and bend those 3/16" steel plates you have balls of cast iron. In fact I would be seriously willing to wager $1,000 that you could not do so. You could take these out, put one of them on its side and stand on it and it wouldn't bend. I will allow that something could go wrong.....I'll address it when it does. I appreciate the points to ponder though. Cheers.

-

Who's Online 2 Members, 0 Anonymous, 692 Guests (See full list)