CarolinaTZ

Members-

Posts

77 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by CarolinaTZ

-

Yep, Dave.....it's me. Glad to see you're still developing the car. Good luck with the header and other upgrades. Give me a call when you get some time!

-

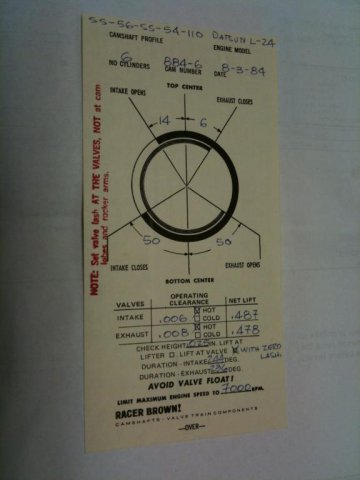

Hey Dave! Long time no see. Hope you are doing well. I was thinking about you and the "ole girl" the other day....was gonna call but couldn't find your number. I wanted to share some information I found in an old '76 Hot Rod magazine Datsun article that shed some light on the history of the Jim Cook body kit. I don't know if I ever told you there were only 14k miles on the Zap when I cut the quarters to install the kit....not sure if it was wise to cut on such a perfectly rust-free Z! I also have a pretty cool keepsake....Jim Cook sent me an actual photo of their Z car showing the "new" airdam because the newest catalog (circa '84ish) didn't have it listed. I bought the airdam based on the photo and it all got installed at the same time. Anyway...onto the cam. Here's a copy of your cam card you sent me when we realized I was running the same RB part number. It looked like my lobes were waring also, the last time I looked at my cam...hopefully not with 30k miles. There may be something better out there but I understand this is supposed to be a good turbo cam.

-

Anyone recognize this draw through setup?

CarolinaTZ replied to gorillaman2012's topic in Turbo / Supercharger

"I need this system like another hole in my head...but..."....seems like you do have a nice collection to showcase the evolution of the hobby/sport. Nothing wrong with that. Good story.....about the Hobbs switch and all! I have one that's supposed to be an oil pressure safety backup with the fuel pump...real hi-tec . I also have an MSD6-BTM to help with ig. timing control....that's about as hi-tec as my TT system is. That had to be some hairy stuff modulating the throttle at those boost levels. What's the connection between the open wastegate dump and winter? Or was it the lower IAT? Those Japanese sytems from then 80's look pretty amazing.....they rarely do anything halfway. I wouldn't mind having one of those analog ITB systems. Were their exhaust manifolds cast or welded tubing?....I doubt they used a modified oem manifold! Sounds like the supercharged 240Z is a well sorted out piece. Just goes to show the different ways to do things reliably. Thanks for sharing! and "keep the red light dimly flickering" -

Anyone recognize this draw through setup?

CarolinaTZ replied to gorillaman2012's topic in Turbo / Supercharger

Absolutely, Texis30O! I know Tony got an awesome setup and I'm glad he's the one. I was stating that I was surprised (not that you were wrong) that you split it up after you dug into the history and spent the time and resources you did to get it back to it's former glory! I enjoyed your youtube videos! Yours is an awesome early car (great survivor condition)....do you have plans for a screamin' powerplant? Thanks for offering to share any knowledge or documentation you have. My second TT car is my current '72 240Z (with all documentation/receipts). I bought it in 2010 from a Z guy who owned it for a short time (it sat in his garage for a few months and he never cranked the car).....he got it from the owner (of almost 30 years) who had Tom work his expertise, essentially turn-key, in the early 80's with TT receipts totalling over 8 grand...not counting the cost of the car. My cylinder head is stamped with the owner's initials...that was TT method of keeping track of customer parts. The original owner stated that there are 30k miles on the engine since Tom built it. I have the car up on stands installing frame connectors, coilovers, wilwoods, 3.90 clsd, ZX 5-speed and so forth...it's a looong term project! I have pretty much all the parts needed to complete it....I just need to put it all together. But life gets in the way . The motor sits on a stand wrapped up and ready to be put back into service. I installed my first TT system on a motor I built in the mid 80's.....I never flew Tom in to have him dial my car in But, I had his number memorized and used to call him and Nancy regularly when I was putting the system together and dialing it in! I put that motor in one of the famed and funky '77 Zap striped cars. That car has had a colorful history...it currently resides in Ohio and puts down almost 500rwhp...not with TT system though. Boy, sorry if we hijacked your thread Gorillaman2012. Yours has a cool factor (see what you started) for sure and you are "lucky" to have it. Is it a working system....if so, you oughtta be able to surprise some unsuspecting Mustang and Camaro owners! -

Anyone recognize this draw through setup?

CarolinaTZ replied to gorillaman2012's topic in Turbo / Supercharger

You got it, Tony...."Best in the Dessert"......just kidding but that's funny stuff. You are correct, and sorry to say it has fallen prey to this abbreviated world we live in ...."Back in the Day". I spent several years collecting and restoring vintage BMX bikes and that was a popular acronym in that community. I'm a little familiar with Texis300's car/system and the history of the PO and Turbo Tom's personal involvement. We were in touch some back when he was getting it going again. While I was a little surprised he split up the system from the car it was built on and the history it represented, I was glad to read you ended up with it. I'm nostalgic about TT's systems and I believe you are too and you'll appreciate it for what it is. You were fortunate to find the late model TT manifold. That's the one I would use. My system uses that manifold and besides supposedly flowing better, I like how the wastegate flange is designed into it. The first generation TT system I used to have used a saddle-mount Turbonetics wastegate, and while I doubted the design, it never leaked. That early system always ran rich in the low to mid range....I tried different jetting but it was always rich. I had Tom's optional 600 double-pumper with the standard 2-1/2" head pipe.....I think it would have run better with the optional 3-1/2" head pipe. My current system uses his Holley 390. I'm not familiar with the HKS or SK systems but I don't doubt they were well designed and possibly superior....but I am biased Did they use Mikunis or SKs? I would like to see some literature from these systems. The TBI injection sounds like a good direction. Did someone on here go with a TBI before or was it just discussed? I know you have a lot going on but, I would like to hear how that turns out. -

Anyone recognize this draw through setup?

CarolinaTZ replied to gorillaman2012's topic in Turbo / Supercharger

That is also similar to a BAE system. There were several companies BITD doing similar things to this. Tom Wyatt (Turbo Tom) did more in the way of R&D and motor prep than any of the others. You could buy one of his systems....what I'll call "mail order" just like any of the other brands (Crown, Cartech, BAE, etc) and just bolt it on. But Tom's desire was to offer more than a bolt on system.....his basic system was better sorted out/refined than the others. It included a modified Holley, his water injection was very well engineered to control detonation up to 15++ psi, he modified the ignition advance weights in the distributor, etc. His 1st gen system used a modified oem exhaust manifold - his last gen system used his own cast manifold which had bigger ports and flowed better...he never used an elbow to bolt the turbo onto the end of a stock manifold like the others did...this kept the turbo closer to the ports to increase efficiency. He used a Turbonetics wastegate...some of the others didn't even use a wastegate. MSD ignition. There was a particular Racer Brown camshaft as an option. The list goes on! I had one of these 1st gen systems in the mid 80's and it was very quick....and reliable. My '72 240Z currently have his last gen. system which has his own cast manifold....this was available in late '82. This is a turn-key motor.....I have all the original receipts and the cost of the kit alone in 1982 was $2685. I also have the receipts for modifying/building the engine in-house. This included CCing the head to drop compression and O-ringing the head. As well as extra time spent polishing/fitting the crank and balancing the engine. My point is he loved Datsuns and knew them well. And while no carburetor system is as refined nor can be finely tuned like a modern EFI system, Turbo Tom's system was the best you could get in a carbed turbo setup BITD. His literature is a joy to read. He made claims of his system making 400+hp at 21psi. And his claims of making a street turbo Porsche look like it's anchored to a tree stump is funny stuff! -

Def. interested ritrebor....sure it's a rear or did someone beat me to the reply. Not looking for a stock size, 88dangerdan but thanks. Zentech....thanks for the response....I'll be in touch if I can't find a cad plated one. Still looking if anyone has a front approx. 1" cad plated....thanks!

-

Hi, Hopefully someone has a front sway bar lying around you don't need any more. I would like to find a cad plated one to match the NOS BRE rear that I just bought. But I'm not too picky....just looking for a good deal. Thanks, Joe

-

Who is running 16x8's with no flares

CarolinaTZ replied to 415DZ's topic in Brakes, Wheels, Suspension and Chassis

This is my BBS RS 16x8.5 with +14 offset and 225/55-16. No fender lip issues. The tire barely touched the spring perch but I'm running coilovers now so, there are no clearance issues. -

Thanks or the response guys. I got ahold of the 2-piece design which, according to the FSM, is correct for my car. I know the one piece seems to work as testified many times here. But, I decided to go with the 2-piece.

-

One experience I had with coolant temps. was with my new GSXR750...some years back. It ran 195f consistently right outta the box. The roadrace guys were adding Redline Water Wetter to their bikes. I added it and immediately dropped to 175f and it has always stayed there....no thermostat change...just the Water Wetter. Some say that the most power is developed at 190f. I'm not sure if that's true but I like the idea of running 20f cooler across the board.

-

Thanks Tony....I will keep this trick in mind if I ever have to change out my head gasket.

-

Tony...does the aluminum sealant not cause unwanted blockages? Also, will an all metal head gasket with ARP bolts eliminate any head leakage problems? I have a Turbo Tom's setup which has the head O'ringed for better cylinder sealing. I figured if I ever developed a leak, I'd go with a metal head gasket and ARP studs...any opinions?

-

Hi...I'm looking for a '70 - early '72 transmission crossmember. The style that bolts to the chassis from the bottom. Thanks, Joe

-

73 240z Brake Hardlines- what to do?

CarolinaTZ replied to J-hop's topic in Brakes, Wheels, Suspension and Chassis

I can agree with making/flaring your own lines. My car sat in storage for many years so I decided to make my own lines and while I had never made brake lines, it went great. Part of the reason is using Cunifer...I totally agree with Snailed....the stuff is softer than steel so it bends, flares and seals very well and is very forgiving. It was developed by Volvo to be used as brake lines and it won't corrode like steel. Taking your time, following directions carefully and having an eye for detail (to get the flares right) and you will be able to make them yourself. Keep us posted. -

BBS RS wheel build

CarolinaTZ replied to brianZortiz's topic in Brakes, Wheels, Suspension and Chassis

I don't disagree, John. I'm no metallurgist and don't know if my wheels are weaker than they were before I modified them...it's a calculated risk I'm willing to take. I do know they originally had 10 holes and now they have 8...that may have made them weaker....it may have made them stronger...I doubt I'll ever know. The issue I had with the lug hole pattern won't have any bearing on the strength of the wheel...just whether or not it mounts up true. And that is corrected now. -

BBS RS wheel build

CarolinaTZ replied to brianZortiz's topic in Brakes, Wheels, Suspension and Chassis

Excellent choice brianZ...I love the color you chose and that huge polished lip will look awesome! I always thought these wheels would be an obvious choice for a flared S30 since they can be customized so easily! The RS's are classic and a super quality wheel...as you know! I spoke w/ a guy at BBS North American Hq and he said they get calls about these wheels every single day and that he wishes they still made them. I bought a set a couple of years ago and here's the thread of my trial fit. My link I went with a polished lip w/ matte black centers and gloss black bolts. I don't have any updated pictures but here's the barrels after I powdercoated them the same matte black that I used on the centers: I bought mine from VR Wheels as well, and while they do have an incredible selection, I had them do the redrilling for the 4x114.3 and the measurements were way off. I had my machinist bore the hub centers and redrill the lug pattern to correct their mistake....now they are perfect! So, I would just caution anyone buying from them to double check their machine work. Good luck and I look forward to following your progress. -

Another frame rail question......Hear me out and

CarolinaTZ replied to CarolinaTZ's topic in Fabrication / Welding

The car has a turbo motor, coilovers and 4 wheel discs. It won't be a track monster but the chassis will definitley see some added stress and possible do a track day or 2. You guys have me strongly considering the Bad Dog rails. It seems that all I need are their front rail caps (which are longer and continue all the way to tie into the rears)...Is that correct or do you have to buy something differnt from them to tie into the rear? Do you do rosette welds into the stock rails and the floor pans (once you clear the stock rails)? Or do you do more of a continuous stitch weld along the edge of the new rail? Thanks in advance for the guidance guys! -

Another frame rail question......Hear me out and

CarolinaTZ replied to CarolinaTZ's topic in Fabrication / Welding

Thanks for the advice PalmettoZ. While the replacement rails are thicker, I believe it would better maintain the integrity of the chassis if I don't disrupt the connection of the orignal rails to the front frame sections. That may not be the best choice but after seeing the condtiton of he originals, I don't want to cut them out. I know about capping the originals with stronger ones but don't want to spend the money for those. I was hoping someone had an idea about what works to beef up the orignals from the inside. Or would it be useless? Anyone? Josh, I will keep this in mind if I decide to sell these...thanks. -

OK....I'm replacing some of the obligatory floor pan rot, although very minor, on my 72 240Z. I've cut out what little metal was swiss-cheesed and have revealed the frame rails which are in perfect condition. I cut out what I needed from the Zedd Findings replacement pans and will also be left with a full set of their replacement frame rails....I just don't need them. My question is...while I have the top sides of the frame rails exposed, is there something I can do to strengthen them from the upper side (inside) that would be worthwhile? I have read many of the threads on here about how most of the benefit to be had is from strengthening the rockers and not the frame rails. That said, will I have any regrets if I do nothing while I have access to the inside of the stock frame rails? Would it be worth it to weld some kind of bracing or rib inside the stock frame rail? Please offer your opinions, either way (something or nothing), about what to do while I have the chance. Thanks in advance!

-

Jon, I really appreciate you responding w/ your knowledge. I'm in the middle of p'coating parts and pieces and about to take the tubing cutter to my strut tubes. Soon to follow will be moving the LCA pivot...I will look some more at using the old JTR numbers but may have more ??? before I start drilling and grinding. Thanks again, Joe

-

That makes sense. I won't be using rod ends or employing any type of adjustment in my LCA....just poly bushings. I hoped to help correct bumpsteer/camber with the one act of moving the LCA pivot. I see that moving the pivot up, like yours, will help correct bumpsteer but you also have the rod ends to adjust camber. I won't have that option. That's why I was hoping there were some tried and true specs for slotting (I guess with some horizontal adjustment...not just vertical) that would give me both. Is the Ford F150 eccentric washer in the other thread the best way to go and/or do you do you know of some other slotting specs? Thanks again....

-

I'm in the process of sectiong struts/rebuilding suspension. This will be a street/maybe sometime track car. I don't want to use camber plates but am looking into slotting/moving the LCA pivot to correct camber and/or roll center. On a car w/ this intended use, should I slot the pivot point or simply re-locate a single hole. Jon, are you using the stock pivot bolts or do you have to use a different bolt based on the thikness of the welded on backing plate? Thanks in advance...

-

Thanks a lot johnc! That's what I was thinking...basically treat the 280Z struts as if they were 240Z struts. Will this perch measurement allow me to run approx. 6" ride height and be able to go up or down an inch or so?