-

Posts

224 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Cannonball89

-

Odd oil pressure situation...?

Cannonball89 replied to Krisndan's topic in S30 Series - 240z, 260z, 280z

L28 doesn't need much pressure at idle. If in doubt remove the sending unit and adapt a mechanical fuel pressure gauge to the hole. If you see 10PSI at idle your fine, and if you see at least 5PSI at idle your likely still fine but it is an indication that bearing clearances are getting large from wear. Also from my personal experience with other engines, a chirping sound coming from a certain cylinder is an indication of a blown headgasket. That chirping may be air getting sucked in/blown out during the intake/compression stroke. I must say though that my old L24 with something like 100,000 miles on it would show very little to no pressure on the factory gauge at idle once warmed up and it never seized up in the time I used it, and as to the chirping sound, I have won several races in a Legends Car with a motor that had a blown headgasket that made it chirp like a canary at idle, so obviously power loss was minimal. So that's my 2 cents, do some more investigating and don't tear the motor apart until your absolutely sure that you have a real problem. -

Turbine Housing and Wastegate Porting

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

Very interesting. That is definitely something to consider if my creep continues, or even if it doesn't, bleeding off flow could make the turbo pull harder at low RPM. I have to go to work now, but later tonight I will continue researching and learning about this, and look into the controllers. If they could write some code to enable Megasquirt to control a bleed valve that would be perfect... -

Turbine Housing and Wastegate Porting

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

Oh ok, like the factory relief valve on the rear portion of the intake that I removed! Yeah that would work as an emergency overboost protection (as the factory Nissan part was designed for) but I wouldn't want to rely on that as part of my boost control system. I know that people on here have relied on that to help regulate boost but I'd rather control boost entirely from the exhaust side. Seems like making the turbo produce all of that excess airflow that will be dumped before it reaches the combustion chamber would result in more heat for less boost (I.E. out of the ideal effeciency islands on the T3/T04E compressor maps). Still not sure what Tony means by "mismatched compressor" Are you saying my compressor is too big/small? I have a T3/T04E with a .63AR turbine and .50 compressor which I though was ideal for my setup which is a stock F54 bottom end with a stock non-ported P90 head with the stock ZX turbo cam. The only real modifications are an intercooler, full 3" exhaust from the turbo back, and megasquirt. -

Turbine Housing and Wastegate Porting

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

Not sure if I follow... Can you elaborate a bit? -

Turbine Housing and Wastegate Porting

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

If your not seeing creep at 15psi then you should be fine if you turn the boost up. More boost means less gas has to go through the wastegate. In my case I was trying to run 10psi initially but saw creep up to 20psi. My goal is to get my setup to hold around 15psi, and I might run 20psi down the road. But if I can get it to hold 10psi then I know ill be safe at higher boost levels. -

This is a follow-up to my Divorced Port thread: http://forums.hybridz.org/index.php/topic/99036-3-downpipe-38mm-divorced-port-wastegate/ I'm trying to eliminate the boost creep I'm seeing by enlarging the internal wastegate hole and also making the path leading up to it easier for exhaust gases to flow into. While I was at it I also gasket matched the inlet of the Turbine housing to match the T3 gasket because their was a lot of room between the edge of the gasket and the edge of the inlet, which probably was creating some turbulence at the inlet of the Turbine. I used a Rotary Rasp in an electric drill to do this. It wasn't too hard, but I did destroy the drill LOL. This is the size of the wastegate hole as it came originally. About 3/4" diameter I enlarged it to about 1" diameter Internally the hole was simply drilled in at a 90 degree angle and the internal casting was not molded to divert flow into it. I removed a lot of metal to direct the exhaust gases into the hole easier. The casting left a lot of room between the the inside of the Turbine housing and the edge of the gasket. Now it is matched nice and tightly to a T3 gasket. Hopefully this will eliminate my creep, if not then I will be drilling the exhaust manifold and going to a regular External Wastegate and ditch the Divorced Port design. This was still a good thing to do because the turbo should theoretically spool faster with the inlet of the turbine housing gasket matched. The exhaust manifold needs to be gasket matched now too though, I am debating if I want to pull it off now or just do it some other time.

-

Check the classifieds they pop up pretty often. Probably some for sale right now.

-

http://wot.motortrend.com/subaru-confirms-turbocharged-version-of-brz-engine-143015.html ^^^ They have all ready designed turbo direct injected version of the engine^^^ They haven't said if it will eventually make it's way to the BRZ, but it seems logical. The only thing is that with it being direct injected, it may have a pretty high compression ratio, so turning up the boost may not be as easy as it has been for previous STI owners.

-

You can turn idle advance on in tunerstudio and set the parameters so that it holds ten degrees (or any degree, but ten is easy). Then mark you timing marks and crank pulley at ten degrees with white paint and hook up your light. Then you can either turn the distributor or change the trigger offset in tunerstudio until your ttiming marks line up. Also you shouldn't need a 15 amp fuel pump fuse. Especially just at idle. Something is wrrong there.

-

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

Still in the market for side axles -

I could see that being a problem in the rain... like filling up with water and stalling the engine lol

-

3" Downpipe, 38MM Divorced Port Wastegate

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

Wow that is a beautiful piece of piping man! Is that Jet-Hot coating? I got to say I like your whole car. I never thought I'd like a purple car but yours is so clean and sweet, not to mention fast based on the timeslip on your site. Nice work man. -

I'd love to have one. "Engineered to Be Feared" is such a great slogan. It really represents how many of us in the Z community feel about our cars.

-

3" Downpipe, 38MM Divorced Port Wastegate

Cannonball89 replied to Cannonball89's topic in Turbo / Supercharger

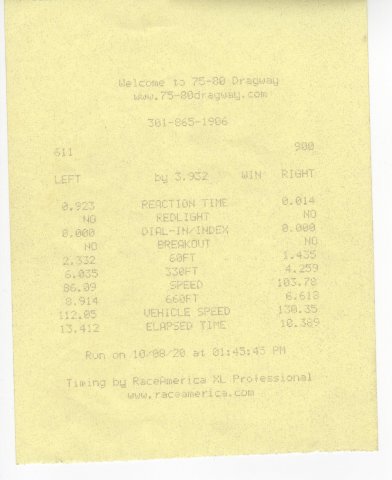

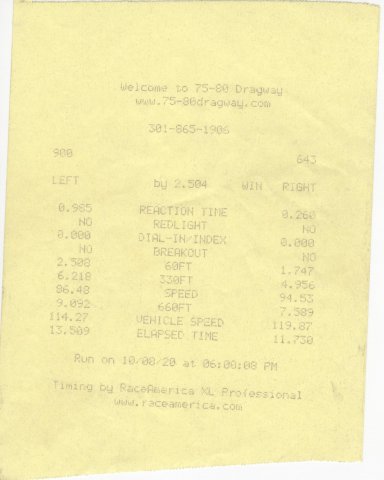

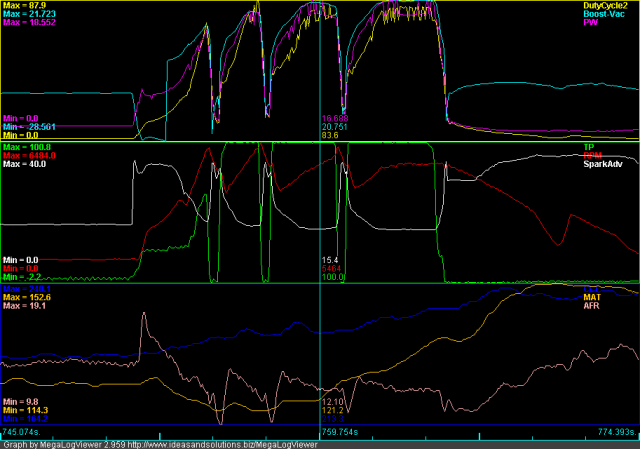

I've been meaning to update this thread for a while now, got busy with school and forgot about it for a while though. Anyway I was able to get out to the dragstrip in early October. The car was fast, a 13.4 @ 112 MPH and a 13.5 @ 114 MPH were my best times for the day. Obviously at those MPH's my E.T. should be well into the 12's but traction simply doesn't exist with my current rear end set-up of open differential and old hard Sumitomo radials. I will cure that over the winter with a Torsen LSD and Nitto 555R drag radials on all four corners. Here are my two best time slips (left lane both passes) Unfortunately that day also revealed that my divorced port set-up in it's current configuration is not effectively controlling boost. I saw over 20 PSI of boost with the 10 PSI spring in the wastegate. On my dyno run it held to 12 PSI, but for some reason it is seeing creep in real world conditions. Here is the datalog of the 13.4 pass: I am not giving up on the divorced port design though. I have too much time invested in making this to give up on it that easily. I found this great article by Corky Bell about how to port the wastegate hole to make it flow more, basically you dig a channel out in front of the wastegate hole leading up to the mouth of the turbine housing to kind of channel exhaust gases into the wastegate. Here is a link to that article: http://www.bellengineering.net/article_info.php?articles_id=273 I am also going to enlarge the hole quite a bit. People always say that you cannot enlarge the internal wastegate hole, but that is because they are running the flapper style wastegate, and having too big of a hole won't allow it to seal properly. However in my divorced port set-up I can enlarge it safely as long as I don't weaken the turbine housing. So that's the next step in Divorced Port Evolution, porting! Unfortunately we won't find out if my porting is effective for a litte while. I most likely won't be driving the car until my new differential is in, and that requires me having the side axles that John Coffey sells to let you run an STI diff with stock propeller shafts. It's cold outside anyway.I have just pulled the turbo out today (man what a PITA that was) and will update with some pictures of my porting before I start reassembling. -

It's got nothing to do with the turbo compressing air in the cylinders on cranking. The turbo is not capable of producing any positive pressure during the cranking phase. If the starter is sounding funny then it is almost definetely a problem with the battery or alternator not charging the battery fully. I would start by using a multimeter to check battery voltage at rest and at idle. If battery voltage is less than 12V at rest or less than 14V at idle then you need to go to Sears or some other place that will check batteries for free. A bad battery is nothing but a headache in an EFI system. If you read low voltages and the battery checks out good then you need to check your alternator. As far as the hard starting, I would imagine that you mainly notice this within 5 to 45 minutes after being run? If so then you are probably experiencing heat soak. Search and ye shall find a myriad of remedies on this site. From my experience it is not one ultimate fix, but a combination of all to make an L series EFI engine favorable to hot starts. Heat soak is the main cause of it all. Solutions you will find will include a vented hood, a check valve in the fuel system to maintain fuel pressure in the fuel rail after engine shutoff (especially important if you are running an aftermarket FPR), and of course lots of heat sheilding. You mention that the IAT sensor is in the middle of the intake. Mine is as well. I have mounted my IAT sensor in the large hole at the base of the #4 intake runner, which was I believe part of the factory BOV circuit. It sounds like yours is mounted in the same place. I have noticed that the sensor mounted in this location is more susceptable to heat soak than if mounted in a bung on the intake piping after the I/C. And also I have read that Tunerstudio software under the Advanced Engine-MAT Correction Tables will lean out your mixture when certian IAT's are reached. After a run (either on a simple drive on the street or after back to back 1/4 mile runs) I have noticed that within 5-45 minutes after engine shutoff the IAT's are actually registering higher than they were during the run due to heat soaking from the cylinder head, turbo, and exhaust system than they were during the run. A solution may be to mount the IAT sensor in a bung in the intake piping, but if you insist on keeping the IAT in the manifold as I have, search the MS Extra forums for the appropriate fix. I have read of it on their but forget the exact fix, and my car will still run, albeit poorly for a few minutes after hot start so I have not yet looked thouroghly into the fix myself. I believe it involved changing the default MAT correction values such as that they did not lean out the mixture during high IAT's though. Good luck, and I'm sure the solution is some simple hardware or software changes like I suggested. That's the beauty of Megasquirt, it is completely fixable by YOU!

-

Gotcha. I hope we never have to start deleting technical posts. Some of those ancient posts from the early 2000's have really been helpful.

-

What happened to all the threads in the tool shed? All of the old entries are gone. I used to really enjoy reading through some of the old posts in there for laughs. Now I will have to go back to Zcar.com to read useless non-technical crap. Bummer.

-

I am running an AEM UEGO now. It works every time, no re-calibrations either. They may not be as accurate (according to some reviews I've read) but as long it is within a 1-2 tenths of an AFR it is close enough to tune with. I'll take reliability over accuracy. I might sell my LC-1 but my conscience probably wont't let me since I could never get it to work. The cranking problem does sound like it is what was causing mine to act up. But I'm not going to try mine again, I'm happy with the AEM. Basically everything about the LC-1 sounds too overly complicated. I never would have thought that after wiring up an entirely custom EFI system it would be the supposedly well engineered plug and play Wideband unit that would cause me the most problems.

-

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

Bump for side axles -

What have you done to your car to require you to need bigger injectors? If your car is stock then bigger injectors aren't going to get you any power.

-

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

Thanks but I have already purchased a differential. I am just looking for a used set of john's side axles so I can use my stock propeller shafts. If I can't find any I will wait until the next group buy. -

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

I have already found a diff on a Subie forum.... Still looking for side axles though. -

I have some power window doors from an 83 turbo out in my trailer. If I recall they are pretty straight and clean. If interested ill send you some pictures. Im in westminster md.

-

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

Hey ill call you later today... thanks -

WTB: 2006 or 2007 STI R180 and/or Side Axles

Cannonball89 replied to Cannonball89's topic in Parts Wanted

Bump... Anybody? Maybe I should put this on a Subie forum.